Professional Documents

Culture Documents

Alev Geri̇ Tepmesi̇

Uploaded by

ozdoguOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alev Geri̇ Tepmesi̇

Uploaded by

ozdoguCopyright:

Available Formats

TECHNCAL

Kaynak Hortumlarndaki Oksijen-Asetilen Geri Tepmeleri

Investigation of Oxygen-Acetylene Flashback Reactions in Welding Hoses

Victor Ekipmanlar irketi 1913 de L. W. Stettner tarafndan kuruldu. Aslen kaynak olan Stettner, bir kaynak kazasnda bir gzn kaybetti ve ondan sonra daha gvenli kaynak ekipmanlar tasarlamak iin almalara girdi. Tasarlad kaynak ve kesme torlar ve gaz reglatrleri ksa zamanda kabul grd ve Victor Oksi-Asetilen Kaynak Ekipmanlar irketi sratle byd. Victor mhendisleri bu makaleyi Stettnerin vurgulam olduu gvenlik ruhu ile kaleme aldlar. ZET: VICTOR EQUIPMENT COMPANY was founded in 1913 by L. W. Stettner. Stettner , a welder by trade, suffered the loss of one eye from a welding accident and subsequently set out to design and build better, safer welding products. His designs for welding and cutting torches and regulators were quickly accepted and VICTOR Oxy-Acetylene Welding Equipment Company grew rapidly. In the spirit of Stettners emphasis on SAFETY, VICTOR engineers did co-write this article. Victor is represented by ZENSAN A.. in Turkey.

Kaynak sektrnde hakim kayglardan biri, bir oksijen-asetilen (oksiasetilen) geri tepme tepkisinin bir kaynak hortumunun iine yaylarak oksijen-asetilen parlamasna ve hzl toplanma basncndan dolay patlamaya neden olmasdr. Tank olunan bir kaynak hortumu yangn hangi artlar altnda kaynak hortumlarnn ierisinde patlamalarn olacan ve hangi kaynak hortumlarnn bu durumlara maruz kaldnda patlayacan gsteren testle sonulanmtr. Bu yaz kaynak hortumu yangn gzlemini, geri tepme tepkilerini oluturan artlar ve kazann yeniden yaplmas srasnda sradan kaynak hortumlarnn iindeki parlama-patlama geiinin zelliklerini grmek amacyla ortaya konan analitik almalar bildirmektedir. Bu yaz ayn zamanda geri tepme patlamalarndan kaynaklanan hortum yarlmalarna zgn fiziksel ve kimyasal kriterleri sunmaktadr. ANAHTAR KELMELER: Patlama, oksiasetilen, kaynak, geri tepme, forensik yeniden yapma, ate tepmesi, tutulan ate tepmesi. ABSTRACT: A common concern in the welding industry is the development of conditions wherein an oxygen-acetylene (i.e., oxyacetylene) flashback reaction can propagate into a welding hose causing it to burst due to the rapid localized pressurization associated with an oxygen-acetylene deflagration-to-detonation transition. The investigation of a recent welding hose fire resulted in testing to evaluate the conditions under which detonations could be generated within welding hoses and the conditions in which welding hoses would burst when exposed to these events. This paper reports on elements of the welding hose fire investigation, the conditions for flashback reactions to develop, and the analytical work performed during the accident reconstruction to characterize deflagration-to-detonation transition within typical weld-ing hoses. This paper also suggests physical and chemical criteria that are characteristic to welding hose ruptures due to flashback detonations. KEYWORDS: detonation, oxyacetylene, welding, flashback, backfire, forensic reconstruction, backfire, sustained-backfire Giri Yazarlar bir operatrn ciddi ekilde yanmasyla sonulanan bir oksiasetilen kaynak hortumu patlamasn aratrmlardr. Kaynak hortumu ticari bir kaynak toruyla ve stma ulu bir kartrma ekipmanyla kullanld srada meydana gelmitir. Yangn, operatr hem oksijen hem de asetilen reglatrn 15 psig deerine ayarlayp toru yakmaya alt esnada meydana gelmitir. Kendi ifadesine gre asetilen akn balatmak iin tor sapnn zerindeki asetilen ine valfini am ve asetilen akn normal olarak torun ucunda yakmtr. Tor zerindeki oksijen ine valfini amaya baladnda bir pop sesi Introduction The authors recently investigated an oxyacetylene welding hose rupture that led to severe burns to an operatr. The welding hose was being used with a commercial welding torch and mixing attachment equipped with a heating tip. The fire developed when the operator was attempting to light the torch after setting both the oxygen and acetylene regulators each to 15 psig. According to his statement he opened the acetylene needle valve on the torch handle to initiate the flow of acetylene and lit the acetylene flow normally at the tip of the torch. He indicated that when he started opening the oxygen needle valve

