Professional Documents

Culture Documents

Hovercraft

Uploaded by

Sibasish SahuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hovercraft

Uploaded by

Sibasish SahuCopyright:

Available Formats

HOVERCRAFT

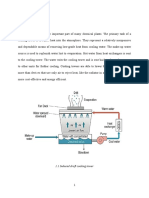

Vehicles designed to travel close to but above ground or water. These vehicles are supported in various ways. Some of them have a specially designed wing that will lift them just off the surface over which they travel when they have reached a sufficient horizontal speed (the ground effect). Hovercrafts are usually supported by fans that force air down under the vehicle to create lift, Air propellers, water propellers, or water jets usually provide forward propulsion. Air-cushion vehicles can attain higher speeds than can either ships or most land vehicles and use much less power than helicopters of the same weight. Air-cushion suspension has also been applied to other forms of transportation, in particular trains, such as the French Aero train and the British hover train. Hovercraft is a transportation vehicle that rides slightly above the earths surface. The air is continuously forced under the vehicle by a fan, generating the cushion that greatly reduces friction between the moving vehicle and surface. The air is delivered through ducts and injected at the periphery of the vehicle in a downward and inward direction. This type of vehicle can equally ride over ice, water, marsh, or relatively level land. 2. HOVERCRAFT 2.1. HOVERCRAFT HISTORY The first recorded design for a hovercraft was in 1716 put forward by Emmanual Swedenborg, a Swedish designer and philosopher. The project was short-lived and a craft was never built. Swedenborg realized that to operate such a machine required a source of energy far greater than any available at that time. In the mid-1870s, the British engineer Sir John Thornycroft built a number of model craft to check the aircushion effects and even filed patents involving air-lubricated hulls, although the technology required to implement the concept did not yet exist. From this time both American and European engineers continued work on the problems of designing a practical craft. In the early 1950s the British inventor Christopher Cockerell began to experiment with such vehicles, and in 1955 he obtained a patent for a vehicle that was "neither an airplane, nor a boat, nor a wheeled land craft." He had a boat builder produce a two-foot prototype, which he demonstrated to the military in 1956 without arousing interest. Cockerell persevered, and in 1959 a commercially built one-person Hovercraft crossed the English Channel. In 1962 a British vehicle became the first to go into active service on a 19-mi (31-km) ferry run. 2.2. CREATION OF HOVERCRAFTS When building a hovercraft it is imperative that you are sure you have a firm grasp of the important concepts and principles involved. An elementary knowledge

