Professional Documents

Culture Documents

Wheel Bearing.20121215.115406

Uploaded by

anon_879945347Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wheel Bearing.20121215.115406

Uploaded by

anon_879945347Copyright:

Available Formats

Wheel Bearing

Animation of ball bearing(An best image with no cage) Be aware that the crimson dots meet every single one.five revolutions There are at the very least 6 typical principles of operation: basic bearing, also recognized by the certain variations: bushings, journal bearings, sleeve bearings, rifle bearings rolling-aspect bearings this kind of as ball bearings and roller bearings jewel bearings, in which the load is carried by rolling the axle somewhat off-middle fluid bearings, in which the load is carried by a fuel or fluid magnetic bearings, in which the load is carried by a magnetic field flexure bearings, in which the motion is supported by a load element which bends. [edit]Motions Common motions allowed by bearings are: axial rotation e.g. shaft rotation linear movement e.g. drawer spherical rotation e.g. ball and socket joint hinge movement e.g. door, elbow, knee [edit]Friction Reducing friction in bearings is often important for efficiency, to lessen dress in and to aid extended use at large speeds and to stay away from overheating and premature failure of the bearing. Primarily, a bearing can reduce friction by virtue of its condition, by its materials, or by introducing and that contains a fluid among surfaces or by separating the surfaces with an electromagnetic field. By shape, gains edge generally by using spheres or rollers, or by forming flexure bearings. By content, exploits the nature of the bearing materials used. (An example would be employing plastics that have very low surface friction.) By fluid, exploits the very low viscosity of a layer of fluid, these kinds of as a lubricant or as a pressurized medium to keep the two sound parts from touching, or by minimizing the standard power between them. By fields, exploits electromagnetic fields, such as magnetic fields, to hold strong parts from touching. Combos of these can even be employed inside of the identical bearing. An illustration of this is the place the cage is manufactured of plastic, and it separates the rollers/balls, which minimize friction by their form and complete. [edit]Hundreds Bearings change significantly above the size and directions of forces that they can assist. Forces can be predominately radial, axial (thrust bearings) or bending moments perpendicular to the major axis. [edit]Speeds

Distinct bearing types have various working speed limitations. Speed is normally specified as maximum relative floor speeds, usually specified ft/s or m/s. Rotational bearings normally explain overall performance in phrases of the product DN in which D is the diameter (usually in mm) of the bearing and N is the rotation fee in revolutions for each minute. Generally there is significant speed variety overlap among bearing sorts. Plain bearings usually handle only reduced speeds, rolling component bearings are more quickly, adopted by fluid bearings and lastly magnetic bearings which are limited in the end by centripetal force overcoming substance strength. [edit]Perform Some apps implement bearing masses from different directions and settle for only minimal engage in or "slop" as the used load changes. 1 resource of movement is gaps or "play" in the bearing. For case in point, a 10 mm shaft in a 12 mm hole has two mm participate in. Allowable perform may differ drastically depending on the use. Wheel Bearing

You might also like

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- What Loads or Movements Will The Bearing Need To Support or Allow?Document1 pageWhat Loads or Movements Will The Bearing Need To Support or Allow?SarvagnaMNNo ratings yet

- BearingsDocument50 pagesBearingsHazim Hazim100% (2)

- Basic of BearingDocument16 pagesBasic of BearingSNEHAL PATEL100% (1)

- Bearings: 7.0 Table of ContentsDocument16 pagesBearings: 7.0 Table of ContentsT ThirumuruganNo ratings yet

- Bearings Types of Damages and Their Causes: Kushal Dhungana Ab13 Professor: José Brigas and Pedro Alves IndiceDocument12 pagesBearings Types of Damages and Their Causes: Kushal Dhungana Ab13 Professor: José Brigas and Pedro Alves Indiceuploadz upNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Notes On BearingsDocument42 pagesNotes On BearingsPRAVEEN KUMAR SINGHNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Rolling Element BearingDocument9 pagesRolling Element Bearingstallone21No ratings yet

- General Bearing DesignDocument99 pagesGeneral Bearing DesignDr_M_Soliman100% (1)

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- General Bearing Basics: SKF NotesDocument37 pagesGeneral Bearing Basics: SKF NotesVinod Varadan SNo ratings yet

- Bearing NotesDocument132 pagesBearing NotesSarvagnaMNNo ratings yet

- BearingsDocument63 pagesBearingsYeabsraNo ratings yet

- BearingsDocument16 pagesBearingsayush100% (2)

- Bearing IntroductionDocument62 pagesBearing IntroductionsbkulkNo ratings yet

- Bearings: Case of Shafts) or Free LinearDocument12 pagesBearings: Case of Shafts) or Free LinearsathishjeyNo ratings yet

- BearingDocument1 pageBearingproxywarNo ratings yet

- Many Body ApproachDocument596 pagesMany Body Approachchvar80No ratings yet

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Roller BearingDocument5 pagesRoller BearingEagleMenaceNo ratings yet

