Professional Documents

Culture Documents

Effect of Temperature and Age of Concrete On Strength - Porosity Relation

Uploaded by

Fahid AslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Temperature and Age of Concrete On Strength - Porosity Relation

Uploaded by

Fahid AslamCopyright:

Available Formats

Czech Technical University in Prague

Acta Polytechnica Vol. 44 No. 1/2004

Effect of Temperature and Age of Concrete on Strength Porosity Relation

T. Zadrail, F. Vodk, O. Kapikov

The compressive strengths of unsealed samples of concrete at the age of 180 days and have been measured at temperatures 20 C, 300 C, 600 C and 900 C. All of tests were performed for cold material. We compared our results with those obtained in [10] for the same type of concrete (age 28, resp. 90 days and measured at temperature ranging from 20 C to 280 C). Dependencies of compressive strength and porosity were correlated together and compared for the samples of age 28, 90 and 180 days. Behaviour of concrete of the age 90, resp. 180 days confirms generally accepted hypothesis that with increasing porosity strength of the concrete decreases. It has to be stressed out, howerer, that concrete samples of the age 28 days exhibit totally opposite dependency. Keywords: compressive strength, temperature dependency, porosity.

Table 1: Composition of 1 m3 of concrete mixtures Temeln

1 Introduction

As known from experimental studies of concrete behaviour at room temperature, there is a close correspondence between compressive strength S and its porosity P Commonly . this dependence is decreasing function, i.e. strength S decreases with porosity P There are many attempts to express . the relation S = S(P) in an analytical form. It has to be pointed out, however, that such expressions (as, for example, Balshin relation, Ryshkewitch expression, Schiller law, Hasselman formula for details see, e.g., [1]) have been mostly derived for different type of materials. The present paper is based on the assumption that changes in porosity P are the main factor effecting changes in compressive strength S of hardened cement pastes and concrete (see, e.g., [2]). The hypothesis is generally accepted, howerer, some doubts exist [3,4]. Moreover, practically in all articles cited above the dependence S = S(P) porosity was modified by a change of w/c ratio. In the present paper all specimens were prepared at the some w/c coefficient for all tested samples and the porosity varied due to heat treatment at different temperature levels. It is therefore interesting to the dependence of compressive strength S on porosity P in that case and check, if S = S(P) is at least qualitatively the same as for the porosity modified by w/c ratio. Cement Water Plasticizer (Ligoplast SF) 499 kg 215 kg 4.9 kg 710 kg (04 mm) Aggregates 460 kg (816 mm) 530 kg (1622 mm)

Table 2: Quantitative composition of cements in % by volume

CEM I 42.5 Mokr Phase clinker composition C3S C2S C3A C4AF Cfree Total 70.0 11.4 7.9 9.7 1.0 100.0

2 Experiment

2.1 Composition of concrete

The tested specimens for the whole experimental program were made from the concrete mixture, the composition of which is given in Table 1. Composition corresponds to the concrete composition applied in real structures (in the containment of NPP Temelin). The mineral composition of cement in percentage by weight can be found in [5]. The mineral composition of cement in percent per volume is given in Table 2. Applied starting material is Portland cement with a small amount of fly ash and traces of slag. The clinker used for its production was burnt on the optimum content of free CaO and has a high fraction of alite and C4AF prevailing over C3A in it. An average size of crystals ranges between 0.0250.030 mm and a size of belite grains is about 0.20 mm in average.

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

Fraction of components in cement Clinker Gypsum Fly ash Slag Total 93.3 4.7 1.8 0.2 100.0

2.2 Manufacturing of samples

Mixing of concrete mixtures was carried out in the laboratory mixer with the forced circulation. The careful procedure of loading the ingredients to the mixer and kept time schedule of mixing guaranteed the homogeneous concrete mixture 53

Acta Polytechnica Vol. 44 No. 1/2004

Czech Technical University in Prague

compressive strength [MPa]

of constant quality in all batches. The tested specimens for the experimental program were manufactured in two relays. Attention was paid to the specimens curing. First, the specimens were covered with a polyethylene foil that restrained the leakage of excessive water from the surface bed of the tested body. Then, approximately six hours after the manufacturing ended, the samples including the forms were covered with a damp fabric and then they were recovered with a polyethylene foil. The basic specimen of the experimental program was 0.1/0.1/0.4 m beam.

