Professional Documents

Culture Documents

PS 3103

Uploaded by

JayeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PS 3103

Uploaded by

JayeshCopyright:

Available Formats

Purchase Specification

Technical Quality Sulzer Pumps

Page: 1 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas 1.0 Scope

This purchase specification details the minimum inspection, testing and certification requirements for castings requiring certified material test reports, 100% surface examination using magnetic particle or liquid penetrant methods and radiographic examination of critical areas. Note:- Sulzer procedures referred to in this specification can be down loaded from www.sulzerpumps.com/spukstds

2.0 3.0

3.1

Materials

Material type specification and grade shall be as stated in the Sulzer Purchase Order.

Manufacturers Certification

The following documentation shall be provided as appropriate: a) Certified material test report (e.g. EN 10204 type 3.1) b) Heat treatment details including any post weld heat treatment c) NDE report on completion of surface examinations d) Location and size of major repair excavations e) NDE report of repair excavations f) NDE report on completion of a weld repair

3.2

All documentation shall be in the English language, legible and suitable for reproduction.

4.0

4.1 4.2

Inspection

Examinations shall be carried out on completion of heat treatment. Visual examination: a) Test Procedure Sulzer TP-0012 Visual examination of castings b) All surfaces of the casting shall be examined and shall be free of adhering sand, scale, cracks and hot tears. Other surface indications shall meet the requirements of MSS-SP55 c) Hydraulic surfaces are to be clean and free from obtrusions with a surface finish in the order of 25m (N11) / SCATA A1

4.3

Magnetic particle examination a) Test Procedure Sulzer TP-0002 Magnetic particle testing of ferromagnetic materials b) Areas to be examined 100% accessible surfaces c) Acceptance ASME VIII App 7 Para 7-3 (3)

4.4

Liquid penetrant examination: Note:- Liquid penetrant shall only be carried out when magnetic particle examination is not feasible due to casting configuration or metallurgy. a) Test Procedure Sulzer TP-0001 Liquid penetrant examination b) Areas to be examined 100% accessible surfaces c) Acceptance ASME VIII App 7 Para 7-3 (4)

4.5

Radiographic Examination: a) Test procedure Sulzer TP-0007 Radiographic examination of castings b) Area to be examined Areas to be examined are as shown in Appendix A. Where a suitable sketch is not shown then the supplier shall submit to Sulzer details of the proposed areas to be radiographed for approval c) Acceptance ASME App 7 clause 7.3 (1)

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 2 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

4.6

Sulzer and/or their clients representatives shall be afforded access and assistance at all reasonable times to carry out inspections at the manufacturers premises.

5.0

5.1 5.2 5.3

Repairs

Unacceptable surface imperfections shall be removed and blended into their surrounding surfaces to avoid any sharp contours. Iron castings shall not be weld repaired, without Sulzer's written agreement. Whenever an imperfection is to be weld repaired, the excavation shall be examined by the liquid penetrant method (clause 4.4) to verify that the imperfection has been removed or reduced to an acceptable size. All weld repairs shall be carried out using welding procedures and operators qualified in accordance with: a) ASTM A 488 / ASME IX or b) ISO EN 15614 / EN 287 Weld procedures and supporting qualifications shall be submitted to Sulzer for review prior to welding. Whenever impact testing is required by the purchase order or base material specifications then welding procedure qualifications shall include impact testing to the same test criteria. Definition of a major weld repair: a) Removal of more than 20% of the wall thickness or 25mm which ever is the smaller or b) Area of excavation exceeding 65cm

5.4

5.5 5.6 5.7

5.8

On completion of welding, repaired areas shall be blended into their surrounding surfaces to avoid any sharp contours and be examined by the liquid penetrant method (clause 4.4.) When subsequent heat treatment is required, examination shall be conducted after heat treatment.

6.0

Product Marking

To provide traceability between the material and the documentation, each piece of material/component shall be individually marked at a prominent location with the following: a. Casting melt/heat number b. Material grade and class c. Sulzer Purchase Order number, line item number and material number

7.0

7.1 7.2 7.3 7.4 7.5

General Notes

All certification and delivery advice documentation shall include the Sulzer Purchase Order number, line item number and material number. Certification shall be provided on or prior to delivery of the material. Acceptance of the material shall be on satisfactory compliance to the Purchase Order requirements. All standards referenced shall be current issues unless stated otherwise. Failure to comply with the above requirements could result in rejection or delayed payment of invoices.