- Centrifugal Pumps Bearings - Part 1Document23 pagesCentrifugal Pumps Bearings - Part 1visitabhinav80% (5)

- University of Gaziantep Bearing PresentationDocument17 pagesUniversity of Gaziantep Bearing PresentationHazim Hazim100% (1)

- E336 2005Document11 pagesE336 2005Chingalata Costel100% (1)

- Rotary Airlock Feeder (Valve)Document6 pagesRotary Airlock Feeder (Valve)Ali Hüthüt100% (3)

- Wheel Bearing.20121215.121806Document2 pagesWheel Bearing.20121215.121806anon_781354927No ratings yet

- BearingDocument8 pagesBearingOmkar Kumar JhaNo ratings yet

- Acknowledgement: Dharmendra ChouhanDocument15 pagesAcknowledgement: Dharmendra ChouhanLokesh KansaraNo ratings yet

- English Task 1 Mesin A Ball BearingDocument3 pagesEnglish Task 1 Mesin A Ball BearingSofyan HakikiNo ratings yet

- Machine element that reduces friction and supports motionDocument3 pagesMachine element that reduces friction and supports motionNororahman SalihNo ratings yet

- Bearing Lub SealingDocument29 pagesBearing Lub SealingmuazmaslanNo ratings yet

- BearingDocument13 pagesBearingabduallah rabahNo ratings yet

- Rolling Bearing PerformanceDocument15 pagesRolling Bearing PerformanceHafwan AffiqNo ratings yet

- Bearings - Innovation - Real Insertions in Industry: 1. Bearing Load MeasurementDocument30 pagesBearings - Innovation - Real Insertions in Industry: 1. Bearing Load MeasurementSaurabh KwatraNo ratings yet

- Bearing Basics and Types of Bearings: Satyendra Ispat Digest 1 CommentDocument6 pagesBearing Basics and Types of Bearings: Satyendra Ispat Digest 1 CommentFallo SusiloNo ratings yet

- Mod 6 Book 5 Springs Bearings Control Systems GearsDocument40 pagesMod 6 Book 5 Springs Bearings Control Systems Gearsranjit prasadNo ratings yet

- Kami Export - Rolling Element Bearing-16!9!21Document38 pagesKami Export - Rolling Element Bearing-16!9!21Dr Atul WaghmareNo ratings yet

- Bearing ProjectDocument6 pagesBearing ProjectbabublsNo ratings yet

- Chapter No Title Page - No: Table of ContentDocument31 pagesChapter No Title Page - No: Table of Contentyusuf ahamedNo ratings yet

- Machine Element Moving Parts Linear Rotation Around A Fixed Axis Vectors Normal ForcesDocument8 pagesMachine Element Moving Parts Linear Rotation Around A Fixed Axis Vectors Normal Forceslavish100% (1)

- Differences of Plain Bearings & Roller BearingsDocument3 pagesDifferences of Plain Bearings & Roller BearingsAkshay SetlurNo ratings yet

- Bearings: IndexDocument9 pagesBearings: IndextanmayNo ratings yet

- Vol19 03 08 Thrust Bearings SPE Extrusion Division 1 0 WikiDocument2 pagesVol19 03 08 Thrust Bearings SPE Extrusion Division 1 0 WikiSh.nasirpurNo ratings yet

- Thrust BearingDocument8 pagesThrust Bearingsonu_saurabh100% (1)

- Bbasics TranscriptDocument12 pagesBbasics TranscriptjoshuaNo ratings yet

- Bearing - Types, Applications, Failures, Selection, AdvantagesDocument5 pagesBearing - Types, Applications, Failures, Selection, AdvantagesDanyal KhattakNo ratings yet

- Yaw bearing guideDocument6 pagesYaw bearing guideJuan CNo ratings yet

- Machines and MechanismsDocument29 pagesMachines and Mechanismsmerily.sandyNo ratings yet

- Rolling Contact Bearing FundamentalsDocument34 pagesRolling Contact Bearing FundamentalshamooodiiiNo ratings yet

- Practical Applications of Journal BearingsDocument16 pagesPractical Applications of Journal Bearingsgao379100% (1)

- Bearings-An Introduction-NPTIDocument59 pagesBearings-An Introduction-NPTISakthi MuruganNo ratings yet

- Ball Bearings GuideDocument10 pagesBall Bearings GuideAsst.Prof MECHNo ratings yet

- Design, Materials &processes Identifying BearingDocument23 pagesDesign, Materials &processes Identifying BearingKirk SwabyNo ratings yet

- Design, Modeling, Assembly & Motion Study of BearingsDocument9 pagesDesign, Modeling, Assembly & Motion Study of BearingsFahad khalidNo ratings yet

- DMM 2 Lecture Notes PDFDocument258 pagesDMM 2 Lecture Notes PDFalagar krishna kumar50% (2)

- Rolling Element Bearings: Fitting of Balls in A Ball BearingDocument17 pagesRolling Element Bearings: Fitting of Balls in A Ball BearingSiva KulanjiNo ratings yet

