Professional Documents

Culture Documents

Top End Install GY6

Uploaded by

a10526268Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top End Install GY6

Uploaded by

a10526268Copyright:

Available Formats

THE SCOOTDAWG

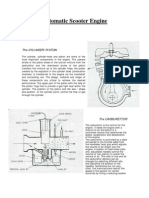

GY6 BIG BORE KIT AND TOP END REBUILD GUIDE

2005 SCOOTDAWG ENTERPRISES ALL RIGHTS RESERVED Visit www.ScootDawg.com

The following is a general guide for installing a big bore kit or rebuilding the GY6 type engine. It is not complete and I hope to improve on it over time. I encourage anyone who has photos or suggestions for improving this guide to email Lee@ScootDawg.com The photographs in this booklet are installing an 80cc bore kit in a 50cc GY6. Readers should take not that there can be minor variations in this as there are numerous companies in China who manufacture the GY6. The first step in the install is to take an inventory of the parts you have received in the kit. Depending on who you buy from, you may or may not have a new camshaft. Then you need to read, research and feel comfortable that you have a basic understanding of every step before you even touch a wrench. Some of the photographs used show the engine removed from the scooter. It is not necessary to remove the engine from the scooter. As a matter of fact the scooter provides a solid place to hold the engine while you work. It is very helpful to get the scooter elevated so the engine is at a good working level. Remove all the body panels from around the engine. Keep your work area clean and lay out parts in an orderly manner as you remove them. Take pictures and notes. It s easy to forget how things go back together.

Fig 1. Body panels removed for full access to engine

Fig. 2. Remove fan cover

Fig. 3. Remove carb inlet tube.

Fig. 4. Remove plastic cover around engine

Fig. 5. Remove cylinder head cover.

Fig. 6. Remove camshaft caps (before)

Fig. 7. After

Fig. 8. Remove the chain regulator

Figs. 9 a & b. Remove the camshaft.

Fig. 10. Remove Gasket.

Fig. 11. Remove cylinder head.

Fig. 12. Remove gasket 8

Fig. 13. Remove chain guide.

Fig. 14. Remove cylinder. This is starting to get fun!

Fig. 15. Remove circlips and piston pin from the piston. Don t throw out those circlips. My kit was missing one and I needed to re-use one of the old ones.

10

Fig. 16, remove the piston. At this point you want to protect the engine by stuffing a clean dry rag into the opening

Fig. 17. Protect engine opening. Now you ve done it. It s all in pieces. I hope you can get it back together!

11

12

Top End Install for GY6 Part B

NOTE: Not all steps are included. Use a little common sense and install gaskets, washers, pins, nuts and bolts at the proper time. Hey, I can t do everything for you!

A word about the rings before we go any further. You should have five piston rings. The two thin rings along with the wavy ring are your oil rings. They will all need to fit into the wider groove on the lower side of the piston. This is no easy chore. These rings are brittle and you must be careful not to bend them too much installing them or they will break. The way to install these rings is as follows: It is imperative that you make sure the rings are properly gapped before proceeding with the install. Mine happened to be gapped properly from the factory but that is not always the case. If the rings don t have enough gap, they will expand when heated and the ends will butt against each other and shatter. Too much gap and you will loose compression. I found several formulas on the net to figure what the ring gap should be. I don t have the formulas written down but I do have a note that I ended up setting my gap at .008 . The following instructions were written by William Longyard in the Yahoo Geely Group and I quote here with his permission:

13

Gapping rings is not hard IF you GO SLOW.

1. Gently insert ring into cylinder bore. 2. Bring piston (without any rings) up into cylinder so that it just touches the ring. Press the ring down so that it "seats" on top of the piston. 3. With a feeler gauge measure the gap. 4. If it is within spec do nothing. 5. If it is too small reinsert the piston and slowly push the ring out of the cylinder. MOST RINGS ARE CAST IRON, THEY BREAK EASILY. 6. Clamp a VERY thin file upright in a vise. Carefully with two hands JUST slightly open the ring gap so that the ends meet the file. Do a couple of strokes. 7. RECHECK gap. 8. Repeat until gap with within specs.

I know this sounds like a PITA, but if you don't do it when the rings expand under heat, IF the ends touch each other the ring will instantly disintegrate. Most aftermarket rings are NOT properly gapped.

Two more points: Some people like to use ring expanders to install rings. Also, you can call a lawnmower shop and tell them the diameter of your piston and they can ballpark the right gap for you. Tell them whether it is two or four stroke.

