Professional Documents

Culture Documents

Carillo Rod Bolts Tech Info

Uploaded by

agrandi12Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carillo Rod Bolts Tech Info

Uploaded by

agrandi12Copyright:

Available Formats

The CARRILLO connecting rod is a precision, high strength, quality connecting rod, which when properly installed and

maintained, will perform

flawlessly in today’s racing and high performance internal combustion engines. We would like to offer some suggestions and specifications that

should be helpful in your installation.

BOLTS

All bolts should be lubricated under the heads as well as on the threads. We recommend the bolt lube included, or as an alternative, molybde-

num base paste mixed with engine oil.

The preferred method to torque the bolt is by using the stretch figure listed in the table below. In order to check bolt stretch, simply fixture one

rod, leaving the cap portion free from clamping load. Measure both bolt lengths loose, then progressively tighten the bolt until the measured

increase in length correlates with the figures below. Use the indicated torque reading to tighten all the connecting rods in final assembly.

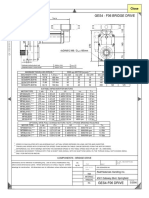

STRETCH STRETCH TORQUE TORQUE

Head

THREAD TYPE RECOMMENDED RECOMMENDED NOT TO EXCEED NOT TO

Marking

English Metric English EXCEED Metric

1/4 CARR S4 .0040 to .0060in 0.102 to 0.152 275 inlb 31 Nm

5/16 WMC H5 .0040 to .0060in 0.102 to 0.152 30 ftlb 41 Nm

5/16 CARR S5 .0050 to .0070in 0.127 to 0.178 40 ftlb 54 Nm

3/8 WMC H6 .0050 to .0065in 0.127 to 0.165 40 ftlb 54 Nm

3/8 CARR S6 .0050 to .0070in 0.127 to 0.178 58 ftlb 79 Nm

7/16 WMC H7 .0050 to .0070in 0.127 to 0.178 70 ftlb 95 Nm

7/16-1 WMC H71 .0050 to .0070in 0.127 to 0.178 70 ftlb 95 Nm

7/16 CARR S7 .0050 to .0070in 0.127 to 0.178 100 ftlb 136 Nm

M8 WMC HM8 .0040 to .0055in 0.102 to 0.140 20 ftlb 27 Nm

M8-1 CARR SM81 .0040 to .0055in 0.102 to 0.140 30 ftlb 41 Nm

M8 CARR SM8 .0045 to .0060in 0.114 to 0.152 30 ftlb 41 Nm

M9 WMC HM9 .0045 to .0060in 0.114 to 0.152 40 ftlb 54 Nm

M9 CARR SM9 .0045 to .0060in 0.114 to 0.152 45 ftlb 61 Nm

M10 WMC HM10 .0045 to .0060in 0.114 to 0.152 45 ftlb 61 Nm

M10 CARR SM10 .0050 to .0070in 0.127 to 0.178 55 ftlb 75 Nm

DO NOT MAGNAFLUX CARRILLO CONNECTING RODS WITH BOLTS INSTALLED

CLEARANCES

Bearing clearances are dictated primarily by the bearing, not by the housing bore of the connecting rods. The connecting rod bore determines

crush. Bearing clearances vary as to the application, diameter of the journal and bearing design. An approximate factor would be .001 per

1.000” diameter of crankshaft pin measured at the crown of the bearing surface.

Wrist pin to bushing clearance is variable per diameter as well. The following is a reference scale:

WRIST PIN DIAMETER CLEARANCE MAXIMUM CLEARANCE

.500 to 0.750” .0010” .0016”

.751 to 1.094” .0012” .0020”

Prior to disassembly of the connecting rod, number the connecting rod and matching cap. DO NOT use a metal stamp!

GUARANTEE

We guarantee the quality of the steel, the forging, the heat treat process, and the dimensional sizes. We have no control over the assembly or

customer modification of the connecting rod in the engine. There are no further guarantees either expressed or implied by CARRILLO INDUS-

TRIES or any of their agents or representatives.

