Professional Documents

Culture Documents

Mud Contaminant

Uploaded by

Ciputra 'Boy' TampubolonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mud Contaminant

Uploaded by

Ciputra 'Boy' TampubolonCopyright:

Available Formats

Mud contaminants

Rev: 1.0 18/04/01

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

MUD contaminants

Table of contents

MUD CONTAMINANTS ...............................................................................................................2

Table of contents ...........................................................................................................................2

Introduction ...................................................................................................................................3

Solids.............................................................................................................................................3

High Gravity (HGS).................................................................................................................................3

Low Gravity (LGS) ..................................................................................................................................3

Source of solids in mud’s........................................................................................................................4

Symptoms...............................................................................................................................................4

Preventative Measures and Remedial Action ........................................................................................5

Calcium and Magnesium...............................................................................................................7

Source ....................................................................................................................................................7

Symptoms...............................................................................................................................................7

Preventative Measures and Remedial Action ........................................................................................8

Carbonates and Bicarbonates ......................................................................................................11

Source ..................................................................................................................................................12

Symptoms.............................................................................................................................................12

Preventative Measures and Remedial Action ......................................................................................13

Lime ......................................................................................................................................................14

Gypsum + Lime or Gypsum + Caustic Soda ........................................................................................14

Salts Formations and Brine Flows ..............................................................................................15

Source ..................................................................................................................................................15

Symptoms.............................................................................................................................................15

Preventative Measures and Remedial Action ......................................................................................16

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Introduction

In general a drilling fluid is in its best condition after its initial formulation prior to being

displaced to the hole although it is true that some mud’s benefit from downhole shear.

As soon as drilling commences, the mud is exposed to a range of contaminants, e.g. type

and extent that depend upon the formation being drilled and the fluids within the formations.

This section details the effects of the major contaminants and how these effects can be

minimised.

Solids

In oilfield terminology solids are classified by their density or specific gravity into two

basic categories e.g. High and low gravity solids.

These figures are used to calculate the relative percentage of each solids type in the

mud.

Variations in the relative concentrations give valuable indications of the condition of the

mud and of the efficiency of the solids removal equipment.

High Gravity (HGS)

High gravity solids SG > 4.2 usually a weighting agent such as barite and haematite.

Low Gravity (LGS)

Low gravity solids SG 1.6 - 2.9 usually commercial bentonite and drilled solids with an

assumed SG of 2.5.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Source of solids in mud’s

High gravity solids are added to the mud to increase fluid density.

Even though they are added deliberately and are essentially non-reactive solids, they still

adversely affect fluid rheology, particularly when they degrade by attrition to ultra fine

particles.

Low gravity solids are often referred to as drilled solids and are derived from the drilled

formation.

Symptoms

Drilled solids are the most common contaminant in drilling mud’s.

Any particle of rock that is not removed by the solids removal equipment is re-circulated

and reduced in size by attrition.

- This process increases the exposed surface area,

- More mud is required to wet the surfaces and increased product is required to

maintain the desired fluid parameters.

- The increase in the number of particles in the mud results in an increase in inter

particle action and hence an increase in rheology, particularly plastic viscosity.

- The irregular shape and size of drilled solids produces poor filter cake quality

which in turn tends to result in an increase in filtrate volume and cake thickness.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Preventative Measures and Remedial Action

The efficient use of the best available solids removal equipment is essential in preventing

a build up of undesirable drilled solids.

Primary separation

Primary separation equipment (i.e. shale shakers) is by far the most important tool in the

control of drilled solids in the mud.

Efficiently operated and correctly screened shale shakers will remove the vast majority of

drilled solids before they have the opportunity to degrade significantly.

Modern linear motion shakers will allow the use of screens as find as 230 mesh,

particularly when drilling with an oil mud.

The implications of barite removal must be considered if the use of screens finer than

this is contemplated.

Hydro-cyclones

Hydro-cyclones (de-sanders and de-silters) should be used with caution.

The action of the centrifugal feed pump can aid in the attrition process and compound

any existing problem.

Hydro-cyclones should not be used when drilling with an oil mud as the large volumes of

liquid discarded will have adverse effects on the environment and on mud costs.