of physics is required. Ease of use, cost, availability and safety are all significant considerations when building a hovercraft. Care must be taken in selecting a motor and propeller for the proper function and stability of the hovercraft and to meet your needs for thrust and lift. A good skirt design is essential for stability and of course, body designs must be well thought-out in order to meet your needs for speed and stability. Finally, the rudders must be well weighed out in order to avoid weighing down your hovercraft and also well shaped in order to move air as efficiently as possible. 2.3. HOW DOES A HOVERCRAFT WORK Hovercrafts work on the two main principles of lift and propulsion. When dealing with a hovercraft, the existence of lift is imperative for the proper function of the vehicle. Lift is an essential factor because it is that which allows the craft to ride on a cushion of air several inches off the ground. This process, the process of attaining lift begins by directing airflow under the craft. In order to quarantine the air under the air cushion, a skirt is required. This is done in order to create pressure under the hovercraft which forces the vehicle off the ground. Attaining the proper amount of airflow is imperative for the maintenance of the crafts stability. If too much airflow is directed under the craft, it will then hover too high above the ground, resulting in the hovercraft to tip. Not enough lift will cause the craft to remain on the ground which defeats the very purpose of the hovercraft altogether. The source of the airflow which propels the craft of the ground is a fan. The fan can be used for lift and thrust. It can be dedicated to lift or thrust or even both simultaneously. In either case the passage where the air flows through to reach the air cushion affects the stability of the hovercraft. This passage is a hole located on the base of the craft. Another vital component is the motor. The motor is usually located in the rear of the vehicle and is the heaviest of the components. Due to the weight of the motor, extra pressure is required under the area where the motor is positioned in order to attain hovering capabilities. That which makes hovercrafts so efficient and different from other vehicles of its category is that very little force is required for it to move. Propulsion is that which makes the craft move. The source of this effect is the fan, which is used to move the air for propulsion. However odd as it may seem, the fan produces more than enough force for the hovercraft to move. This is achieved through the existence of another major factor: Hovercrafts have no contact with the ground; therefore any resistance the ground may produce under other circumstances is now non-existent for the craft. As explained above, the propulsion of the craft requires a fan but a normal fan is not sufficient. This is because a normal fan does not blow air straight back. Instead it spins the air in a spiral shape. Therefore engineers decided to use turbines or stationary blades, that un-spin the air. When air does not spin more of its kinetic energy can be used for translation and less is required for rotation. The shape of the body also affects the stability of the hovercraft. The larger the area of the base, the more stable it will be. Wider base implies greater stability. Longer and narrower shapes increase speed but decrease stability. Most hovercrafts have rounded ends, and offer both stability and speed. The skirt is another vital component. The common skirt is known as a bag skirt. It is comprised of a bag that covers the bottom of the base and has holes in it to allow air to escape and push the craft off the ground. Each part of the skirt inflates independently which makes repairs much easier and improves stability. Unfortunately, the more stable a skirt, the slower it will go.

When the hovercraft is finally able to move it will most definitely require steering capabilities. This is achieved through the use of rudders. These rudders can be controlled by a variety of devices including computers. Rudders cannot be too heavy otherwise they will weigh down the craft because they are located very close to the motor. The shape of the rudder dictates how well it will be able to move air. When riding a hovercraft the natural state of motion is easily seen to be constant vector velocity with a constant rate of rotation. A sloping floor will definitely change your velocity vector without changing your rate of rotation. In addition to Newtons three laws of motion it will become obvious that to avoid spinning or tilting the hovercraft you must apply the forces in line with the center of mass of the combination of the craft and your body. 2.4. PARTS OF A HOVERCRAFT 2.4.1. Lifting Fan Firstly the volume of air needed is very large and a propeller is designed to be most efficient in open air like on an aircraft. Also the fan needs to force air into the chamber below the craft so creating a specific pressure under the craft. Propellers again are not efficient in applications when an air backpressure will be applied to the propeller blades as they rotate. Because of this the lifting fan on most Hovercraft uses what is known as a centrifugal fan. This is a fan in which two discs and fitted together and looks rather like a doughnut with angled slats at their edges. When the assembly is rotated at high-speed air is sucked into the center hole in the fan and the slats force it out at the edges. The advantages of the fan are two fold. They operate efficiently in an environment when backpressure is high and they will move larger volumes of air for a given rotation speed than a propeller with the same speed and power input. The lifting fan is coupled via a gearbox to the engine. The engine also drives the propeller on the craft, which provides thrust for forward motion of the Hovercraft. 2.4.2. Thrust Propellers The propeller used to drive the hovercraft along is usually an aircraft type with variable pitch blades. Its speed of rotation must remain fixed to that of the engine and the lift fan. This is because the amount of lift air required dictates the engine speed to drives the lift fan. In turn the amount of propulsion, which the propellers provide, must be obtained by varying the propeller pitch and not its rate of rotation. This system is termed 'integrated lift/propulsion'. A Hovercraft having more than one lift fan and propeller generally has a separate engine for each fan-and propeller unit. The propellers used on hovercraft can vary from four-bladed versions and about nine feet in diameter on the smaller craft to the four propellers on the SRN4 crossChannel hovercraft. These are four-bladed and nineteen feet in diameter! On the SRN 4 the pylons on which they are mounted can be rotated to change the direction of thrust. On smaller craft, rudders like on aircraft, are used for direction control. 2.4.3. Momentum Curtain When early models were built and analysis was done on the airflow using the plenum chamber type of hovercraft it showed that there were problems with stability. In addition the craft would require enormous power to maintain a reasonable hover

