Professional Documents

Culture Documents

KEN Bangalore

Uploaded by

Well WisherCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KEN Bangalore

Uploaded by

Well WisherCopyright:

Available Formats

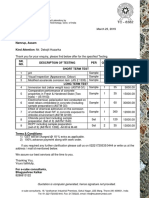

ADVANCED

METALLURGICAL

LABORATORY

(An IS/ISO/IEC:17025-2005, Accredited by NABL, Dept. of Science & Technology, Govt of India )

#18&18/1( Old no 118/193) Peeny Ist stage, Tumkur Road, Bangalore -58. Phone: 080-28371911, Fax:080-28371912, Email: admetlab@rediffmail.com, Web: admetlab.com

TESTING CHARGES

1. CHEMICAL ANALYSIS ( SPECTRO METHOD) 2. MECHANICAL TESTING 3. METALLURGICAL TESTING A. CHEMICAL ANALYSIS ( BY SPECTRO METHOD)

1 2 3 4 5 6 7 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 2 3 4 5 6 Low alloy steel, Stainless steel, tool steel - C, Si, Mn S, P, Cr, Ni, Mo ( up to 8 elements). Cast iron/ SG Iron - chilled sample-C, Si, Mn S, P, Cr, Ni, Mo ( up to 8 elements). Aluminium and its alloys ( up to 10 elements) Copper and its alloys ( brass, bronze. Etc, up to 10 elements) Nickel and its alloys Titanium and its alloys Single element or additional elements Tensile Test ( Tensile, Yield, Elongation & RA) ( sample Hardness <45 HRC ) Load test (proof load / breaking load) Spring deflection test on springs Bend Test / compression test Transverse rupture strength ( TRS, sample size 5x5x30 mm) Hardness Test Rockwell HRB/HRC/HRA , BHN Impact test- Charpy & IZOD at Room temperature Charpy Impact at low Temp up to -50 deg C Tensile testing of wires, wire ropes up to 12 mm dia Macro etching of machined & prepared samples of bars, weld, forging flow lines( with out photograph ) Macro etching of machined & prepared sample with photograph Microstructure of low alloy steel, stainless steel, & cast iron, with photograph Microstructure of aluminium alloy, Copper alloy, Nickel alloy, etc. Total case depth, ( carburised, nitrided, white layer by microscopic method) Plating, painting, coating thickness ( microscopic method) Inclusion rating Apparent grain size ( excluding heat treatment) Depth of decarburisation ( microscopic method) Effective case depth by micro Hardness survey method( maximum 8 indentation) Subsequent / additional indentations Surface Hardness micro Vickers ( load 100 gm to 2000 gm) Inter granular corrosion test of SS ( IGC, ASTM A 262, practice E) Plating/ Coating Hardness in transverse direction by Micro Vickers hardness ( including sample moulding) Failure Analysis Case to case basis For steel chips , small samples, cast iron chips ( min 50 gm) Melting & coining charges Small components compatible for forging forging charges Sample preparation for tensile / impact / macro etching Notch Making Charge ( < 30 HRC ) V or U, 2 mm depth broaching) For bigger samples, bars, weld plates, pipes - cutting charges if required

350 / Sample 375 / Sample 375/ Sample 450 / Sample 600 / Sample 750/Sample 100 / element 250 / Samples 250 / Samples 250/ sample 250 / Sample 300 / Sample 200 / Sample 200 / Sample 250/ sample 300 / sample 350 / Sample 500 / sample 550 / sample 400 / sample 350 / sample 400 / sample 350 / sample 350 / sample 850 / sample

B. Mechanical testing ( UTM, Impact, Hardness)

100/sample

C METALLURGICAL TESTING

50/ indent 150 / sample

Optional - Sample preparation

1200 / sample 350 / sample

150/ sample 50 / sample

200/ sample

175/Sample 100 / sample

Note: 1. Pan No. AAOFA1489M, Service tax registration no: AAOFA1489MST001 2. Service tax extra @ 10.3% 3. Delivery time 1-2 days for prepared samples 4. Payment : 50% Advance and final while collecting report 5. No emailing of reports 6. Appropriate fixtures to be provided for special tests 7. Other tests if any, like salt spray, Nitrogen in steel, wet analysis etc. to be discussed with QM 8. Sample size for spectro analysis: 25 mm dia x 20 mm thick solid, homogeneous sample 9. Approved by Boeing aerospace 10:Unless otherwise specified by the customer The testing method will be adopted as per the scope of accreditation