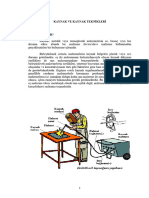

TEKNK

duymu ve alev ktn grm, bunun zerine iki ine valfini de kapatmtr. Daha sonra asetilen ine valfini tekrar am ve asetilen akn torun ucunda tekrar yakmtr. Oksijen ine valfini ikinci kez amaya baladnda ate byk bir grltyle yeniden tor ucundan ieri girmitir. Asetilen kayna hortumu annda yarlarak operatrn ciddi lde yaralanmasna sebep olan ak asetilen atei balamtr. Kaynak hortumunun ve patlayan asetilen hortumunun (ekil 1 ve 2) incelenmesi sonucunda asetilen kayna hortumunun tor sap balantsna doru yaklak 48.3 cm (19 in) yarldn grlmtr. Aratrmaya gre hortum yarldktan sonra bir asetilen-hava alevi hortumun yarlm olan ksmndan balayarak hortumun tora, asetilen aknn olduu tarafa doru olan ksmn kesmitir. ekil 2de gsterilen fotorafta kaynak hortumunun zerindeki yark yakndan grlmektedir. Hortumun yarlm ksm ile ilk yarlmadan sonra yanan ksm arasnda gzle grlr bir fark vardr. Bu yaz forensik yeniden yapmann detaylarn tartmaktan kanrken, kaynak hortumlar iindeki geri tepme tepkilerini deerlendirmek iin gerekletirilen test ve tutuma olaynn karakteristik zellikleri oksiasetilen geri tepmesi sonucu oluan kaynak hortumu yarklarnn daya iyi anlalmas iin sunulmutur. 1 Bakan Yardmcs, R&D, Wendell Hull and Associates INC, 1020 S. Main, Las Cruces, NM 88005. 2. Ba Mhendis, Victor Equipment Company, Denton, TX. 3 Test Tesisi Mdr, Wendell Hull and Associates INC, 1020 S. Main, Las Cruces, NM 88005. 4 NASA-WSTF,Laboratuar ef Yardmcs, Las Cruces, NM.

on the torch he heard a pop and the flame when out so he closed both torch needle valves. He then reopened the acetylene needle valve and relit the acetylene flow at the torch tip. When he started opening the oxygen needle valve the second time the flame again regressed into the torch tip with a pop and a squealing sound. The acetylene welding hose immediately ruptured resulting in an open-air acetylene fire which severely burned the operator. Examination of the welding torch and the ruptured acetylene hose (Figs. 1 and 2) revealed that the acetylene welding hose had ruptured approximately 48.3 cm (19 in.) upstream of the connection to the torch handle. The investigation revealed that after the hose ruptured, a lancing acetylene-air flame at tached to the ruptured area of the hose and burned away a segment of the welding hose extending toward the torch, in the direction of the acetylene flow. The photograph shown in Fig. 2 depicts a close-up view of the welding hose near the rupture. A clear distinction was observed between the ruptured portion of the hose and the segment of hose liner that was burned after the initial rupture. While this paper will avoid discussing the details of the forensic reconstruction, the testing that was performed to evaluate flashback reactions within welding hoses will be presented and the characteristic elements of the combustion event will be discussed to better understand welding hose rupture due to an oxy-acetylene flashback 1 Vice President, R&D, Wendell Hull and Associates Inc., 1020 S. Main, Las Cruces, NM 88005. 2 Principal Engineer, Victor Equipment Company, Denton, TX. 3 Test Facility Manager, Wendell Hull and Associates, Inc., 1020 S. Main, Las Cruces, NM 88005. 4 NASA-WSTF, Laboratories Office Deputy Chief, Las Cruces, NM.