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 3 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix A Radiographic Shooting Sketches

Application Description Inlet and outlet casing Inlet and outlet casing Weld neck flanges castings

Typical Pump Type Remarks

Reference Appendix 1 2 3

VCR JVCR VCR JVCR MSD HSB SM HPDM BBS BBT CD HZB OHH OHV ZE ZF

Critical casting areas Critical casting areas and weld preparations Suction tank weld preparations

Axial split casing castings

Axial split casing castings

Volute casing casting

Axial split casing castings

End suction pump casing

Axial split casing castings

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 4 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

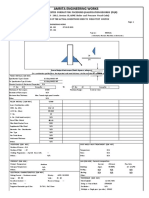

Appendix A 1 Inlet and Outlet Casting

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus comprising one shot at each area location. 3. The largest practical film size shall be used to ensure adequate coverage of the areas indicated, but shall not be less than 150 mm x 100 mm.

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 5 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix A 2 Inlet and Outlet Casting with Weld Preparations

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus 3. The largest practical film size shall be used to ensure adequate coverage of the areas indicated, but shall not be less than 150 mm x 100 mm.

100% Coverage of weld preparation

One shot

One shot

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 6 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix A 3 Inlet and Outlet Casting

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus .

100mm min

100% Coverage of weld preparation

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 7 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix A 4 Axial Split Casing Casting

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus comprising one shot at each area location. 3. The largest practical film size shall be used to ensure adequate coverage of the areas indicated, but shall not be less than 150 mm x 100 mm.

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 8 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix A 5 Volute Casing Casting

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus comprising one shot at each area location. 3. The largest practical film size shall be used to ensure adequate coverage of the areas indicated, but shall not be less than 150 mm x 100 mm.

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

Purchase Specification

Technical Quality Sulzer Pumps

Page: 9 of 9

Castings - Requiring certified material test reports, 100% surface examination (MP or DP) and radiographic examination of critical areas

Appendix - A 6 End Suction Pump Casing Casting

1. Radiographic shooting sketch for axial split casing casting that require radiographic examination of critical sections. 2. Areas to be radiographed are marked thus comprising one shot at each area location. 3. The largest practical film size shall be used to ensure adequate coverage of the areas indicated, but shall not be less than 150 mm x 100 mm.

Revision: 1 Date: 14-01-08 Amendment: RT sketches 5 and 6 added to appendices This document has been prepared & published under the authority of the Technical Quality Working Group

Doc No:

PS

3103

Uncontrolled valid at time of printing

You might also like

- Shop Manual WA380-3LE SN A50001Document758 pagesShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Cutting A GemDocument18 pagesCutting A Gemmobsivac100% (1)

- Fabrication Inspection RequirementsDocument10 pagesFabrication Inspection Requirementsnaoufel1706No ratings yet

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 pagesTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- BS 7371-6 Ad.1 2011 Hot Dip Galv. of Metal FastenersDocument10 pagesBS 7371-6 Ad.1 2011 Hot Dip Galv. of Metal FastenersJayesh0% (1)

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocument15 pagesA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNo ratings yet

- Practical Ultrasonic Testing-Weld CaseDocument6 pagesPractical Ultrasonic Testing-Weld CaseJayeshNo ratings yet

- Checkpoint Physics Notes Chapter 1-5Document5 pagesCheckpoint Physics Notes Chapter 1-5Siddhant Srivastava50% (2)

- CRSP ManualDocument140 pagesCRSP ManualCarlos Andrés Buenahora BallesterosNo ratings yet

- Eco Solutions - Saving Resources, Creating ValueDocument17 pagesEco Solutions - Saving Resources, Creating ValueChayon MondalNo ratings yet

- D7803 2012 Preparation of Zinc Coated Steels For Powder CoatDocument5 pagesD7803 2012 Preparation of Zinc Coated Steels For Powder CoatJayeshNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- WPS - EngineerDocument20 pagesWPS - Engineerhunghoanglong100% (1)

- BSi Jacking PipeDocument56 pagesBSi Jacking PipeJayesh100% (1)

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BDocument11 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BAliasgar100% (1)

- Nuclear Radioactivity WorksheetDocument3 pagesNuclear Radioactivity Worksheet14569874No ratings yet

- Welding Procedure Casing Pump PDFDocument4 pagesWelding Procedure Casing Pump PDFdethamrnNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Radiography CalculationsDocument2 pagesRadiography Calculationsshahgardez100% (2)

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- Title: Minimum Requirements On Welding From Supplier and Sub-SupplierDocument10 pagesTitle: Minimum Requirements On Welding From Supplier and Sub-SupplierDeepak DasNo ratings yet

- Cat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónDocument8 pagesCat 120H, 12H, 140H, 143H, 160H, 163H TransmisiónJefferson Maldonado.No ratings yet

