Professional Documents

Culture Documents

Position of Welds Comparison

Uploaded by

Yuvaraj SathishOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Position of Welds Comparison

Uploaded by

Yuvaraj SathishCopyright:

Available Formats

ASME Definitions, Consumables, Welding Positions

Page 1 of 3

ASME Definitions, Consumables, Welding Positions

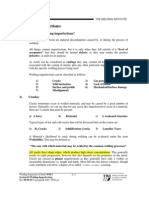

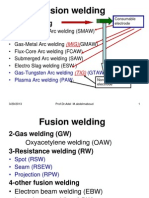

ASME P Material Numbers Explained ASME has adopted their own designation for welding processes, which are very different from the ISO definitions adopted by EN24063. Designation OFW SMAW SAW GMAW FCAW GTAW PAW Description Oxyfuel Gas Welding Shielded Metal Arc Welding (MMA) Submerged Arc Welding Gas Metal Arc Welding (MIG/MAG) Flux Cored Wire Gas Tungsten Arc Welding (TIG) Plasma Arc Welding

Straight polarity = Electrode -ve Reverse polarity = Electrode +ve ASME F Numbers F Number 1 2 3 4 5 6 2X 3X 4X 5X 6X 7X General Description Heavy rutile coated iron powder electrodes :- A5.1 : E7024 Most Rutile consumables such as :- A5.1 : E6013 Cellulosic electrodes such as :- A5.1 : E6011 Basic coated electrodes such as : A5.1 : E7016 and E7018 High alloy austenitic stainless steel and duplex :- A5.4 : E316L-16 Any steel solid or cored wire (with flux or metal) Aluminium and its alloys Copper and its alloys Nickel alloys Titanium Zirconium Hard Facing Overlay

file://E:\Welding Documents\ASME Definitions, Consumables, Welding Positions.htm

7/27/2009

ASME Definitions, Consumables, Welding Positions

Page 2 of 3

Note:- X represents any number 0 to 9

ASME A Numbers These refer to the chemical analysis of the deposited weld and not the parent material. They only apply to welding procedures in steel materials. A1 A2 to A4 A8 Plain unalloyed carbon manganese steels. Low alloy steels containing Moly and Chrome Moly Austenitic stainless steels such as type 316.

ASME Welding Positions Graphic Representation Note the welding progression, (vertically upwards or downwards), must always be stated and it is an essential variable for both procedures and performance qualifications. Welding Positions For Groove welds:Welding Position Flat Horizontal Vertical Upwards Progression Vertical Downwards Progression Overhead Pipe Fixed Horizontal Pipe Fixed @ 45 degrees Upwards Pipe Fixed @ 45 degrees Downwards Welding Positions For Fillet welds:Welding Position Flat (Weld flat joint at 45 degrees) Horizontal Horizontal Rotated Vertical Upwards Progression Vertical Downwards Progression Overhead Pipe Fixed Horizontal Welding Positions QW431.1 and QW461.2

Test Position 1G 2G 3G 3G 4G 5G 6G 6G

ISO and EN PA PC PF PG PE PF HL045 JL045

Test Position 1F 2F 2FR 3F 3F 4F 5F

ISO and EN PA PB PB PF PG PD PF

file://E:\Welding Documents\ASME Definitions, Consumables, Welding Positions.htm

7/27/2009

ASME Definitions, Consumables, Welding Positions

Page 3 of 3

Basically there are three inclinations involved. Flat, which includes from 0 to 15 degrees inclination 15 - 80 degrees inclination Vertical, 80 - 90 degrees For each of these inclinations the weld can be rotated from the flat position to Horizontal to overhead.

Brief Introduction Procedure Qualification Record (PQR) Welding Performance Qualification (WPQ) ASME definitions for welding processes, consumables and welding positions Welding Qualifications Sub Menu

Page last updated 19 March 2001

file://E:\Welding Documents\ASME Definitions, Consumables, Welding Positions.htm

7/27/2009

You might also like

- ASME P Material Numbers ExplainedDocument6 pagesASME P Material Numbers Explainedsagar1503100% (1)

- List of Welding CodesDocument10 pagesList of Welding CodesVijayakumar Samy0% (2)

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- IS Standard Changes for Steel Grades and Chemical CompositionDocument2 pagesIS Standard Changes for Steel Grades and Chemical CompositionTuhin Subhra Mondal100% (4)

- Wis5 TermsDocument29 pagesWis5 Termsravi00098No ratings yet

- Welding Gauge: Crown Height Fillet Weld Leg HeightDocument1 pageWelding Gauge: Crown Height Fillet Weld Leg Heightabhics67No ratings yet

- 008a.rtfi - AbbrevationsDocument2 pages008a.rtfi - AbbrevationsVivekanandan JNo ratings yet

- Welder Qualification Certificate for MainuddinDocument1 pageWelder Qualification Certificate for MainuddinAnirban Sen SharmaNo ratings yet

