Professional Documents

Culture Documents

Milk Collection

Uploaded by

ghost675Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Milk Collection

Uploaded by

ghost675Copyright:

Available Formats

Vol. 40, No. 2, MarchApril 2010, pp.

130143

issn0092-2102 eissn1526-551X 10 4002 0130

informs

doi 10.1287/inte.1090.0475

2010 INFORMS

A Milk Collection Problem with

Incompatibility Constraints

Massimiliano Caramia

Dipartimento di Ingegneria dellImpresa, Universit di Roma Tor Vergata, 00133 Roma, Italy,

caramia@disp.uniroma2.it

Francesca Guerriero

Dipartimento di Elettronica, Informatica e Sistemistica, Universit della Calabria, 87036 Rende, Italy,

guerriero@deis.unical.it

The milk collection problem is well known in rural areas of the world. This paper considers this real-life

problem for an Italian dairy company that collects raw milk from farmers. In our milk collection problem, we

address the constraint that some farms are small and inaccessible by large vehicles; moreover, these farmers

produce different milk types, and the tank trucks used for transporting the milk have multiple compartments.

This generates the additional constraint that at most one milk type can be assigned to a tank compartment.

The goal of this paper is to show how operations research techniques helped the company to improve its

daily performance. In particular, we present a solution approach based on two mathematical formulations and

local search, all embedded within a multiple-restart mechanism. The rst mathematical formulation minimizes

the number of vehicles to be routed in the network; the second minimizes the tour length. We also discuss

experiments we conducted as part of our case study and compare our solution with the process that the company

used previously.

Key words: industries: agriculture, food, transportation shipping; networks; graphs; heuristics.

History: This paper was refereed. Published online in Articles in Advance December 30, 2009.

I

n this paper we study a real-life problem faced

by ASSO.LA.C., an Italian dairy company that col-

lects raw milk from farmers. The considered milk col-

lection problem can be interpreted as a specialized

instance of the vehicle routing problem (VRP).

In the VRP, a set of (homogeneous) vehicles located

at a depot must be routed to serve geographically dis-

tributed customers. Routes must be optimized based

on one or more objective functions, e.g., the mini-

mization of the eet size and (or) the total routing

cost. Each customer has a known demand and ser-

vice duration, and each must be visited only once by

exactly one vehicle. Each route starts and ends at a

depot, and a vehicles capacity may not be exceeded.

The VRP is NP-hard and is usually solved by using

(meta)heuristics (Toth and Vigo 2002; Cordeau et al.

2000, 2002).

A general VRP assumption is that customers can

always be reached by the vehicles; i.e., the size of

a truck and (or) the location of the customer is not

relevant. In practice, this might not be true; indeed, a

truck with a trailer might not be able to reach some

customer locations. In such situations, the trailer must

be uncoupled from the complete vehicle (i.e., the truck

plus the trailer) in ad hoc parking areas before vis-

iting these customer locations; after visiting the loca-

tions the trailer must be coupled again to the pure

truck (i.e., the truck without the trailer), forming a

complete vehicle that continues its tour. This prob-

lem is known as the truck and trailer routing problem

(TTRP); the milk collection problem is a generaliza-

tion of the TTRP.

Assume that the set S of customers is divided

into

customers S

|r

who are accessible with or without

a trailer, and

customers S

.|

who are only accessible without a

trailer.

To address the needs of both customer types, we

must consider a possible uncoupling of the trailer

from the complete vehicle at a parking place to serve

customers in S

.|

. Therefore, following the denition

in Chao (2002), we denote the section of the route in

which a trailer is assigned as the main tour of the

130

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 131

complete vehicle route (CVR). In a CVR, uncoupling a

trailer at a parking place and starting a subtour from

the point of the uncoupling is possible. In a subtour,

which must start and end at the same parking place,

the company can service customers in S

|r

and S

.|

.

Therefore, a CVR is formed by a main tour and possi-

bly a certain number of subtours. Following the TTRP

model of Chao (2002), the depot and any customer in

S

|r

could be selected as a trailer parking place.

For a complete vehicle, the sum of all demands col-

lected on the CVR may not exceed the vehicle total

capacity C +C

(the truck and trailer capacity, respec-

tively), and a subtour cannot exceed the remaining

pure truck capacity, which is C units when the truck

leaves the depot. It is important to note that current

models in the literature assume that at the parking

places, the transported commodities can be trans-

ferred between the truck and the trailer. This is not

possible in our model because of the heterogeneous

milk types.

Unlike a complete vehicle, a pure truck is always

able to service both customer types. Its corresponding

route is called a pure truck route (PTR); it starts and

ends at the depot, does not include any subtours, and

is limited by the pure truck capacity C.

