Professional Documents

Culture Documents

Raft Foundation Analysis and Design Example

Uploaded by

Eng Obadah HarastaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raft Foundation Analysis and Design Example

Uploaded by

Eng Obadah HarastaniCopyright:

Available Formats

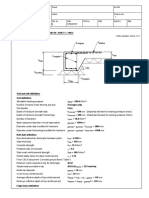

Chapter6:DesignofFoundations 79

6.1 INTRODUCTION

The substructure or foundation is the part of a structure that is usually placed below

the surface of the ground.

Footings and other foundation units transfer the loads from the structure to the soil or

rock supporting the structure.

Because the soil is generally much weaker than the concrete columns & walls that

must be supported, the contact area between the soil & the footing is much larger than

that between the supported member & the footing.

The more common types of footings are illustrated in figure (6.1). Strip footings or

wall footings display essentially one-dimensional action, cantilevering out on each side of

the wall. Spread Footings are pads that distribute the column load to an area of soil

around the column. These distribute the load in two directions. Sometimes spread footing

have pedestals, are stepped, or are tapered to save materials. A pile cap transmits the

column load to a series of piles, which in turn, transmit the load to a strong layer at some

depth below the surface hard strata. Combined footings transmit the loads from two or

more columns to the soil. Such a footing is often used when one column is close to a

property line. A mat or raft foundation transfers the loads from all the columns in a

building to the underlying soil. Mat foundations are used when very weak soils are

encountered.

The choice of foundation type is selected in consultation with the geotechnical

engineer. Factors to be considered are:

The soil strength,

The soil type,

The variability of the soil type over the area and with increasing depth, and

The susceptibility of the soil and the building to deflections.

The most basic and most common types are strip, spread, combined footings.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 80

Figure6.1:(Types of Footings)

The two essential requirements in the design of foundation are that the total settlement

of the structure be limited to a tolerably small amount and that differential settlement of

the various parts of the structure be eliminated as nearly as possible. With respect to

possible structural damage, the elimination of differential settlement, i.e., different

amounts of settlement within the same structure, is even more important than limitations

on uniform overall settlement.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 81

To limit settlements as indicated, it is necessary to:

Transmit the load of the structure to a soil stratum of sufficient strength.

Spread the load over a sufficiently large area of that stratum to minimize bearing

pressure.

A shallow single Foundation unit that supports all columns & walls of a structure or

parts of a structure may be called a raft foundation. A raft foundation is also called as mat

foundation. They are usually provided for multi-story buildings, overhead water tanks,

chimneys, etc. A raft foundation becomes unavoidable in submerged structure, in some

multi-story structures with basement and in retaining walls, etc. The raft foundation is

usually designed as a flat slab.

Foundation engineering often consider mats when dealing with any of the following

conditions:

9 The structural loads are so high or the soil conditions so poor that

spread footings would be exceptionally large. As a general rule of thumb,

if spread footings would cover more than about one-third of the building

footprint area a mat or some type of deep foundation will probability be

more economical,

9 The soil is very erratic & prone to excessive differential settlements.

The structural continuity & flexural strength of a mat will bridge over

these irregularities. The same is true of mats on highly expansive soils to

prone to differential heaves,

9 The structural loads are erratic, and thus increase the likelihood of

excessive differential settlement. Again, the structural continuity and

flexural strength of the mat will absorb these irregularities,

9 Lateral loads are not uniformly distributed through the structure and thus

may cause differential horizontal movement in spread footing or pile caps.

The continuity of a mat will resist such movements,

9 The uplift loads are larger than spread footings can accommodate. The

greater weight and continuity of a mat may provide sufficient resistance,

and

9 The bottom of the structure is located below the ground table, so

waterproofing is an important concern. Because mats are monolithic, they

are much easier to waterproof. The weight of the mat also helps resist

hydrostatic uplift forces from the groundwater.

In this project; due to the heavy load, earthquake design, and some of the

previous provisions the mat foundation might be used.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 82

Many buildings are supported on mat foundations, as are soils, chimneys, and other

types of tower structures. Mats are also to support storage tanks and large machines.