- Overview of NDT Methods & ApplicationsDocument7 pagesOverview of NDT Methods & Applicationsgeorgescribd1103No ratings yet

- Casting Material CA15BASD PDFDocument4 pagesCasting Material CA15BASD PDFAditya GuptaNo ratings yet

- Ultrasonic NotesDocument5 pagesUltrasonic NotesannapoornaavulaNo ratings yet

- Drawing Design: EngineeringDocument25 pagesDrawing Design: Engineeringsukarlan98No ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney DukeNo ratings yet

- Cast Steel GradesDocument5 pagesCast Steel Gradessohan_miyawala1906No ratings yet

- PQR Group V-Asme (WI74)Document7 pagesPQR Group V-Asme (WI74)Gusrizam DanelNo ratings yet

- Weld GaugesDocument15 pagesWeld GaugesHaleemUrRashidBangashNo ratings yet

- ASTM Standards 1Document4 pagesASTM Standards 1balajiNo ratings yet

- Major Differences Between API 5L PSL 1 & PSL 2 PipesDocument1 pageMajor Differences Between API 5L PSL 1 & PSL 2 PipesvijayachiduNo ratings yet

- Welding Inspection Consumables PDFDocument28 pagesWelding Inspection Consumables PDFJoseph PeterNo ratings yet

- CV FormateDocument8 pagesCV Formatetariq_hussain_20No ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Visual TestingDocument1 pageVisual TestingAnonymous GE8mQqxNo ratings yet

- Project Report On Electroforged Steel GratingDocument6 pagesProject Report On Electroforged Steel GratingEIRI Board of Consultants and PublishersNo ratings yet

- Home Education Resources NDT Course Material Ultrasound: Calibration MethodsDocument7 pagesHome Education Resources NDT Course Material Ultrasound: Calibration MethodspanduranganraghuramaNo ratings yet

- WeldDocs WPSDocument2 pagesWeldDocs WPSMDSIKKU_2005No ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- Resistance WeldingDocument8 pagesResistance Welding0502raviNo ratings yet

- Rfi Request FormDocument1 pageRfi Request Formvishnu300022No ratings yet

- How To Read Welding Gauges PDFDocument5 pagesHow To Read Welding Gauges PDFjimbox88No ratings yet

- ASTM Grades Explained for Pipes, Fittings, Flanges & MoreDocument4 pagesASTM Grades Explained for Pipes, Fittings, Flanges & Moremohan babuNo ratings yet

- Material Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberDocument3 pagesMaterial Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberErcan YilmazNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- Consumable LasDocument35 pagesConsumable LasAfifYantoMutuHNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- PFI Document DatabaseDocument1 pagePFI Document DatabaseedwinramonNo ratings yet

- Fundamentals of Welding TechDocument29 pagesFundamentals of Welding TechAshwani DograNo ratings yet

- List of AWSDocument5 pagesList of AWSkoneidinNo ratings yet

- Chemical Composition of Carbon Steel GuideDocument2 pagesChemical Composition of Carbon Steel GuideAkilanNo ratings yet

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDocument43 pagesProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- Imp-Comparison of SpecificationsDocument7 pagesImp-Comparison of SpecificationsKetan PatelNo ratings yet

- Qap Wo 7 r0 (Ion Exchange)Document1 pageQap Wo 7 r0 (Ion Exchange)KailasNo ratings yet

- Piping Test Pack Clearance ReportDocument2 pagesPiping Test Pack Clearance ReportKarthikNo ratings yet

- 03 Welding Imperfections 29-11-03Document17 pages03 Welding Imperfections 29-11-03bizhanjNo ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- Welding Electrode Classifications WallchartDocument1 pageWelding Electrode Classifications Wallchartask101100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- QAP Seamless PipeDocument2 pagesQAP Seamless PipeashokkahirwarNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- ASME ASTM Difference PDFDocument5 pagesASME ASTM Difference PDFSiddharth PawarNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- Welding Asme4Document3 pagesWelding Asme4raguhvacind4620No ratings yet

- Welding Electrode NomenclatureDocument3 pagesWelding Electrode NomenclaturedcevipinNo ratings yet

- ASME P Material Numbers ExplainedDocument4 pagesASME P Material Numbers ExplainedFaisal MbmNo ratings yet

- Welding TerminologyDocument4 pagesWelding TerminologyShahid HussainNo ratings yet

- ASME P and F Material Numbers ExplainedDocument17 pagesASME P and F Material Numbers ExplainedArfanAliNo ratings yet

- Amca 210-99 EscaneadaDocument81 pagesAmca 210-99 EscaneadaEric AsaadNo ratings yet

- AWS Welding SymbolsDocument11 pagesAWS Welding SymbolsYuvaraj SathishNo ratings yet

- Fracture TestDocument1 pageFracture TestYuvaraj SathishNo ratings yet

- Is 1897Document9 pagesIs 1897Yuvaraj SathishNo ratings yet

- Indian Standard: Methods of Chemical Analysis of Copper (Document32 pagesIndian Standard: Methods of Chemical Analysis of Copper (Yuvaraj SathishNo ratings yet