height.Stability of the hovercraft on its cushion of air remained a real problem despite some design efforts and a new approach was needed. To solve these problems, a plenum chamber with a momentum curtain was developed by Sir Christopher Cockerall. 2.4.4. Hovercraft Skirt Despite the momentum curtain being very effective the hover height was still too low unless great, and uneconomical, power was used. Simple obstacles such as small waves, or tide-formed ridges of shingle on a beach, could prove to be too much for the hover height of the craft. These problems led to the development of the 'skirt'. The skirt is a shaped, flexible strip fitted below the bottom edges of the plenum chamber slot. As the hovercraft lifts, the skirt extends below it to retain a much deeper cushion of air. The development of the skirt enables a hovercraft to maintain its normal operating speed through large waves and also allows it to pass over rocks, ridges and gullies. The skirt of a hovercraft is one of its most design sensitive parts. The design must be just right or an uncomfortable ride for passengers or damage to the craft and the skirts results. Also, excessive wear of the skirt can occur if its edges are flapping up and down on the surface of the water. The skirt material has to be light flexible and durable all at the same time. For the skirt to meet all of its requirements the design and use of new materials has slowly evolved. The current skirts use fingers at the lower edge of the skirt envelope which can be unbolted and replaced. By doing this there is a quick and easy way to counter the effects of wear without having to replace the whole skirt structure. A shocking example of the costs is the replacement of the skirt assembly on the SRN 4s which used to cross the English Channel from the UK to France. The replacement cost for a set of skirts for this craft is over 5 million US Dollars. 2.4.5. The Engine The SRN 1 and other early hovercrafts used piston type engines. As models like the SRN 4 and SRN 6 were brought into service they tended to favor the use of gas turbines. This type of engine is smaller and lighter for a given horsepower and has been used extensively in turbo prop aircraft. The engine has a main shaft on which is mounted a compressor and a turbine. A starter motor is connected to one end of the shaft and the other end is connected to the lift fan and propeller gearboxes. Both compressor and turbine look like fans with a large number of blades. When the engine is started, the compressor compresses air from the engine intakes and pushes it into combustion chambers mounted around the engine. Fuel is squirted into the combustion chambers and ignited. The compressed air then rapidly expands as it is heated and forces its way out through the turbine to the exhaust. As the gas pressure rises, the turbine speeds up, thereby driving the compressor faster. The engine speed increases until it reaches the engine's normal operating speed. However, the use of these engines results in a very high level of engine noise outside the craft. In the SRN 6 this meant that it was possible to hear the craft traveling across the Solent between Portsmouth and the Isle of Wight in the UK several miles away. With the newer generation of craft close attention was paid to engine noise and fuel efficiency. The current AP188craft that runs on the old SRN6