Typically, the thickness, (T), is 1-2 m (3-6 ft), so mats are massive structural elements.

Although most mat foundation are directly supported on soil, sometimes engineers use

pile or shaft- supported mats, these foundation are often called piled rafts, and they are

hybrid foundations that combine features of both mat and deep foundations.

Figure6.2:(aMatFoundationSupportedDirectlyonSoil)

Figure6.3:(APileorShaftSupportedMatFoundation)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 83

6.2 RIGID VS. NON-RIGID

There are various methods have been used to mat foundations. They can be divided

into two categories: RIGID METHOD & NON-RIGID METHODS.

6.2.1 Rigid method:

The simplest approach to structural design of mats is the rigid method (also known as

the conventional method or the conventional method of static equilibrium). This method

assumes the mat is much more rigid than the underlying soils, which means any

distortion in the mat are too small to significantly impact the distribution of bearing

pressure depends only on the applied loads and the weight of mat, and either uniform

across the bottom of the mat (if the normal acts through the centroid and no moment load

is present) or varies linearly a cross the mat (if eccentric or moment loads are present) as

shown in figure (6.4), this is the same simplifying assumption used in the analysis of

spread footings.

Figure6.4:(BearingPressureDistributionforRigidMethod)

This simple distribution makes it easy to compute the flexural stresses and deflections

(differential settlements) in the mat. For analysis purposes, the mat becomes an inverted

and simply loaded two-way slab, which means the shears, moments, and deflection may

be easily computed using the principles of the structural mechanics. The engineer can

then select the appropriate mat thickness & reinforcement.

Although this type of analysis is appropriate for spread footings, it doesn't accurately

model mat foundations becomes the width-to-thickness ratio is much greater in mats and

the assumption of rigidity is no longer valid.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 84

Portions of a mat beneath columns and bearing walls settle more than the portions

with loss load, which means the bearing pressure will be greater beneath the heavily-

loaded zones, as shown in figure (6.5).

Figure6.5:(ThedistributionofSoilBearingPressure)

This redistribution of bearing pressure is most pronounced when the ground is stiff

compared to the mat as shown in figure (6.6), but is present to some degree in all soils.

Figure6.6:(ThedistributionofBearingPressureunderaMatFoundation)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 85

Because the rigid method does not consider this redistribution of bearing pressure, it

doesn't produce reliable estimates of the shear, moments, and deformations in the mat. In

addition, even if the mat was perfectly rigid, the simplified bearing pressure distribution

in figure (6.6) are not correct-in reality; the bearing pressure is greater on the edges and

smaller in the center than shown in this figure.

6.2.2 Non-Rigid methods:

To become the in accuracies of the rigid method by using analyses that consider

deformations in the mat and their influence on the bearing pressure distribution. These

are called non-rigid methods, and produce more accurate values of mat deformations and

stresses, unfortunately non-rigid analyses also are more difficult to implement because

they require consideration of soil-structure interaction and because the bearing pressure

distribution is not as simple.

Coefficient of subgrade reaction:

Because non-rigid method consider the effects of local mat deformations on the

distribution of bearing pressure, it is necessary to define the relation slip between

settlement & bearing pressure. This is usually done using the coefficient of subgrade

reaction, Ks (also known as the modulus of subgrade reaction, or the subgrade modulus).

K

s

=

q

6

Where:

K

s

= coefficient of subgrade reaction.

q = Bearing pressure.

= Settlement.

The coefficient K

s

has units of force length cubed. Although we use the same units to

wt., K

s

is not the same as the same as the unit wt. and they are not numerically equal.

The interaction between the mat and the underlying soil may there be represented as a

"bed of springs" each with a stiffness K

s

per unit area, as shown in fig (6.7). Portions of

the mat that experience more settlement produce more compression in the "springs,"

which represents the higher bearing pressure, whereas portions that settle less don't

compress the springs as for and thus have less bearing pressure. The sum of these spring

forces must equal the applied structural loads plus the wt. of the mat:

p + W

- u

D

=]q dA=]6 k

x

dA

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 86

Where:

P= sum of structural loads acting on the mat.

