Professional Documents

Culture Documents

Sap

Uploaded by

tamz14Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sap

Uploaded by

tamz14Copyright:

Available Formats

R E S E A R C H M E T H O D L O G Y Firstly a project on the material management with reference to Samtel Glass Ltd. wasassigned me as a trainee.

I have completed my project by going through the followingresearch methodology:1. Firstly keeping the research objectives mentioned I contacted different managers working in Samtel Glass Ltd. in different department. DATA COLLECTION:Primary data Personal interview with manager and officers

Secondary data Books Internet Manuals LIMITATIONS: Some confidential Data are removed as per the company polices like agreementwith transporters, custom house agent (CHA), agreements with vendors. Global glass market trend presently show that the demand supply gap has shrunk due to shutdown major glass plants all over the world. The decline in global CRE market has now stabilised at the level of 112 million in 2005 to 14 million 2009.Samtel Glass team under the leadership of Mr. Uttam Bose able to grab the opportunities available in external market by drawing on its internal strength to swiftly adopt itself to meet the fresh challenges in the market.The need for conceiving & pursuing a turnaround strategy was focused on both the enhancement of value & production volume. In an environment in which the price of major inputs SWOT ANALYSIS OF SAMTEL:STRENGTH: Largest manufacturer of TV glass in India. Increasing trend in volume. Redesigning of glass chemistry. WEAKNESS: Marginal profits. Continues decrease in pricing. Increasing trend in price of major raw material like Litharge, neck tubing.

OPPORTUNITIES: Introduction of new market of both export & domestic. Shutting down trend of TV glass furnace worldwide. Continues focus in cost reduction. Continues focus on process establishment system by using 6 sigma methodologies.

THREATS: Continues reduction in price. Dependency on Samtel color (sell more than 95% of funnel to Samtel color. Continues import of picture tube.

FINDINGS: The planning of the material o Depend on the Fund o Depend on period of material requirement i.e. in how frequently it is required. o Whether imported or local purchase The amount of material depends on the requirement of the user and store. Vendors are selected on the basis of o Quality of material o Quantity of material o lead time taken by supplier o Payment terms o Price of material o Major client of the vendor Relation with the vendors are maintain by o Timely payment to vendor o Transparency in the deal and communication o Visits to vendor if possible Reasons for delay in purchasing of material o Specifications of the material is not properly mention by the user o Unavailability of material with the supplier o Unavailability of funds Accept raw material, material are not stocked for more than two days The means of transportation of material depends on the o Urgency of material o Money required in the transportation

SUGGESTIONS: The work in purchase department should be divided on the basis of the work likemaking PO, follow up the vendor and transporter. User should interact with only one person in purchase department which will ensurethe proper working of purchase officer

You might also like

- NAV Issue StatusDocument3 pagesNAV Issue Statustamz14No ratings yet

- Employee Management SystemDocument83 pagesEmployee Management SystemhusseinNo ratings yet

- Lanka TestingDocument1 pageLanka Testingtamz14No ratings yet

- CS Gate 2010 ExpDocument10 pagesCS Gate 2010 ExpPramod PindipoluNo ratings yet

- DiffrnceDocument2 pagesDiffrncetamz14No ratings yet

- Blue Eyes AppDocument4 pagesBlue Eyes Apptamz14No ratings yet

- Training Workshop On Nss 67Thrd Registartion Officer'S List: Guests From DPD (HQ)Document3 pagesTraining Workshop On Nss 67Thrd Registartion Officer'S List: Guests From DPD (HQ)tamz14No ratings yet

- Mobile CommunicationsDocument24 pagesMobile CommunicationsdeardestinyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vidler Anthony 1977 1998 The Third TypologyDocument11 pagesVidler Anthony 1977 1998 The Third TypologyAlexandros ZomasNo ratings yet

- PNTC Colleges: Form No. BPM2-CME 20 F-010 Rev.00Document3 pagesPNTC Colleges: Form No. BPM2-CME 20 F-010 Rev.00Rheyl ReyesNo ratings yet

- Exercise Chapter 1 MGT 162Document1 pageExercise Chapter 1 MGT 162Azizi Gji50% (2)