Good luck, Bill Longyard

Once you know you have your rings properly gapped, you can proceed with installing them on the piston. Lubricate the piston and rings lightly with oil. The wavy ring goes on first. This part is TRICKY, proceed with caution. Two pairs of hands is useful. The two thin rings so on either side of the wavy ring. The only way you will get these rings into this groove is to put the wavy ring in first, then you must approach the groove with each ring from it s own direction. In other words, one thin ring from the top of the piston and one from the bottom. Keep at it until all three rings are fully in the groove. The larger rings are next. One of them is designed for the top of the piston. The top one should have a mark or letter on one side of the ring. The mark should face up. Also, these rings are beveled and the bevel should face UP. Often the beveled edges are shiny.

14

Fig. 1. Rings finally in after many smokes, grunts and curses.

15

Fig. 2. Piston and Rings. This illustration shows the rings with a 120degree gap. Most knowledgeable people I have spoken with recommend a180degree gap with the ring gaps being perpendicular to the wrist pin. In other words, the ring gaps should NOT be on the side of the piston thrust as it rides the cylinder. Installing the rings is the most tedious part of the build and you must be patient and do it right. It s critical.

16

Figs. 3 a, b & c. Installation of Piston.

17

Install piston, pin with circlips.

Fig. 4. Install the cylinder over the piston. Most people us a ring compressor or even a hose clamp to keep the rings tight when sliding the cylinder on. Again, make sure everything is lightly lubricated.

18

Fig. 5. Install the chain guide.

Fig. 6. Install two alignment pins.

19

Fig 7. a & b. Install the cylinder head. Rotate the magneto and chain until the markings are lined up.

20

Fig. 8. Install the camshaft.

Fig. 9 a & b. Note the lines must be even with the edge of the head. 21

Fig. 10. Install alignment pins

22

Fig. 11. Install valve seat and washers

Fig. 12. Install chain tension assembly.

23

Fig. 12b. Install chain tension.

24

Fig 13 a & b. Adjust valve clearance. Use a feeler guage. Inlet valve .008 Outlet valve .010. Others have reported better results with a little wider clearance.

25

Fig. 14. Install gasket

Fig. 15. Install head cover.

26

. Fig. 16. Install carb inlet tube.

Fig. 17. Install fan cover, wires etc.

27

Fig. 18. Installation complete. Start her up and hope for the best.

28

You might also like

- Harley Davidson Sportster 1986 2003 Troubleshooting Manual OPTDocument81 pagesHarley Davidson Sportster 1986 2003 Troubleshooting Manual OPTFiggyNo ratings yet

- 12 Volt ConversionDocument14 pages12 Volt ConversionRanko LazicNo ratings yet

- Essential Scooter Maintenance for the Absolute BeginnerFrom EverandEssential Scooter Maintenance for the Absolute BeginnerNo ratings yet

- King Quad 700 Tips 101 Ver 1.2Document36 pagesKing Quad 700 Tips 101 Ver 1.2Andy House100% (1)

- Two Cycle Carburetor and the Back Alley MechanicFrom EverandTwo Cycle Carburetor and the Back Alley MechanicRating: 4.5 out of 5 stars4.5/5 (2)

- CV Carb TuningDocument7 pagesCV Carb Tuningmark_dayNo ratings yet

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- 2003 ExhaustDocument47 pages2003 ExhaustThip ZazaNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Mikuni Motorcycle Carburetor Theory 101: Understanding Atmospheric Pressure and JettingDocument8 pagesMikuni Motorcycle Carburetor Theory 101: Understanding Atmospheric Pressure and JettingRiski HartonoNo ratings yet

- 125cc MotorcyclesDocument53 pages125cc Motorcyclesdannnnu67% (3)

- GY6 ModsDocument5 pagesGY6 ModsKevin TagorNo ratings yet

- Gy6 Big Bore Kit and Top End Rebuild GuideDocument28 pagesGy6 Big Bore Kit and Top End Rebuild GuideDodea Nicu100% (1)

- Scooter Tuning GuideDocument22 pagesScooter Tuning GuideCarlos Simões100% (4)

- 6 0LDies PDFDocument101 pages6 0LDies PDFscodavnx100% (1)

- Motorcycle Ignition FAQDocument115 pagesMotorcycle Ignition FAQgtc1981100% (5)

- 2017 JEP MPS Catalog FIN LR SPR PDFDocument28 pages2017 JEP MPS Catalog FIN LR SPR PDFEdwinNo ratings yet

- Two Stroke Low EndDocument60 pagesTwo Stroke Low EndPete MoonNo ratings yet

- Ignition Control: From Carb To EFI, With Ignition Control, On Just A Fistful of DollarsDocument6 pagesIgnition Control: From Carb To EFI, With Ignition Control, On Just A Fistful of DollarsJameel KhanNo ratings yet