- Bearing Types and SelectionDocument22 pagesBearing Types and Selectionsivajirao70No ratings yet

- Bearing (Mechanical) - Wikipedia, The Free EncyclopediaDocument12 pagesBearing (Mechanical) - Wikipedia, The Free EncyclopediaSumit ShrivastavaNo ratings yet

- No Backlash DrivesDocument28 pagesNo Backlash Drivesmustafa taiforNo ratings yet

- BearingsDocument33 pagesBearingsRavishanker BaligaNo ratings yet

- DMM 2 NotesDocument258 pagesDMM 2 NotesXyz AbcNo ratings yet

- Bearings: Plain BearingDocument4 pagesBearings: Plain BearingTrevaughn ParkinsonNo ratings yet

- Coupling and Constraint EquationsDocument19 pagesCoupling and Constraint EquationsZachary EllisNo ratings yet

- Laws of Motion: Comparing Aristotle and Galileo's ViewsDocument13 pagesLaws of Motion: Comparing Aristotle and Galileo's Viewsjal bayani0% (1)

- An Overview of Recent Nanofluid ResearchDocument6 pagesAn Overview of Recent Nanofluid ResearchKamaljeet SinghNo ratings yet

- 4.2.2 Assignments - 4.2 Separation - Solid - Liquid - Material Del Curso CHEM01x - EdxDocument7 pages4.2.2 Assignments - 4.2 Separation - Solid - Liquid - Material Del Curso CHEM01x - EdxRicardo NuñezNo ratings yet

- Corrosion preventive zinc coatings standardDocument28 pagesCorrosion preventive zinc coatings standardAce LeeNo ratings yet

- Batangas State University: T 300K H 50 W/M KDocument2 pagesBatangas State University: T 300K H 50 W/M KNixon LagrisolaNo ratings yet

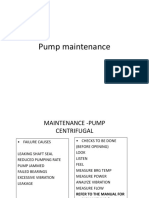

- Pump Maintenance PDFDocument9 pagesPump Maintenance PDFkamelNo ratings yet

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument10 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method ForPavan KumarNo ratings yet

- Thermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of AirDocument9 pagesThermodynamics Lab Report - Application of The Perfect Gas Laws in The Determination of Adiabatic Index of Airqiaunus69% (13)

- EET 3153: Physical Electronics: Job Kerosi EmailDocument77 pagesEET 3153: Physical Electronics: Job Kerosi EmailOdhiambo MeshackNo ratings yet

- Wmi Alhap Final Report 2006Document149 pagesWmi Alhap Final Report 2006John UnderwoodNo ratings yet

- POF 100 Specifications and Requirements For ILI - Nov 2021Document62 pagesPOF 100 Specifications and Requirements For ILI - Nov 2021Fernando ViurquesNo ratings yet

- What Is Filtration?Document17 pagesWhat Is Filtration?Muhammad Awais SiddiquiNo ratings yet

- CX Series CompressorDocument16 pagesCX Series Compressorwoalid hossenNo ratings yet

- Solutions Manual Chapter10Document41 pagesSolutions Manual Chapter10linearequNo ratings yet

- 1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineDocument19 pages1st Presentation - Analyzing Dynamic Line Rating of Distribution Tower LineMohamed Nihaj100% (1)

- Bearing Angle Model For Bond of Reinforcing Bars To ConcreteDocument4 pagesBearing Angle Model For Bond of Reinforcing Bars To ConcreteRicardo EscobarNo ratings yet

- Overhauling of Boiler Burner AssemblyDocument4 pagesOverhauling of Boiler Burner AssemblyAayush AgrawalNo ratings yet

- C311 HMTDocument9 pagesC311 HMTGajendran A MECH KIOTNo ratings yet

- Diesel Engine For Fire Pump-Fm ApprovedDocument8 pagesDiesel Engine For Fire Pump-Fm Approvedazul julianNo ratings yet

- MANIPAL UNIVERSITY JAIPUR Sieve Plate Distillation Column ExperimentDocument5 pagesMANIPAL UNIVERSITY JAIPUR Sieve Plate Distillation Column ExperimentAmoluck BhatiaNo ratings yet

- States of Matter (Gaseous & Liquid) : Gaseous State: Measurable Properties of Gases Gas Laws - Boyle's LawDocument6 pagesStates of Matter (Gaseous & Liquid) : Gaseous State: Measurable Properties of Gases Gas Laws - Boyle's LawIhtisham Ul HaqNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- BS 1161 (Aluminium Sections For Structural Purposes)Document20 pagesBS 1161 (Aluminium Sections For Structural Purposes)Arun NagrathNo ratings yet

- 2Document13 pages2VNSAramakiNo ratings yet

- Analyzing Projectile Motion with Capstone SoftwareDocument5 pagesAnalyzing Projectile Motion with Capstone SoftwarepatelNo ratings yet