80

age 180 days

60

40

20

2.3 Heating of specimens

The concrete samples were placed in the high-temperature furnace BVD 100/KY (temperature range up to 1250 C) with the programmable heating and cooling regulator. Temperature increases 100 C each 15 minutes during the heating up to final temperature 300 C, 600 C, 900 C, respectively. Samples were exposed to high temperatures for 2 hours. Cooling rate was 100 C per 30 minutes. Duration of exposure at elevated temperatures (2 hours) practically guarantees that the samples are heated uniformly within whole specimen volume. This time period was estimated from solution of heat conductivity equation. Appropriate input parameters (in particular, thermal conductivity coefficient, resp. specific heat capacity and its dependency on temperature) were taken from [6].

0 0 200 400 600 800 1000

temperature [C]

Fig. 1: Effect of temperature on compressive strength for concrete of age 180 days

compressive stregth ratio

1.2 1 0.8 0.6 0.4 0.2 0 0 200 400 600 800 1000

age 180 days

2.4 Tests of concrete mechanical properties

The compressive strength was determined on the fragments of the beams of the original dimensions 0.1/0.1/0.4 m after the fracture toughness measurement referred in the previous paper [11]. All of the tests were performed according to the method of the Czech National Standard CSN 73 13 18. The measurements of the compressive strength were performed on 6 specimens for each temperature level.

2.5 Tests of concrete porosity properties

The small fragments of the beam after strength tests were utilized to determine the concrete texture. Samples were dried at temperature 105 C for 4 hours before measurement. The porosity of hardened cement paste has been measured by the method of mercury porosimetry using high-pressure porosimeter Micrometrics Auto-Pore 9200 (with pressure range up to 400 MPa). The porosity was measured on 6 specimens for each temperature level.

temperature [C]

Fig. 2: Effect of temperature on compressive strength ratio for concrete of age 180 days

30 25

age 180 days

porosity [%]

3 Results and discussion

Dependence of compressive strength on the temperature level of heating is shown in Fig. 1. Furthermore, the ratio of strength value after cooling of the sample and its original strength value (determined by indoor temperature before heat pretreatment) is generally referred to be residual stregth ratio [7]. These results are depicted in Fig. 2. The changes of the porosity with temperature of heating are presented in Fig. 3. (Each point of these curves corresponds to the average of six values measured on different specimens heated at the same temperature level). According to these measurements representative values of strength (S) and porosity (P) for a given temperature were obtained and successively functional dependency S = S(P) was established, see Fig. 4. The analogical results for concrete at the age of 28 days 54

20 15 10 5 0 0 200 400 600 800 1000

temperature [C]

Fig. 3: Effect of temperature on porosity for concrete of age 180 days

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

Czech Technical University in Prague

Acta Polytechnica Vol. 44 No. 1/2004

compressive strength [MPa]

80

age 180 days

20

age 28 days

18

porosity [%]

60

age 90 days

16 14 12 10

40

20

0 5 10 15 20 25 30

50

100

150

200

250

300

porosity [%]

temperature [C]

Fig. 7: Effect of temperature on porosity for concrete of age 28 and 90 days

Fig. 4: Dependence of compressive strength on porosity for concrete of age 180 days

compressive strength [MPa]

80

age 28 days

70

age 90 days

60

50

40 0 50 100 150 200 250 300

and 90 days treated in the temperature range 20 C280 C are in Figs. 59 [10]. These dependences S = S(P) were compared for different ages of concrete samples (Figs. 4, 8, 9). Behaviour of concrete samples aged 90 and 180 days (Figs. 4, 9) confirms decreasing compressive strength with the increasing porosity. Samples of the age 28 days behave quite oppositely, the compressive strength increases with the increasing porosity (Fig. 8). Practically in all published papers dependence S = S(P) is studied at constant (room) temperature and specimens porosity is modified only by change of w/c ratio. Our atypical dependence for samples aged 28 days is due to temperature effect. Usually three competitive factors result from the analysis of temperature influence on properties of concrete: a) Drying in the temperature range 100 C200 C increases the strength [7]. b) The increasing content of hydration products occurring in the temperature range 100 C to 300 C (note that the bound water starts to be released at 180 C [9]) leads to an increase of concrete strenght [8]. A probable reason is larger mobility of water molekules in gaseous phase (as compared with their mobility in liquids).

compressive strength [MPa]

80 75 70 65 60 55 50 45 12 14 16 18 20

age 28 days

temperature [C]

Fig. 5: Effect of temperature on compressive strength for concrete of age 28 and 90 days

1.2

compressive stregth ratio

1.1 1 0.9 0.8 0.7 0 50 100

age 28 days age 90 days

150

200

250

300

temperature [C]

porosity [%]

Fig. 6: Effect of temperature on compressive strength ratio for concrete of age 28 and 90 days