For Advanced Metallurgical Laboratory

ADVANCED METALLURGICAL LABORATORY

ADVANCED METALLURGICAL LABORATORY

You might also like

- ASTM Volume 01.06, February 2010 Coated Steel Products: Standard Number TitleDocument3 pagesASTM Volume 01.06, February 2010 Coated Steel Products: Standard Number TitleMohamad AlqaruteeNo ratings yet

- SteelDocument38 pagesSteelArdeela IlezNo ratings yet

- Manual Mould and Tool SteelsDocument38 pagesManual Mould and Tool Steelsodhiles1No ratings yet

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsDocument9 pagesA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXNo ratings yet

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- Tech BS 4449 2005Document10 pagesTech BS 4449 2005Syed RizwanNo ratings yet

- Brochure & Price List May 2012Document7 pagesBrochure & Price List May 2012jccntNo ratings yet

- Steel Investment Castings General Requirements, For Pressure-Containing PartsDocument12 pagesSteel Investment Castings General Requirements, For Pressure-Containing PartsManivannanMudhaliarNo ratings yet

- Coatings Testing - ASTM StandardsDocument3 pagesCoatings Testing - ASTM StandardsthuronNo ratings yet

- Testing Lab Accredited for Steel AnalysisDocument5 pagesTesting Lab Accredited for Steel Analysisraja319No ratings yet

- Metal & Alloy Testing LabDocument2 pagesMetal & Alloy Testing LabJavian CampbellNo ratings yet

- ADI Two-Step Austempering StudyDocument26 pagesADI Two-Step Austempering StudyartikscindianNo ratings yet

- PeekayDocument8 pagesPeekayChef HouseNo ratings yet

- CSC STEEL PRODUCT GUIDEDocument43 pagesCSC STEEL PRODUCT GUIDEedgarc999No ratings yet

- Astm Standard List PDFDocument4 pagesAstm Standard List PDFSunil Pulikkal0% (1)

- Destructive Testing - TYPES & TECHNIQUEDocument18 pagesDestructive Testing - TYPES & TECHNIQUESean AkirangaNo ratings yet

- Materials Testing Lab Brochure 2013.04.18Document2 pagesMaterials Testing Lab Brochure 2013.04.18hali10No ratings yet

- Destructive TestingDocument18 pagesDestructive TestingnithingrmeNo ratings yet

- Materials Selection Modeling & SimulationDocument21 pagesMaterials Selection Modeling & Simulationleila hanjani hanantoNo ratings yet

- SS GP1 M270 - 04 09 - enDocument5 pagesSS GP1 M270 - 04 09 - enPiotr PawłowskiNo ratings yet

- Section 08500 Windows Rev 0Document35 pagesSection 08500 Windows Rev 0Our SalahEddineNo ratings yet

- Corrosion Testing TCR Engineering IndiaDocument9 pagesCorrosion Testing TCR Engineering Indiaelangopi89No ratings yet

- A 732/a732m-02Document8 pagesA 732/a732m-02mutluNo ratings yet

- Physical Metallurgy Lab ScheduleDocument40 pagesPhysical Metallurgy Lab ScheduleMADHAV AGARWALNo ratings yet

- China Structural Steel and Alloy Steel GBT Q345Document3 pagesChina Structural Steel and Alloy Steel GBT Q345bkprodhNo ratings yet

- Machine Design, Vol.5 (2013) No.1, ISSN 1821-1259 Pp. 1-10Document10 pagesMachine Design, Vol.5 (2013) No.1, ISSN 1821-1259 Pp. 1-10Sirajuddin ANo ratings yet

- SS BarsDocument26 pagesSS BarsFadelPrawiraErwinNo ratings yet

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pages2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNo ratings yet

- Heat Treatment of SteelDocument11 pagesHeat Treatment of Steel12babonNo ratings yet

- 5 PrototypingDocument29 pages5 PrototypingNur HidayatNo ratings yet

- C1e 010Document9 pagesC1e 010Agung SumargoNo ratings yet

- PV PIPE - CONNECTING OIL AND GASDocument2 pagesPV PIPE - CONNECTING OIL AND GASKyNo ratings yet

- QA-QC TPL of Ecube LabDocument1 pageQA-QC TPL of Ecube LabManash Protim GogoiNo ratings yet

- Steel Plates For Offshore StructuresDocument8 pagesSteel Plates For Offshore StructuresYiengeChanYeeNo ratings yet

- C83600 (Red Brass) PDFDocument2 pagesC83600 (Red Brass) PDFshawntsungNo ratings yet