- Education For WeldingDocument13 pagesEducation For Weldingmohammed amjad aliNo ratings yet

- Welding Coordinator WeldMap Weld Data SheetDocument1 pageWelding Coordinator WeldMap Weld Data Sheetquocphong199No ratings yet

- Construction Companies in IndiaDocument11 pagesConstruction Companies in Indiashobhit.goel33% (3)

- Inspection and Test Plan for TEA Product CoolerDocument7 pagesInspection and Test Plan for TEA Product CoolerJamal Mohamed Rahamathullah100% (1)

- MSRP A1Document110 pagesMSRP A1JayeshNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- Paut Vs RTDocument4 pagesPaut Vs RTinvilink87No ratings yet

- Fabrication Procedur 1Document33 pagesFabrication Procedur 1Hermansyah PratamaNo ratings yet

- Infiltration Ventilation LeakageDocument42 pagesInfiltration Ventilation LeakageBulut YildizNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1185 A/BDocument10 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1185 A/BAliasgarNo ratings yet

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- CH4 2 Welding Joint PreparationDocument46 pagesCH4 2 Welding Joint PreparationMatija BušićNo ratings yet

- As 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisDocument7 pagesAs 2560.2.1-2003 Sports Lighting Specific Applications - Lighting For Outdoor TennisSAI Global - APAC0% (1)

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinNo ratings yet

- AA4Document19 pagesAA4Karthik P MuraliNo ratings yet

- Gtaw+smaw 3G 566Document2 pagesGtaw+smaw 3G 566YASAR ALINo ratings yet

- PQR - WPQ Witness ReportDocument1 pagePQR - WPQ Witness Reportsdkeskar40No ratings yet

- Inspection & Test Plan: Dangote Oil Refinery CompanyDocument7 pagesInspection & Test Plan: Dangote Oil Refinery CompanyGowtham VenkatNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- Procedure Demonstration RecordDocument5 pagesProcedure Demonstration RecordSantanu SahaNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- 05 MDCC Scogen DiffusersDocument1 page05 MDCC Scogen DiffusersGarimaSinghNo ratings yet

- Welder Job Clearance Card Saudi AramcoDocument3 pagesWelder Job Clearance Card Saudi AramcoMohamed Reda Hussein SengarNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document1 pageDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Lithika - 001Document1 pageLithika - 001Harkesh RajputNo ratings yet

- Preparación de WPS SDocument10 pagesPreparación de WPS SPercyFloresNo ratings yet

- ValveDocument6 pagesValvetharmarajuNo ratings yet

- 08 PawDocument30 pages08 PawAnupam KushwahaNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- WPQ Is 2062 Haresh Shah W1Document1 pageWPQ Is 2062 Haresh Shah W1Anand KesarkarNo ratings yet

- Repair, NOTscrapDocument10 pagesRepair, NOTscrapThan Zaw HtayNo ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- CV Ram Deo Yadav Quality EngineerDocument7 pagesCV Ram Deo Yadav Quality Engineerkbpatel123No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- Pressure Vessel Material Selection GuidelinesDocument3 pagesPressure Vessel Material Selection Guidelinesarjun SinghNo ratings yet

- Weldingdefects 150915053459 Lva1 App6892Document22 pagesWeldingdefects 150915053459 Lva1 App6892Star GlacierNo ratings yet

- Inspection and Test Plan For Pressure Vessel - Important PointsDocument21 pagesInspection and Test Plan For Pressure Vessel - Important PointsNorman MoralesNo ratings yet

- V-2158-103-A-851 - 4 ITP For PumpDocument4 pagesV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- SB 762 IndentDocument200 pagesSB 762 Indentanon_687665429No ratings yet

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 pageTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- TH 4 5 3 PDFDocument9 pagesTH 4 5 3 PDFJayeshNo ratings yet

- API 653 Minimum Qualification 2013 PDFDocument1 pageAPI 653 Minimum Qualification 2013 PDFJayeshNo ratings yet

- Msrp-As 14Document20 pagesMsrp-As 14JayeshNo ratings yet

- Practical Hardness Testing Made SimpleDocument25 pagesPractical Hardness Testing Made Simplekukuriku13No ratings yet

- B860 2009 Zinc Master Alloy For Hot Dip Galv.Document4 pagesB860 2009 Zinc Master Alloy For Hot Dip Galv.JayeshNo ratings yet

- Storage Tanks Selection and Sizing: Richardhaw@sympatico - CaDocument50 pagesStorage Tanks Selection and Sizing: Richardhaw@sympatico - CaJayeshNo ratings yet

- A143 2007 Safeguarding Against Embritlement of Galv. StructuDocument3 pagesA143 2007 Safeguarding Against Embritlement of Galv. StructuJayeshNo ratings yet

