Professional Documents

Culture Documents

Article Coolant

Uploaded by

nafpaktosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article Coolant

Uploaded by

nafpaktosCopyright:

Available Formats

COOLANT CONFUSION

WHAT KIND OF COOLANT REALLY BELONGS IN WHICH CAR?

BY JACQUES GORDON, TECHNICAL EDITOR

Coolant in an engine must do three things: carry heat to the radiator, prevent freezing and protect against corrosion. The glycol-based coolants on the market today can handle the first two tasks almost indefinitely, but corrosion protection relies on chemicals in the coolant that are eventually consumed as they do their job. Corrosion protection has always been a chemical balancing act, and with so many different types of coolant to choose from, its getting easy to inadvertently tip the balance the wrong way during cooling system service. Fortunately, its not hard to make the right choices, if you know what to look for.

While there are some minor variations, three basic types of coolant are available today: Inorganic Additive Technology (IAT), Organic Additive Technology (OAT) and Hybrid Organic Additive Technology (HOAT). To some extent, each will work in any cooling system, but each has been developed to meet car manufacturers specific needs for warranty and/or maintenance intervals. Filling a vehicle that was designed for one type of coolant with another type can sometimes cause problems, and you shouldnt expect the same corrosion protection as the factory fill. So what can a technician expect? What happens when coolant is added that is different from whats already in the system? What happens when a system is drained and refilled with a different coolant? How do we decide which coolant to use? ence of moisture, even the little bit of moisture in the air. OAT coolants anneal this metal-oxide layer into a thin surface coating that protects against further corrosion. With either type of inhibitor, there must be enough in the coolant solution to occasionally re-establish the barrier as needed. Silicates plate out quickly on metal engine parts; thus, the silicates in a coolant solution can drop to less than 20 percent of the starting level in less than 10,000 miles. Another problem with silicates is that, under certain conditions, they can drop out of solution and form minute deposits. If this occurs between a shaft and seal, the resulting abrasion will eventually cause a leak. In a cooling system that turns off coolant flow to the heater core when the heater is not in use, silicates can form a gummy deposit that, over the course of a summer season, might clog the core tubes. So why even use silicates? Because theyre really good at what they do, especially in iron block/aluminum head engines. Thats why some manufacturers still specify using coolants with silicate corrosion inhibitors. It took almost 20 years of OAT development to make a coolant that would effectively protect against corrosion without using any silicates at all. Some of those intermediate products are still in

Photo illustration: Michael Stassus; Source: Getty Images

CORROSION INHIBITORS The IAT coolants have been around for generations. They contain silicates that form a protective barrier on everything in the cooling system, even rubber hoses. The newer OAT coolants work very differently. Aluminum and ferrous metals form a surface-layer of corrosion in the pres38 | Motor Age

April 2005 www.motorage.com

WHAT COLOR COOLANT CAN I USE IN MY VEHICLE?

