Professional Documents

Culture Documents

Lecture 05

Uploaded by

Murad JafarovOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 05

Uploaded by

Murad JafarovCopyright:

Available Formats

LECTURE FIVE 054410 PLANT DESIGN

054410 Plant Design

LECTURE 5:

PUMP DESIGN

Alon Goldis

Department of Chemical Engineering

Technion, Haifa, Israel

5- 1 PLANT DESIGN - Alon Goldis Pump Design

Objectives

After reviewing this lecture you should:

1. Be familiar with the nomenclature used in the

design of centrifugal pumps.

2. Be able to use pump characteristic curves.

3. Be able to compute the total dynamic head

(TDH) of a pump, given its suction and discharge

lines and installed fittings.

5- 2 PLANT DESIGN - Alon Goldis Pump Design

1 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Head

o The pressure at any point in a liquid can be

thought of as being caused by a vertical column

of the liquid

o The height of the column is called the Static

Head and is expressed in terms of feet of liquid.

o The Static Head corresponding to any specific

pressure is dependent upon the weight of the

liquid according to the following formula:

2.31 ⋅ Pressure [psi]

Head [ft] =

Specific gravity

5- 3 PLANT DESIGN - Alon Goldis Pump Design

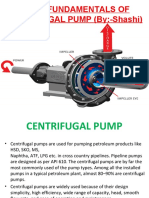

Centrifugal Pumps Fundamentals

o A Centrifugal pump imparts velocity to a liquid.

o This velocity energy is transformed largely into

pressure energy as the liquid leaves the pump.

o The relationship between the head developed in

pump and it’s velocity is expressed by:

V2

H =

2g

H - Total head developed (feet)

V - Velocity of impeller (feet/sec)

g - 32.2 feet/sec2

5- 4 PLANT DESIGN - Alon Goldis Pump Design

2 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Centrifugal Pumps Fundamentals

The approximate head of any centrifugal pump can

predicted by calculating the velocity of the

impeller. Use the next equation to calculate the

impeller velocity in case the impeller diameter is

given:

RPM ⋅ D

V =

229

D - Impeller diameter (inch)

V - Velocity (ft/sec)

5- 5 PLANT DESIGN - Alon Goldis Pump Design

Centrifugal Pumps – Exercise 1

Find the pressure in the inlet (impeller line) of

centrifugal pump for Gasoline (S.G.=0.75), Water

(S.G.=1), Brine (S.G.=1.2)

Gasoline Water Brine

5- 6 PLANT DESIGN - Alon Goldis Pump Design

3 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Centrifugal Pumps - SUCTION LIFT

SUCTION LIFT exists when

the source of supply is below

the center line of the pump.

Thus the STATIC SUCTION

LIFT is the vertical distance in

feet from the centerline of the

pump to the free level of the

liquid to be pumped.

Pump

Source of supply

5- 7 PLANT DESIGN - Alon Goldis Pump Design

Centrifugal Pumps - SUCTION HEAD

SUCTION HEAD exists when

the source of supply is above

the centerline of the pump.

Thus the STATIC SUCTION

HEAD is the vertical distance

in feet from the centerline

of the pump to the free

level of the liquid to be

pumped. Source of supply Pump

5- 8 PLANT DESIGN - Alon Goldis Pump Design

4 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Centrifugal Pumps - CAPACITY

Capacity (Q) is normally expressed in gallons per

minute (GPM). Since liquids are essentially

incompressible, there is a direct relationship

between the capacity in a pipe and the velocity of

flow. This relationship is as follows:

Q = 449 ⋅ A ⋅V

where

A = area of pipe cross section (ft2)

V = velocity of flow (ft/sec)

Q = Capacity (GPM=gallons per minute)

5- 9 PLANT DESIGN - Alon Goldis Pump Design

Centrifugal Pumps - Power & Efficiency

• The work performed by a pump is a function of the

total head and the weight of the liquid pumped in a

given time period.

• Pump input or brake horsepower (BHP) is the

actual horsepower delivered to the pump shaft.

Q ⋅TDH ⋅ S .G

BHP =

3960 ⋅ Pump Efficiency

• Pump output or hydraulic horsepower (WHP) is

the liquid horsepower delivered by the pump.

Q ⋅TDH ⋅ S .G

WHP =

3960

5- 10 PLANT DESIGN - Alon Goldis Pump Design

5 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Centrifugal Pumps – Power & Efficiency

The brake horsepower or input to a pump is greater

than the hydraulic horsepower or output due to the

mechanical and hydraulic losses incurred in the

pump.