W

f

= Pore of the mat.

u

D

= Bearing pressure between mat & soil.

A = mat-soil contact Area.

= settlement at a point on the mat.

Figure6.7:(TheCoefficientofSubgradeReactionbedofsprings)

This method of describing bearing pressure is called a soil-structure interaction

analysis because the bearing pressure depends on the mat deformations, and the mat

deformations depends on the bearing pressure.

Methods in non-rigid:

1. Winkler method.

2. Coupled method.

3. Pseudo-coupled method.

4. Multiple-parameter method.

5. Finite element method.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 87

Determination of the coefficient of subgrade reaction:

Most mat foundation designs are currently developed using either the Winkler method

or the pseudo-coupled method, both of which depend on our ability to define the

coefficient of subgrade reaction, Ks. Unfortunately, this task is not as simple as it might

first appear because Ks is not a fundamental soil property. Its magnitude also depends on

many other factors, including the following:

1. The width of the loaded area:

A wide mat will settlement more than a narrow one with the same q

because it mobilizes the soil to a greater depth, therefore, each has a different

(k

s

).

2. The shape of the loaded area:

The stresses below long narrow loaded areas are different from those

below square loaded areas therefore, ks will differ.

3. The depth of the loaded area below the ground surface At greater depths,

the change in stress in the soil due to q is a smaller percentage of the initial

stress, so the settlement is also smaller and k

s

is greater.

4. The position on the mat To model the soil accurately, k

s

need to be larger

near the edges of the mat and smaller near the center.

5. Time - Much of the settlement of mats on deep compressible soils will be due

to consolidation and thus may occur over a period of several years. Therefore,

it may be necessary to consider both short-term and long-term cases.

Actually, there is no single k

s

value, even if we could define these factors because the

q- relationship is nonlinear and because neither method accounts for interaction between

the springs.

Engineers have tried various techniques of measuring or computing k

s

. Some rely on

plate load test to measure k

s

in situ. However, the test results must be adjusted to

compensate for the differences in width, shape, and depth of the plate and the mat. Plate

load tests include dubious assumption that the soils within the shallow zone of influence

below the plate are comparable to those in the much deeper zone below the mat.

Therefore, plate load test generally do not provide good estimates of k

s

for mat foundation

design.

Others have derived relationships between k

s

and the soils modulus of elasticity, E

(Vesic & Saxena, 1970). Although these relationships provide some insight, they too are

limited.

Another method consists of computing the average mat settlement using the

techniques of settlement and expressing the results in the form of ks using equation:

k

s

=

q

6

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 88

6.3 STRUCTURAL DESIGN:

6.3.1 General Methodology:

The structural design of mat foundations must satisfy both strength and serviceability

requirements. This requires two separate analyses, as follows:

Step (1):

Evaluate the strength requirements result from the load combinations and LRFD

design methods (which ACI calls ultimate strength design). The mat must have a

sufficient thickness, T, and reinforcement to satisfy resists these loads. As with spread

footings, T should be large enough that no shear reinforcement is needed.

Step (2):

Evaluating mat deformations (which is the primary serviceability requirement) using

the unfactored loads. These deformations are the result of concentrated loading at the

column locations, possible non-uniformities in the mat, and variations in the soil stiffness.

In effect, these deformations are the equivalent of differential settlement. If they are

excessive, then the mat must be made stiffer by increasing its thickness.

6.3.2 Closed-Form solutions:

When the Winkler method is used (i.e., when all springs have the same Ks) and the

geometry of the problem can be represented in two-dimensions, it is possible to develop

closed-form solutions using the principles of structural mechanics. These solutions

produce values of shear, moment, and deflection at all points in the idealized foundation.

When the loading is complex, the principle of superposition may be used to divide the

problem into multiple simpler problems.

These closed-form solutions were once very popular, because they were the only

practical means of solving this problem. However, the advent and widespread availability

of powerful computers and the associated software now allows us to use other methods

that are more precise and more flexible.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 89

6.3.3 Finite Element Method:

Today, most mat foundations are designed with the aid of a computer using the finite

element method (FEM). This method divides the mat into hundreds or perhaps thousands

of elements. Each element has certain defined dimensions, a specified stiffness and

strength (which may be defined in terms of concrete and steel properties) and is

connected to the adjacent elements in a specified way.