CARRILLO INDUSTRIES reserves the right to alter the design or initiate product changes without incurring liability or obligation with respect to similar products previously manufac-

tured by this concern.

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Camshaft List DetroitDocument6 pagesCamshaft List Detroitcristian picadoNo ratings yet

- SpecificationsDocument366 pagesSpecificationsDanmer Wilian CcosccoNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Standard Bolt Specs and Torque ValuesDocument85 pagesStandard Bolt Specs and Torque Valuescpgmotors83% (6)

- Service Manual Cat G3416eDocument753 pagesService Manual Cat G3416eUsaha MandiriNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Briggs & Stratton Discount Parts GuideDocument171 pagesBriggs & Stratton Discount Parts Guidedatgoodbook100% (7)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Hummer H3 Manual TransmissionDocument369 pagesHummer H3 Manual TransmissionmohamedezeldinNo ratings yet

- MSS SP-89 (1998) PDFDocument20 pagesMSS SP-89 (1998) PDFadprimNo ratings yet

- Book of Making v1 PDFDocument180 pagesBook of Making v1 PDFOmar Bucio100% (2)

- Honda XR200 engine tuning optionsDocument14 pagesHonda XR200 engine tuning optionsCamilo Gomez100% (1)

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- 093400-5350 Mitsubishi PDFDocument2 pages093400-5350 Mitsubishi PDFBaytolgaNo ratings yet

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20From EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20No ratings yet

- Training Manual - S8000 Complete (Tier 3) PDFDocument26 pagesTraining Manual - S8000 Complete (Tier 3) PDFJUNA RUSANDI S100% (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Technical Information On Wire Ropes BridonDocument14 pagesTechnical Information On Wire Ropes BridonAndrew PeterNo ratings yet

- The Portfolio and The DiagramDocument404 pagesThe Portfolio and The DiagramNuno Arnaud100% (1)

- Engine Service Specifications: © 1998-2009 American Honda Motor Co., Inc. - All Rights Reserved AHMDocument42 pagesEngine Service Specifications: © 1998-2009 American Honda Motor Co., Inc. - All Rights Reserved AHMazry_alqadry0% (1)

- A1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1Document20 pagesA1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1khabiranNo ratings yet

- 1600 Kva GTPDocument3 pages1600 Kva GTPBADRI VENKATESHNo ratings yet

- HydrojettingSafeWorkProcedureRPNC151982 PDFDocument21 pagesHydrojettingSafeWorkProcedureRPNC151982 PDFasdfse100% (2)

- Training Manual - S8000 Complete (Tier 3) PDFDocument26 pagesTraining Manual - S8000 Complete (Tier 3) PDFJUNA RUSANDI S100% (1)

- Service Manual Engine 4nn Muz 660 e YamahaDocument139 pagesService Manual Engine 4nn Muz 660 e YamahaKozakSaasdejhtyNo ratings yet

- How Steam is Generated and Circulated in BoilersDocument58 pagesHow Steam is Generated and Circulated in BoilersRahul Jawda80% (5)

- Simulation Study of Cryogenic Air Separation PDFDocument58 pagesSimulation Study of Cryogenic Air Separation PDFAHMEDNo ratings yet

- Design Calculation For L Angle - Eurocode DesignDocument2 pagesDesign Calculation For L Angle - Eurocode Designvikramjain660% (1)

- Doosan Common Rail Diesel Engine OverviewDocument34 pagesDoosan Common Rail Diesel Engine Overviewvarthot0% (1)

- AIS Best Teaching MaterialDocument121 pagesAIS Best Teaching MaterialHay Jirenyaa100% (1)

- Engine Service Manual Renegade 300 SeriesDocument76 pagesEngine Service Manual Renegade 300 SeriesArul Gnana JohnNo ratings yet

- TS90, TS100, TS110 Equipment Repair Specifications ManualDocument51 pagesTS90, TS100, TS110 Equipment Repair Specifications ManualAmanda NunesNo ratings yet

- Mbnz-om906la-Om926la Manual Repair - PDF Versión 12Document3 pagesMbnz-om906la-Om926la Manual Repair - PDF Versión 12Aron Emanuel Mendoza LopezNo ratings yet