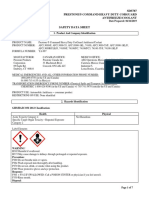

corrosion inhibitor technologies are mixed. By this he means that no sludge will form, there will be no damaging chemical reactions and the coolant will still carry heat and protect against freezing. However, when adding an IAT to an OAT, the recommended coolant change interval will degrade to that of the shorter-life coolant. Typically, when the mixture stays below 25 percent new coolant on top of 75 percent of the original coolant, the corrosion protection performance will remain that of the original coolant. But as the mix of coolant technologies deepens that is, if a cooling system has a slow leak and you continue to top it up with a type of coolant thats different from what is already in there eventually the original corrosion inhibitor will be replaced by the new corrosion MIXING COOLANTS inhibitor. This will determine the To quote Dr. Paul Fritz, senior resulting mixtures overall performcoolants technologist for ance. If you continue to top up a fiveChevronTexaco Products Co., year coolant with a two-year coolant, Nothing bad will happen when two the resulting coolant mixture should brand-name coolants with different now be changed every two years. According to Dr. David Turcotte of Valvoline Co., coolETHYLENE GLYCOL-BASED ENGINE COOLANT PROTECTION ing systems are mechanically PROTECTION CHART Capacity designed to work with specific Quarts of Engine Coolant Required for Protection to Temperatures (F) Shown Cooling System types of coolant. Filling a sys(Quarts) 2 3 4 5 6 7 8 9 10 11 12 tem with the wrong coolant 6 0 -34 A 50/50 mixture (coolant/distilled water) is could cause problems. In a 7 6 -18 -54 recommended as it provides freeze protection down 300-hour test of OAT coolant to -34F (-36.7C) and boiling protection up to 265F 8 10 -8 -34 (129C). DO NOT ALLOW the concentration of coolant in a Ford engine designed for 9 14 0 -21 -50 to fall below 40% or exceed 60% as engine parts could HOAT coolant, the water 10 16 4 -12 -34 -62 become damaged or not work properly. Shaded blocks show 50% concentration to the next higher full quart. 11 18 8 -6 -23 -47 pump impellor and backing 12 19 10 0 -15 -34 -57 plate were seriously damaged -45 13 21 13 3 -9 -25 by cavitation corrosion. 14 22 15 6 -5 -18 -34 -54 Turcotte and Fritz both told -43 15 23 16 8 0 -12 -26 us that its not possible to have 16 23 17 10 2 -8 -19 -34 -52 one product that meets the 17 24 18 12 5 -4 -14 -27 -42 coolant requirements of all the 18 24 19 14 7 0 -10 -21 -34 -50 different automakers. Because 19 25 20 15 9 2 -7 -16 -28 -42 some OEMs require silicate20 25 21 16 10 4 -3 -12 -22 -34 -48 free coolant and others mandate -41 21 22 17 12 6 0 -9 -17 -28 the presence of silicate, one 22 22 18 13 8 2 -6 -14 -23 -34 -47 size does not fit all. ETHYLENE GLYCOL HYDROMETER SCALE - For cooling systems larger than shown, use double the quantity required for cause raw coolant has no color at all. Every manufacturer adds color to the coolant as a dye marker, and they can add any color they want. In fact when red (heavy-duty) and orange (automotive) non-IAT coolants started selling well, some companies began to add similar colors to their coolants with conventional inhibitors and increased their prices. Also, there are green coolants from other countries that are more like OAT or hybrids than IAT coolants. The IAT coolants intended for heavy-duty diesel engines range from blue to green to purple, and hybrids might be any color at all. Some companies are now dying their coolants yellow regardless of the technology and indicating that it can be mixed with any other technology.

a system one-half as large. For systems smaller than shown, use half the quantity required for a system twice as large.

use today. These are the hybrid coolants (HOAT) that use both silicate and organic acid corrosion inhibitors, and one of them is currently the factory fill on all Ford and Chrysler vehicles with gasoline engines. Even in todays IAT coolants, the silicate concentration has been reduced to only 250 parts per million (ppm), which still provides excellent protection when used as directed. Those last two words, as directed, are more important now than ever, because its difficult to know which coolant technology belongs in which vehicle. Look up the coolant specifications in a factory manual or information system, and youre most likely to see a part number or proprietary name such as Toyota Engine Coolant or equivalent. Because few independent shops buy their coolant from auto dealers, most of us have come to rely on color to identify the coolant. This, however, is a bad idea, be-

40 | Motor Age

April 2005

www.motorage.com

Table source: Ford Motorcraft

WHAT COLOR COOLANT CAN I USE IN MY VEHICLE?