- Experimental Investigation For Welding Aspects of AISI 304 & 316 by Taguchi Technique For The Process of TIG & MIG WeldingDocument6 pagesExperimental Investigation For Welding Aspects of AISI 304 & 316 by Taguchi Technique For The Process of TIG & MIG Weldingsurendiran123No ratings yet

- The Complete Guide to Hot Rolling of SteelDocument13 pagesThe Complete Guide to Hot Rolling of SteelAndréNo ratings yet

- A 985 - A 985M - 03 Qtk4ns9botg1tq - PDFDocument14 pagesA 985 - A 985M - 03 Qtk4ns9botg1tq - PDFMung Duong XuanNo ratings yet

- Supreme Technology 2-Zinc Alloy&ZincDocument6 pagesSupreme Technology 2-Zinc Alloy&ZincTran Duong QuangNo ratings yet

- Chemical Composition, Mechanical, Physical and Environmental Properties of Q235Document6 pagesChemical Composition, Mechanical, Physical and Environmental Properties of Q235Wellington AnaluisaNo ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- Astm A 924Document8 pagesAstm A 924djfreditoNo ratings yet

- Small Punch Creep Test in A 316 Austenitic Stainless Steel: 51 (1) January-March 2015, E034 ISSN-L: 0034-8570Document9 pagesSmall Punch Creep Test in A 316 Austenitic Stainless Steel: 51 (1) January-March 2015, E034 ISSN-L: 0034-8570milton delacruzNo ratings yet

- Testing of Materials: 1.destructive Testing 2.non Destructive TestingDocument11 pagesTesting of Materials: 1.destructive Testing 2.non Destructive Testingbaskaran ayyapparajNo ratings yet

- Machine Design Standards and Material SelectionDocument46 pagesMachine Design Standards and Material SelectionMadhurima BhandariNo ratings yet

- PKL Welding Qualification ProcedureDocument8 pagesPKL Welding Qualification ProcedureDeri Agung WicaksonoNo ratings yet

- Sae J1993 (Sep1996) PDFDocument4 pagesSae J1993 (Sep1996) PDFDiogoNo ratings yet

- Corrosion Issues & Test Methods: Jerry ByersDocument42 pagesCorrosion Issues & Test Methods: Jerry ByersbalakaleesNo ratings yet

- Destructive TestingDocument18 pagesDestructive Testingnizam1372No ratings yet

- BRTC Test Types Mme 2Document9 pagesBRTC Test Types Mme 2Tajul islamNo ratings yet

- 4.5-02 Test Request For Testing-NEWDocument5 pages4.5-02 Test Request For Testing-NEWearth metallurgical services pvt.ltd.No ratings yet

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocument8 pagesStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- RWH Final On 1848HRSDocument18 pagesRWH Final On 1848HRSWell WisherNo ratings yet

- Rain Water Harvesting APS AltDocument8 pagesRain Water Harvesting APS AltWell WisherNo ratings yet

- Rain Water Harvesting APSDocument8 pagesRain Water Harvesting APSWell WisherNo ratings yet

- Rain Water Harvesting APS AltDocument8 pagesRain Water Harvesting APS AltWell WisherNo ratings yet

- Desert CoolerDocument14 pagesDesert CoolerWell WisherNo ratings yet

- Aps Rain Water Harvesting SketchDocument1 pageAps Rain Water Harvesting SketchWell WisherNo ratings yet

- GFR 2017 PDFDocument208 pagesGFR 2017 PDFhareeshgs80% (20)

- Aps Rain Water Harvesting SketchDocument1 pageAps Rain Water Harvesting SketchWell WisherNo ratings yet

- RWH Final On 1848HRSDocument18 pagesRWH Final On 1848HRSWell WisherNo ratings yet

- Rain Water Harvesting APSDocument8 pagesRain Water Harvesting APSWell WisherNo ratings yet

- DGSD Email AddDocument1 pageDGSD Email AddWell WisherNo ratings yet

- CMPTR StyDocument11 pagesCMPTR StyWell WisherNo ratings yet

- NABL-accredited calibration services and CRMs for testing equipmentDocument8 pagesNABL-accredited calibration services and CRMs for testing equipmentWell WisherNo ratings yet

- Alpine CoolerDocument14 pagesAlpine CoolerWell WisherNo ratings yet

- CementsDocument2 pagesCementsWell WisherNo ratings yet

- Is: 875 (Part 2)Document20 pagesIs: 875 (Part 2)amoudi101100% (7)

