Professional Documents

Culture Documents

Trouble KV e

Uploaded by

Sylvester SullivanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trouble KV e

Uploaded by

Sylvester SullivanCopyright:

Available Formats

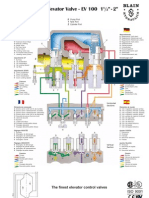

Hydraulic Elevators Technical Info No.

K10a

KV Elevator Control Valve

Trouble Shooting Up Travel

Jan. 2000

I Valves are fully adjusted at the factory. Check electrical operation before changing valve setting. II For checking operation of the solenoids, remove the top nuts. By lifting the solenoids a few millimeters the magnetic pull of the solenoid can be felt as well as the operation of the elevator car. Problem Possible cause 1) Solenoid A not energised or voltage too low. 2) Solenoid A tube not screwed down tight. 3) Solenoid valve A dirt between needle and seat. 4) Orifice in bypass valve blocked. 5) Adjustment 1 is too far back (not enough pilot pressure, minimum 5 bar) or bypass flow guide too large (slots too wide). 6) Relief valve set too low. 7) Down valve 7 or 9 is open due to contamination in its orifice. (Especially if the elevator settles back on the buffers after pump is stopped). 8) Pump running in the wrong direction. 9) The pump is undersize or worn. 10) The pump connection flange is leaking excessively. 11) See 7), 9) and 10) above. 12) Solenoid C not energised or voltage too low. 13) 14) 15) Up Start too hard 16) 17) 18) 28) 29) 30) floor level. Relief-Valve not adjustable to lower value. 31) 32) Recommended See note II at top of page. Turn adjustment 5 all the way in. If the elevator now starts upwards the problem is at solenoid A. Change bypass valve at U. With the pump running, turn adjustment 1 in, or if already too far, insert smaller bypass flow guide (see diagram literature EV). Set higher Replace down valves 7 (KV2 only) and 9.

No Up-Start (Elevator remains at floor)

Up Start but no Full Speed

Elevator slows down but travels

If by turning adjustment 1 with the pump running the pressure does not rise above 5 bar, even with a smaller bypass valve inserted, the problem should be sought under 8), 9) or 10). --See note II at top of page. Turn restriction 3 all the way in. If the elevator now travels with full Dirt in solenoid C or solenoid tube not pulled speed, the cause is 12) or 13). up tight. Adjustment 1 turned in too far. Open adjustment 1. Bypass flow guide U too small (slots too Change to flow guide with wider slots. narrow). See also 32) below. Star to delta motor switch period is too long. 0,2 - 0,3 secs. is sufficient. UO O-ring on the bypass valve U is leaking. Change O-ring. Excessive friction on the guide rails or in the Can not be eliminated through valve adjustment. cylinder head. Solenoid A (Up stop) is de-energised too See note II at top of page. late. Adjustment 5 (Soft Stop) not far enough Open further out. open. Adjustment 1 Bypass not far enough open Open adjustment 1 two turns further out. and pump flow does not completely by-pass. Adjustment 1 too far in. Open adjustment 1 further out. pipe thread connection in return line T With tape threads, 4 6 threads of engagement should not exceed 14 mm. is sufficient.

Page 1/2

Hydraulic Elevators Technical Info No. K10a

KV Elevator Control Valve

Trouble Shooting Down Travel

Jan. 2000

Problem No Down Start (Elevator remains at floor) KV2 only: Down start but no full speed KV2 only: Down full speed but no Down leveling Elevator travels

Possible cause Recommended 51) Solenoid D not energised or voltage too low. See note II at top of page 1. 52) 53) 54) 55) Adjustment 6 not open enough. O-ring XO on down valve, leaking. Solenoid C not energised or voltage too low. Adjustment 7 (Full speed down) not far enough open. 56) Solenoid D not energised (possibly solenoids C and D reversed). 57) Adjustment 9 (Down Leveling speed) not far enough open. 58) Down flow guide too small (slots too narrow). 59) Down Leveling speed 9 too fast. Open 6 further out. Replace. See note II at top of page 1. Open 7 further. See note II at top of page 1. Open 9 further out. Change flow guide. Adjust to between 6 and 10 cm/sec. Clean or change needle and seat. Replace flow guide. Replace and test in sequence. Where possible, isolate and check. Consider oil cooler to keep oil temperatures down.

Page 2/2

through the lower floor. 60) Solenoid Valve C leaking at needle. 61) Orifice in flow guide contaminated. 62) Leak at DN, XO, VO, WO or HO. With KVH valve, HN instead of DN. 63) Other valve or handpump in system leaking. 64) Contraction of oil during cooling especially from above 35C.

Leakage (Elevator sinks away from floor).

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 21016 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

You might also like

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain Sys Leak EVDocument1 pageBlain Sys Leak EVSylvester SullivanNo ratings yet

- Troubleshooting GuideDocument8 pagesTroubleshooting GuideSylvester SullivanNo ratings yet

- Trouble Ev eDocument2 pagesTrouble Ev eSylvester SullivanNo ratings yet

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDocument1 pageEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDocument5 pagesRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanNo ratings yet

- Sys Leak EVDocument1 pageSys Leak EVSylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- HPDocument2 pagesHPSylvester SullivanNo ratings yet

- MD eDocument4 pagesMD eSylvester SullivanNo ratings yet

- Ev eDocument6 pagesEv eSylvester SullivanNo ratings yet

- Quick Adj Ev eDocument2 pagesQuick Adj Ev eSylvester SullivanNo ratings yet

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Document1 pageSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanNo ratings yet

- Full KV Valves InfoDocument6 pagesFull KV Valves InfoSylvester Sullivan100% (1)

