Professional Documents

Culture Documents

Application Note 058: Connector Maintenance

Uploaded by

osto72Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Note 058: Connector Maintenance

Uploaded by

osto72Copyright:

Available Formats

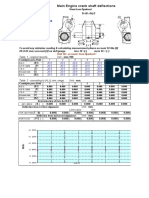

APPLICATION NOTE 058

CONNECTOR MAINTENANCE

Optical Business Unit Connectors are designed to require minimum maintenance and provide reliable operation for many years. However, to ensure optimal operation and minimum insertion loss, it is important that fiber ends and optical ports be clean at all times. Proper cleaning also prevents the buildup of dirt, dust and other foreign substancesespecially between connector pins. This application note presents the proper maintenance procedures for connectors (FC, SC, ST and E-2000), fibers (singlemode and multimode) and other components such as bulkhead connectors, fiber-optic adapters (FOAs), detector ports and EUI connectors. This procedure ensures safe and effective inspection and cleaning techniques for long-lasting connectors. Before any proper cleaning procedure can begin, it is important to make sure that the following standard cleaning equipment is on-hand: Cartridge cleaning tools Cotton swabs or lint-free wipes Specialized/specific alcohol and solvents used for wet cleaning Compressed air A fiber inspection probe (such as the FIP-400) to check for cleanliness and scratches

General Cleaning Instructions

The cleaning instructions below also contain some general safety precautions that must be observed during all cleaning phases. 1. Whenever alcohol or solvent is used to perform wet cleaning, make sure you have all the tools needed to prevent any evaporation and to ensure that the solvent will be completely removed from the connector afterwards. Evaporated (or absorbed) alcohol will leave a residue on the ferrule. This residue is extremely difficult to removeusually, even more difficult to remove than the original contaminantand will require a second wet cleaning. Some solvents do not contain alcohol and thus will not present this problem. Make sure to verify the content of the product you are using. Simply moisten a small section of a lint-free wipe or swab with a single drop of alcohol or solvent. Gently wipe the ferrule with this portion of the swab/wipe using a figure-8 motion. Then, immediately perform a similar wiping action using the dry portion of the swab/wipe to remove any residual liquid. 2. Never use the wet cleaning technique on multifiber, E-2000 or F-3000 connectors, as the guide pins and connector caps can trap some alcohol or solvent and cause recontamination of the connector. 3. When using compressed air, however, make sure that the product (air) is certified to be clean and exempt of any traces of water or oil. Before you begin, send the first spray in the air, as it can contain condensation or propellant, which can leave residue on the surface being cleaned. Always apply a very gentle spray of air at an angle, as the pressure may be strong enough todamage fragile devices such as detector windows. Compressed air is only good for dust, not grease, and care must be taken not to trap dust into small crevices on the surface being cleaned.

Next-Generation Network Assessment

APPLICATION NOTE 058

Figure 1: Scratched connectors must be rejected.

Figure 2: Worn connectors must be rejected.

To properly carry out connector maintenance, you must be familiar with the visual inspection procedure. It is imperative that there be no dirt on the connector core. Any connector that has a scratch across the core or a scratch that appears to affect the core/cladding transition region must be rejected. Any connector with more than one scratch or a deep scratch (visible to the human eye) must also be eliminated. In addition, any patchcord showing obvious signs of wear on the ferrule, cladding or core must be rejected (see Figures 1 and 2).

General Tips on Cleaning Connectors

Below are a few tips on how to keep your connectors in the best possible condition. When inserting a connector ferrule into a sleeve or adapter, ensure that the ferrule tip does not touch the outside of the mating sleeve or adapter. Otherwise, the fiber end will rub against an unsuitable surface, producing scratches and dirt deposits on the fiber. Please note that the ceramic or metal sleeves inside the adapter are tightly fitted. Carefully rotate the ferrule in the adapter in order to align it with the connector key. Do not force the ferrule into the adapter. Every time there is a disconnection or an undesirable contact, you must carry out the inspection and, if needed, the cleaning procedure. This helps ensure that patchcords remain in the best condition possible and, consequently, that transmission will not be affected or that measurement readings remain accurate. Still, this procedure does not replace careful handling of patchcords. The use of protective caps is also necessary, but does not guarantee the cleanliness or the quality of a patchcord. This procedure conforms to the GR-326 standard entitled Singlemode Optical Connectors and Jumper Assemblies. Cleaning connectors is difficult because the core diameter of a singlemode fiber is only about 9 m. This generally means that you will not be able to see scratches on its surface without special equipment. In order to be certain of the connections surface condition and to be able to check it before and after cleaning, you need a fiber inspection probe such as the FIP-400. The use of a probe prevents the risk associated with damaging ones eyes since the image of the connector can be viewed on screen. Warning: Never look into the end of an optical cable that is connected to an active light source!