Centrifuges

Correctly set up centrifuges are effective at removing fine solids however, they are not

capable of treating large volumes (typically 1 - 1.5 bbl/min) and as such are really only of

benefit when using an oil mud where dilution rates are low or when drilling small

diameter hole.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Dilution

Eventually solids will degrade to so small a diameter that they cannot be removed even

with the use of a high speed centrifuge.

In such circumstances some dilution method must be employed. The addition of base

fluid (water or oil) may help in the short term by increasing the liquid phase of the mud,

hence increasing the separation and therefore inter-particle action of the solids.

However this approach does not actually remove any solids from the system and the

solids attrition process and mud property degradation continues. The ultra fine solids

can only be removed from the system by removing a portion of the mud from the

circulating system.

In the case of water based mud’s “whole mud dilution” should be used. This process

involves dumping large volumes of solids laden mud (less than 500 bbls will have little

effect on an average circulating system) and replacing it with newly formulated clean mud.

This process is not viable with oil mud’s or synthetic oil mud’s.

When this type of mud becomes laden with ultra fine solids it must be returned to the

shore based mud plant for treatment. Fortunately, as oil mud’s tend to maintain the

integrity of cuttings, thus allowing effective removal by the shale shakers, this

requirement for this action is rare.

When using a dispersed mud, the addition of chemical thinners (.e.g. lignosulphonate,

Drill-Thin etc.) can be used to treat the symptoms of increasing solids content. However,

the cause is still present and dilution will ultimately be required.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Calcium and Magnesium

Either of these divalent ions may, even at low concentrations, have adverse effects on

some water based mud’s particularly when these mud’s have a high solids content.

Very high concentrations of either of these ions may have adverse effects on the

performance of polymers in water-based mud’s and on the emulsification packages of

some oil based mud’s.

Source

Both calcium and magnesium can be present in make up water (particularly sea water),

formation water and mixed salt evaporite formations.

Calcium is encountered in greatest quantity when drilling cement or anhydrite.

Magnesium often accumulates in the mud when drilling in magnesium rich shales (e.g.

North and Central North Sea) or mixed salt formations (e.g. the Zechstein evaporites of the

southern North Sea).

Symptoms

Magnesium

The major effect of magnesium is to react with hydroxyls in the mud system thus

depleting mud alkalinity and pH. This can in turn allow the undesirable carbonate and

bicarbonate components of alkalinity to become dominant.

Calcium

Calcium ions flocculate bentonite based mud’s and other water based mud’s containing

reactive clays giving rise to changes in rheology (decrease in plastic viscosity and

increase in yield point and gels) and loss of filtration control. The presence of increased

calcium levels can be verified from chemical analysis of the filtrate. The combination of

high calcium levels and high pH will precipitate most common polymers used in water

based mud’s - loss of rheology and filtrate control will result.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Preventative Measures and Remedial Action

Magnesium

Small quantities of magnesium such as those present in seawater can be readily

removed with additions of caustic soda.

Magnesium hydroxide is precipitated at a pH of approximately 10.5.

When large quantities of magnesium are encountered (magnesium shales, evaporites or

brine flows) it is not practical to treat out the contaminant.

Large scale gelatinous precipitation of magnesium hydroxide will adversely effect

rheology, increasing gel strengths in particular.

The large surface area of this precipitate consumes huge quantities of mud chemicals.

This is particularly problematic in oil mud’s where surfactants are effectively stripped

from the mud and can cause the whole system to “flip”. In these cases no attempt

should be made to adjust the alkalinity until clear of the source of magnesium.

Modern surfactant packages do not generally require a big excess of lime so oil mud

performance should not be compromised.

A low pH in a water based mud could promote corrosion of drill pipe so consider the

application of oxygen scavengers and filming amines until the pH can be restored.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Calcium

Small quantities of calcium (<400 mg/lt) are acceptable, even desirable, in most water

based mud’s. A background level of calcium acts as a buffer against the presence of

undesirable carbonate alkalinity.

High concentrations of calcium can, however, have major adverse effects on water

based mud’s. The major sources of large quantities of calcium are discussed below:

Cement

The chemistry of cement is complex. However, from the mud contamination point of

view, it can be considered to be lime, Ca(OH)2. The major contaminant is calcium but in

some circumstances, the hydroxide ion will compound the problem. At high

temperatures (> 250°F) severely contaminated bentonite based mud’s can solidify.

When it is planned to drill cement, particularly when it is not completely hard, some

precautions can be made to minimise the potential effects of the contamination.