The mat elements are connected to the ground through a series of springs, which are

defined using the coefficient of subgrade reaction. Typically, one spring is located at each

corner of each element.

The loads on the mat include the externally applied column loads, applied line loads,

applied area loads, and the weight of the mat itself. These loads press the mat downward,

and this downward movement is resisted by the soil springs. These opposing forces

along with the stiffness of the mat can be evaluated simultaneously using matrix algebra

which allows us to compute the stresses, strains, and distortions in the mat. If the results

of the analysis are not acceptable, the design is modified accordingly and reanalyzed.

This type of finite element analysis does not consider the stiffness of the

superstructure. In other words, it assumes the superstructure is perfectly flexible and

offers no resistance to deformations in the mat. This is conservative.

The finite element analysis can be extended to include the superstructure, the mat, and

the underlying soil in a single three-dimensional finite element method. This method

would, in principle, be a more accurate model of the soil structure system, and thus may

produce a more economical design. However, such analyses are substantially more

complex and time-consuming, and it is very difficult to develop accurate soil properties

for such models. Therefore, these extended finite element analyses are rarely performed

in practice.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 90

6.4 DESIGN PROCESS:

6.4.1 General Description:

After performing analysis on 3-D ETABs software Model, all results were obtained;

the base plan then imported with all loads and load combinations to SAFE software in

order to analyze the base as raft foundation.

Figure6.8:(UndeformedShapeforRaftFoundation)

Raft dimensions were selected in order to primarily achieve no bearing capacity and

punching shear problems then serviceability criteria to be checked based on the selected

dimensions.

F The raft covers the base plan with the following offsets relative to the above

raft sketch:

2.4 m to the right,

1.0 m to the left,

1.3 m up, and

1.5 m down.

F Starting with depth, T = 500 mm and by trial and error procedure a depth of T

= 700 mm was selected.

F Due to large variation in loads on columns; for economic wise a suitable drop

of 600 mm was made under heavy load columns.

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 91

6.4.2 SAFE Outputs:

Figure6.9:(DeformedShapeofRaftFoundationforUltimateCombination)

Figure6.10:(BearingPressureforSoilbeneaththeRaftFoundationforServiceCombination)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 92

Figure6.11:(PunchingShearRatiosunderInteriorColumnsforUltimateCombination)

Figure6.12:(PunchingShearRatiosunderallColumnsforUltimateCombination)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 93

Figure6.13:(BendingMomentDiagramsforGivenXStrips)

Figure6.14:(BendingMomentDiagramsforGivenYStrips)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 94

Figure6.15:(ShearDiagramsforGivenXStrips)

Figure6.16:(ShearDiagramsforGivenYStrips)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 95

6.4.3 Sample Calculation:

General Raft (depth = 700 mm):

A

s, min

= 0.0018 b h = (0.0018) (1000) (700) = 126u mm

2

/ m

1260

5

= 252 mm

2

/ 200 mm

Use 118 / 200 mm Top & Bottom

Drop (depth = 600 mm) :

A

s, min

= 0.0018 b h = (0.0018) (1000) (1300) = 2S4u mm

2

/ m

2340

5

= 268 mm

2

/ 200 mm

Use 125/ 200 mm Top & Bottom

Wherever minimum reinforcement exceeded; an additional reinforcement must

be added. This depends on the values of moment in each strip in both X & Y

directions. The following tables can ease this mission.