Hortumun Yarlmas ve Yanmas

ekil 1- Torun ve kaynak hortumunun fotoraf (yarlan yer belirtilmitir).

FIG. 1Photograph of torch and welding hose (area of hose rupture is indicated).

TECHNCAL

Arka Plan Aratrmaclar bir kaynak hortumu burada bahsedilenle (ekil 1 ve 2) benzer bir biimde yarldnda oluan hatay aklamak iin geri tepme tepkisi denilen bir olaya dikkat ekmektedirler. Tutulan geri tepme olarak da bilinen geri tepme torun ucundaki alevin torun iine girerek torun gaz kartrcsnda yanmaya devam etmesini anlatmak iin kullanlmaktadr. Ancak, geri tepme ayn zamanda alevin tortan tamamen ieri girerek gaz tedarik hortumlarnn birinin iine girmesini anlatmak iin de kullanlmaktadr. Geri tepme teriminin bu kafa kartrc kullanmlar ve ate tepmesi ve tutulan ate tepmesi gibi dier terimlerle bir arada kullanlmas yznden bu terimlerle neyin anlatldna karar vermek ounlukla zordur. Anlatmn anlalabilir olmas iin bu yazda yazar oksiasetilen ekipman iinde ortaya kabilecek bu eit olay birbirinden ayran Broden et al [1] iinde yer alan tanmlar tercih etmitir. Bu tanmlar aadaki gibidir: Ate tepmesi - Ate tepmesi torun iine keskin bir patlamayla (pop) dnen alevi anlatmaktadr. Alev sndrlr ya da nozul ucunda yeniden yaklr. Bu durum ekil 3te gsterilmitir. Tutulan ate tepmesi Tutulan ate tepmesinde alev tortan ieri girerek kartrcnn iinde, genelde karm noktasnda yanmaya devam eder.

Background Investigators often point to an event called a flashback reaction to explain the failure when a welding hose ruptures in a manner similar to the one discussed here (Figs. 1 and 2). Flashback is frequently used to describe a regression of the torch tip flame into the torch to continue burning at the torchs gas mixer element, also known as sustained-backfire. However, flashback is also used to describe regression of the flame fully through the torch and into one of the gas supply hoses. Due to these confusing uses of the term flashback, and the simultaneous use of other terms such as backfire and sustained-backfire, agreement on what is referred to by the various terms is often difficult. For the sake of clarity, and as used in this paper, the authors prefer the definitions provided by Broden et al. [1] since they distinguish clearly between the three types of events that can develop within oxy-acetylene equipment. These definitions are provided as follows: BackfireA backfire implies that the flame burns back into the torch with a sharp bang (pop). Either the flame is extinguished, or it is reignited at the nozzle opening. Graphically, this is illustrated in Fig. 3. Sustained BackfireIn a sustained backfire the flame burns back into the torch with continued burning in the mixer, often at the mixing point itself. A sustained backfire is characterized by an initial

lk yarlma

Yarlma sonras yanma

ekil 2 lk yarlmann ve hortumun devam eden yannn yakndan grnm.

FIG. 2Close-up view of the upstream initial rupture and the burning of the hose downstream.

TEKNK

Oxygen Oksijen

Ate tepmesi -Backfire

Acetylene Asetilen

pop

Momentary regression of flame into the torch tip accompanied by a pop Alevin pop ile tor ucuna anlk geri girmesi The flame eiter extinguishes or re-ignites at the tip Alev sner ya da tor ucunda yeniden balar. ekil 3Tor ate tepmesinin grafik izimi FIG. 3Graphic illustration of a torch backfire.