routes has now moved back towards piston engines and uses marine diesel engines that are much quieter and fuel efficient. 2.4.6. Air box The box-like structure at the rear of the hovercraft, right behind the propeller, the box-like structure is called an air box. The air box takes about 10% of the air being pushed backward by the propeller and forces it downward, underneath the hovercraft. There are three small ducts cut into the base of the hovercraft, underneath the air box. Two of these ducts lead into the skirt, which is basically a bag that goes all the way around the perimeter of the craft, while the third duct leads directly underneath the hovercraft. 2.5. HOVERING POWER Take a hovercraft which, complete with crew, fuel and load, weighs 2,000 pounds (lbs.), and is 15 feet (ft.) long and 7 ft. wide. Its area would be 15 ft x 7 ft. = 105 square (sq.) ft. If the craft is to hover, the pressure of air forming the cushion must be 2,000 pounds or greater. This represents 19 pounds. Per sq. ft. Yes, only 19 pounds per square feet is required to lift the hovercraft which seems much smaller than you might imagine. From existing designs of Hovercraft that have been developed, it is possible to make some simple estimate of the power needed to lift a Hovercraft. Using 19 pounds per square foot it is estimated 4 horsepower for each sq. ft. of curtain or skirt area can maintain that hover. Curtain area is its length times its height. A hovercraft 15 ft. long by 7 ft. wide would have a curtain length of 44 ft.-twice the length plus twice the width. If we want it to hover one foot high we would need sufficient power to provide a curtain of 44 x 1 sq. ft. At 4 horsepower per sq, ft. we would need 176 horsepower Just to lift the craft up to hover one foot above the ground. Don't forget we now need to push the craft along as well so that engine is the minimum size we can use. 2.6. RUDDERS When the hovercraft is finally able to move it will most definitely require steering capabilities. This is achieved through the use of rudders. These rudders can be controlled by a variety of devices including computers. The rudders must be well weighed out in order to avoid weighing down your hovercraft and also well shaped in order to move air as efficiently as possible. Rudders cannot be too heavy otherwise they will weigh down the craft because they are located very close to the motor. The shape of the rudder dictates how well it will be able to move air. 2.7. HOVERCRAFT OPERATION Piloting a hovercraft is an interesting proposition. Since very little of it actually touches the ground, there isn't much friction, making it very difficult to steer and also very susceptible to strong winds. Imagine trying to drive around on top of an airhockey puck! We've discovered that the best way to drive it is treat it like a jetski, i.e. leaning back and forth and steering very carefully. It is also possible to do a 360degree turn without stopping, which is quite a sight. 2.8. AERODYNAMICS

Aerodynamics is defined as the branch of fluid physics that studies the forces exerted by air or other gases in motion. Examples include the airflow around bodies moving at speed through the atmosphere (such as land vehicles, bullets, rockets, and aircraft), the behavior of gas in engines and furnaces, air conditioning of buildings, the deposition of snow, the operation of air-cushion vehicles (hovercraft), wind loads on buildings and bridges, bird and insect flight, musical wind instruments, and meteorology. For maximum efficiency, the aim is usually to design the shape of an object to produce a streamlined flow, with a minimum of turbulence in the moving air. The behavior of aerosols or the pollution of the atmosphere by foreign particles are other aspects of aerodynamics. 3. CONCLUSION Hovercrafts are generally simple mechanisms in theory. Yet the process from theory to manifestation is not as easy as it may seem. A plethora of problems exist and must be faced in order to attain a well functioning hovercraft. The plans and designs must be flawless. One must take under consideration the weight and the shape of each component in order to avoid problems such as instability and dysfunction. This is a marvelous machine which greatly cuts down the friction which in turn helps it to attain greater speed and more stability. Varieties of problems and factors have to be taken into account in designing and constructing a hovercraft. The difficulties involved in maintaining stability and functional competency has limited the application to only transportation or for military purpose. The cost involved in the developing of a hovercraft is also another impediment to the widespread use of this machine.

You might also like

- Quad CopterDocument42 pagesQuad CopterShanaka JayasekaraNo ratings yet

- Literature Review VtolDocument14 pagesLiterature Review VtolFahadZamanMalikNo ratings yet

- RobotDocument132 pagesRobotPhong Ngo100% (1)

- A Vision-Based Automatic Landing Method For Fixed Wing UAVsDocument15 pagesA Vision-Based Automatic Landing Method For Fixed Wing UAVsAli YasinNo ratings yet

- Quadcopter Design DocumentDocument23 pagesQuadcopter Design Documentapi-556772195No ratings yet

- "A Quadcopter Using K.K.2.1.5 Flight Controller".: A Project Presentation OnDocument17 pages"A Quadcopter Using K.K.2.1.5 Flight Controller".: A Project Presentation OnAkshay SinghalNo ratings yet