Table6.1: (ReinforcementGuidelineforGeneralRaft)

ReinforcementBars AreaofSteel(mm

2

permeter)

518 1272

518+512 1838

518+514 2042

518+516 2277

518+518 2544

518+520 2843

518+525 3173

518+532 3726

Table6.2: (ReinforcementGuidelineforDrops)

ReinforcementBars AreaofSteel(mm

2

permeter)

525 2454

525+512 3020

525+514 3224

525+516 3459

525+518 3726

525+520 4025

525+525 4908

525+532 6475

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 96

For X-strip:

F M

u

,

bottom

= 2150 kN.m / m

h = 1300mm

d = 1150mm

R

u

=

Mu - 10

6

0.9 - b - d

2

=

2150 - 10

6

0.9 - 1000 - 1150

2

= 1.806

=

0.85 - Ic

Iy

( 1 _1 -

2 Ru

0.85 -Ic

)

=

0.85 - 28

420

(1 _1 -

2- 1.806

0.85 - 28

)

= 0.0045

A

s, required

= * b * d = 0.0045 * 1000 * 1150 = 5175 mm

2

Use 525 + 532

F M

u

,

Top

= - 250 kN.m / m

h= 700mm

d= 575mm

R

u

=

Mu - 10

6

0.9 - b - d

2

=

250 - 10

6

0.9 - 1000 - 575

2

= 0.840

=

0.85 - Ic

Iy

( 1 _1 -

2 Ru

0.85 -Ic

)

=

0.85 - 28

420

( 1 _1 -

2- 0.840

0.85 - 28

)

= 0.0020

A

s req

= * b * d = 0.0020 * 1000 * 575 = 1150 mm

2

A

s req

< A

s min

Use A

s,min

= 1272 mm

2

Use 518

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 97

For Y-strip:

F M

u

,

bottom

= 1686 kN.m / m

h= 1300mm

d= 1150mm

R

u

=

Mu - 10

6

0.9 - b - d

2

=

1686 - 10

6

0.9 - 1000 - 1150

2

= 1.416

=

0.85 - Ic

Iy

( 1 _1 -

2 Ru

0.85 -Ic

)

=

0.85 - 28

420

( 1 _1 -

2- 1.416

0.85 - 28

)

= 0.0035

A

s req

= * b * d = 0.00348 * 1000 * 1150 = 4025 mm

2

Use 525+ 525

F M

u

,

Top

= - 490 kN.m / m

h = 700mm

d = 575mm

R

u

=

Mu - 10

6

0.9 - b - d

2

=

490 - 10

6

0.9 - 1000 - 575

2

= 1.647

=

0.85 - Ic

Iy

( 1 _1 -

2 Ru

0.85 -Ic

)

=

0.85 - 28

420

( 1 _1 -

2- 1.647

0.85 - 28

)

= 0.00406

A

s req

= * b * d = 0.00406 * 1000 * 575 = 2338 mm

2

Use 518 + 518

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 98

Check Punching shear:

For the purpose of checking punching shear; an Equivalent 800 mm side

Square column corresponding to the circular column of diameter of D = 900 mm

was taken;

F C = 800 mm.

F d = 1150 mm. assumed

F b

0

= c +d = 800 + 1150 =1950 mm

F M

u

= 3110 kN.m "From SAFE Model"

F P

u

= 8791 kN from ETABS Model

F V

uc

= [

P

u

4

+

M

u

c+d

(

B

2

-(c+d)

2

B

2

)

= [

8791

4

+

3110

0.8+1.15

(

3

2

-(0.8+1.15)

2

3

2

= 3085.2 kN

F V

c

=

1

3

b

0

J

c

= (0.75)

1

3

(19Su)(11Su)28 = 3955.4 kN

F Punching Shear Ratio =

v

uc

Vc

= 0.78 "OK"

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 99

Figure6.17:(RaftFoundationDetails)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

Chapter6:DesignofFoundations 100

Figure6.18:(SectionsinRaft)

Eng Ahmad Al Omari Eng Essam Ghaith Eng Qutaiba Hameedi

You might also like

- Design Procedure For Raft FoundationDocument5 pagesDesign Procedure For Raft FoundationOmkarnath YadavNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Structural Design of Raft FoundationDocument31 pagesStructural Design of Raft Foundationshakirhamid668780% (15)

- Design of Pile Caps FinalDocument50 pagesDesign of Pile Caps FinalImam Shakil100% (2)

- Pile Foundation Design ExampleDocument62 pagesPile Foundation Design Examplethanzawtun1981100% (1)