- 21 Steel Bolt Instruction SheetDocument2 pages21 Steel Bolt Instruction SheetAndrew LiebermannNo ratings yet

- TorquimetrosDocument1 pageTorquimetrosRommel CalleNo ratings yet

- Click Torque Wrenches Metal Handle Dual ScaleDocument1 pageClick Torque Wrenches Metal Handle Dual ScaleGuido MorenoNo ratings yet

- S01 General InformationsDocument8 pagesS01 General Informationsmartin medinaNo ratings yet

- Prueba Resorte de EmbragueDocument2 pagesPrueba Resorte de Embraguejohan gomezNo ratings yet

- 303-01c Engine - V8 (4V)Document94 pages303-01c Engine - V8 (4V)Darren ANo ratings yet

- Service SpecificationsDocument24 pagesService SpecificationsBob DesmetNo ratings yet

- HT Series Frameless Torque Motors DatasheetDocument14 pagesHT Series Frameless Torque Motors DatasheetwaqargilllNo ratings yet

- 038 - Disc BrakesDocument114 pages038 - Disc BrakesGedas GvildysNo ratings yet

- Two Stage Snow Engine Service Manual: Residential ProductsDocument48 pagesTwo Stage Snow Engine Service Manual: Residential ProductsBJ DixNo ratings yet

- wlt600 2enDocument26 pageswlt600 2enAldo BravoNo ratings yet

- Service Specifications Guide for Vehicle Maintenance and RepairDocument34 pagesService Specifications Guide for Vehicle Maintenance and Repairalvaro garciaNo ratings yet

- Engine t14 t16 Technical DataDocument7 pagesEngine t14 t16 Technical DataJefferson Humbereto Herrera AlfonsoNo ratings yet

- 2005 FZ6-S Service ManualDocument20 pages2005 FZ6-S Service ManualBratkó BenceNo ratings yet

- TMP - 20393 Barmex Ruland Oldham 07101550358290Document8 pagesTMP - 20393 Barmex Ruland Oldham 07101550358290Ramsay BoltNo ratings yet

- HT0500x FramelessTorqueMotors Datasheet R5Document4 pagesHT0500x FramelessTorqueMotors Datasheet R5MouliNo ratings yet

- Design & Development of Copaction Trail With PMDocument13 pagesDesign & Development of Copaction Trail With PMArunKumarNo ratings yet

- Walk Behind Mower Engine Service Manual: Residential ProductsDocument46 pagesWalk Behind Mower Engine Service Manual: Residential ProductsZachary CurtisNo ratings yet

- 19-Tec1416 TSDocument1 page19-Tec1416 TSIndra burnamaNo ratings yet

- No. No. Part Deskripsi Jumlah Keterangan (Torque/Clearance/Dll) Ref. CB150R 2012Document16 pagesNo. No. Part Deskripsi Jumlah Keterangan (Torque/Clearance/Dll) Ref. CB150R 2012BEY ONENo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin TtitoNo ratings yet

- Especificaciones de Servicio Toyota 4AFE - 2Document5 pagesEspecificaciones de Servicio Toyota 4AFE - 2Jhonny Nahin Ventura AkdNo ratings yet

- Omni Motors Data Sheet English 060122Document12 pagesOmni Motors Data Sheet English 060122Stjepan CrnkovićNo ratings yet

- Eibach Molle Ems-CatalogDocument16 pagesEibach Molle Ems-CatalogLorenzo Otto Otto ValdarnottiNo ratings yet

- Clicker Wrench: Quick Release Button Ratchet Reversing Lever Lock RingDocument2 pagesClicker Wrench: Quick Release Button Ratchet Reversing Lever Lock RingCristinaPradaNo ratings yet

- 602 Ssab Toolox Machining Rec 6 PDFDocument20 pages602 Ssab Toolox Machining Rec 6 PDFRodolfoMarín100% (1)