Therefore, the pump efficiency is the ratio of these

two values.

WHP Q ⋅TDH ⋅ S .G

Pump Efficiency = =

BHP 3960 ⋅ BHP

5- 11 PLANT DESIGN - Alon Goldis Pump Design

NPSH & Cavitation

The definition of NET POSITIVE SUCTION HEAD:

NPSH - is defined as the total suction head

determined at the suction nozzle, less the vapor

pressure of the liquid in feet absolute. Simply

stated, it is an analysis of energy conditions on the

suction side of a pump to determine if the liquid will

vaporize at the lowest pressure point in the pump.

5- 12 PLANT DESIGN - Alon Goldis Pump Design

6 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

NPSH & Cavitation

• NPSH required is a function of the pump design.

• As the liquid passes from the pump suction to the

impeller region, the pressure decreases.

• The centrifugal force of the impeller vanes further

increases the velocity and decreases the pressure

of the liquid.

• The NPSH Required is the positive head in feet

required at the pump suction to overcome these

pressure drops in the pump and maintain the

majority of the liquid above its vapor pressure.

5- 13 PLANT DESIGN - Alon Goldis Pump Design

NPSH & Cavitation

To overcome the phenomenon called “Cavitation”,

NPSH available must be greater than available –

NPSH required

NPSHA > NPSHR

NO CAVITATION

5- 14 PLANT DESIGN - Alon Goldis Pump Design

7 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Pump Characteristic Curves

A performance of a pump can be shown graphically on

a characteristic curve. A typical pump curve shows:

• Total Dynamic Head

(TDH)

• Brake horse-power

• Efficiency

• NPSH

5- 15 PLANT DESIGN - Alon Goldis Pump Design

Pump Characteristic Curves

Operating Lines

Efficiency Line

BHP

NPSH

5- 16 PLANT DESIGN - Alon Goldis Pump Design

8 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Class Exercise 1

100 GPM of HCl is

to be pumped by a

centrifugal pump

from a reservoir

located 50 ft

below a storage

reservoir.

Find the TDH of

the system.

5- 17 PLANT DESIGN - Alon Goldis Pump Design

Class Exercise 1 - Solution

Let’s divide the

system in to two

sub-systems:

1. Suction Area

2. Discharge Area

5- 18 PLANT DESIGN - Alon Goldis Pump Design

9 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Class Exercise 1 - Solution

Suction Area – in GENERAL:

• The total Pipe length:

5+7+5 = 17ft

• The Static Head – 10ft

• One 3” 90o Knee – 7.7ft

• One fully opened 3” Gate

Valve - 1.6 ft

• Lummus Rules: ∆P allowed in

case of non-boiling liquids

entering pump - 1psi/100ft

5- 19 PLANT DESIGN - Alon Goldis Pump Design

Class Exercise 1 - Solution

Hence the pressure drop in the pipe and its fittings

is: (17+7.7+1.6)ftx1psi/100 ft = 0.26 psi

The static pressure in reservoir is calculated from:

2.31 ⋅ Pressure( psi )

Head(ft) = ⇒

S .G .

Head(ft) ⋅ S .G 10ft ⋅ 1.1

Pressure(psi) = = = 4.76 psi

2.31 2.31

Hence, the suction head is:

2.31 ⋅ Pressure(psi)

Head(ft) =

S .G .

2.31 ⋅ (4.76 − 0.26)

= = 9.45ft

1.1

5- 20 PLANT DESIGN - Alon Goldis Pump Design

10 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Class Exercise 1 - Solution

Discharge Area – in GENERAL:

• The total Pipe length: 172ft

• The Static Head – 60ft

• Two 2” 90o Elbow – 5ft each

• One fully opened 2” Gate

Valve - 1.25 ft

• One 2” Check Valve – 15ft

• Lummus Rules: ∆P allowed

in case of 0-250 GPM is

6psi/100ft

5- 21 PLANT DESIGN - Alon Goldis Pump Design

Class Exercise 1 - Solution

Hence the pressure drop in the pipe and its fittings

is:(172+1.25+2×5+15)ft x 6psi/100 ft = 11.9 psi.

The static pressure in reservoir is calculated from:

2.31 ⋅ Pressure(psi)

Head(ft) = ⇒

S .G .