- Raft Foundation DesignDocument6 pagesRaft Foundation DesignstructuralengNo ratings yet

- Strap footing design analysisDocument16 pagesStrap footing design analysisWaqar Ahmed75% (4)

- Deep Beam Flexure and Shear DesignDocument40 pagesDeep Beam Flexure and Shear DesignPragya Roy95% (39)

- Anchored Sheet Pile WallDocument10 pagesAnchored Sheet Pile Wall12151973No ratings yet

- Cantilever Retaining Wall DesignDocument6 pagesCantilever Retaining Wall DesignAgha Sikander0% (1)

- Project foundation design calculationsDocument10 pagesProject foundation design calculationsGautam PaulNo ratings yet

- DESIGN OF MAT FOUNDATIONSDocument43 pagesDESIGN OF MAT FOUNDATIONSaminjoles100% (3)

- Design Pile Cap Dimensions and ReinforcementDocument17 pagesDesign Pile Cap Dimensions and ReinforcementMd. Adilur Rahman100% (9)

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationHani AboobackerNo ratings yet

- Raft Foundation DesignDocument5 pagesRaft Foundation Designmihai_serban13No ratings yet

- Design of Base Plate and Bolts FinalDocument4 pagesDesign of Base Plate and Bolts FinalManoj Jaiswal100% (1)

- Reinforced Concrete Design ReportDocument11 pagesReinforced Concrete Design ReportAchala Fernando67% (3)

- Design of Foundations PDFDocument41 pagesDesign of Foundations PDFolomizanaNo ratings yet

- Pile Cap For 3 PileDocument3 pagesPile Cap For 3 Pilehemantkle2u50% (2)

- Basement Wall DesignDocument19 pagesBasement Wall DesignwaikenNo ratings yet

- Design of Raft FoundationDocument13 pagesDesign of Raft Foundationewanz89No ratings yet

- SAFE Tutorial For Slab DesignDocument38 pagesSAFE Tutorial For Slab Designbahaa_alamiri7476100% (9)

- Seismic Design of Retaining WallsDocument23 pagesSeismic Design of Retaining WallsRutvik ShethNo ratings yet

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- Retaining WallDocument11 pagesRetaining Wallardi rahadianNo ratings yet

- Chapter 6.0 Slab Design TheoryDocument19 pagesChapter 6.0 Slab Design TheoryMohd Afzal100% (1)

- Foundation Design: Theory and PracticeFrom EverandFoundation Design: Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- The Design of Piled Foundations: Structures and Solid Body MechanicsFrom EverandThe Design of Piled Foundations: Structures and Solid Body MechanicsRating: 4 out of 5 stars4/5 (8)

- FOOTING DESIGN GUIDEDocument12 pagesFOOTING DESIGN GUIDEAbdirahman Ahmed IsseNo ratings yet

- Design of Piled - Raft Foundation PDFDocument48 pagesDesign of Piled - Raft Foundation PDFDrYoussefHammida100% (2)

- Concrete Foundations 59ccc9e8e7cb9Document20 pagesConcrete Foundations 59ccc9e8e7cb9Ragu VaranNo ratings yet

- Raft CWDocument5 pagesRaft CWEkky Cecil100% (1)

- Coduto10 PDFDocument9 pagesCoduto10 PDFJumadil SyamNo ratings yet

- Literature Review On FoundationDocument6 pagesLiterature Review On FoundationAhmed Shah100% (3)

- Footing Analysis Nad DesignDocument50 pagesFooting Analysis Nad Designabdul haseebNo ratings yet

- BCM Model AnswersDocument5 pagesBCM Model AnswersMahesh RamtekeNo ratings yet

- Finite Element Analysis of Flexible Spread FootingsDocument92 pagesFinite Element Analysis of Flexible Spread FootingsJunaidAhmedNo ratings yet

- Raft FoundationDocument13 pagesRaft FoundationA KNo ratings yet

- Mini ProjectDocument21 pagesMini Projectlawrence100% (1)

- Design of Foundations According to ES EN 1997Document24 pagesDesign of Foundations According to ES EN 1997Abebe Wolde100% (1)