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

Fig. 8: Dependence of compressive strength on porosity for concrete of age 28 days

55

Acta Polytechnica Vol. 44 No. 1/2004

Czech Technical University in Prague

compressive strength [MPa]

70

age 90 days

65

60

55

50 13 14 15 16 17

porosity [%]

Fig. 9: Dependence of compressive strength on porosity for concrete of age 90 days

c) Microcracking due mainly to thermal incompatibility of the hardened cement paste and aggregate which increases porosity and decreases strength [7]. This process takes place throughout whole temperature interval. From presented measurements may be deduced that resulting balance of these three influences essentially depends on the age of concrete. Increasing content of hydration products plays dominant role, especially for concrete at the age of 28 days (with relatively large volume of unhydrated cement) due to intensifying hydration with temperature (between 100 C300 C). This process causes similar behaviour of strength as certain curing treatments (so-called steam curing). These facts result in extraordinary dependence of strength on porosity (Fig. 8), which behaves as increasing function, contrary to original hypothesis. On the other hand, hydration processes are practically terminated in concretes at the age of 90 days and the functional dependence S = S(P) (Fig. 9) corresponds to initial hypothesis, since the major role is now played by microcracking. Additional minihydration is caused mostly by water molecules of relatively high kinetic energies released at temperatures above 250 C. This phenomenon, which leads to low increasing of the strength and decreasing of the porosity (see Figs. 5 and 7), is again in good agreement with initial hypothesis. The results for the concrete at the age 180 days are quite problemless. The function S = S(T) decreases, the function P = P(T) increases and the dependency S = S(P) is the decreasing function. We may suppose that all significant hydration processes are finished at this age and changes of porosity and strength are influence only by microcracing.

[2] Odler I., Rossler M.: Investigations on the Relationship between Porosity, Structure and Strength of Hydrated Portland Cement Pastes I a II. Cem. Concrete Res., Vol. 15 (1985), p. 320330, 401410. [3] Jambor J.: Influence of Phase Composition of Hardened Binder Pastes on its Pore Structure and Porosity. In: Pore Structure and Properties of Materials (Editor: S. Modr). Prague: Academia, 1973, p. D75D95. [4] Fagerlund G.: Strength and Porosity of Concrete. In: Pore Structure and Properties of Materials (Editor: S. Modr). Prague: Academia, 1973, p. D57D73. [5] Vydra V., Vodk F., Kapikov O., Hokov .: Effect of Temperature on Porosity of Concrete for Nuklear-safety Structures. Cem. Concr. Res., Vol. 301 (2001), p. 10231026. [6] Vodk F. et al: Tables of Physical Properties of Concretes for Nuclear-safety Structures. In: CTU Reports 4 (2000) (Editor: F.Vodk). Prague: CTU Publ. House, 2000. [7] Baant Z. P., Kaplan M. F.: Concrete at High Temperatures. Essex: Longman, 1996. [8] Jambor J.: Porosity, Pore Structure and Strength of Cementeous Composites. Staveb. as., Vol. 33 (1985), p. 743764. [9] Komarovskij A. N.: Design of Nuclear Plants. Moscow: Atomizdat, 1965. [10] Hokov ., Kapikov O., Trtk K., Vodk F.: Experimental study of relation among elevated temperature exposure, strength and structure of concrete employed in contaiment of NPP Temelin. In: Research activities of Physical Departments of Civil Engineering Faculties in the Czech and Slovak Republics. (Eds: L. Pazdera and M. Koensk). Brno, 2001, p. 2528. [11] Zadrail T., Vodk F., Trtk K.: Vliv teploty na pevnost betonu uitho pi stavb kontejnmentu jadern elektrrny Temeln. Stavebn obzor, Vol. 9 (2003), p. 272274.

Ing. Tom Zadrail phone: +420 224 354 693 e-mail: xzadrazt@stu.fsv.cvut.cz Prof. Frantiek Vodk, DrSc. phone: +420 224 353 886 e-mail: vodak@fsv.cvut.cz RNDr. Olga Kapikov, CSc. phone: +420 224 354 696 e-mail: kapickov@fsv.cvut.cz Department of Physic Czech Technical University in Prague Faculty of Civil Engineering Thkurova 7 166 29 Praha 6, Czech Republic

Acknowledgement

This work was partially supported by the MSMT CR (contract No J304-098:210000020).

References

[1] Taylor H. F. W.: Cement Chemistry. London: Thomas Telford Publ., 1997.