- Flow - Pressure Chart (US and Metric)Document4 pagesFlow - Pressure Chart (US and Metric)Sylvester SullivanNo ratings yet

- Blain BVDocument2 pagesBlain BVSylvester SullivanNo ratings yet

- EV Poster34Document1 pageEV Poster34Sylvester SullivanNo ratings yet

- Blain CX-EDocument1 pageBlain CX-ESylvester SullivanNo ratings yet

- Blain Sys Leak KVDocument1 pageBlain Sys Leak KVSylvester SullivanNo ratings yet

- Blain Service Manual LowDocument15 pagesBlain Service Manual LowSylvester SullivanNo ratings yet

- EV Poster1-12Document1 pageEV Poster1-12Sylvester SullivanNo ratings yet

- Blain Spare Parts EV KVDocument2 pagesBlain Spare Parts EV KVSylvester SullivanNo ratings yet

- Blain RL-EDocument4 pagesBlain RL-ESylvester SullivanNo ratings yet

- Blain Price List 300 Euro 2008Document1 pageBlain Price List 300 Euro 2008Sylvester SullivanNo ratings yet

- Blain MD - GBDocument4 pagesBlain MD - GBSylvester SullivanNo ratings yet

- Blain KV-GBDocument6 pagesBlain KV-GBSylvester SullivanNo ratings yet

- Blain HP - 4spDocument2 pagesBlain HP - 4spSylvester SullivanNo ratings yet

- Blain KV Trouble-GbDocument2 pagesBlain KV Trouble-GbSylvester Sullivan100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tigo Pesa Account StatementDocument7 pagesTigo Pesa Account StatementPeter Ngicur Carthemi100% (1)

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilNo ratings yet

- Attributes and DialogsDocument29 pagesAttributes and DialogsErdenegombo MunkhbaatarNo ratings yet

- Conv VersationDocument4 pagesConv VersationCharmane Barte-MatalaNo ratings yet

- Reader's Digest (November 2021)Document172 pagesReader's Digest (November 2021)Sha MohebNo ratings yet

- ERP Complete Cycle of ERP From Order To DispatchDocument316 pagesERP Complete Cycle of ERP From Order To DispatchgynxNo ratings yet

- Site Visit Risk Assessment FormDocument3 pagesSite Visit Risk Assessment FormAmanuelGirmaNo ratings yet

- Android software download guideDocument60 pagesAndroid software download guideRizky PradaniNo ratings yet

- Oxford Digital Marketing Programme ProspectusDocument12 pagesOxford Digital Marketing Programme ProspectusLeonard AbellaNo ratings yet

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- GlastonburyDocument4 pagesGlastonburyfatimazahrarahmani02No ratings yet

- ABP - IO Implementing - Domain - Driven - DesignDocument109 pagesABP - IO Implementing - Domain - Driven - DesignddoruNo ratings yet

- SEG Newsletter 65 2006 AprilDocument48 pagesSEG Newsletter 65 2006 AprilMilton Agustin GonzagaNo ratings yet

- Tension field beams: Aircraft wing spar analysisDocument19 pagesTension field beams: Aircraft wing spar analysisPrajeesh RajNo ratings yet

- IoT BASED HEALTH MONITORING SYSTEMDocument18 pagesIoT BASED HEALTH MONITORING SYSTEMArunkumar Kuti100% (2)

- Social Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityDocument9 pagesSocial Media Exposure and Its Perceived Impact On Students' Home-Based Tasks ProductivityJewel PascuaNo ratings yet

- AZ-900T00 Microsoft Azure Fundamentals-01Document21 pagesAZ-900T00 Microsoft Azure Fundamentals-01MgminLukaLayNo ratings yet

- Postgraduate Notes in OrthodonticsDocument257 pagesPostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- UTP3-SW04-TP60 Datasheet VER2.0Document2 pagesUTP3-SW04-TP60 Datasheet VER2.0Ricardo TitoNo ratings yet

- Rohit Patil Black BookDocument19 pagesRohit Patil Black BookNaresh KhutikarNo ratings yet

- Dole-Oshc Tower Crane Inspection ReportDocument6 pagesDole-Oshc Tower Crane Inspection ReportDaryl HernandezNo ratings yet

- Three-D Failure Criteria Based on Hoek-BrownDocument5 pagesThree-D Failure Criteria Based on Hoek-BrownLuis Alonso SANo ratings yet

- Striedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsDocument22 pagesStriedter - 2015 - Evolution of The Hippocampus in Reptiles and BirdsOsny SillasNo ratings yet

- Experiences from OJT ImmersionDocument3 pagesExperiences from OJT ImmersionTrisha Camille OrtegaNo ratings yet

- Phys101 CS Mid Sem 16 - 17Document1 pagePhys101 CS Mid Sem 16 - 17Nicole EchezonaNo ratings yet

- DNA Gel Electrophoresis Lab Solves MysteryDocument8 pagesDNA Gel Electrophoresis Lab Solves MysteryAmit KumarNo ratings yet

- Journal Entries & Ledgers ExplainedDocument14 pagesJournal Entries & Ledgers ExplainedColleen GuimbalNo ratings yet

- GATE ECE 2006 Actual PaperDocument33 pagesGATE ECE 2006 Actual Paperkibrom atsbhaNo ratings yet

- Tech Data: Vultrex Production & Drilling CompoundsDocument2 pagesTech Data: Vultrex Production & Drilling CompoundsJeremias UtreraNo ratings yet

- Oracle Learning ManagementDocument168 pagesOracle Learning ManagementAbhishek Singh TomarNo ratings yet