- Two-Stroke Engine Top-End Inspection: Study UnitDocument53 pagesTwo-Stroke Engine Top-End Inspection: Study UnitDiego CRNo ratings yet

- Adly ATV-300SU (I) 9261-2006 ServiceDocument95 pagesAdly ATV-300SU (I) 9261-2006 ServicestuderkNo ratings yet

- Tank sports service manual scooter repair guideDocument182 pagesTank sports service manual scooter repair guideDavid Vellet100% (1)

- Cdi 4 Stroke EngineDocument21 pagesCdi 4 Stroke EngineJose Ricardo WilsonNo ratings yet

- GY6 50cc 150ccDocument200 pagesGY6 50cc 150ccWillie Sykes100% (5)

- Yager200i Gy6 Scooter ManualDocument76 pagesYager200i Gy6 Scooter ManualBob GinelNo ratings yet

- Chaparral Models 1968 1974Document4 pagesChaparral Models 1968 1974Paul MartinNo ratings yet

- Tuning For Speed P E Irving 1965 Tuning Racing Motorcycle EnginesDocument154 pagesTuning For Speed P E Irving 1965 Tuning Racing Motorcycle EnginesFranz100% (7)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- Crankcase Volume 2 StrokesDocument19 pagesCrankcase Volume 2 Strokespistonbreaker100% (4)

- Jonway 150 Long GY6 Engine Parts CatalogDocument13 pagesJonway 150 Long GY6 Engine Parts Catalogsymjr200jr0% (1)

- How to re-jet your bike's carburetor for optimal performanceDocument4 pagesHow to re-jet your bike's carburetor for optimal performanceviks505100% (1)

- Service Manual for 150cc Product 6150/7150/200 Series /TITLEDocument82 pagesService Manual for 150cc Product 6150/7150/200 Series /TITLEbgarvosNo ratings yet

- Egae02mcyt00 PDFDocument34 pagesEgae02mcyt00 PDFMyBriggsNo ratings yet

- Scooter Troubleshooting &tuning GuideDocument7 pagesScooter Troubleshooting &tuning GuidestuhougNo ratings yet

- FaureciaDocument34 pagesFaureciaIonut Eduard100% (2)

- GY6 Big Bore Kit InstallationDocument80 pagesGY6 Big Bore Kit InstallationAndrew McGovern100% (1)

- Ford and ToyotaDocument10 pagesFord and ToyotaRica de GuzmanNo ratings yet

- Ways To Modify and Increase The Performance of GY6 ScootersDocument4 pagesWays To Modify and Increase The Performance of GY6 Scooterssteve_t_davis100% (1)

- 2 Stroke Guide r2Document177 pages2 Stroke Guide r2Larry Terrell100% (1)

- 2 Stroke Top End and PerformanceDocument41 pages2 Stroke Top End and PerformancePaul Martin0% (1)

- Mikuni AgulhasDocument4 pagesMikuni AgulhasJaKa1No ratings yet

- Higher - Compression - Two - Stroke PDFDocument8 pagesHigher - Compression - Two - Stroke PDFImung Pernah SehatNo ratings yet

- Bitumen price list updateDocument16 pagesBitumen price list updatedinesh543100% (1)

- Owner's Manual Safety and Operation GuideDocument68 pagesOwner's Manual Safety and Operation GuideHameleo100050% (2)

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarFrom EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNo ratings yet

- Go KartDocument20 pagesGo KartVikas PuppalaNo ratings yet

- ZAMA Carburetor ServiceDocument5 pagesZAMA Carburetor ServiceJEF GRAY100% (1)

- Bajaj Auto Limited Spare Parts Catalogue for Discover 100/125 M MotorcyclesDocument79 pagesBajaj Auto Limited Spare Parts Catalogue for Discover 100/125 M Motorcyclesraja100% (10)

- 70 Car 58 en WebDocument16 pages70 Car 58 en WebVagner AugustoNo ratings yet

- Report - Electric VehiclesDocument32 pagesReport - Electric VehiclesTechSci Research100% (2)

- Go Cart Build ManualDocument24 pagesGo Cart Build Manualtimeport24100% (3)

- Service Manual 157QMJDocument60 pagesService Manual 157QMJGeert Verfaillie67% (3)

- 1973 Oil Crisis - Wikipedia, The Free EncyclopediaDocument17 pages1973 Oil Crisis - Wikipedia, The Free EncyclopediaCarl CordNo ratings yet