Cleaning Fiber Ends

To adequately clean fiber ends, follow the steps below: 1. Make sure the fiber is not active. 2. Remove the protective caps. 3. Verify the cleanliness of the connector with your FIP (see Figure 3). The patchcord is clean when there is no debris touching the cladding or the core. 4. If the connector is not clean, gently wipe the fiber end with a cotton swab or lint-free wipe a second time (see Figure 4). 5. Verify the cleanliness of the connector with your FIP a second time. The patchcord is clean when there is no debris touching the cladding or the core. 6. If the connector is still not clean after two dry cleanings, perform a wet cleaning on the connector and then gently wipe the fiber end with a cotton swab or lint-free wipe. 7. Verify the cleanliness of the connector with your FIP a third time.

APPLICATION NOTE 058

Figure 3: Verify connectors with your FIP-400.

Figure 4: Cleaning fiber ends.

Cleaning Bulkhead Connectors

To clean bulkhead connectors, follow the steps below: 1. First inspect and, if needed, use a clean, dry swab to remove any debris that may be inside the sleeve (see Figures 5, 6 and 7). 2. Lightly press and turn the cleaning tip to clean the inside portion of the bulkhead adapter (see Figure 7). 3. When wet cleaning is required, make sure to use as little liquid as possible and rapidly dry the remaining alcohol or solvent with another dry tip.

Figure 5: Cleaning setup.

Figure 6: Cleaning tips.

Figure 7: Cleaning bulkhead connectors.

Cleaning Fiber-Optic Adapters

To clean fiber-optic adapters, follow the steps below: 1. Some fiber-optic adapters (FOAs) have an anti-reflection coating, which is very sensitive to abrasion and solvents. Therefore, the best cleaning method for these types of FOAs is dry cleaning (i.e., using compressed air). 2. To remove debris, take a clean, dry swab and wipe the FOA using a very gentle rotation movement, ensuring that you are not leaving any other debris (see Figure 8). 3. Remove any remaining lint on both the internal and external sides with a gentle spray of clean compressed air (see Figure 9).

Figure 8: Cleaning the FOA.

Figure 9: Using compressed air to end the procedure.

APPLICATION NOTE 058

Cleaning Detector Ports

To ensure the maximum accuracy of power measurements, power meter detectors must be kept clean at all times. When not in use, the detector(s) should be covered with a protective cap. In addition, the optical source port and fiber end should be occasionally cleaned to minimize insertion loss. The cleaning tips supplied with EXFOs test equipment are specially designed to clean the detector port(s) without having to disassemble the unit. You should clean detector ports only when it is absolutely necessary, as it is very difficult to remove any residue that may be trapped in a glass-housing interface. To clean the detector port(s), follow the steps below: 1. Remove the protective cap from the detector. 2. If the detector is dusty, remove the dust using compressed air, applying low pressure and at a slight angle. 3. If you can still see some dust, carefully remove a clean, dry swab (1.25 mm may be appropriate for small surfaces) from the package without touching the cleaning end (tip) with your fingers. 4. Slowly and carefully insert the cleaning tip into the port until it reaches the detectors protective window (gently rotating the cleaning tip clockwise may help). Remember that, the detector window is very fragile and this step should be avoided if not really needed. 5. Using a gentle rotating movement, turn the clean tip one full turn to clean the detector. Ensure that you are not leaving any debris behind (see Figure 10a). 6. Gently withdraw the cleaning tip. 7. Using compressed air, blow on the detector to remove any remaining debris (see Figure 10b) or repeat steps 4 to 7. Note: Always blow air at a 45 angle on the detector window and always clean fiber ends before connecting them to the power meter port.

Figure 10a: Cleaning the detector port(s) using cleaning tips.

Figure 10b: Cleaning the detector port(s) using compressed air.

APPLICATION NOTE 058

Cleaning EUI Connectors

To clean EUI connectors, follow the steps below: 1. First inspect and, if needed, use a clean, dry swab to remove any debris that may be inside. 2. For removable connector adapters that need to be turned and pulled out before inspection, make sure that any test jumper is disconnected, as it may damage both connectors. This applies to the EXFO Universal Interface (EUI). 3. Lightly press and turn the swab inside the EUI (see Figure 11). 4. When wet cleaning is required, make sure to use as little liquid as possible and rapidly dry the remaining alcohol or solvent with another dry swab (see Figures 12, 13 and 14). 5. Install the EUI connector back onto the instrument (see Figure 15).