Head(ft) ⋅ S .G 60ft ⋅ 1.1

Pressure(psi) = = = 28.57 psi

2.31 2.31

Hence, the discharge head is:

2.31 ⋅ Pressure(psi) 2.31 ⋅ (28.57 + 11.9)

Head(ft) = = = 84.98ft

S .G . 1.1

Note – the reason for the sum of the static head and the head

loss is due to the fact that the pump must overcome the static

pressure of the storage reservoir as well as that of the piping

5- 22 PLANT DESIGN - Alon Goldis Pump Design

11 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Class Exercise 1 - Solution

Finally, the total dynamic head of this system is:

TDH = Disc.Head – Suct.Head

= 85.72 - 9.45 = 75.27 ft

5- 23 PLANT DESIGN - Alon Goldis Pump Design

Class Exercise 2

Compute the pump required to deliver a liquid stream

from the bottom of distillation column to filter.

Given:

1. Dist. Column bottoms pressure: 1.72 bar

2. Filter inlet pressure: 1.5 bar

3. Heat Exchanger pressure drop: 0.77bar

4. Control Valve pressure drop is equal to 30% of

pump suction pressure.

5. Process data table

5- 24 PLANT DESIGN - Alon Goldis Pump Design

12 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Class Exercise 2

Process Data Table

Capacity ( Normal ), m3/hr 69.6

Temperature, deg C 117

Viscosity, cP 1

Spec. Gravity 0.947

Bottoms pipe diameter, inch 8

Pump discharge diameter, inch 6

5- 25 PLANT DESIGN - Alon Goldis Pump Design

Class Exercise 2 – Pump Detailed Design

Solution ( Excel )

Data-Sheet

Request Form

5- 26 PLANT DESIGN - Alon Goldis Pump Design

13 Alon Goldis, Technion

LECTURE FIVE 054410 PLANT DESIGN

Summary

After reviewing this lecture you should:

1. Be familiar with the nomenclature used in the

design of centrifugal pumps.

2. Be able to use pump characteristic curves.

3. Be able to compute the total dynamic head

(TDH) of a pump, given its suction and discharge

lines and installed fittings.

5- 27 PLANT DESIGN - Alon Goldis Pump Design

14 Alon Goldis, Technion

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- PumpsDocument133 pagesPumpssuave_artistNo ratings yet

- Sucker Rod PresentionDocument46 pagesSucker Rod PresentionWunna Htun100% (3)

- 1 Pump CurvesDocument39 pages1 Pump Curvesmoxlinde100% (1)

- Fundamentals of Centrifugal PumpsDocument120 pagesFundamentals of Centrifugal Pumpswholenumber100% (1)

- Rod Pump& PCPDocument17 pagesRod Pump& PCPsouthliNo ratings yet

- Subsea Fasteners Guideline - 10002444011 PDFDocument28 pagesSubsea Fasteners Guideline - 10002444011 PDFbert berry100% (1)

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 pagesBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (1)

- 3 Centrifugal PumpDocument36 pages3 Centrifugal PumpReza Dhony WijayaNo ratings yet

- Training - Flowserve Apm Pump CW Pump Part 2Document12 pagesTraining - Flowserve Apm Pump CW Pump Part 2hasan099No ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Pressure Vessels 2 PDFDocument24 pagesPressure Vessels 2 PDFDasari VenkateshNo ratings yet

- Piping Design Guide for PumpsDocument58 pagesPiping Design Guide for PumpsSkr9143 Shiv100% (1)

- ESP Design & Analysis With Pressure GradientADocument16 pagesESP Design & Analysis With Pressure GradientAAldi RiyaldiNo ratings yet

- Pump Basics1Document34 pagesPump Basics1sambasivammeNo ratings yet

- Industrial Plant Engineering Reviewer Complete PDFDocument93 pagesIndustrial Plant Engineering Reviewer Complete PDFNovaCastillo100% (2)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- 10 Marking Scheme: Worksheet (AS) : 1 B 2 D 3 A 4 A 5 D 6 D 7 Q I TDocument2 pages10 Marking Scheme: Worksheet (AS) : 1 B 2 D 3 A 4 A 5 D 6 D 7 Q I TRuby ChongNo ratings yet

- Surface Production Operations 6Document106 pagesSurface Production Operations 6Сергей ВельдяксовNo ratings yet

- SG12 L1 - Rotating Equipment (Pumps)Document21 pagesSG12 L1 - Rotating Equipment (Pumps)mohammadazraiNo ratings yet

- Performance of Centrifugal PumpsDocument52 pagesPerformance of Centrifugal Pumpsvisitabhinav100% (4)