Tutulan Ate Tepmesi - Sustained Backfire

Oxygen Oksijen

Acetylene Asetilen

squeal yksek ses

Regression of flame into torch tip followed by sustained burning in the at the mixing chamber Alevin torun iine girmesinden sonra karm noktasnda yanmaya devam etmesi. Accompanied by a hissing or squealing sound Tslama ya da yksek ses ile olur. ekil 4Tor tutulan ate tepmesinin grafik izimi.

Oxygen Control Vave OPEN High Oxygen Pressure Yksek Oksijen Basnc Oksijen Kontrol Valfi AIK

FIG. 4Graphic illustration of a sustained backfire.

Ters Ak - Reverse flow

Low/Depleted Acetylene Pressure Dk/azaltlm Asetilen Basnc Check Valve Missing or noperative Koruma Valfi Yok ya da almyor

Oxygen Reverse Flow nto Acetylene Hose Asetilen Hortumuna Oksijen geri Ak Fuel Control Valve OPEN Yakt Kontrol Valfi AIK Tip Plugged or Restricted U kapal ya da tkanm

Geri Tepme- Flashback

Fire Propagetes Through Mixed Acetylene/Oxgen Flame Front Accelerates Throung Hose Alevin Ucu Hortum Boyunca Hzlanyor Asetilen/Oksijen Karmndan Ate kyor Flame Regresses Into Torch Tip Alev Tor Ucundan Geri Giriyor

ekil . 5 Geri tepme tepkisinin paralar

FIG. 5Elements of a flashback reaction.

TECHNCAL

TABLO 1 Fazla basn hesaplar.

TABLE 1Calculated overpressures.

Reactants

Oxygen-acetylene Oxygen-acetylene

Fuel

Detonation,

Tutulan ate tepmesinin zellii bir ilk patlama (ate tepmesi) ve ardndan devam eden yanmadan gelen sla benzer sestir. Bu durum ekil 4te gsterilmitir. Geri tepme Geri tepme alevin yanarak torun iinden gaz kaynana (hortuma) geri dnmesidir. Geri tepmenin temel nedeni geri ak, yani oksijenin asetilen hortumunun iinde girerek orada patlayc bir karm olumasdr. Bu karm daha sonra tor yakldnda oluan ate tepmesiyle yanabilir. Normalde, bir kaynak hortumuna geri tepme sadece ok istisnai durumlarda olur. Tecrbeler sonunda anlalmtr ki, aadakiler dahil birok gerekli koul olumaldr: (1) Oksijen hortumunun iine asetilen ya da asetilen hortumunun iine oksijen girmesi gibi bir geri gaz ak olmaldr. (2) Bir geri ak olumas iin, gaz basnlarndan birinin dierinden daha yksek olmas gerekir. Basnlar arasndaki fark ne kadar byk olursa, dier uygun koullar da salandnda geri ak o kadar muhtemel olur. (3) Torta geri basn oluturup ters aka sebep olmak iin kartrc birim ynnde gaz aknda bir bozulma olmaldr (yani tor ucunu tkayan bir cruf, allan malzemeye bastrlmas sonucu tor ucundan akn kstlanmas, vs.). (4) ki ine valf de ak olmal ve tor kontrol valfleri bulunmamal ya da bozuk olmaldr ki dier koullar olumusa gazlarn biri dier hortumdan ieri girebilsin. (5) Yakt ve oksijen gazlar yeterli lde karmaldr, bylece tortan hortumun iine giren alevi ynlendirmek iin gerekli alev alan gaz oluur. Bir alevin tortan hortumlarn birinin iine doru yaylmas iin bir geri tepme tutucusunun olmamas gerekir yoksa alev yaylmas gereklemez. (6) Yanmadan patlamaya gei hortumun iinde olursa hortum alevin hzlanmasndan dolay oluan ok dalgas yznden yarlabilir. Yoksa tecrbeler gsteriyor ki kaynak hortumlar bir yanmay emebilecek kadar kuvvetlidir ancak patlamayla ortaya kan enerji salnm yksekse (yksek basnla balamsa) hortum yarlabilir. Patlama, ok zel bir yanma olaydr ve sadece belli artlar altnda gerekleir. Geri tepme tepkisinin gsterilmitir. nemli safhalar ekil 5 ile