• If viable, drill out as much cement as possible with seawater before displacing to mud.

• Minimise caustic soda additions during operations, including the mixing of new mud, preceding the

drilling of cement.

• Pre-treat with small amounts of sodium bicarbonate - 0.25 lb/bbl is usually sufficient, perhaps twice this

if green cement is anticipated. Avoid over treatment, as an excess of bicarbonate in the mud system

can flocculate mud solids and adversely affect rheology and filtration control.

• Closely monitor pH and Pf while drilling the cement and adjust treatments as required to prevent

polymer precipitation (keep pH below 11.0) and clay flocculation. Sodium bicarbonate will reduce

calcium and pH. Any acid, conventionally citric acid, will reduce pH as will SAPP, Lignosulphonate

and lignite.

• When it is known that large amounts of green or soft cement are to be drilled consideration should be

given to converting the mud to a lime system, which is tolerant of cement contamination. Large

amounts of a suitable dispersant (e.g. Lignox) must be available to successfully accomplish this

conversion.

Oil based and synthetic oil based mud’s are largely unaffected by cement. However, the

water fraction of green cement may reduce oil water ratios.

Whenever possible drill out cement with seawater or water based mud, prior to

displacing to oil based mud.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Anhydrite

Anhydrite (CaSO4) is the anhydrous form of gypsum and is sufficiently soluble to provide

calcium ions for clay flocculation. The calcium effects will be as for cement, but gypsum

contamination generally has no direct effect on the pH of the mud.

When only small stringers are anticipated the excess calcium can be treated out with

soda ash (sodium carbonate).

Care should be taken to avoid over treatment, as the adverse effects of carbonate

contamination are equally as bad as those of calcium.

Small additions of a deflocculant such as Lignosulphonate will smooth out the rheology

during treatment.

If massive anhydrite is prognosed and a water-based mud is being used, consideration

should be given to converting the mud to a gypsum system which is tolerant of calcium

contamination.

Oil based mud’s are unaffected by anhydrite contamination.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Carbonates and Bicarbonates

There are three species of contaminant in the “carbonate system”

1. carbonic acid (H2CO3),

2. bicarbonate (HCO3)

3. and carbonate (CO3).

Figure 1 shows the equilibrium levels of these species at varying pH levels.

Figure 1: Equilibrium levels of carbonates and bicarbonates

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Source

There are four common sources of carbonate system contaminants:

1. Carbon dioxide from formation gases. E.g. Over treatment when removing calcium

from the mud i.e. excess use of soda ash and sodium bicarbonate.

2. Thermal degradation of organic mud products (e.g. FCL, lignite and starch).

3. Contaminated barite, particularly when drilling HTHP wells with water based mud’s.

It is essential that QA/QC procedures are applied to all batches of barite prior to

shipment to such wells.

4. Contaminated bentonite.

Symptoms

Characterised by general increases in rheology, particularly yield point and gel strengths,

and increases in filtrate.

Typically these effects are worse in high solids mud’s and in high temperature

applications.

The symptoms will not respond to chemical deflocculation such as Lignosulphonate

treatment.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Preventative Measures and Remedial Action

Prior to treatment the situation should be assessed with all available data - over

treatment with the calcium ion must be avoided. Several mud testing options are

available to the mud engineer none of which, however, render definitive information in

the field.

• pH, Pf and Mf are determined by pH meter and by titration. The ratio and

relationship between these values will, in theory, allow carbonate species to be

determined.

Table 1: Ph, Pf, & Mf, Alkalinity concentration mg/lt

Criteria OH- CO3-2 HCO3-

Pf = 0 0 0 1220 Mf

2Pf > Mf 0 1200 Pf 1220 (Mf – Pf)

2Pf = Mf 0 1200 Pf 0

2Pf < Mf 340 ( 2Pf – Mf) 1200 (Pf – Mf) 0

Pf = Mf 340 Mf 0 0

• P1 and P2 is another titration method which generally gives more reliable results than

the Pf, Mf method.

Table 2: P1, & P2, Alkalinity concentration mg/lt

Criteria OH- CO3-2 HCO3-

P1 > P2 340 ( P1 – P2) 1200 ( Pf – (P1-P2)) 0

P1 = P2 0 1200 Pf 0

P1 < P2 0 1200 Pf 1200 ( P2 – P1)

• The Garrett Gas Train is another method that uses weak acid to convert all

carbonate species to CO2 which is then measured in a Drager Tube. A conversion

factor is then used to determine the carbonate concentration.