- 054-Micro Aerial Vehicles Design Challenges State of The Art ReviewDocument17 pages054-Micro Aerial Vehicles Design Challenges State of The Art Reviewkrishnamoorthy_krishNo ratings yet

- SystemVision Intro TrainingDocument205 pagesSystemVision Intro TrainingRafael SouzaNo ratings yet

- Modelling and Control of A QuadrocopterDocument10 pagesModelling and Control of A QuadrocopterAdi Mulyadi100% (1)

- Experimental Investigation of Stepped Aerofoil Using Propeller Test RigDocument4 pagesExperimental Investigation of Stepped Aerofoil Using Propeller Test RigesatjournalsNo ratings yet

- 2021 - Design of A Small Qadrotor UAV and Modeling of An MPC-based SimulatorDocument96 pages2021 - Design of A Small Qadrotor UAV and Modeling of An MPC-based SimulatorterenceNo ratings yet

- Modelling & Control of A QuadrotorDocument15 pagesModelling & Control of A Quadrotorvidc87No ratings yet

- Military Applications of Autonomous SystemsDocument30 pagesMilitary Applications of Autonomous SystemsElena JelerNo ratings yet

- TwincopterDocument5 pagesTwincopterRinson RajNo ratings yet

- Intelligent Control of A Ducted-Fan VTOL UAV With Conventional Control SurfacesDocument285 pagesIntelligent Control of A Ducted-Fan VTOL UAV With Conventional Control SurfacesTushar KoulNo ratings yet

- Modeling, Estimation and Attitude Control of An Octorotor Using PID and L1 Adaptive Control TechniquesDocument137 pagesModeling, Estimation and Attitude Control of An Octorotor Using PID and L1 Adaptive Control TechniquesColDfireNo ratings yet

- Stability augmentation systems: Acquiring dynamic and static stabilityDocument4 pagesStability augmentation systems: Acquiring dynamic and static stabilitySuraj ChaurasiyaNo ratings yet

- Flight Vehicle Design Aircraft DesignDocument18 pagesFlight Vehicle Design Aircraft DesignKarthikeya ReddyNo ratings yet

- Tiltrotor Download ReductionDocument11 pagesTiltrotor Download Reductiont8e7w2koNo ratings yet

- Arduino DroneDocument6 pagesArduino Dronemahesh giteNo ratings yet

- Flight Performance of A Package Delivery Quad Rotor BiplaneDocument12 pagesFlight Performance of A Package Delivery Quad Rotor BiplaneBreno Brito MirandaNo ratings yet

- A Thesis On QuadcopterDocument85 pagesA Thesis On Quadcopterasraa mahdiNo ratings yet

- Raptor 90 3DDocument65 pagesRaptor 90 3DOle Kristian FlatøyNo ratings yet

- Brock Technologies Antenna Pointing System V2 BrochureDocument1 pageBrock Technologies Antenna Pointing System V2 BrochureUAVs AustraliaNo ratings yet

- Presented By: Ranjeet Singh Sachin AnandDocument24 pagesPresented By: Ranjeet Singh Sachin AnandSachin AnandNo ratings yet

- One: Introduction and FeaturesDocument59 pagesOne: Introduction and Featurestharun100% (2)

- Atmel Studio Integrated Development Environment With FreeRTOS AwarenessDocument8 pagesAtmel Studio Integrated Development Environment With FreeRTOS AwarenessAshok ObuliNo ratings yet

- Lynx Vertical Axis Wind TurbineDocument46 pagesLynx Vertical Axis Wind TurbineEric MajaoNo ratings yet

- Autopilot Control SystemDocument13 pagesAutopilot Control SystemGamePlay DistinctNo ratings yet

- Motor of VTOL Aircraft PDFDocument22 pagesMotor of VTOL Aircraft PDFvimarsh joshiNo ratings yet

- Turbopump Turbines Developed by VolvoDocument7 pagesTurbopump Turbines Developed by VolvoSungGu LeeNo ratings yet