bang (backfire) followed by a whistling or screeching sound from the continuous combustion. Graphi-cally, this is illustrated in Fig. 4. Flashback Flashback implies that the flame burns back through the torch and into the gas supply (i.e., the hose). Flashback is mostly caused by reverse flow, e.g., flow of oxygen into the acetylene hose so that an explosive mixture is present in the hose. This mixture can then be ignited by a backfire which occurs when the torch is ignited. Normally, a flashback into a welding hose will only occur under very exceptional circumstances. Experience indicates that many of the necessary conditions that must be present include the following: (1) A reverse flow of gas must occur into one of the hoses, either the acetylene into the oxygen hose or the oxygen into the acetylene hose. (2) For a reverse flow to occur, one of the gas pressures must be higher than the other. The greater the difference in the pressures, the more likely that reverse flow could occur if the conditions are present. (3) There must be a disruption of the gas flow downstream of the mixing element (i.e., slag occluding the torch tip, restriction of flow from the torch tip by pressing it into the work piece, etc.) to create a backpressure in the torch such that a reverse flow can develop. (4) Both needle valves must be open and either the torch check valves are not present or are inop-erative such that a reverse flow of one of the gases can proceed into the other hose if the other conditions are present. (5) Sufficient mixing of the fuel and oxygen gases must occur so that a premixed flammable gas is present for a flame front to propagate from the torch into the hose that contains the mixed gas. For a flame front to propagate from the torch into one of the hoses, either a flashback arrestor must be absent or be failed in a manner that will allow flame propagation. (6) Hose rupture may occur if a deflagration to detonation transition takes place within the hose due to the formation of a shock wave from the accelerating flame front. Otherwise, experience indicates that typical welding hoses are sufficiently strong to absorb a deflagration but that the higher energy release as-

You might also like

- Celik Yapi Uygulamalarinda Kullanilacak Kaynak YontemleriDocument10 pagesCelik Yapi Uygulamalarinda Kullanilacak Kaynak YontemleriyusamengNo ratings yet

- Celik Yapi Uygulamalarinda Kullanilacak Kaynak YontemleriDocument10 pagesCelik Yapi Uygulamalarinda Kullanilacak Kaynak YontemleriCüneytNo ratings yet

- Oksi-Gaz KaynağiDocument28 pagesOksi-Gaz KaynağiismailcikatayNo ratings yet

- Exproof Elekrik ŞartnamesiDocument242 pagesExproof Elekrik Şartnamesitimur2705No ratings yet

- Buhar Kazani ProjesiDocument30 pagesBuhar Kazani ProjesiYasinYıldızNo ratings yet

- Oxi AsetilenDocument7 pagesOxi Asetilenkeles11No ratings yet

- Kimya 3Document95 pagesKimya 3Sakarya IkyNo ratings yet

- GB Borularda SürtünmeDocument26 pagesGB Borularda SürtünmegozdebstnciNo ratings yet

- Reaksiyon Hizina Etki Eden FaktorlerDocument7 pagesReaksiyon Hizina Etki Eden FaktorlerBurcu BasakNo ratings yet

- EkstrüzyonDocument4 pagesEkstrüzyonturambar254No ratings yet

- KAYNAK İŞLERİNDE İŞ SAĞLIĞI Ve GÜVENLİĞİ IlkerDocument111 pagesKAYNAK İŞLERİNDE İŞ SAĞLIĞI Ve GÜVENLİĞİ IlkerBURAK YETİMNo ratings yet

- Bölüm7a - İleri Nötron Ve Reaktör FiziğiDocument6 pagesBölüm7a - İleri Nötron Ve Reaktör Fiziğigokcen87No ratings yet

- Kaynak Ve Kaynak Tekni̇kleri̇Document45 pagesKaynak Ve Kaynak Tekni̇kleri̇AHMET DURAN CEYHANNo ratings yet