Experienced mud engineers place little faith in the results of these tests when

determining the required treatment. There are a number of reasons for this.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Primarily the titration methods and end points are notoriously subject to error and

secondly, by the time the analysis has been completed, changes in mud chemistry will

have already occurred. A combination of judgement and pilot testing usually corrects the

problem.

In cases where the system does not respond to treatment or where continuous CO2

influxes occur, consideration should be given to converting the mud to a lime system.

The basic treatment for carbonate contamination is to precipitate the carbonate with the

calcium ion derived from either line (Ca OH2) or gypsum (CaSO4). The addition of

calcium will, however, have effect on bicarbonates. These must first be converted to

carbonates by the addition of hydroxyls. Conventionally this would be achieved either

with caustic soda or with lime. Bicarbonate cannot exist in the presence of hydroxyls.

Under normal conditions bicarbonates begin to convert to carbonates at a pH above 9.5.

The basic reactions that take place during the treatment are:

Lime

CO3-2 + HCO3- + 2Ca(OH)2 - CaCO3 + H2) + 3OH-

Gypsum + Lime or Gypsum + Caustic Soda

CO3-2 + HCO3- + 2Ca2+ + OH- - 2CaCO3 + H2O

A gypsum/caustic combination tends to be the preferred treatment in polymer mud’s as

good control of pH is possible. The combination of calcium and high pH in lime can be

detrimental to polymer performance. The use of large amounts of gypsum should be

avoided in clay-based fluids as the sulphate ion can itself cause severe flocculation.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Salts Formations and Brine Flows

By far the most commonly encountered salt in the drilling industry is sodium chloride.

Potassium chloride, calcium chloride and magnesium chloride are however, sometimes

drilled in complex evaporite sequences.

Source

Various chlorides are found in seawater, brine flows, salt domes, salt stringers and

massive complex evaporite formations.

Symptoms

Water Based Mud’s

The extend of the effects of contamination depends largely upon the mud type and the

concentration and type of contaminating salt. Divalent salts (calcium and magnesium)

will have a greater contaminating effect on water-based mud’s than mono-valent salts

(sodium and potassium). Freshwater bentonite mud or low salinity mud with active

drilled solids will be flocculated by high chlorides or by divalent ions in the salt. Viscosity

will initially increase but at very high chloride levels may decrease due to collapse of the

clay structure. Low solids polymer mud’s exhibit good resistance to salt contamination.

Oil Based (and Synthetic Oil Based) Mud’s

Oil based mud’s are largely unaffected by drilled salts although the water phase of the

mud will increase in salinity and may well reach saturation if massive salt is drilled.

Large brine flows can adversely affect oil mud’s. The mud tends to take on a grainy

appearance, rheology tends to increase as oil/water ratio decreases due to the water

content of the brine flow. Chloride content can show marked changes depending upon

the salt content of the brine flow. In extreme cases saturated brine flows can result in

re-crystallisation of the brine phase of the mud. This can result in removal of crystals at

the shakers and a corresponding loss of surfactant. If rapid remedial action is not taken

(i.e. replacement of surfactants water wetting of solids will occur and phase separation will

result). This can be disastrous in terms of borehole stability and well control. Similar

problems can occur if the brine flow contains magnesium chloride - this reacts with lime in

the mud and the resulting precipitation of magnesium hydroxide will strip surfactants from the

system.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

Preventative Measures and Remedial Action

The use of the correct mud weight will minimise brine flows into the system and

adjustment of mud weight must be the initial step in the prevention of further influx. Early

detection of a brine flow will minimise the volume and hence the effects of the brine

influx.

Water Based Mud’s

Chloride levels cannot practically be reduced by chemical precipitation. Dilution with

freshwater may reduce chlorides to tolerable levels but this is only feasible in low density

mud’s - the additions of barite required to maintain mud weight in a high weight mud

would be prohibitive in terms of time and cost. When using a bentonite system, pre-

hydration of the clay in drill water prior to addition to the active system will provide some

short term viscosity and filtration control. For longer term stability it will be necessary to

substitute salt resistant polymers (e.g. PAC, XC and Starch) for the bentonite.