- Blue StarDocument13 pagesBlue StarWell WisherNo ratings yet

- Green BuildingDocument49 pagesGreen BuildingWell WisherNo ratings yet

- BIS Addl LabsDocument2 pagesBIS Addl LabsWell WisherNo ratings yet

- GCS Rate ListDocument3 pagesGCS Rate ListWell WisherNo ratings yet

- Group-1 List of Bis Recognised Laboratoires (An On 13 Dec 2011)Document6 pagesGroup-1 List of Bis Recognised Laboratoires (An On 13 Dec 2011)Well WisherNo ratings yet

- NABL 500 Directory of Accredited Calibration LaboratoriesDocument68 pagesNABL 500 Directory of Accredited Calibration LaboratoriesWell WisherNo ratings yet

- Is: 875 (Part 2)Document20 pagesIs: 875 (Part 2)amoudi101100% (7)

- CPE 1ST YR CHEM ENGDocument3 pagesCPE 1ST YR CHEM ENGKhairie MahadiNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- Wro 300 HDocument68 pagesWro 300 Hivancalderon867374No ratings yet

- Brochure Covalumine PigmentsDocument3 pagesBrochure Covalumine PigmentsMamadou Lamine FallNo ratings yet

- Unit III Engine Exhaust Emission ControlDocument49 pagesUnit III Engine Exhaust Emission ControlMani Karthi100% (1)

- A Project of Mechanics of MaterialsDocument13 pagesA Project of Mechanics of MaterialsShahZaib AnwarNo ratings yet

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Test Bank For Essentials of Genetics 8th Edition by KlugDocument9 pagesTest Bank For Essentials of Genetics 8th Edition by Klugminhkhoit8cua3No ratings yet

- Turbichem D-Dimer Test OverviewDocument2 pagesTurbichem D-Dimer Test OverviewDharmesh PatelNo ratings yet

- Cane Sugar Handook 12ed Chen, ChouDocument110 pagesCane Sugar Handook 12ed Chen, ChouArdhaFananiAslam50% (6)

- General PHARMAKOLOGY - Загальна фармакологія - Курс лекцій - изд.2005-215 сDocument219 pagesGeneral PHARMAKOLOGY - Загальна фармакологія - Курс лекцій - изд.2005-215 сSahil Saini100% (4)

- CH 7 ObjDocument4 pagesCH 7 ObjchongpeisiNo ratings yet

- Medicina Mitocondrial Vol 1Document485 pagesMedicina Mitocondrial Vol 1ArianPedrozaNo ratings yet

- Lead Acid Batteries in Critical ApplicationsDocument24 pagesLead Acid Batteries in Critical Applicationsger80100% (1)

- Die-Materials classEDITDocument45 pagesDie-Materials classEDITSatya AsatyaNo ratings yet

- Periodic Table Display Poster A4Document1 pagePeriodic Table Display Poster A4Sarah Khan100% (1)

- Reanna DixonDocument10 pagesReanna DixonElvin BucknorNo ratings yet

- Dna Repair MechanismsDocument49 pagesDna Repair MechanismsayeshaNo ratings yet

- Thermal Expansion of Solids and LiquidsDocument14 pagesThermal Expansion of Solids and LiquidsMrsriyansyahNo ratings yet

- Cocaine in Blood of Coca ChewersDocument10 pagesCocaine in Blood of Coca ChewersKarl-GeorgNo ratings yet

- KinemaxDocument2 pagesKinemaxJoe BloggsNo ratings yet

- Effect of geotextiles on low plastic sandy clayDocument9 pagesEffect of geotextiles on low plastic sandy clayRajesh Prasad ShuklaNo ratings yet

- Biology The Core 2nd Edition Simon Solutions ManualDocument26 pagesBiology The Core 2nd Edition Simon Solutions Manualaureliacharmaine7pxw9100% (20)

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Document11 pages(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifNo ratings yet

- Jacketed Weld Strength CheckDocument10 pagesJacketed Weld Strength CheckKshitiz SikkaNo ratings yet

- Thermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)Document3 pagesThermodynamics - Theory T-V Diagram: Phase Change Process Under Constant Pressure (112 KB)rajaraghuramvarmaNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Unit 1.5 - Stress and Strain in Lifting EquipmentDocument14 pagesUnit 1.5 - Stress and Strain in Lifting EquipmentnitharsunNo ratings yet

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocument4 pagesKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsNo ratings yet

- TDS CHEMCLEAR EnglishDocument3 pagesTDS CHEMCLEAR EnglishthirdNo ratings yet