Figure 1 illustrates a tour in which a complete vehi-

cle starts from the depot with a complete vehicle and

visits customers A, B, and C with the trailer; then, at

a parking area, the trailer is uncoupled and the truck

serves a subset of customers in areas that are inacces-

sible to complete vehicles, forming a subtour (dashed

arcs). When the pure truck reaches the parking area

again, the trailer is reattached and the complete vehi-

cle goes back to the depot to complete its tour.

Depot

Parking area

A

B

C

Figure 1: A TTRP solution is shown.

In general, the TTRPs objective is to nd routes

that minimize the total travel cost or time, respecting

the aforementioned constraints, with a possible limi-

tation on the tour length. Solving the TTRP can also

include nding the optimal number of subtours and

the location of the parking places for complete vehicle

routes.

Because farms at which milk is collected are often

small and inaccessible by complete vehicles, milk col-

lection is an important application of the TTRP. Dairy

companies that collect milk are interested mainly in

two cost components: the cost of transport and the

cost of paying the farmers for the milk. Hence, to

maintain the same marginal prot, any increase in

the price paid to the farmers must be balanced by a

reduction in the cost of collecting the milk. Therefore,

optimizing transport cost can allow the company to

pay a higher milk price to farmers, thus attracting

higher volumes and possibly producing economies of

scale in collecting milk (Butler et al. 2005).

This paper presents our experience as opera-

tions researchers in a real milk collection problem.

ASSO.LA.C. collects milk from farmers (we use the

terms customer and farmer synonymously) who live

in different towns and moves it from each produc-

tion site to a central warehouse. It uses a eet of tank

trucks to collect milk (Figure 2). Unlike milk collec-

tion problems studied in the literature, the company

must collect different milk types; when milk of a par-

ticular type has been transferred into a compartment,

that compartment cannot be used to hold milk of a

different type until it has been sanitized and cleaned

at the central warehouse at the end of the day. This

constraint renders the studied milk collection problem

a generalization of the TTRP.

Furthermore, in the problem we consider, pure

trucks and trailers have heterogeneous capacities;

thus, it can be interpreted as a generalization of the

heterogeneous VRP (HVRP), which we denote as het-

erogeneous milk collection with heterogeneous eet

(HMCHF). Baldacci et al. (2008) provide a recent sur-

vey on the HVRP.

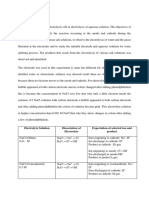

Milk collection consists of multiple tasks: (1) milk

selection based on milk quality, (2) a prerefrigera-

tion process of the selected milk, (3) transfer of milk

into a tank by means of pumps capable of loading

1.1 tons in ve minutes, and (4) writing of a report to

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

132 Interfaces 40(2), pp. 130143, 2010 INFORMS

Figure 2: A milk collection tank truck consists of different compartments, each characterized by its capacity.

record information about the milk type and the quan-

tity picked up.

The collected milk is transported to the central

warehouse for inspection. As a tank truck arrives at

the warehouse, a member of a quality control unit

draws samples of the milk to check the correctness of

the information in the report. If a milk sample fails

the quality inspection, the milk is rejected, and the

rejection is reported to the corresponding farmer. The

truck tank is weighed each time a compartment is

emptied to determine the exact quantity of each milk

type collected. This information is important to the

quality control unit, which must determine a price for

each milk type.

In our HMCHF problem, we consider the following

set of operational constraints:

each node in the network can be a loading point

or a parking area,

the tank truck cannot contain a load greater than

its capacity,

multiple tank trucks can pick up milk from a par-

ticular farmer,

the time required for a tour cannot exceed the

work shift,

only one milk type can be assigned to a

compartment.

We propose a multistart optimization approach

based on two mathematical formulations and a local

search that exploits such formulations. The two math-

ematical formulations minimize the size of the eet

and the total route length, respectively. This is one of

the strengths of our approach, because state-of-the-art

milk collection approaches do not consider the num-

ber of vehicles used to service clients.

Milk Collection Problem Review

In this section, we review previous decision support

system (DSS) work on the milk collection problem.

For example, Sankaran and Ubgade (1994) proposed

and implemented CARS, a DSS that utilizes route

construction heuristics for an instance with about 70

milk collection centers in Etah, India. Butler et al.

(2005) showed how a DSS integrated with a geo-

graphic information system allows a scheduler to

interact with route optimization algorithms. Claassen

and Hendriks (2007) studied the development of a

pilot DSS for collecting goats milk and proposed an

operations research (OR)-based approach to support

the milk collection.