- Kay TekDocument45 pagesKay TekKaan çelikoğluNo ratings yet

- AasdasdasDocument6 pagesAasdasdascanNo ratings yet

- PsvodevyusufkuzuDocument13 pagesPsvodevyusufkuzuYusuf Kuzu100% (2)

- Doğalgaz Ve Petrol Boru Hatlarinda Hi̇drojeni̇n Neden Olduğu ÇatlamalarDocument10 pagesDoğalgaz Ve Petrol Boru Hatlarinda Hi̇drojeni̇n Neden Olduğu ÇatlamalarozcanNo ratings yet

- Çeli̇k Yapilarda Bi̇rleşi̇m AraçlariDocument42 pagesÇeli̇k Yapilarda Bi̇rleşi̇m AraçlariMurat CKNo ratings yet

- Kaynakçı Eğitimi 2Document17 pagesKaynakçı Eğitimi 2muratcanNo ratings yet

- Çentik Darbe DeneyiDocument6 pagesÇentik Darbe DeneyiKadir KancaNo ratings yet

- Organik Kimyada Teorik YontemlerDocument113 pagesOrganik Kimyada Teorik YontemlerGökhan GömekNo ratings yet

- RRA Işleminin 7075 Alaşımının Mekanik Özelliklerine EtkisiDocument9 pagesRRA Işleminin 7075 Alaşımının Mekanik Özelliklerine EtkisiMehmet UysalNo ratings yet

- Elektrik Enerji Kaynagi Olarak UreteclerDocument4 pagesElektrik Enerji Kaynagi Olarak UreteclerCEVHERNo ratings yet

- ÇELİK YAPILAR DERS NOTU 4-BİRL ARAÇLARI KaynakDocument73 pagesÇELİK YAPILAR DERS NOTU 4-BİRL ARAÇLARI KaynakVeysel YUSUFOĞLUNo ratings yet

- Deney RaporuDocument2 pagesDeney RaporuasfgghNo ratings yet

- Borularda Sürtünme KaybıDocument22 pagesBorularda Sürtünme KaybıUmut AtamanNo ratings yet

- Elektroslag (Elektrocuruf) KaynagiDocument15 pagesElektroslag (Elektrocuruf) KaynagisinanicikNo ratings yet

- Devrim Ozhendekci Celik1 Ders-Notu-6Document7 pagesDevrim Ozhendekci Celik1 Ders-Notu-6niybiroNo ratings yet

- Kaynak Tekni I Ders NotlarDocument71 pagesKaynak Tekni I Ders NotlarMarian Gabriel VasilescuNo ratings yet

- 2012 13 Gerilme Analizi Deney Foyu 28092012Document13 pages2012 13 Gerilme Analizi Deney Foyu 28092012mertkemalsavurrrNo ratings yet

- Deniz Beğen Dekoratif Radyatör TasarımıDocument58 pagesDeniz Beğen Dekoratif Radyatör TasarımıAli ŞengülNo ratings yet

- TS 818 FlanşlarDocument16 pagesTS 818 FlanşlarEnes EginNo ratings yet

- Kesikli ReaktörlerDocument35 pagesKesikli ReaktörlersebzelimakarnaNo ratings yet

- SUPERILETKENLIKDocument54 pagesSUPERILETKENLIKGökçen Aslan AydemirNo ratings yet

- Kaynak Çeşitleri HTTPTR - Wikipedia.orgwikikaynak - (Imalat)Document28 pagesKaynak Çeşitleri HTTPTR - Wikipedia.orgwikikaynak - (Imalat)Alpar DalgicNo ratings yet

- İngilizce Türkçe Teknik Terimler Sözlüğü PDFDocument243 pagesİngilizce Türkçe Teknik Terimler Sözlüğü PDFMustafa Temel50% (2)

- Bölüm 8Document31 pagesBölüm 8AgahNo ratings yet

- Mazlum Yılmaz Sürtünme KayıplarıDocument14 pagesMazlum Yılmaz Sürtünme KayıplarıMazlum YılmazNo ratings yet

- 10.metallerin Yüksek Hızda ŞekillendirilmesiDocument38 pages10.metallerin Yüksek Hızda Şekillendirilmesiberkay uysalNo ratings yet