- Analysis Print MediaDocument5 pagesAnalysis Print MediaromiNo ratings yet

- The 1914 Debate Continues: Fritz Fischer and His CriticsDocument14 pagesThe 1914 Debate Continues: Fritz Fischer and His CriticssaipraneethNo ratings yet

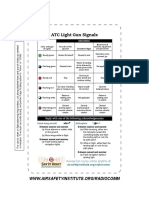

- At C Light Gun SignalsDocument1 pageAt C Light Gun SignalsJorge CastroNo ratings yet

- Long and Short Term Causes of The Spanish Civil WarDocument4 pagesLong and Short Term Causes of The Spanish Civil WarantopantoNo ratings yet

- Survey On Energy Management System: InstructionDocument7 pagesSurvey On Energy Management System: InstructionFadzilah MohamadNo ratings yet

- Stonecrest 2022 BudgetDocument29 pagesStonecrest 2022 BudgetZachary HansenNo ratings yet

- CBLM Template Common LO #3Document24 pagesCBLM Template Common LO #3Joshua CondeNo ratings yet

- Bar Syllabus 2020 - Criminal LawDocument7 pagesBar Syllabus 2020 - Criminal LawmvgeNo ratings yet

- Software Requirement Specification: 3.1.1 PurposeDocument4 pagesSoftware Requirement Specification: 3.1.1 Purposevishalmate10No ratings yet

- PT - Snt-Tc-1a 2006 (Study Test)Document8 pagesPT - Snt-Tc-1a 2006 (Study Test)DESTINY SIMON67% (3)

- Bellis Vs BellisDocument2 pagesBellis Vs BellisedmarkbaroyNo ratings yet

- Walls Ice CreamDocument17 pagesWalls Ice Creamusman16380% (5)

- Marketing Plan: Market Analysis Target MarketDocument4 pagesMarketing Plan: Market Analysis Target MarketRaymund GatocNo ratings yet

- 91 19 Human Resource Management InfoDocument23 pages91 19 Human Resource Management InfoRakshita SolankiNo ratings yet

- Relationship Powerpoint LessonDocument26 pagesRelationship Powerpoint LessonJan Rafael ReyesNo ratings yet

- The Chicago Debate League Blue Conference Novice Division Affirmative Previewed CasesDocument18 pagesThe Chicago Debate League Blue Conference Novice Division Affirmative Previewed CasesjohnsonNo ratings yet

- Application Form BIR 1916Document2 pagesApplication Form BIR 1916Rodel Ryan YanaNo ratings yet

- ING Info Sheet (2016 - 09) 2 Harvard Analytical Framework (Ludgate)Document3 pagesING Info Sheet (2016 - 09) 2 Harvard Analytical Framework (Ludgate)Ibra MalikiNo ratings yet

- The Role of Civil Society OrganizationsDocument113 pagesThe Role of Civil Society OrganizationsGracePolendeGuzmanNo ratings yet

- What Is EEO?: Enforcing The LawDocument5 pagesWhat Is EEO?: Enforcing The LawAishaNo ratings yet

- Social Network Theory Is The Study of How PeopleDocument2 pagesSocial Network Theory Is The Study of How PeopleLYCA DELA CRUZ100% (1)

- Index 2 PDFDocument1 pageIndex 2 PDFOmkar KaigudeNo ratings yet

- 4 Marketing Plan Serco GroupDocument23 pages4 Marketing Plan Serco GroupMitchell LazarroNo ratings yet

- 11 September 2001Document208 pages11 September 2001keramatboy88No ratings yet

- Afp Organization SLDocument31 pagesAfp Organization SLFrancis PimentelNo ratings yet

- ABE Level 5 Diploma in Business Management and Marketing: Buyer and Consumer BehaviourDocument27 pagesABE Level 5 Diploma in Business Management and Marketing: Buyer and Consumer BehaviourArjun KhanNo ratings yet

- New Challenges in Recruitment and Selection - Attraction of The Y GenerationDocument13 pagesNew Challenges in Recruitment and Selection - Attraction of The Y GenerationAyzaa NatasyaNo ratings yet