Oil Based (and Synthetic Oil Based) Mud’s

The symptoms detailed above must be addressed as soon as they are recognised.

• When magnesium salts are present, from drilled formation or from brine flows,

addition of lime to the mud should cease.

When a brine flow is encountered, oil-wetting surfactants must be added steadily until

any hint of water wetting is removed.

There is an API test for water wetting but an experienced mud engineer will be aware of

the problem and begin treatment before the test is underway.

* Any trace of water or emulsion in the HTHP filtrate must be eradicated by the addition of an

appropriate combination of primary and secondary emulsifiers.

Edited: Peter Aird www.kingdomdrilling.co.uk Ref: MC001

You might also like

- The Use and Misuse of Centrifuges PDFDocument4 pagesThe Use and Misuse of Centrifuges PDFChandrasekar Srinivas MohanNo ratings yet

- All About Mud PDFDocument91 pagesAll About Mud PDFMASAGUS MANGKU GAMANo ratings yet

- OBM Syntethic PDFDocument23 pagesOBM Syntethic PDFzahid latifNo ratings yet

- All About MudDocument91 pagesAll About MudShamia Essam100% (1)

- Chemical Test (WBM) : SalinityDocument3 pagesChemical Test (WBM) : SalinityShamia EssamNo ratings yet

- Drilling Fluid IntroductionDocument11 pagesDrilling Fluid IntroductiongasmigasmiNo ratings yet

- 13 Contaminants - Part 1 NEWDocument18 pages13 Contaminants - Part 1 NEWLuis CarrilloNo ratings yet

- Lecture 2 - Drilling Fluids - Lab and MeasurementsDocument41 pagesLecture 2 - Drilling Fluids - Lab and MeasurementsJacob TuminskiNo ratings yet

- Designing & Managing Drilling FluidDocument11 pagesDesigning & Managing Drilling Fluidfisco4rilNo ratings yet

- Oil Based Mud Properties and UsesDocument7 pagesOil Based Mud Properties and Usesmmohsinaliawan100% (1)

- Drilling Fluids Lab FinalDocument24 pagesDrilling Fluids Lab FinalHameed Bin AhmadNo ratings yet

- A Drilling Guide To Shales and Related Borehole ProblemsDocument41 pagesA Drilling Guide To Shales and Related Borehole ProblemsNitul DoleyNo ratings yet

- PNG 451 Lab Manual 2012Document96 pagesPNG 451 Lab Manual 2012Alex RobertNo ratings yet

- Oil Based Mud or Fluids (OBM)Document7 pagesOil Based Mud or Fluids (OBM)mmohsinaliawanNo ratings yet

- BP Lost Circulation TechniquesDocument6 pagesBP Lost Circulation TechniquesInderjeet HoodaNo ratings yet

- Deep Water Drilling Fluid Design ExampleDocument65 pagesDeep Water Drilling Fluid Design Examplecrown212No ratings yet

- Mud FactsDocument91 pagesMud FactsShamia EssamNo ratings yet

- All About MudDocument91 pagesAll About MudDavide Boreaneze100% (1)

- Shale ProblemsDocument12 pagesShale ProblemsShirley Hernandez JimenezNo ratings yet

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Strengthen Wellbores During DrillingDocument32 pagesStrengthen Wellbores During Drillingrıdvan duranNo ratings yet

- 2 SPE 58793 OptibridgeDocument8 pages2 SPE 58793 OptibridgePT100% (1)

- LINEAR SWELL TEST MEASURES SHALE REACTIVITYDocument3 pagesLINEAR SWELL TEST MEASURES SHALE REACTIVITYAhmer AkhlaqueNo ratings yet

- Drilling ShaleDocument5 pagesDrilling ShaleJorge Garcia CardosoNo ratings yet

- Shale ProblemsDocument13 pagesShale ProblemsInggit Yulias Saputri100% (2)

- Cementing CalcDocument68 pagesCementing CalcEmad JamshidiNo ratings yet

- Low Viscosity Drilling Fluid, LSRVDocument8 pagesLow Viscosity Drilling Fluid, LSRVMohitTagotraNo ratings yet

- Surge and swab pressure calculationsDocument2 pagesSurge and swab pressure calculationsSyed IrtazaNo ratings yet

- Mud DF SystemDocument83 pagesMud DF Systemayman mohamed100% (1)