- PE Jaw crusher manual-英文Document22 pagesPE Jaw crusher manual-英文Edwin Forero100% (3)

- PEG 4102 - Sucker Rod Pump Project PresentationDocument22 pagesPEG 4102 - Sucker Rod Pump Project PresentationAlex StollNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryshunmugeshNo ratings yet

- Pump Maintenance EssentialsDocument29 pagesPump Maintenance EssentialsnaushadmnnitNo ratings yet

- GTU Question Bank-TPDocument5 pagesGTU Question Bank-TPlata sinsinwar100% (3)

- Centrifugal Pump Performance CharacteristicsDocument16 pagesCentrifugal Pump Performance CharacteristicsAvik SahaNo ratings yet

- Centrifugal Pump Basics Terms IndustryDocument18 pagesCentrifugal Pump Basics Terms IndustrymishraenggNo ratings yet

- c7 PDFDocument34 pagesc7 PDFAnjaana PrashantNo ratings yet

- PumpsDocument30 pagesPumpsratankale0401No ratings yet

- Pump BasicsDocument18 pagesPump Basicsnbharath1988No ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustrysahilchemNo ratings yet

- Centrifugal Pump GuideDocument18 pagesCentrifugal Pump GuideBhuneshwar ChelakNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industryismail_69No ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industrysuraj7266No ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryRaman SrivastavaNo ratings yet

- An Introduction To Centrifugal PumpsDocument10 pagesAn Introduction To Centrifugal Pumpsjoe silverNo ratings yet

- Pump BasicsDocument18 pagesPump BasicsBernadus Andy Kristian PamungkasNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustrySamuel PalisNo ratings yet

- Pump BasicsDocument18 pagesPump BasicssparthaelfNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industrykomed diNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryArnold Arung100% (1)

- 3-1-Unit IIDocument40 pages3-1-Unit IIGroup-4 CommonNo ratings yet

- m150contentDocument74 pagesm150contentwael72No ratings yet

- Design of a Centrifugal PumpDocument10 pagesDesign of a Centrifugal Pumpharsh rikameNo ratings yet

- Pump Sump-Design General PrinciplesDocument14 pagesPump Sump-Design General Principlesspnatu0% (1)

- CPump PresentationDocument118 pagesCPump PresentationTalha Ahmad100% (1)

- Hydraulics Model Study; Pump Selection and ApplicationDocument55 pagesHydraulics Model Study; Pump Selection and ApplicationIsbelNo ratings yet

- Overview, Installation and Maintenance of Pumps, Valves and PipingDocument72 pagesOverview, Installation and Maintenance of Pumps, Valves and PipingKushen ScottNo ratings yet

- Useful Pump & Hydraulic Engineering Data Definitions, Equations, Testing, Tables, Charts DeterminationsDocument12 pagesUseful Pump & Hydraulic Engineering Data Definitions, Equations, Testing, Tables, Charts DeterminationsDiana Catalina Molano BayonaNo ratings yet

- Pump Performance Variables & Series Parallel ConfigurationsDocument12 pagesPump Performance Variables & Series Parallel ConfigurationsKumaravel PadmaroopaNo ratings yet

- Centrifugal PumpDocument44 pagesCentrifugal PumpAmishaan KharbandaNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument49 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryAvi ChNo ratings yet

- Calculation of Pump HeadDocument34 pagesCalculation of Pump HeadKAIVALYA TIWATNENo ratings yet

- Chapter - 1: Name - 409 Marine EngineeringDocument42 pagesChapter - 1: Name - 409 Marine Engineeringisrat jahanNo ratings yet

- Selection of PumpDocument39 pagesSelection of PumpM. Nasikhun WahidinNo ratings yet

- Centrifugal PumpsDocument3 pagesCentrifugal PumpsHemant ChaudhariNo ratings yet

- How To Read A Centrifugal Pump Performance Curve - Mechanical Engineering SiteDocument14 pagesHow To Read A Centrifugal Pump Performance Curve - Mechanical Engineering SiteUrvesh D PrajapatiNo ratings yet

- Chapter 6 - PumpDocument39 pagesChapter 6 - PumpAbubakar abdullahiNo ratings yet

- Lesson 7 SlidesDocument22 pagesLesson 7 SlidesBryan ScofieldNo ratings yet

- Lecture 4 - Pump CharacteristicsDocument43 pagesLecture 4 - Pump Characteristicsisrat jahanNo ratings yet