MAINTENANCE Both coolant scientists told us that cooling system maintenance is more important now than ever before. Dr. Fritz has been working to support and develop extended-life coolants for 10 years, and some of what hes learned has convinced him that the two most important cooling system maintenance items are freeze point and proper coolant level. Almost all coolants are formulated to work best at the ideal freeze point mixture, which for most parts of the country means a 50/50 mixture. Freeze point not only offers the best protection against freezing, but also makes sure the corrosion inhibitors are present at the intended levels. The proper freeze point mixture also is the most effective coolant, because the fluids ability to carry heat (heat capacity) is best at a 50/50 mix. Freeze point is best tested using a refractometer. Other test methods are available, but the refractometer is the most reliable due to its accuracy, its ability to be kept clean and the fact that coolant color does not affect the results. Cooling systems are designed to operate full of coolant. A system thats constantly low on coolant can be an extremely corrosive environment due to the aggressive nature of the vapors of a glycol/water mix. These steam vapors are more aggressive than either fluid by itself. After shutting off an engine, the coolant stops flowing and the engine temperature can increase dramatically in localized areas. Keeping the system full can help prevent localized boiling. Checking coolant level by looking at the overflow bottle is not always accurate. The best way is to remove the radiator cap on a cold engine and make sure the coolant level is correct. If the coolant is low in the radiator, check to make sure the cap is working correctly (holding pressure) and that the transfer line to the overflow tank is not clogged. Water quality also is an important factor. In almost every part of the world, tap water contains minerals like magnesium and calcium that can form deposits in a cooling system, especially on the engines hottest parts. These deposits can impede the flow of heat, and if they break loose, they can clog radiator and heater core tubes. Other contaminants such as iron and chlorine are relatively common, and at high enough levels, they can be corrosive. The only way to avoid minerals and other contaminants in the coolant is to mix it with distilled water instead of tap water. Coolants that are sold premixed are mixed at the factory with distilled water. The equipment needed to make distilled water at your shop is available, but distilled water is not the same as filtered water, so choose the equipment carefully. When a new metal cooling system part has been installed, for instance a new water pump, it has no corrosion protection at all. No matter what coolant the system is designed for, the worst thing to do at this point is to reinstall the old coolant. Adding fresh coolant will insure that there are enough corrosion inhibitors in the coolant to provide protection for the new components. Regardless of coolant type, adding new coolant is also recommended to avoid contamination from dirt, oil or other chemicals that are common in the shop. Coolant can play a role in repeated heater core failures on the same vehicle, partly because heater core tubes are so thin. Tap water with a high mineral content or coolant with too much silicate can cause abrasion in the core tubes. High flow rate can cause the same problem, and some vehicles now have restrictors in the heater hoses to slow the coolant flow through the heater core. Coolant thats intended for heavyduty diesel engines (high nitrite content) will attack aluminum chemically.

REPLACEMENT NEEDED For most of the history of glycol automotive coolant technology, every car manufacturer has recommended replacing the coolant periodically. Again, its not because old coolant wont carry heat or protect against freezing, its because the corrosion inhibitors literally wear out. Todays extended-life coolants work as advertised, but they need two conditions. First, they must be used as instructed and not mixed with a different type of coolant. Second, the system must be maintained properly as noted earlier, using only the same coolant and distilled water to keep the radiator full. Anything else will reduce the amount of time the coolant will protect against corrosion. After flushing a cooling system, the brand-name coolants will protect against corrosion as advertised as long as you follow the instructions. When adding coolant to top-off a system, its best to add the same type of coolant. Mixing different types of coolant will not cause problems, but once the mixture passes 25 percent, theres really no way to know how long the corrosion protection will last. And finally, never reuse old antifreeze, and always use distilled water or premixed coolant. When considering all thats in the balance, the few extra dollars for distilled water and a gallon of fresh antifreeze is never a bad choice. READER INTEREST SURVEY

Circle the appropriate number on the Reader Service Card to indicate your level of interest in this article. High 154 Average 155 Low 156

www.motorage.com April 2005 Motor Age

| 47

You might also like

- MaxxForce 11, 13 Maintenance Guide PDFDocument20 pagesMaxxForce 11, 13 Maintenance Guide PDFAlfonso Martinez Roman100% (2)

- D33x44 Service ManualDocument435 pagesD33x44 Service Manualmostafafouad19707723No ratings yet

- 3044C Industrial Engine-Maintenance IntervalsDocument28 pages3044C Industrial Engine-Maintenance Intervalsyoga_jpbmbm67% (3)

- ATV-320 SERVICE MANUALDocument125 pagesATV-320 SERVICE MANUALAlessioSonaglioNo ratings yet

- 1.2 63 77 KW TSI EngineDocument257 pages1.2 63 77 KW TSI Engineteodor1974100% (3)

- Owner'S Manual: 2.4L 25kW ModelsDocument68 pagesOwner'S Manual: 2.4L 25kW ModelsCarlos AngaritaNo ratings yet