- Mettler Bernard 2000 1Document25 pagesMettler Bernard 2000 1sanjesh100% (1)

- Multirotor Control - A First Look at Flight Controllers For Quadcopters and Other Unmanned Aerial VehiclesDocument24 pagesMultirotor Control - A First Look at Flight Controllers For Quadcopters and Other Unmanned Aerial VehiclesSpacePortKmortNo ratings yet

- 75 - Build Your Own UAVDocument66 pages75 - Build Your Own UAVmido siboNo ratings yet

- ME4241 - Aircraft Performance and Stability Course Assignment Stability and Control of Quadcopter DronesDocument7 pagesME4241 - Aircraft Performance and Stability Course Assignment Stability and Control of Quadcopter Dronesliuxc000No ratings yet

- x8 Skywalker Conversion Procedure e FDocument18 pagesx8 Skywalker Conversion Procedure e Fhung dangNo ratings yet

- Unmanned Aerial VehicleDocument178 pagesUnmanned Aerial Vehicletanveershariff13No ratings yet

- T110D Manual - First PartDocument90 pagesT110D Manual - First PartPaulo PereiraNo ratings yet

- Spherical VTOL UAV ProjectDocument23 pagesSpherical VTOL UAV ProjectMunawar AliNo ratings yet

- Convoy ProtectionDocument10 pagesConvoy ProtectionUAVs Australia100% (1)

- Design and Development of Unmanned Ground and Aerial Vehicle With The Concept of Integration of Drone and RoverDocument10 pagesDesign and Development of Unmanned Ground and Aerial Vehicle With The Concept of Integration of Drone and RoverkoftamNo ratings yet

- NR - Numerical Model of Single Main Rotor Helicopter DynamicsDocument10 pagesNR - Numerical Model of Single Main Rotor Helicopter DynamicsHossam T BadranNo ratings yet

- 1.2b Water Tunnel:: Fig 1.2: Trapezoidal Wing at The End of The Wind TunnelDocument2 pages1.2b Water Tunnel:: Fig 1.2: Trapezoidal Wing at The End of The Wind Tunnelirctcsbt6bimblikipilNo ratings yet

- MA 4701 AY 15 S1 Aircraft Design - Course Activities and PlanningDocument26 pagesMA 4701 AY 15 S1 Aircraft Design - Course Activities and PlanningKhim YangNo ratings yet

- Micro UAVDocument8 pagesMicro UAVMOST PASONNo ratings yet

- Linear AerodynamicsDocument45 pagesLinear Aerodynamicsparvaz747No ratings yet

- Aerial Photography Quadcopter ProjectDocument2 pagesAerial Photography Quadcopter ProjectDraculagNo ratings yet

- Pitch Control System PDFDocument6 pagesPitch Control System PDFGraig LenoNo ratings yet

- Full Thesis PDFDocument116 pagesFull Thesis PDFAdrian SelgasNo ratings yet

- Executive Summary: Design and Build A Small AirshipDocument238 pagesExecutive Summary: Design and Build A Small AirshipErnesto Delfino AguirreNo ratings yet

- Electric Propeller Aircraft SizingDocument35 pagesElectric Propeller Aircraft SizingZenon CortezNo ratings yet

- The Realization of Virtual Reality of Launching Rocket Based On Simulink and VRMLDocument4 pagesThe Realization of Virtual Reality of Launching Rocket Based On Simulink and VRMLIJEC_EditorNo ratings yet

- VTOL Modeling (Student)Document5 pagesVTOL Modeling (Student)juanNo ratings yet

- Drone PresentationDocument9 pagesDrone PresentationAkarshit PachyalaNo ratings yet

- ADP 1 LAB ManualDocument54 pagesADP 1 LAB ManualdhanajayanNo ratings yet

- Tilt Wing Model Design PDFDocument23 pagesTilt Wing Model Design PDFpadmanabhanrameshNo ratings yet

- Unmanned Aircraft SystemsFrom EverandUnmanned Aircraft SystemsElla AtkinsNo ratings yet