- PTP 07.1 HandoutDocument25 pagesPTP 07.1 HandoutJayNo ratings yet

- Captura de Tela 2022-08-03 À(s) 15.59.58Document141 pagesCaptura de Tela 2022-08-03 À(s) 15.59.58Max MarquesNo ratings yet

- Anchor Bolt DesignDocument3 pagesAnchor Bolt DesignDanielNo ratings yet

- Development of A Chest Freezer - Optimum Design of An Evaporator CoilDocument15 pagesDevelopment of A Chest Freezer - Optimum Design of An Evaporator CoilJss Aircond & ElectricalNo ratings yet

- Application of Solar Thermal Desorption To Remediation of Mercury-Contaminated SoilsDocument11 pagesApplication of Solar Thermal Desorption To Remediation of Mercury-Contaminated Soilskaren avilaNo ratings yet

- CV BaxterDocument3 pagesCV BaxterGYANNo ratings yet

- Ficha Tecnica Equipo Bombeo 250 GPM San SalvadorDocument31 pagesFicha Tecnica Equipo Bombeo 250 GPM San Salvadorgabriel240371100% (1)

- 8.3.1 Inducing E.M.F. and Current: 8.3.2 Determining The Direction of The Induced CurrentDocument9 pages8.3.1 Inducing E.M.F. and Current: 8.3.2 Determining The Direction of The Induced CurrentMoses AhmedNo ratings yet

- Finite Element Analysis Notes and Question BankDocument375 pagesFinite Element Analysis Notes and Question Bankfgh fghfghfNo ratings yet

- En J02.DAI.73 Daikin RZAG N Technical Data RZAG NV1 Data BookDocument51 pagesEn J02.DAI.73 Daikin RZAG N Technical Data RZAG NV1 Data BookTheEngineer - المهندسNo ratings yet

- EX 10 Range and EnduranceDocument14 pagesEX 10 Range and EnduranceMrunali MhatreNo ratings yet

- Hydrofoil Seminar Report 2010Document27 pagesHydrofoil Seminar Report 2010Abhiram P Mohan100% (1)

- Magnetic IDocument34 pagesMagnetic IDeepesh SureshNo ratings yet

- JOSÉ e DANIELA Blow Up of Solutions To Fractional Quasilinear Hyperbolic ProblemDocument6 pagesJOSÉ e DANIELA Blow Up of Solutions To Fractional Quasilinear Hyperbolic ProblemJosé VanterlerNo ratings yet

- Specifications PDFDocument1 pageSpecifications PDFRazvan SasuNo ratings yet

- This Preview Is Downloaded From WWW - Sis.se. Buy The Entire Standard Via HTTPS://WWW - Sis.se/std-18918Document11 pagesThis Preview Is Downloaded From WWW - Sis.se. Buy The Entire Standard Via HTTPS://WWW - Sis.se/std-18918adrianioantomaNo ratings yet

- 10.3 EllipsesDocument2 pages10.3 EllipsesKeri-ann MillarNo ratings yet

- 240-56063867 Transformer and Reactor Rapid Pressure Rise RelayDocument6 pages240-56063867 Transformer and Reactor Rapid Pressure Rise RelayMichael NgubaneNo ratings yet

- Power System Iii: Automatic Generation Control (AGC)Document54 pagesPower System Iii: Automatic Generation Control (AGC)31Abhinav AkashNo ratings yet

- TDS Byk-1780 enDocument2 pagesTDS Byk-1780 enabhijit.home2022No ratings yet

- DH - Ch4-1 Relative Motion of A Particle - 4x3Document22 pagesDH - Ch4-1 Relative Motion of A Particle - 4x3Kevin AlexNo ratings yet

- Problem 1A.4Document2 pagesProblem 1A.4NI PUTU AGNES SUARINo ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/22Document16 pagesCambridge International AS & A Level: PHYSICS 9702/22Noor MuhammadNo ratings yet

- ME414 Section 1Document12 pagesME414 Section 1OvaizOwaisNo ratings yet

- Chemistry Data Booklet - 220524 - 195215 PDFDocument12 pagesChemistry Data Booklet - 220524 - 195215 PDFIbrahim ZubairiNo ratings yet

- 11.5 Applications of Right-And Non-Right-Angled TrigonometryDocument2 pages11.5 Applications of Right-And Non-Right-Angled TrigonometryAanya RalhanNo ratings yet

- Stal9781607500315 1088Document3 pagesStal9781607500315 1088Tariq SufianNo ratings yet