- BS en 1123 1999 Galv. Welded Pipe & Fitting For Water SysDocument16 pagesBS en 1123 1999 Galv. Welded Pipe & Fitting For Water SysJayeshNo ratings yet

- DAC Distance Amplitude Curve PDFDocument2 pagesDAC Distance Amplitude Curve PDFJayeshNo ratings yet

- Storage Tanks Selection and Sizing: Richardhaw@sympatico - CaDocument50 pagesStorage Tanks Selection and Sizing: Richardhaw@sympatico - CaJayeshNo ratings yet

- Table 5 - Wire Type IQI SelectionDocument3 pagesTable 5 - Wire Type IQI SelectionMehmet SoysalNo ratings yet

- Iscrimination Between Planner and Volumetric DefectsDocument8 pagesIscrimination Between Planner and Volumetric DefectsJayeshNo ratings yet

- What Exactly Is TGDocument2 pagesWhat Exactly Is TGJason GonzalezNo ratings yet

- 160Q Torsional Test Machine 87Document2 pages160Q Torsional Test Machine 87JayeshNo ratings yet

- Low Temperature Dry-Ice Bath CompositionsDocument4 pagesLow Temperature Dry-Ice Bath CompositionsspolverinoNo ratings yet

- BrederoShaw PDS 3LPPDocument2 pagesBrederoShaw PDS 3LPPHamzaHashimNo ratings yet

- MCA13a Ventilating Attic FiresDocument5 pagesMCA13a Ventilating Attic FiresJayeshNo ratings yet

- Safelight For Darkroom Illumination - ANSI PH2.22 PDFDocument6 pagesSafelight For Darkroom Illumination - ANSI PH2.22 PDFJayesh100% (1)

- 316 Family Test Machine 79Document1 page316 Family Test Machine 79JayeshNo ratings yet

- Five keys effective writing 40 charactersDocument24 pagesFive keys effective writing 40 charactersRajat SharmaNo ratings yet

- 2-8 Kodak Digital Imaging PlatesDocument6 pages2-8 Kodak Digital Imaging PlatesJayeshNo ratings yet

- Cisco SD-WAN Policy Architecture - Dana Yanch PDFDocument1 pageCisco SD-WAN Policy Architecture - Dana Yanch PDFEmilio PazNo ratings yet

- Formulation - Beton - Dreux - Gorisse Good - Fr.enDocument9 pagesFormulation - Beton - Dreux - Gorisse Good - Fr.enRabnawaz ImamNo ratings yet

- Ahmed Mohammed EL Desouky 2007Document8 pagesAhmed Mohammed EL Desouky 2007Hazem MohamedNo ratings yet

- Calibration of A Pressure GaugeDocument6 pagesCalibration of A Pressure GaugeThapelo100% (2)

- Subnetting PracticeDocument5 pagesSubnetting PracticeUncleSamNo ratings yet

- Manage Payment Process Profiles - 1Document1 pageManage Payment Process Profiles - 1I'm RangaNo ratings yet

- Float Trap PennantDocument2 pagesFloat Trap PennantJinalkumarNo ratings yet

- PilotstarD AP02-S01 Mar09Document168 pagesPilotstarD AP02-S01 Mar09Dharan NarayananNo ratings yet

- Oral and Practical Tests: MechanicDocument19 pagesOral and Practical Tests: MechanicHugo AlmeidaNo ratings yet

- Sectional Results: Sofistik 2020Document28 pagesSectional Results: Sofistik 2020ec05226No ratings yet

- LKPRDocument58 pagesLKPRcatchman86No ratings yet

- STP of Ethifen SyrupDocument5 pagesSTP of Ethifen SyrupBejoy KarimNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument12 pagesFM Global Property Loss Prevention Data Sheets: List of Figuresdaniela hritucNo ratings yet

- Revit Domoty 1Document1 pageRevit Domoty 1SAN RAKSANo ratings yet

- MEITRACK MVT100 User Guide V2.4Document19 pagesMEITRACK MVT100 User Guide V2.4MeitrackNo ratings yet

- Jeepney Demand and Supply in Baguio CityDocument19 pagesJeepney Demand and Supply in Baguio CityJanna CrowNo ratings yet

- Us01cphy02 Unit 1 2014 THPDocument18 pagesUs01cphy02 Unit 1 2014 THPapi-264723824No ratings yet

- Solidworks SyllabusDocument7 pagesSolidworks SyllabusArun SubramanianNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Section11 Proportional ValvesDocument52 pagesSection11 Proportional ValvesyogitatanavadeNo ratings yet