- ANSYS Advantage V4 I1 2010Document52 pagesANSYS Advantage V4 I1 2010j_c_garcia_d100% (1)

- Condensate Drain DesignDocument3 pagesCondensate Drain Designjdietz4606No ratings yet

- G21/GSR21 Service LiteratureDocument99 pagesG21/GSR21 Service Literatureschrieberdieses100% (1)

- Fan Industry in Pakistan/1Document8 pagesFan Industry in Pakistan/1Sohaira ZahraNo ratings yet

- Air Coolers LiteratureDocument11 pagesAir Coolers Literatureyinkaakins200133% (3)

- Noise reduction in centrifugal blowerDocument11 pagesNoise reduction in centrifugal blowerGanesh ThoratNo ratings yet

- MD6290 Features and BenefitsDocument43 pagesMD6290 Features and Benefitsnikbeam100% (3)

- 1851697361-4ee1f045 (Ahu-1)Document8 pages1851697361-4ee1f045 (Ahu-1)Ferid QuliyevNo ratings yet

- Guidelines For The Safe Installation and Use of Cryogenic Food Freezing and Cooling EquipmentDocument15 pagesGuidelines For The Safe Installation and Use of Cryogenic Food Freezing and Cooling EquipmentsgsalvaNo ratings yet

- VENTILATION SYSTEMS VENTS CatalogueDocument120 pagesVENTILATION SYSTEMS VENTS CatalogueVanessa JonesNo ratings yet

- NovaDocument29 pagesNovacpoliNo ratings yet

- Ducted Chilled Water Fan Coil Units for District Cooling ApplicationsDocument21 pagesDucted Chilled Water Fan Coil Units for District Cooling Applicationscantorband8234100% (2)

- Energy 400Document58 pagesEnergy 400fv740% (1)

- Sam ManualDocument67 pagesSam ManualmarioNo ratings yet

- Silencers For HVACDocument12 pagesSilencers For HVACZaw Moe KhineNo ratings yet

- Cooling Tower REPORTDocument25 pagesCooling Tower REPORTSaroj KumarNo ratings yet

- MBDCDocument2 pagesMBDCRachel RobinsonNo ratings yet

- Impulse Cleaning SystemDocument18 pagesImpulse Cleaning SystemgjanklesariaNo ratings yet

- Product Catalog: Packaged Rooftop Air Conditioners Voyager™ Commercial With Reliatel™ControlsDocument106 pagesProduct Catalog: Packaged Rooftop Air Conditioners Voyager™ Commercial With Reliatel™ControlssdvitkoNo ratings yet

- Standard Operating ProcedureDocument11 pagesStandard Operating ProcedureproteoglycanNo ratings yet

- 101 ways save energy & moneyDocument12 pages101 ways save energy & moneyHeine NtuliniNo ratings yet

- 2-2.5TPH Wood Pellet Production LineDocument8 pages2-2.5TPH Wood Pellet Production LineddtyuriNo ratings yet

- Geovent CatalogDocument108 pagesGeovent CatalogadnanNo ratings yet

- Briefing Paper - IceDocument62 pagesBriefing Paper - IcePanagiotis RappasNo ratings yet

- ATA Codes 2Document8 pagesATA Codes 2Steven ReidNo ratings yet

- D55SP - D75KS Blasthole DrillDocument4 pagesD55SP - D75KS Blasthole DrillIrvan Aryo Prakoso0% (1)

- V2500 TM Airbus PDFDocument562 pagesV2500 TM Airbus PDFBernard Xavier83% (6)

- Bladeless FanDocument28 pagesBladeless FanShailen Patel80% (15)

- Bebederos Elkay FD7003Document2 pagesBebederos Elkay FD7003Enver Ernesto Miranda RiosNo ratings yet

- 23soft Starter HandbookDocument36 pages23soft Starter HandbookCarlos_Duque1958No ratings yet