56

Czech Technical University Publishing House

http://ctn.cvut.cz/ap/

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TCVN 6882-2001 PH Gia Khoáng Cho Xi MăngDocument9 pagesTCVN 6882-2001 PH Gia Khoáng Cho Xi MăngNam HuynhNo ratings yet

- Portland Cement Plaster - SpecDocument7 pagesPortland Cement Plaster - Speclinga2014No ratings yet

- Capital StructureDocument91 pagesCapital StructureyvNo ratings yet

- On Fly Ash by Sumit SumanDocument20 pagesOn Fly Ash by Sumit SumanSumit Suman100% (3)

- Building Construction and Materials Notes - Civilenggforall PDFDocument254 pagesBuilding Construction and Materials Notes - Civilenggforall PDFDebrahanath100% (2)

- Advanced Concrete Design Module 1 KtuDocument28 pagesAdvanced Concrete Design Module 1 Ktushalu R FNo ratings yet

- Green ConcreteDocument20 pagesGreen ConcretePankajKumar75% (12)

- Aci-305r 91 PDFDocument20 pagesAci-305r 91 PDFSiddharth Garg100% (1)

- DPWH department orders and memorandums quizDocument9 pagesDPWH department orders and memorandums quizKaizer DAnNo ratings yet

- Development and Preliminary Mix Design of Ultra-High-Performance Concrete Based On GeopolymerDocument17 pagesDevelopment and Preliminary Mix Design of Ultra-High-Performance Concrete Based On GeopolymerJoaoengNo ratings yet

- Effect of Curing Conditions On The Strength of Soil CementDocument8 pagesEffect of Curing Conditions On The Strength of Soil CementHugoNo ratings yet

- Pakistan cement sector overviewDocument32 pagesPakistan cement sector overviewZohaib AhmedNo ratings yet

- RCC Box Drain SpecificationDocument110 pagesRCC Box Drain SpecificationMaulik RavalNo ratings yet

- Sulfate Resistance of RFCC Spent Catalyst-Blended Portland CementDocument12 pagesSulfate Resistance of RFCC Spent Catalyst-Blended Portland CementAylin Portillo OliveraNo ratings yet

- 11 SpecificationDocument199 pages11 SpecificationAshish DevreNo ratings yet

- Research PaperDocument16 pagesResearch PaperpoornimavenkatramanNo ratings yet

- Section 04 Concrete WorksDocument32 pagesSection 04 Concrete WorksMarvin MessiNo ratings yet

- Australasian (Iron & Steel) Slag AssociationDocument6 pagesAustralasian (Iron & Steel) Slag AssociationNickNo ratings yet

- Strength and Shrinkage Properties of Mortar Containing A Nonstandard High-Calcium Fly AshDocument4 pagesStrength and Shrinkage Properties of Mortar Containing A Nonstandard High-Calcium Fly AshTarek ChikerNo ratings yet

- Spinor Microfine Cement BrochureDocument16 pagesSpinor Microfine Cement BrochurePauSilleroNo ratings yet

- Properties and Classification of Fly AshDocument15 pagesProperties and Classification of Fly AshprabhuwbNo ratings yet

- Kamal Cement Test CertificateDocument115 pagesKamal Cement Test CertificateKuldeep ChakerwartiNo ratings yet

- ASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsDocument35 pagesASTM D 653-97 Standard Terminology Relating To Soil, Rock, and Contained FluidsPablo Antonio Valcárcel VargasNo ratings yet

- A Revew On The Use of Waste Glasses in The Production of Cement and ConcreteDocument14 pagesA Revew On The Use of Waste Glasses in The Production of Cement and ConcreteA. ELIZABETH VELASCONo ratings yet

- UI Students Develop Acid-Resistant Tile GroutDocument48 pagesUI Students Develop Acid-Resistant Tile GroutArdiansah -No ratings yet

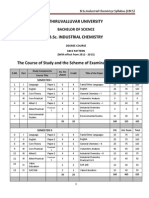

- B.sc. Industrial ChemistryDocument79 pagesB.sc. Industrial ChemistryOmar Abd Elsalam0% (1)

- BT2 ConcreteDocument7 pagesBT2 ConcreteMicah Dianne DizonNo ratings yet

- Mortar Cement: Standard Specification ForDocument4 pagesMortar Cement: Standard Specification ForMaiNo ratings yet

- Influence of Water To Cement Ratio (W/C) On Slump Flow and Compressive Strength of Self Compacting Concrete (SCC) Containting Portland Pozzolan CementDocument6 pagesInfluence of Water To Cement Ratio (W/C) On Slump Flow and Compressive Strength of Self Compacting Concrete (SCC) Containting Portland Pozzolan Cementmanikandan4strlNo ratings yet