- The Importance of A Sound FoundationDocument5 pagesThe Importance of A Sound Foundationsantosh kumarNo ratings yet

- Shallow FoundationDocument7 pagesShallow FoundationWøñdë Ðç BøîîNo ratings yet

- Foundations: Further Reading of Geotechnical Books Is Recommended To Get in Depth DetailsDocument9 pagesFoundations: Further Reading of Geotechnical Books Is Recommended To Get in Depth DetailsYousef AmassiNo ratings yet

- Types of Foundation: Why A Foundation Is ProvidedDocument12 pagesTypes of Foundation: Why A Foundation Is ProvidedMin Min IINo ratings yet

- SC Foundation Chapt4 A11yDocument25 pagesSC Foundation Chapt4 A11yJuan Pablo Moreno CárdenasNo ratings yet

- Building Foundation Types and StructuresDocument42 pagesBuilding Foundation Types and StructuresVishal R100% (1)

- EV314 RCC Design 2: Taha AlesawyDocument48 pagesEV314 RCC Design 2: Taha AlesawySam KhorNo ratings yet

- Soil Foundations IntroductionDocument18 pagesSoil Foundations IntroductionrenrenzNo ratings yet

- Mat/Raft Foundation Design & AnalysisDocument12 pagesMat/Raft Foundation Design & AnalysiskissistvanNo ratings yet

- Foundation Design - Day 1-Day 2Document86 pagesFoundation Design - Day 1-Day 2ochukoikogho0% (1)

- 2700 yd3 Concrete Mat Foundation Harrisburg PADocument41 pages2700 yd3 Concrete Mat Foundation Harrisburg PAAizat HermanNo ratings yet

- Combined FootingsDocument8 pagesCombined FootingsJason Rodriguez100% (1)

- 4 LectureDocument37 pages4 LecturePranto KhanNo ratings yet

- Raft Foundation DesignDocument16 pagesRaft Foundation DesignGeniuskuga Kugas50% (2)

- Building Maintenance & RehabilitationDocument92 pagesBuilding Maintenance & RehabilitationEng Obadah HarastaniNo ratings yet

- Annex 1.4 European I BeamsDocument24 pagesAnnex 1.4 European I BeamsEng Obadah HarastaniNo ratings yet

- Si Units PDFDocument4 pagesSi Units PDFசெல்வ குமார்No ratings yet

- Liebherr Custom Solutions Direct From The Manufacturer Tcs enDocument28 pagesLiebherr Custom Solutions Direct From The Manufacturer Tcs enEng Obadah HarastaniNo ratings yet

- Foundation On Sloping GroundDocument1 pageFoundation On Sloping GroundEng Obadah HarastaniNo ratings yet

- دورة قراءة المخططات الهندسية - إنشائيDocument37 pagesدورة قراءة المخططات الهندسية - إنشائيEng Obadah Harastani100% (12)

- Combined Footig DesignDocument3 pagesCombined Footig DesignEng Obadah Harastani100% (1)

- دورة قراءة المخططات الهندسية - كهرباءDocument20 pagesدورة قراءة المخططات الهندسية - كهرباءEng Obadah HarastaniNo ratings yet

- دورة قراءة المخططات الهندسية - عينة لفحص التربة /Document67 pagesدورة قراءة المخططات الهندسية - عينة لفحص التربة /Eng Obadah HarastaniNo ratings yet

- دورة قراءة المخططات الهندسية - معماريDocument22 pagesدورة قراءة المخططات الهندسية - معماريEng Obadah Harastani75% (4)

- دورة قراءة المخططات الهندسية - إنشائيDocument37 pagesدورة قراءة المخططات الهندسية - إنشائيEng Obadah Harastani100% (12)

- Elevated Water TankDocument16 pagesElevated Water TankEng Obadah Harastani100% (3)

- Scope of Work gasGDUDocument24 pagesScope of Work gasGDUvienergresourcesNo ratings yet

- CMG Home Ownership Accelerator Example Doc Set CA050207Document94 pagesCMG Home Ownership Accelerator Example Doc Set CA050207Robert Emmett McAuliffeNo ratings yet