- Drilling FluidsDocument7 pagesDrilling FluidsAgus Riza RomadlonNo ratings yet

- 2-Drilling Fluids AdidtivesDocument36 pages2-Drilling Fluids AdidtivesHayder AliNo ratings yet

- Hole Cleaning 2Document7 pagesHole Cleaning 2Ramniwash SinghNo ratings yet

- Pilot Test: ScientificDocument12 pagesPilot Test: ScientificHomam MohammadNo ratings yet

- Advances in Inhibitive Water-Based Drilling Fluids - Can They Replace Oil-Based MudsDocument8 pagesAdvances in Inhibitive Water-Based Drilling Fluids - Can They Replace Oil-Based MudsNA NANo ratings yet

- Lost CirculationDocument11 pagesLost CirculationJulio Roca BrunoNo ratings yet

- Walid Questions, 2020Document69 pagesWalid Questions, 2020MoNo ratings yet

- Drilling Fluid Programme For PetromineDocument35 pagesDrilling Fluid Programme For Petrominejoonak konwarNo ratings yet

- DrilplexDocument6 pagesDrilplexLoganBohannonNo ratings yet

- 13 - Drilling Fluid FinalDocument20 pages13 - Drilling Fluid Finalمحمد سعيد100% (1)

- Drilling Fluids SelectionDocument16 pagesDrilling Fluids SelectionRashid Ali SheikhNo ratings yet

- Rule of Thumbs For MudDocument2 pagesRule of Thumbs For MudUsama Bin Sabir67% (3)

- Drilling Fluid 2 (C5)Document44 pagesDrilling Fluid 2 (C5)jibriilmustafa5No ratings yet

- DRILLING FLUID Presentation - TopshotDocument31 pagesDRILLING FLUID Presentation - Topshotjoseph_thana2001638150% (2)

- Mud Factors for Drilling OperationsDocument91 pagesMud Factors for Drilling OperationsRomadona Yoga PutratamaNo ratings yet

- 2 Spe 96798 HPWBM - HodderDocument12 pages2 Spe 96798 HPWBM - HodderPT100% (1)

- Torque Reduction Fluid AdditivesDocument6 pagesTorque Reduction Fluid AdditivesSLACKENGINEERNo ratings yet

- Mud Properties and Measurements Revised 02Document42 pagesMud Properties and Measurements Revised 02Karim Wasi100% (1)

- Swab and Surge Pressures SHBDocument1 pageSwab and Surge Pressures SHBstevebeardsleyNo ratings yet

- HYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughDocument1 pageHYDRO-GUARD® Water-Based Drilling Fluid Delivering Stable Wellbore ThroughFauzan Rahman HaqNo ratings yet

- Flat Rheology Drilling Fluid BenefitsDocument8 pagesFlat Rheology Drilling Fluid Benefitsمحمد سعيدNo ratings yet

- Management of Lost CirculationDocument8 pagesManagement of Lost CirculationKolawole AdisaNo ratings yet

- Flat RheologyDocument16 pagesFlat RheologyAnonymous JMuM0E5YONo ratings yet

- PHPA in Mineral Exploration, Oil Field Drilling & Oil ProductionDocument11 pagesPHPA in Mineral Exploration, Oil Field Drilling & Oil ProductionamistalokNo ratings yet

- TAMU - Pemex Offshore Drilling: Lesson 12A Shallow Water FlowsDocument40 pagesTAMU - Pemex Offshore Drilling: Lesson 12A Shallow Water Flowsdriller22No ratings yet

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDocument8 pagesDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinNo ratings yet

- Completion Fluid ProgramDocument8 pagesCompletion Fluid ProgramMessaoud Amr100% (1)

- Types of Water Based MudsDocument14 pagesTypes of Water Based MudsMuhammad MohtashimNo ratings yet

- Public Bar Contents Data Sheets Web Sales Data Sheets Sds-049Document2 pagesPublic Bar Contents Data Sheets Web Sales Data Sheets Sds-049Pablo Martínez BerenguerNo ratings yet

- Lab Tests For Stimulation PDFDocument14 pagesLab Tests For Stimulation PDFjorge_h_rivero100% (1)

- The Principles and Art of Cure by Homoeopathy by Herbert A Roberts Reading ExtractDocument23 pagesThe Principles and Art of Cure by Homoeopathy by Herbert A Roberts Reading ExtractManvi jainNo ratings yet