- Study Identifies Cooling Problems With Water-Cooled GeneratorsDocument16 pagesStudy Identifies Cooling Problems With Water-Cooled GeneratorsprakashNo ratings yet

- Coolant SelectionDocument31 pagesCoolant Selectionedgar clemente carbajalNo ratings yet

- Coolant Requirement ASTMDocument5 pagesCoolant Requirement ASTMjeganNo ratings yet

- 754CLBTDocument0 pages754CLBTWissem Ratel100% (4)

- 1609571-3 4Document5 pages1609571-3 4Yafiz MalikNo ratings yet

- A Volatile Oxygen Treatment SystemDocument10 pagesA Volatile Oxygen Treatment SystemmallinathpnNo ratings yet

- Jws 0710261Document32 pagesJws 0710261Arjun NNo ratings yet

- 1373-12 Assessment Report BIOCIDASDocument187 pages1373-12 Assessment Report BIOCIDASchaneleitorNo ratings yet

- 97-01 Nafion General InfoDocument8 pages97-01 Nafion General InfoprimekronosNo ratings yet

- Resolving Process Distillation Equipment OpportunitiesDocument13 pagesResolving Process Distillation Equipment Opportunitiesrvkumar61No ratings yet

- Dow Biocides - EnvDocument69 pagesDow Biocides - EnvJose LopezNo ratings yet

- Process Intensification in Lactic Acid ProductionDocument11 pagesProcess Intensification in Lactic Acid ProductionRoxana StoicaNo ratings yet

- Metals: Predicting The Performance of Organic Corrosion InhibitorsDocument8 pagesMetals: Predicting The Performance of Organic Corrosion InhibitorsSimone SanNo ratings yet

- 2 5415941395045155907 PDFDocument19 pages2 5415941395045155907 PDFAlyelXNo ratings yet

- Green Diesel - A Second Generation BiofuelDocument11 pagesGreen Diesel - A Second Generation BiofuelChatkamol KaewbuddeeNo ratings yet

- Sanitron UV-S37C PDFDocument10 pagesSanitron UV-S37C PDFrodriguez.gaytanNo ratings yet

- Mono Ethylene GlycolDocument8 pagesMono Ethylene GlycolBavitha YadavNo ratings yet

- Water Systems Analysis, Design, and PlanningDocument959 pagesWater Systems Analysis, Design, and Planningkubus betonNo ratings yet

- Biogas Quality UpgradeDocument5 pagesBiogas Quality UpgradeIrWan D'little CloudNo ratings yet

- Biodiesel and Renewable DieselDocument10 pagesBiodiesel and Renewable DieselBhavana Singh0% (1)

- Z482-EB Pag 52-123Document126 pagesZ482-EB Pag 52-123JuanAbrahanNo ratings yet

- Extraction of Methane From Biogas - FinalDocument23 pagesExtraction of Methane From Biogas - FinaldhanushNo ratings yet

- Recycling Engine CoolantDocument9 pagesRecycling Engine CoolantYendi Kesuma100% (1)

- CMIT-MIT-Isothiazolone-Biocide-Assessment - StabilityDocument9 pagesCMIT-MIT-Isothiazolone-Biocide-Assessment - Stabilityichsan hakimNo ratings yet

- MitDocument7 pagesMitLam LagNo ratings yet

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Glysantin Coolant 101 EN PDFDocument6 pagesGlysantin Coolant 101 EN PDFChowdhury FatemaNo ratings yet

- Low Heat Rejection EngineDocument9 pagesLow Heat Rejection EnginePradheep SathyamurthyNo ratings yet

- Hydraulic Jumps Lab ExperimentDocument6 pagesHydraulic Jumps Lab Experimentaoi_chiepNo ratings yet

- Engine CoolingDocument7 pagesEngine CoolingpradipNo ratings yet

- Using Demulsifiers For Phase Breaking of Water - Oil EmulsionDocument5 pagesUsing Demulsifiers For Phase Breaking of Water - Oil EmulsionCarlosGamasOchoaNo ratings yet

- Bio-Ethanol from Fruit WastesDocument22 pagesBio-Ethanol from Fruit WastesSwarnalatha Katta0% (1)