- AGV SeriesDocument6 pagesAGV SeriesMAHESHNo ratings yet

- Cylinder Liner Protrusion Specifications for Popular Diesel EnginesDocument2 pagesCylinder Liner Protrusion Specifications for Popular Diesel EnginesmbsstartNo ratings yet

- D16V1 SpecDocument2 pagesD16V1 SpeclavivavapeNo ratings yet

- Material List: Hydraulic WinchDocument13 pagesMaterial List: Hydraulic WinchBimo Cungkring IINo ratings yet

- AMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitDocument11 pagesAMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitIrfan05No ratings yet

- Ges4 - f06 Drive-Imperial 0Document1 pageGes4 - f06 Drive-Imperial 0KracinNo ratings yet

- Ges4 - f06 Drive-Imperial 0Document1 pageGes4 - f06 Drive-Imperial 0KracinNo ratings yet

- Ges4 - f06 Drive-Imperial 0Document1 pageGes4 - f06 Drive-Imperial 0KracinNo ratings yet

- Ges4 - f06 Drive-Imperial 0Document1 pageGes4 - f06 Drive-Imperial 0KracinNo ratings yet

- Maintenance Manual General Informations: Original InstructionsDocument8 pagesMaintenance Manual General Informations: Original InstructionsFer NuñezNo ratings yet

- 09 Manual Transaxle SystemDocument29 pages09 Manual Transaxle SystemMuhammad Eitch-BeeNo ratings yet

- Camshaft Inspection and Clearance CheckDocument1 pageCamshaft Inspection and Clearance Checknetifig352No ratings yet

- Thermodynamic Architecture for Sustainable Port StructuresDocument2 pagesThermodynamic Architecture for Sustainable Port StructuresNiña Jayne GurangoNo ratings yet

- Embankment Settlement Design CriteriaDocument8 pagesEmbankment Settlement Design CriteriaMehdi.MostNo ratings yet

- Process Modelling, Simulation and Control For Chemical Engineers. Solved Problems. Chapter 7: Conventional Control Systems and Hardware: Part IIDocument16 pagesProcess Modelling, Simulation and Control For Chemical Engineers. Solved Problems. Chapter 7: Conventional Control Systems and Hardware: Part IIJohnNo ratings yet

- SR100 PDFDocument6 pagesSR100 PDFSandeep Kumar DangdaNo ratings yet

- Mpofana Municipality General Valuation Roll - 31 March 2019Document144 pagesMpofana Municipality General Valuation Roll - 31 March 2019Sherebanu KajeeNo ratings yet

- Sample Dew Point CalculationDocument3 pagesSample Dew Point Calculationapi-3709413100% (1)

- Cesmm Rev 9Document209 pagesCesmm Rev 9antscarNo ratings yet

- List SSOP Rig 2 - Bridging DocumentDocument11 pagesList SSOP Rig 2 - Bridging DocumentRizki YanuarNo ratings yet

- Manufacturing Technology ME-405: Unit - I BroachingDocument17 pagesManufacturing Technology ME-405: Unit - I BroachingYogesh DewangNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- Hotel Components and Other PartsDocument153 pagesHotel Components and Other PartsmarkalvinbonNo ratings yet

- BNO055 9DOF DatasheetDocument119 pagesBNO055 9DOF DatasheetPaola HasmannNo ratings yet

- 2550CIDocument109 pages2550CITuan NguyenNo ratings yet

- HP 4142Document22 pagesHP 4142Edward ConalNo ratings yet

- STS 1ph-3ph Operating Manual REV B Low ResDocument49 pagesSTS 1ph-3ph Operating Manual REV B Low RessamuraivickyNo ratings yet

- Manual Control Yuhai 1000MdbDocument121 pagesManual Control Yuhai 1000MdbHubert Vásquez Cueva100% (2)

- Filtration+Separation - A New Trend in Mobile Water-Treatment Plant HireDocument3 pagesFiltration+Separation - A New Trend in Mobile Water-Treatment Plant HireMaddenNo ratings yet

- Cairo University Electronics Course Chapter on Operational AmplifiersDocument16 pagesCairo University Electronics Course Chapter on Operational AmplifiersMerna AtefNo ratings yet