- Chapter 2 Chemical ReactionsDocument12 pagesChapter 2 Chemical Reactionskhaled daherNo ratings yet

- Resuscitation MedicationDocument1 pageResuscitation MedicationDen SinyoNo ratings yet

- Service Manual For Oil Samples and Oil Analysis: March 2012Document23 pagesService Manual For Oil Samples and Oil Analysis: March 2012hectorNo ratings yet

- Purification of salt for chemical and human consumptionDocument20 pagesPurification of salt for chemical and human consumptionmr sinaNo ratings yet

- United States Patent 0: Patented Feb. 26, 1957 2Document8 pagesUnited States Patent 0: Patented Feb. 26, 1957 2Muh Ridho YuliantoNo ratings yet

- ElectrochemistryDocument7 pagesElectrochemistrySyed OmerNo ratings yet

- June 2015 Question Paper 21 PDFDocument16 pagesJune 2015 Question Paper 21 PDFHimakshi DhirNo ratings yet

- Magnesium Recovery From Desalination BrineDocument6 pagesMagnesium Recovery From Desalination BrineamirNo ratings yet

- BAMU B.pharmacy First Year SyllabusDocument31 pagesBAMU B.pharmacy First Year SyllabusGajanan Vaishnav0% (1)

- MagChlor PDFDocument6 pagesMagChlor PDFDonte WeberNo ratings yet

- ASTM E 534-98 (Chemical Analysis of Sodium Chloride)Document6 pagesASTM E 534-98 (Chemical Analysis of Sodium Chloride)Said MohamedNo ratings yet

- Characteristic of POME OilDocument2 pagesCharacteristic of POME OilJulie MahadiNo ratings yet

- D2880 380331-1 PDFDocument7 pagesD2880 380331-1 PDFVidyasenNo ratings yet

- Word EquationsDocument6 pagesWord EquationsJohnRenzoMolinarNo ratings yet

- Chemistry: Pearson EdexcelDocument24 pagesChemistry: Pearson EdexcelBryan YeohNo ratings yet

- CC - v34 - n8 - p1275 (The Confused Word of Sulphate Attack On Concrete - Neville 2004)Document22 pagesCC - v34 - n8 - p1275 (The Confused Word of Sulphate Attack On Concrete - Neville 2004)padilhajrNo ratings yet

- Mercuric Chloride MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesMercuric Chloride MSDS: Section 1: Chemical Product and Company IdentificationFitria Wahyu KurniawatiNo ratings yet

- US3936501Document3 pagesUS3936501qaim abbasNo ratings yet

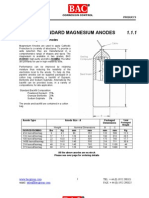

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- Inclusions in MagnesiumDocument18 pagesInclusions in MagnesiumThalia HerreraNo ratings yet

- Chloride: The Forgotten Essential MineralDocument4 pagesChloride: The Forgotten Essential MineralEngga Swari RatihNo ratings yet

- Astm G 97 PDFDocument3 pagesAstm G 97 PDFJORGE ARTURO TORIBIO HUERTA0% (1)

- 22 Jan 21 AFRICAN FLAMINGO (9802322) IFO 180 (RMG 180) : Report Date Vessel Fuel GradeDocument4 pages22 Jan 21 AFRICAN FLAMINGO (9802322) IFO 180 (RMG 180) : Report Date Vessel Fuel GradeNguyễn Hữu DũngNo ratings yet

- Farm To TableDocument12 pagesFarm To TableJacquelynKosNo ratings yet

- Acids and Alkalis SAT Questions 3-6Document10 pagesAcids and Alkalis SAT Questions 3-6balala100% (1)

- Pharmaceutical Inorganic ChemistryDocument26 pagesPharmaceutical Inorganic Chemistryvivek vermaNo ratings yet

- Kertas2 PPT T4 - Soalan SMSSIDocument18 pagesKertas2 PPT T4 - Soalan SMSSINurliana Roslan0% (1)

- Nigerian Standard For Drinking Water QualityDocument28 pagesNigerian Standard For Drinking Water QualityIsa Usman100% (1)

- Salinidad Quimico - ASTM D512-12 PDFDocument8 pagesSalinidad Quimico - ASTM D512-12 PDFEdwin GarzónNo ratings yet