- OILSANDFATSDocument51 pagesOILSANDFATSrosemagnaNo ratings yet

- Ethylene Glycol Heat-Transfer FluidDocument4 pagesEthylene Glycol Heat-Transfer FluiderreagaaNo ratings yet

- Acetic Anhydride Production ProcessDocument10 pagesAcetic Anhydride Production ProcessChellam Siva Chellam SivaNo ratings yet

- The Luxurie E-BrochureDocument32 pagesThe Luxurie E-Brochureapi-124172301No ratings yet

- Sequestrante OxigenioDocument10 pagesSequestrante OxigenioMárcia Elisabete Dos SantosNo ratings yet

- US Patent Manufacturing of Propylene GlycolDocument5 pagesUS Patent Manufacturing of Propylene GlycolRegiyanti RNo ratings yet

- Analisa Teknis Ballast Water Treatment Menggunakan Economizer dan Panas Buang Mesin Kapal untuk Memenuhi Persyaratan IMODocument30 pagesAnalisa Teknis Ballast Water Treatment Menggunakan Economizer dan Panas Buang Mesin Kapal untuk Memenuhi Persyaratan IMOWiwienRohmawatiNo ratings yet

- Large Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009Document26 pagesLarge Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009leo_ombinkNo ratings yet

- Deionized For Cooling Tower PDFDocument8 pagesDeionized For Cooling Tower PDFThipsuree KornboonraksaNo ratings yet

- The Effects of Fuel Additives On Diesel Engine Emissions During Steady State and Transient OperationDocument163 pagesThe Effects of Fuel Additives On Diesel Engine Emissions During Steady State and Transient OperationMohamad El NaggarNo ratings yet

- Cooling Water y AditivesDocument8 pagesCooling Water y AditivesNuryNo ratings yet

- Basic Cooling Water CalculationsDocument12 pagesBasic Cooling Water CalculationsafrinaslamNo ratings yet

- 9 - Annex Guidelines For Onboard SOx Cleaning SystemsDocument21 pages9 - Annex Guidelines For Onboard SOx Cleaning SystemskarloneilzNo ratings yet

- Plant Design Kojic Acid Beta 1Document41 pagesPlant Design Kojic Acid Beta 1Milton Dels RosaNo ratings yet

- Producing High Purity Stearic AcidDocument2 pagesProducing High Purity Stearic AcidMohd AzizanNo ratings yet

- Biofuels Production From Hydrotreating of Vegetable Oil Using SupDocument134 pagesBiofuels Production From Hydrotreating of Vegetable Oil Using SupErika de la RosaNo ratings yet

- MGO ExperienceDocument18 pagesMGO ExperienceCamilo MartinezNo ratings yet

- Validation of Hydrogen Fuel Cell Vehicle and Infrastructure TechnologyDocument4 pagesValidation of Hydrogen Fuel Cell Vehicle and Infrastructure TechnologySachin TatedNo ratings yet

- Hi Media Price List 2013-14Document386 pagesHi Media Price List 2013-14kakoli_bhatt9067% (6)

- Bio-Diesel Production From Food WasteDocument25 pagesBio-Diesel Production From Food WasteAbhishek PandeyNo ratings yet

- InTech-Pyrolysis Gas Chromatography Mass Spectrometry of Polymeric MaterialsDocument21 pagesInTech-Pyrolysis Gas Chromatography Mass Spectrometry of Polymeric MaterialsJose Manuel Oliveira PereiraNo ratings yet

- Chapter # O1: 1.1) Hydraulic FluidDocument9 pagesChapter # O1: 1.1) Hydraulic FluidUmar DrazNo ratings yet

- Feasibility Study of Hexane ProductionDocument3 pagesFeasibility Study of Hexane ProductionIntratec SolutionsNo ratings yet

- 108-1 SL ManualDocument19 pages108-1 SL ManualphongredNo ratings yet

- Water Treatment Chemicals ListDocument7 pagesWater Treatment Chemicals ListAlvin KimNo ratings yet

- 113.ammonium ChlorideDocument19 pages113.ammonium ChloridetadiyosNo ratings yet