- Fundamental Analysis of Amaraja BattariesDocument57 pagesFundamental Analysis of Amaraja BattariesRajkamalChichaNo ratings yet

- D85e SS 2 PDFDocument6 pagesD85e SS 2 PDFroyflo2009100% (3)

- CGen GY6 50cc Service ManualDocument199 pagesCGen GY6 50cc Service Manualrtrs9435100% (1)

- GY6 Top End RebuildDocument28 pagesGY6 Top End RebuildChristian LoibNo ratings yet

- 50cc GY6 Engine 01Document12 pages50cc GY6 Engine 01Milena Bustamante0% (1)

- JM Star Sunny 50 Scooter: WWW - Sunnyscooter.Co - NZDocument25 pagesJM Star Sunny 50 Scooter: WWW - Sunnyscooter.Co - NZRicardo AlexandreNo ratings yet

- Jonway 125cc Parts CatalogueDocument17 pagesJonway 125cc Parts CatalogueAz MørktVargNo ratings yet

- Carbtuning GuideDocument2 pagesCarbtuning GuideChip JordanNo ratings yet

- CRF50 Borekit Fitting How To (82cc)Document6 pagesCRF50 Borekit Fitting How To (82cc)MinibikeTech100% (1)

- How a 2-Stroke Engine WorksDocument6 pagesHow a 2-Stroke Engine WorksifzaeNo ratings yet

- Fiddle II 125 Aw12w PDFDocument182 pagesFiddle II 125 Aw12w PDFPablo Aimar100% (1)

- The rebuild of a 1974 Kawasaki Z1A begins with dismantlingDocument4 pagesThe rebuild of a 1974 Kawasaki Z1A begins with dismantlingpraveshkutowarooNo ratings yet

- 8ss1688 DownblastVentGuideDocument12 pages8ss1688 DownblastVentGuideoopman2002No ratings yet

- Toyota Four Consumer RightsDocument5 pagesToyota Four Consumer Rightstalha riazNo ratings yet

- Operation & Safety Manual: Agrovector 37.6 & 37.7Document184 pagesOperation & Safety Manual: Agrovector 37.6 & 37.7duongpnNo ratings yet

- BMW AssignmentDocument11 pagesBMW AssignmentRavi Parmar100% (1)

- Maybach 2Document2 pagesMaybach 2adam sandsNo ratings yet

- Tire Guide: Product OverviewDocument22 pagesTire Guide: Product OverviewAbdulAziz AlGhamdiNo ratings yet

- BIW Structure Can Be Divided in Following SubstructuresDocument7 pagesBIW Structure Can Be Divided in Following SubstructuresJyoti KaleNo ratings yet

- 5K Car CareDocument11 pages5K Car Carekarthik sNo ratings yet

- Red Bus TicketDocument1 pageRed Bus TicketLokanath Prasad SahooNo ratings yet

- A Short Course On: BrakesDocument10 pagesA Short Course On: BrakesNdung'u Wa WaweruNo ratings yet

- Rema Tip Top Automotive 2012Document380 pagesRema Tip Top Automotive 2012PTT XXKNo ratings yet

- TS 73-87 WEB CAT WebDocument139 pagesTS 73-87 WEB CAT WebBlasterwebservicesNo ratings yet

- Tata 1Document79 pagesTata 1Arun SavukarNo ratings yet

- Indian Motor TariffDocument222 pagesIndian Motor TariffArun Parikshat100% (3)

- Vishal QC EngineerDocument3 pagesVishal QC Engineerg_sanchetiNo ratings yet

- Consumer Expectation Towards C - Segment Cars in Chennai CityDocument9 pagesConsumer Expectation Towards C - Segment Cars in Chennai CityarcherselevatorsNo ratings yet

- CV Brochure - EN - Lores PDFDocument12 pagesCV Brochure - EN - Lores PDFfjaristizabalNo ratings yet

- Toast-Qwik®: Models TQ-10, - 400, - 400BA, - 400H, - 800, - 800BA, - 800H, - 800HBA, - 1200, - 1800, - 1800BA, - 1800H, - 1800HBADocument2 pagesToast-Qwik®: Models TQ-10, - 400, - 400BA, - 400H, - 800, - 800BA, - 800H, - 800HBA, - 1200, - 1800, - 1800BA, - 1800H, - 1800HBARiyas UdheenNo ratings yet

- Schwing SetterDocument6 pagesSchwing Settergsm.nkl60490% (2)

- SX CAT EBook Clutches-Tractors IN 2015 PDFDocument432 pagesSX CAT EBook Clutches-Tractors IN 2015 PDFRuiuNo ratings yet