- ER1100 & ER4043 SpecificationsDocument3 pagesER1100 & ER4043 SpecificationsYuvaraj SathishNo ratings yet

- Is - 513Document11 pagesIs - 513mmkattaNo ratings yet

- Is 10259Document9 pagesIs 10259Yuvaraj SathishNo ratings yet

- QA Course Module 4 on Welding Procedure ApprovalDocument15 pagesQA Course Module 4 on Welding Procedure ApprovalYuvaraj SathishNo ratings yet

- Is 3965 PDFDocument13 pagesIs 3965 PDFYuvaraj SathishNo ratings yet

- BS 6014Document12 pagesBS 6014Yuvaraj SathishNo ratings yet

- Centre PunchesDocument1 pageCentre PunchesYuvaraj SathishNo ratings yet

- Electrical Conductivity and ResistivityDocument3 pagesElectrical Conductivity and ResistivityYuvaraj SathishNo ratings yet

- Centre PunchesDocument1 pageCentre PunchesYuvaraj SathishNo ratings yet

- Radiography Test Course MaterailDocument16 pagesRadiography Test Course MaterailYuvaraj Sathish100% (5)

- Cross Cut Kit ManualDocument5 pagesCross Cut Kit ManualYuvaraj Sathish100% (1)

- Welding Lectures 1-4Document88 pagesWelding Lectures 1-4Thriloknath PallaNo ratings yet

- Symbols For Welding and InspectionDocument24 pagesSymbols For Welding and InspectionRajan Steeve100% (1)

- WPS RB GM 01Document12 pagesWPS RB GM 01hetpinNo ratings yet

- Fundamentals of Vehicle Dynamics by Thomas D GillespieDocument99 pagesFundamentals of Vehicle Dynamics by Thomas D GillespieYogesh Chandrawanshi0% (1)

- 2006 ToolHolders106Document88 pages2006 ToolHolders106Caffe Bar BazaNo ratings yet

- Die CastDocument7 pagesDie CastLokesh BaviskarNo ratings yet

- SB40Document3 pagesSB40autobritaiNo ratings yet

- Training Handbook ENGDocument391 pagesTraining Handbook ENGnagaNo ratings yet

- AssignmentDocument5 pagesAssignmentShailesh PrajapatiNo ratings yet

- UCR ME SOP Manual Lathes v5 PDFDocument13 pagesUCR ME SOP Manual Lathes v5 PDFkinfegetaNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Technology of Machine ToolsDocument31 pagesTechnology of Machine Toolsaqsa_munirNo ratings yet

- MT MLMDocument17 pagesMT MLMSundara MoorthyNo ratings yet

- Din 965Document10 pagesDin 965PacoNo ratings yet

- 10 Different Welding Tools and EquipmentDocument3 pages10 Different Welding Tools and EquipmentHasz Ronquillo87% (15)

- Manufacturing of Components For GPMDocument73 pagesManufacturing of Components For GPMSharad Kumar AgarwalNo ratings yet

- Arc Welding - Introduction and FundamentalsDocument30 pagesArc Welding - Introduction and FundamentalsweldmindNo ratings yet

- Welding Lecture 2 Fusion (Liquid) State Welding Processes (ARC Welding)Document49 pagesWelding Lecture 2 Fusion (Liquid) State Welding Processes (ARC Welding)Adel Abdelmaboud100% (1)

- QW 381Document1 pageQW 381Waqas WaqasNo ratings yet

- Ktu Manufacturing Technology PDFDocument5 pagesKtu Manufacturing Technology PDFseminarprojectNo ratings yet

- True Centrifugal CastingDocument6 pagesTrue Centrifugal Castingmuhammadasrafazmi0% (1)

- Manf Science Gate NptelDocument37 pagesManf Science Gate NptelNavin KumarNo ratings yet

- Form QC ReportDocument6 pagesForm QC ReportDezi KurniawanNo ratings yet

- 110 KG CastingsDocument4 pages110 KG CastingsGurudutta MishraNo ratings yet

- Resistance Spot Welding (RSW) : Effects of Welding TimeDocument2 pagesResistance Spot Welding (RSW) : Effects of Welding TimexharpreetxNo ratings yet

- 14250A ch3 PDFDocument82 pages14250A ch3 PDFKamarul NizamNo ratings yet

- MAZAK M32 ParametersDocument67 pagesMAZAK M32 ParametersJesus Abraham Contreras Hernandez100% (4)

- Gama Welder Follow Up 25-05-09Document264 pagesGama Welder Follow Up 25-05-09machineNo ratings yet

- MTL Cti Metal Casting: by S K MondalDocument26 pagesMTL Cti Metal Casting: by S K MondalRahul VarshneyNo ratings yet

- Bhel ReportDocument44 pagesBhel ReportRoyalAryansNo ratings yet