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsFrom EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsNo ratings yet

- Dell™ Vostro™ 230 Service Manual - Mini Tower: Notes, Cautions, and WarningsDocument30 pagesDell™ Vostro™ 230 Service Manual - Mini Tower: Notes, Cautions, and Warningshola soy rugamaNo ratings yet

- Mercedes G-Class Diesel Focus on EssentialsDocument2 pagesMercedes G-Class Diesel Focus on Essentialsteodor1974No ratings yet

- Finepix S3200s4000series Manual 01Document147 pagesFinepix S3200s4000series Manual 01eeeediNo ratings yet

- Motorcycle Oils Vs Auto OilsDocument9 pagesMotorcycle Oils Vs Auto OilsSiddeNo ratings yet

- Steering in Bicycles and MotorcyclesDocument6 pagesSteering in Bicycles and Motorcyclesteodor1974No ratings yet

- SDS787 MergedDocument14 pagesSDS787 MergedmostafaNo ratings yet

- PDS Petrygo Heavy AntifreezeDocument2 pagesPDS Petrygo Heavy AntifreezemostafaNo ratings yet

- Chery 1.6 EngineDocument76 pagesChery 1.6 EngineXaiNo ratings yet

- S62 Approved Coolants From BMW TISDocument1 pageS62 Approved Coolants From BMW TISOrshanetzNo ratings yet

- Polyols From SorbitolDocument1 pagePolyols From SorbitolA MahmoodNo ratings yet

- CH 12 and 13 Study GuideDocument9 pagesCH 12 and 13 Study GuideLamees El BehearyNo ratings yet

- CoolFlow LV DatasheetDocument2 pagesCoolFlow LV DatasheetReuben WilliamsNo ratings yet

- Use New Machine SafelyDocument42 pagesUse New Machine SafelyOggy ToffyNo ratings yet

- Kodiak Marine: Supercharged 6.2L LSADocument48 pagesKodiak Marine: Supercharged 6.2L LSAmecanica gomesNo ratings yet

- CLG842 (Dcec Ii) Om 201501006-EnDocument192 pagesCLG842 (Dcec Ii) Om 201501006-EnCarlos Astudillo VargasNo ratings yet

- 2.160C Operation and Maintenance - DikonversiDocument59 pages2.160C Operation and Maintenance - DikonversiDedi rahmat100% (1)

- Cooling Systems AssignmentDocument14 pagesCooling Systems AssignmentBecky DavisNo ratings yet

- CAT Operation and Maintenance c27-c32Document144 pagesCAT Operation and Maintenance c27-c32Carlos AparicioNo ratings yet

- Troubleshoot Engine OverheatingDocument4 pagesTroubleshoot Engine Overheatingfrancisca19No ratings yet

- Sxs1000 ServicioDocument735 pagesSxs1000 ServiciofacturacionelectronicavillalazNo ratings yet

- Test Tools For The Cooling SystemDocument4 pagesTest Tools For The Cooling SystemNimNo ratings yet

- Fleet Charge 5050 Premix Antifreeze CoolantDocument8 pagesFleet Charge 5050 Premix Antifreeze CoolantDAnielNo ratings yet

- WSS-M21P40 22-03-2019Document6 pagesWSS-M21P40 22-03-2019Ronald AraujoNo ratings yet

- WSAN-XEM MF 50.4 - 120.4: Installation and Operating ManualDocument66 pagesWSAN-XEM MF 50.4 - 120.4: Installation and Operating ManualMitchel HerreraNo ratings yet

- 2020年杜卡迪Hypermotard 950 -用户手册 PDFDocument302 pages2020年杜卡迪Hypermotard 950 -用户手册 PDF张连杉No ratings yet

- Technical Circular: en 0199 - 99 - 1115 3rd ExchangeDocument6 pagesTechnical Circular: en 0199 - 99 - 1115 3rd ExchangeJulio Alvarado MoralesNo ratings yet

- Symrise Symcool A4 Pages EngDocument6 pagesSymrise Symcool A4 Pages EngJoseph Garci GarciNo ratings yet

- Heritage CatalogDocument44 pagesHeritage CatalogHaitem FarganiNo ratings yet