Figure 11: Removing the EUI.

Figure 12: Cleaning the EUI.

Figure 13: Drying the EUI with compressed air.

Figure 14: Cleaning the ferrule in the connector port.

Figure 15: Putting the EUI connector back onto the instrument.

APPLICATION NOTE 058

EXFO Corporate Headquarters > 400 Godin Avenue, Quebec City (Quebec) G1M 2K2 CANADA | Tel.: +1 418 683-0211 | Fax: +1 418 683-2170 | info@EXFO.com Toll-free: +1 800 663-3936 (USA and Canada) | www.EXFO.com

EXFO America EXFO Asia EXFO China EXFO Europe EXFO NetHawk EXFO Service Assurance 3701 Plano Parkway, Suite 160 151 Chin Swee Road, #03-29 Manhattan House Tower C, Beijing Global Trade Center, Room 1207 36 North Third Ring Road East, Dongcheng District Omega Enterprise Park, Electron Way Elektroniikkatie 2 285 Mill Road Plano, TX 75075 USA SINGAPORE 169876 Beijing 100013 P. R. CHINA Chandlers Ford, Hampshire S053 4SE ENGLAND FI-90590 Oulu, FINLAND Chelmsford, MA 01824 USA Tel.: +1 800 663-3936 Tel.: +65 6333 8241 Tel.: + 86 10 5825 7755 Tel.: +44 2380 246810 Tel.: +358 (0)403 010 300 Tel.: +1 978 367-5600 Fax: +1 972 836-0164 Fax: +65 6333 8242 Fax: +86 10 5825 7722 Fax: +44 2380 246801 Fax: +358 (0)8 564 5203 Fax: +1 978 367-5700

APPNOTE058.4AN

2010 EXFO Inc. All rights reserved.

2008

Printed in Canada 10/05

You might also like

- Connector Maintenance: Application Note 058Document6 pagesConnector Maintenance: Application Note 058api-19786391No ratings yet

- Connector MaintenanceDocument6 pagesConnector MaintenanceZain MalikNo ratings yet

- Inspection and Cleaning Procedures For Fiber Optic ConnectionsDocument23 pagesInspection and Cleaning Procedures For Fiber Optic Connectionsnaveed4k143No ratings yet

- Clean Fiber 2Document23 pagesClean Fiber 2Jabulani Kuta SurfNo ratings yet

- Clean Fiber 2Document23 pagesClean Fiber 2capirot1No ratings yet

- Cleaning Recommendation For Optical TransceiverDocument2 pagesCleaning Recommendation For Optical TransceiverShahimNo ratings yet

- INFINITI OZil AND U-S HANDPIECE (210-1860-001 REV. U) (2012-2014)Document2 pagesINFINITI OZil AND U-S HANDPIECE (210-1860-001 REV. U) (2012-2014)Renata NataNo ratings yet

- Oxford Benchmate ManualDocument28 pagesOxford Benchmate ManualJose MarioNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- Cary Eclipse Fluorescence Preventive Maintenance Scope of WorkDocument10 pagesCary Eclipse Fluorescence Preventive Maintenance Scope of WorkRubia BottiniNo ratings yet

- Fiber Best PracticeDocument2 pagesFiber Best PracticetaowariorNo ratings yet

- Instruction of Disassembly and Assembly of Low-Pressure Relief ValveDocument3 pagesInstruction of Disassembly and Assembly of Low-Pressure Relief ValvemohamedNo ratings yet

- Metcal MX DS1 User GuideDocument70 pagesMetcal MX DS1 User GuideGameBooy2020No ratings yet

- Service FiltrosDocument43 pagesService FiltrosVpemuNo ratings yet

- De Pura DoraDocument53 pagesDe Pura DoraKenneth BlackNo ratings yet

- Gast 23 Series Oilless ManualDocument8 pagesGast 23 Series Oilless Manualclangbird210No ratings yet

- Dyson Dc01 Owners ManualDocument6 pagesDyson Dc01 Owners ManualmagmamystNo ratings yet

- Assembly Instructions For Cable Gland: 755 32R4: Connection SolutionsDocument4 pagesAssembly Instructions For Cable Gland: 755 32R4: Connection Solutionspvalverdea2014No ratings yet