- SPA TO PROCESS (Loss OR CR)Document1 pageSPA TO PROCESS (Loss OR CR)majoy75% (4)

- Editing ScriptsDocument17 pagesEditing ScriptssisyololoNo ratings yet

- Eoir 33 Change of AddressDocument2 pagesEoir 33 Change of Addressm.canodaciogluNo ratings yet

- Remove Excel Password in 5 StepsDocument6 pagesRemove Excel Password in 5 StepsdheerajdorlikarNo ratings yet

- 1 s2.0 S2452223620301115 MainDocument10 pages1 s2.0 S2452223620301115 MainDrawing and Artistic DecorationsNo ratings yet

- Spirit Mandala CrochetDocument5 pagesSpirit Mandala CrochetViviana CastilloNo ratings yet

- Gothic-Architecture HoaDocument37 pagesGothic-Architecture HoaJohn Michael AlocNo ratings yet

- RCSM College of Agriculture, Kolhapur-416004 Agricultural Economics Section, Major SeminarDocument2 pagesRCSM College of Agriculture, Kolhapur-416004 Agricultural Economics Section, Major SeminarKavieswarNo ratings yet

- Performance of Anti-Drug CouncilsDocument161 pagesPerformance of Anti-Drug CouncilsEm ArrNo ratings yet

- ECLYPSE™ Connected Terminal Unit Controller: Product DescriptionDocument16 pagesECLYPSE™ Connected Terminal Unit Controller: Product DescriptionandyvtranNo ratings yet

- Department of Education performance reviewDocument22 pagesDepartment of Education performance reviewztir ecasNo ratings yet

- Cartilla 1 - T.S.B y C.IDocument34 pagesCartilla 1 - T.S.B y C.IPaola BustamanteNo ratings yet

- DNA Structure and FunctionDocument42 pagesDNA Structure and FunctionBenjamin Fernandez Jr.No ratings yet

- G8 DLL Health-2Document6 pagesG8 DLL Health-2MARGIE BOGANOTAN100% (1)

- Work and Energy FormsDocument27 pagesWork and Energy FormsThanu BalaNo ratings yet

- Survey Questionnaire NSTPDocument7 pagesSurvey Questionnaire NSTPedwineiou83% (6)

- Alfred Jensen Paintings and Works On PaperDocument88 pagesAlfred Jensen Paintings and Works On PaperSabri Gutierrez100% (1)

- Eagle Realty Vs RepublicDocument7 pagesEagle Realty Vs RepublicJomar TenezaNo ratings yet

- Case DigestDocument11 pagesCase DigestMaLizaCainapNo ratings yet

- Parables of Jesus: The New Testament of The Holy Bible Contains Many Examples of The Parables of JesusDocument3 pagesParables of Jesus: The New Testament of The Holy Bible Contains Many Examples of The Parables of JesuspaulbucudNo ratings yet

- GloFish: Ethical Considerations Related To The First Widely Available Biotech Animal (Alan Blake)Document19 pagesGloFish: Ethical Considerations Related To The First Widely Available Biotech Animal (Alan Blake)National Academies of Science, Engineering, and MedicineNo ratings yet

- Ayurveda - Rotator Cuff InjuryDocument3 pagesAyurveda - Rotator Cuff InjuryRavi Condamoor100% (1)

- Eastern Mindoro College Child Development CourseDocument2 pagesEastern Mindoro College Child Development CourseJaymar MagtibayNo ratings yet

- Reed - The Micro Politics of CapitalDocument224 pagesReed - The Micro Politics of CapitalAdam AboulafiaNo ratings yet

- Kana-Boon Silhouette Guitar TabDocument4 pagesKana-Boon Silhouette Guitar TabVictoria Ferrer CañedoNo ratings yet

- Elect CVB DSFDocument32 pagesElect CVB DSFShivran RoyNo ratings yet

- PPSC Assistant Architect Question Paper 2016Document15 pagesPPSC Assistant Architect Question Paper 2016Akash Jaglan100% (1)

- Oral-COm WK 1Document3 pagesOral-COm WK 1bernadette domoloanNo ratings yet