- Gaz Türbini Çalışma Donanımlarının Incelenmesi Axstream Programıyla Eksenel Akışlı Kompresör Ve Türbin Dizaynı AnaliziDocument264 pagesGaz Türbini Çalışma Donanımlarının Incelenmesi Axstream Programıyla Eksenel Akışlı Kompresör Ve Türbin Dizaynı AnaliziNebahat PolatNo ratings yet

- SOĞUTUCUDocument25 pagesSOĞUTUCUjourney71No ratings yet

- DÜNYA'DAKİ LNG KAZALARI Ve LNG YANGINI VE SIZINTILARINADocument37 pagesDÜNYA'DAKİ LNG KAZALARI Ve LNG YANGINI VE SIZINTILARINAerdincdeliNo ratings yet

- Endüstriyel Yapılarda Yatay Geniş Tanklar Ile Dikey NarinDocument8 pagesEndüstriyel Yapılarda Yatay Geniş Tanklar Ile Dikey NarinMate JamesNo ratings yet

- Döküm TeknolojisiDocument15 pagesDöküm TeknolojisiÖmer HacıismailoğluNo ratings yet

- Mi̇g Mag KaynağiDocument60 pagesMi̇g Mag KaynağiErsan ArslanNo ratings yet

- Difüzyon KaynağıDocument41 pagesDifüzyon KaynağıFurkan BostancıNo ratings yet

- DoğalgazDocument60 pagesDoğalgazNizamettin YılmazNo ratings yet

- Kaynak İşlerinde İş GüvenliğiDocument7 pagesKaynak İşlerinde İş Güvenliğisinemiz_35No ratings yet

- İgdaş Baca ŞartnamesiDocument8 pagesİgdaş Baca ŞartnamesiBaca TemizlemeNo ratings yet

- Çimento Döner Fırını: Sorular & CevaplarDocument42 pagesÇimento Döner Fırını: Sorular & CevaplarlxqfsjhcgmjjoxwszpNo ratings yet

- TS 1912Document12 pagesTS 1912Yekta KarakoçNo ratings yet

- Türk Loydu Yeni İnşa SörveyleriDocument110 pagesTürk Loydu Yeni İnşa SörveyleriMehmetNo ratings yet

- Steel Products Carriage3Document116 pagesSteel Products Carriage3ozdoguNo ratings yet

- Kobi̇ler İçi̇n İş Sağliği Ve Güvenli̇ği̇ Rehberi̇Document87 pagesKobi̇ler İçi̇n İş Sağliği Ve Güvenli̇ği̇ Rehberi̇ozdoguNo ratings yet

- İş Maki̇neleri̇Document100 pagesİş Maki̇neleri̇ozdoguNo ratings yet

- Motorlu Araçlar Geçi̇ş ÜstünlüğüDocument3 pagesMotorlu Araçlar Geçi̇ş ÜstünlüğüozdoguNo ratings yet

- Gemi̇lerde Aci̇l Durum Müdahale Rehberi̇Document174 pagesGemi̇lerde Aci̇l Durum Müdahale Rehberi̇ozdoguNo ratings yet

- Peri̇yodi̇k Eki̇pman Kontrolleri̇nde Yaşanan SorunlarDocument14 pagesPeri̇yodi̇k Eki̇pman Kontrolleri̇nde Yaşanan SorunlarozdoguNo ratings yet

- Ahşap İskele Kontrol NoktalariDocument3 pagesAhşap İskele Kontrol NoktalariozdoguNo ratings yet

- AisyerisaglikveguvenlikDocument7 pagesAisyerisaglikveguvenlikozdoguNo ratings yet

- Bölüm 6 - Çalışma Koşulları Ve Çalışma Ortamı Ve Bölüm 7-Metot Etüdüne Giriş Ve Işlerin SeçimiDocument6 pagesBölüm 6 - Çalışma Koşulları Ve Çalışma Ortamı Ve Bölüm 7-Metot Etüdüne Giriş Ve Işlerin SeçimiN. Y. ÇolakNo ratings yet