- How To Use Fogger.Document3 pagesHow To Use Fogger.maruti jadhavNo ratings yet

- Mirra530 ManualDocument16 pagesMirra530 ManualMark SeredaNo ratings yet

- WO1224 Fiber Optic Stripper FO 103 SDocument2 pagesWO1224 Fiber Optic Stripper FO 103 ScolinyNo ratings yet

- Fiber Connector Cleaner User GuideDocument8 pagesFiber Connector Cleaner User GuideRocky GreenNo ratings yet

- Swift Vax Vs 190 User GuideDocument12 pagesSwift Vax Vs 190 User GuideJanet CrebbinNo ratings yet

- Light CrimpDocument19 pagesLight CrimpAlejandro PerezNo ratings yet

- 05 7341026 Rev E - Preventive MaintenanceDocument6 pages05 7341026 Rev E - Preventive MaintenancePhong LeNo ratings yet

- Aspirator Philips Cu Spalare - Dfu - RonDocument192 pagesAspirator Philips Cu Spalare - Dfu - RonFlacara IasuluiNo ratings yet

- Engine Air Intake: Service When IndicatedDocument14 pagesEngine Air Intake: Service When IndicatedLeandro Sienra100% (1)

- Instruction C02 78.3Document4 pagesInstruction C02 78.3ВиталийКрутиковNo ratings yet

- ENDO CLEAN 1000 User Manual English Ver.Document28 pagesENDO CLEAN 1000 User Manual English Ver.alberto.vergaraNo ratings yet

- Pioneer RSM400Document69 pagesPioneer RSM400Jurie WesselsNo ratings yet

- Sensor Cleaning GuideDocument3 pagesSensor Cleaning GuideelieNo ratings yet

- API Adaptor ManualDocument2 pagesAPI Adaptor Manualesham2100% (1)

- 497ab 497abf ManualDocument7 pages497ab 497abf ManualPedro MarmolNo ratings yet

- 9-Fiber Inspection & TestingDocument13 pages9-Fiber Inspection & TestinggurungeNo ratings yet

- Electrolux z7040 PDFDocument8 pagesElectrolux z7040 PDFRobert RomanNo ratings yet

- IGT Preventative MaintDocument21 pagesIGT Preventative MaintmiltoncgNo ratings yet

- Introduction To 8 Inc Pressure VesselsDocument23 pagesIntroduction To 8 Inc Pressure VesselsAckmonNo ratings yet

- Teriostar MF Maintenance ManualDocument171 pagesTeriostar MF Maintenance Manualsupportjavier100% (2)

- Harness Insp. and Maint. Daily ChecklistDocument3 pagesHarness Insp. and Maint. Daily ChecklistSarojini VeeraraghavanNo ratings yet

- Niro Sanitary Code For Components DesignDocument10 pagesNiro Sanitary Code For Components DesignJignesh PandyaNo ratings yet

- AD Oracle ManualDocument18 pagesAD Oracle ManualAlexandru Octavian Popîrțac100% (2)

- Eheim 2080 Professional 3Document18 pagesEheim 2080 Professional 3GuleBamse100% (1)

- Teriostar Maintenance ManualDocument380 pagesTeriostar Maintenance ManualCarlos Roberto Honorato Zuñiga100% (1)

- Service Manual: LCD Color TelevisionDocument18 pagesService Manual: LCD Color Televisionsil885No ratings yet

- Lx400 ManualDocument27 pagesLx400 ManualDiana MirandaNo ratings yet

- Toshiba LCD TV Service ManualDocument32 pagesToshiba LCD TV Service ManualKodjabashija Igor100% (1)

- Airial CN-02WJDocument34 pagesAirial CN-02WJDireccion TecnicaNo ratings yet

- Pressure Transmitter Information & Installation Manual (M374)Document10 pagesPressure Transmitter Information & Installation Manual (M374)gusmilexaNo ratings yet

- AMI PrinciplesDocument2 pagesAMI Principlesdomarher85No ratings yet

- STXX28 OperatorsManualDocument8 pagesSTXX28 OperatorsManualم.نور المشاقبةNo ratings yet

- Service Manual: LCD Color TelevisionDocument18 pagesService Manual: LCD Color TelevisionPabloNo ratings yet

- Service Manual: LCD Color TelevisionDocument15 pagesService Manual: LCD Color TelevisionHarold PolkaNo ratings yet

- Appendix Iii - Maintenance: WARNING: Electrical Shock and Flammability Hazard - Always Turn The Monitor Off andDocument2 pagesAppendix Iii - Maintenance: WARNING: Electrical Shock and Flammability Hazard - Always Turn The Monitor Off andMelvin Mayo RojasNo ratings yet

- Toshiba 26av500u SVC ManualDocument22 pagesToshiba 26av500u SVC ManualmobilemadNo ratings yet

- Manual de Instalación Shelco FilterDocument5 pagesManual de Instalación Shelco FilterYeisson Beltran AquinoNo ratings yet

- Polaroid Tla-04011c tlxb-4011 tlxb-4241 (ET)Document48 pagesPolaroid Tla-04011c tlxb-4011 tlxb-4241 (ET)marnel_16242No ratings yet

- Request For Daily Care: 1. Installation EnvironmentDocument8 pagesRequest For Daily Care: 1. Installation EnvironmentOficinahTechniquesNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Electrical Engineering Pocket Handbook - 11Document1 pageElectrical Engineering Pocket Handbook - 11osto72No ratings yet

- LV Extension Box Dimentions, Depth 20cmDocument1 pageLV Extension Box Dimentions, Depth 20cmosto72No ratings yet

- Acs 1208al 1216alDocument70 pagesAcs 1208al 1216alosto72No ratings yet

- NEMA NOMENCLATURE-6 LEADSDocument1 pageNEMA NOMENCLATURE-6 LEADSosto72No ratings yet

- Electrical Engineering Pocket Handbook - 07Document1 pageElectrical Engineering Pocket Handbook - 07osto72No ratings yet

- Electrical Engineering Pocket Handbook - 08Document1 pageElectrical Engineering Pocket Handbook - 08osto72No ratings yet

- Electrical Engineering Pocket Handbook - 09Document1 pageElectrical Engineering Pocket Handbook - 09osto72No ratings yet

- Electrical Engineering Pocket Handbook - 10Document1 pageElectrical Engineering Pocket Handbook - 10osto72No ratings yet

- Style, Comfort and Audio Quality.: Blackwire 3300 SeriesDocument2 pagesStyle, Comfort and Audio Quality.: Blackwire 3300 Seriesosto72No ratings yet

- Electrical Engineering Pocket Handbook - 03Document1 pageElectrical Engineering Pocket Handbook - 03osto72No ratings yet

- Electrical Engineering Pocket Handbook - 05Document1 pageElectrical Engineering Pocket Handbook - 05osto72No ratings yet

- Electrical Engineering Pocket Handbook - 04Document1 pageElectrical Engineering Pocket Handbook - 04osto72No ratings yet

- Electrical Engineering Pocket Handbook - 01Document1 pageElectrical Engineering Pocket Handbook - 01osto72No ratings yet

- Electrical Engineering Pocket Handbook - 06Document1 pageElectrical Engineering Pocket Handbook - 06osto72No ratings yet

- Blackwire 8225: User GuideDocument8 pagesBlackwire 8225: User Guideosto72No ratings yet

- Voyager 6200 UC: Comfort. Versatility. PerformanceDocument2 pagesVoyager 6200 UC: Comfort. Versatility. Performanceosto72No ratings yet

- Al-Sayyed & Sons Trading CoDocument1 pageAl-Sayyed & Sons Trading Coosto72No ratings yet

- Brochure SXTab 7A EN1Document2 pagesBrochure SXTab 7A EN1osto72No ratings yet

- Ultra High Def For Ultra High Expectations.: Logitech BRIODocument3 pagesUltra High Def For Ultra High Expectations.: Logitech BRIOosto72No ratings yet

- IEC 61439 Official ListDocument1 pageIEC 61439 Official Listosto72No ratings yet

- A2 PDFDocument3 pagesA2 PDFLelli KurniaNo ratings yet

- VW3A5207Document4 pagesVW3A5207osto72No ratings yet

- Product OverviewDocument4 pagesProduct Overviewmfarouk1No ratings yet

- Wide. Wider. Widest.: Logitech Webcam C930eDocument3 pagesWide. Wider. Widest.: Logitech Webcam C930eraviezsoftNo ratings yet

- Metal Enclosures - Al Fanar CatalogDocument20 pagesMetal Enclosures - Al Fanar CatalogAkhil MohanNo ratings yet

- Facom 75-10Document1 pageFacom 75-10osto72No ratings yet

- ASTM A-49 (2001) (Heat Treated Carbon Steel Joint Bars Microalloyed Joint Bars and Forged Carbon Steel Compromise Joint Bars)Document3 pagesASTM A-49 (2001) (Heat Treated Carbon Steel Joint Bars Microalloyed Joint Bars and Forged Carbon Steel Compromise Joint Bars)caballerolangNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)jawadhussain1No ratings yet

- Tia s7 1500 Programming 2 (Tia Pro2)Document2 pagesTia s7 1500 Programming 2 (Tia Pro2)osto720% (2)

- JFSC E102Document3 pagesJFSC E102osto72No ratings yet

- Triton X 100Document2 pagesTriton X 100jelaapeNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- Anemometer ActivityDocument4 pagesAnemometer ActivityGab PerezNo ratings yet

- Causarin Act.3 Psychology 9.14-9.20Document2 pagesCausarin Act.3 Psychology 9.14-9.20Denise CausarinNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- 100 Years Werner HeisenbergDocument308 pages100 Years Werner Heisenbergmvmbapple100% (3)

- Shell Horizontal Butt-Weld Minimum RequirementsDocument16 pagesShell Horizontal Butt-Weld Minimum RequirementsBTENo ratings yet

- DEVELOPMENT AND TEST OF THE BO 105 RIGID ROTOR HELICOPTERDocument16 pagesDEVELOPMENT AND TEST OF THE BO 105 RIGID ROTOR HELICOPTERГригорий ОмельченкоNo ratings yet

- Electrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyDocument5 pagesElectrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyShobhit MauryaNo ratings yet

- GSK980TDDocument406 pagesGSK980TDgiantepepinNo ratings yet

- Fundamentals of Surveying - Experiment No. 2Document6 pagesFundamentals of Surveying - Experiment No. 2Jocel SangalangNo ratings yet

- Abutment Design CalculationsDocument13 pagesAbutment Design CalculationsFitsum Abebe100% (1)

- Bagh Bon BondukDocument105 pagesBagh Bon BondukAdnan RahmanNo ratings yet

- J.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064Document20 pagesJ.F.M. Wiggenraad and D.G. Zimcik: NLR-TP-2001-064rtplemat lematNo ratings yet

- Toshiba Just Vision 200Document2 pagesToshiba Just Vision 200kazugawa100% (4)

- 6 Pile GroupDocument4 pages6 Pile GroupAnonymous nwByj9LNo ratings yet

- Equipment Design - BOILERSDocument24 pagesEquipment Design - BOILERSEmyu ClaridadNo ratings yet

- S7-1200 SM 1231 8 X Analog Input - SpecDocument3 pagesS7-1200 SM 1231 8 X Analog Input - Specpryzinha_evNo ratings yet

- DipolesDocument42 pagesDipolesRajat GiriNo ratings yet

- Backdraft Response StrategiesDocument6 pagesBackdraft Response StrategiesShan RaffelNo ratings yet

- All Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013Document2 pagesAll Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013ASHOK KUMAR LENKANo ratings yet

- Electrical Charges and Fields Chapter - 1 PhysicsDocument61 pagesElectrical Charges and Fields Chapter - 1 PhysicsPrasad PallaNo ratings yet

- Sustainability Report Ingeteam 2018 - ENDocument51 pagesSustainability Report Ingeteam 2018 - ENRana Awais KhanNo ratings yet

- Active Suspension Using SkyhookDocument14 pagesActive Suspension Using SkyhookSandor CleganeNo ratings yet

- Henk Colijn 040 Fontana Labs Colijn.1@osu - Edu 292-0674Document66 pagesHenk Colijn 040 Fontana Labs Colijn.1@osu - Edu 292-0674Charles HoNo ratings yet

- Virial TheoremDocument3 pagesVirial Theoremdodge_kevinNo ratings yet

- MV Drop TestDocument5 pagesMV Drop Testrajinipre-1No ratings yet

- Harmonic excitation of 1-degree-of-freedom systemsDocument1 pageHarmonic excitation of 1-degree-of-freedom systemsLetty VianaNo ratings yet

- Ringkasan Optimasi Formula Sediaan Sirup Mukolitik in (Hibiscus Rosa-Sinensis L.)Document30 pagesRingkasan Optimasi Formula Sediaan Sirup Mukolitik in (Hibiscus Rosa-Sinensis L.)rahmi73No ratings yet

- Normal Distribution & Z-ScoresDocument82 pagesNormal Distribution & Z-Scoresgela tinNo ratings yet