For information on algorithmic contributions to

the milk collection problem, we refer the reader to

Butler et al. (1997), Basnet et al. (1999), and Hoff

and Lkketangen (2007). Butler et al. (1997) proposed

to solve the problem for a dairy farm in Dublin,

Ireland by using an extension of the symmetric travel-

ling salesman problem. Basnet et al. (1999) presented

an exact algorithm for a milk-tanker scheduling and

sequencing problem. They modeled a joint problem

of scheduling and sequencing as a linear integer pro-

gram with some nonlinear constraints and solved it

as a real problem for the New Zealand dairy industry;

they also present a fast heuristic algorithm.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 133

Hoff and Lkketangen (2007) modeled the milk col-

lection problem as a TTRP and proposed a solution

algorithm based on tabu search. We also modeled our

milk collection problem as a TTRP. However, because

our problem involves tank trucks with multiple com-

partments and a heterogeneous eet of vehicles, we

developed a generalized TTRP model.

To solve the TTRP, Chao (2002) proposed a method

based on mathematical programming and local search,

Scheuerer (2006) dened two construction heuristics

and a tabu search approach, and Tan et al. (2006)

developed an evolutionary algorithm to cope with the

truck and trailer routing with two objective functions,

i.e., the number of trucks and the routing cost.

In the literature (Chao 2002), mathematical formu-

lation-based approaches for the TTRP dene a gen-

eralized assignment problem (Fisher and Jaikumar

1981) that assigns vehicles to customers with the goal

of minimizing the total distance that trucks travel.

They next nd an optimal solution to the linear relax-

ation of the generalized assignment formulation, and

by exploiting some theoretical arguments (Chao et al.

1995 show details), they round it to produce a pos-

sibly infeasible solution that rst undergoes heuristic

route construction, and then they apply an improve-

ment process.

In this paper, we propose an approach that rst

solves the farmer route assignment problem (FRAP)

assigning farmers to vehicles (each vehicle denes

a route) without considering the sequence in which

farmers are visited. The FRAPs goal is to minimize

the number of trucks used, satisfying the capacity

and demand constraints. Given a FRAP solution, the

route denition problem (RDP), which determines the

routes, is solved.

Unlike state-of-the-art approaches, the FRAP is not

followed directly by a route construction heuristic; the

RDP accomplishes this task. However, the RDP can

fail to nd feasible routes. Thereby, the proposed local

search (1) retrieves feasibility and (2) allows the de-

nition of proper constraints to be added to the formu-

lations to diversify solutions and possibly nd better

solutions.

Another novelty of our proposed approach lies in

its iterative mechanism that permits information to be

tunneled from(to) the FRAP and the RDP to (from) the

heuristic solutions. Furthermore, the FRAP minimizes

the number of vehicles; competing approaches, how-

ever, minimize distance travelled, which we address

as the objective of the RDP.

Milk Collection with Incompatibility

Constraints

Proposed Approach

In this section, we present the strategy we adopted to

solve the HMCHF problem heuristically.

Assume a graph G = (S {s

0

], ) with vertex set

S {s

0

] and arc set . The special vertex s

0

represents

the depot, where m trucks and m

trailers are parked.

The trucks and trailers are considered homogeneous

with capacity C and C

, respectively. Each vertex s

i

S

corresponds to a customer i with a demand d

i

0.

A cost c

i

is associated with each arc (s

i

, s

), which

represents the nonnegative travel time or distance

from vertex s

i

to vertex s

.

Our approach relies on the solutions of the two

mathematical formulations associated with the FRAP

and the RDP, respectively. The latter are extensively

reported in Appendices A and B.

In the FRAP, one is concerned with assigning farm-

ers to vehicles (each vehicle denes a route) consider-

ing capacity, demand, and milk-type constraints, and

neglecting the tour-length constraint. In particular, let

=

1

2

be the eet of trucks, where

1

is the set of

complete vehicles and

2

is the set of pure trucks; the

FRAP constraints are as follows.

1. For farmer s and milk type , the farmer demand

Q

s

must be satised.

2. If a positive amount of milk type is loaded in

compartment | of tank truck i, milk type is assigned

to compartment | of tank truck i, and this quantity

must not be larger than the capacity c

i|

of compart-

ment | of tank truck i.

3. At least one truck must serve each farmer.

4. Complete vehicles must visit at least one farmer

s S

|r

(this prohibits the undesirable assignment of a

complete vehicle to a set of hard-to-access farmers).

5. If a certain quantity of a milk type is loaded from

farmer s in a tank truck i, then tank truck i serves

farmer s.

6. At most, one milk type per compartment is

allowed.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

134 Interfaces 40(2), pp. 130143, 2010 INFORMS

The FRAP objective function is to minimize the

number of tank trucks used. Given the FRAP solu-

tion, the RDP denes a route for each vehicle with

the objective of minimizing the cumulative tour dura-

tion. Let

be the number of routes dened by the

FRAP, and let S

i

, with i =1, . . . ,

, be the collection

of subsets of farmers assigned to each vehicle i .

Let S

i

be the set of customers served by truck and

trailer, and let S

i

be the set of customers served by

truck only.

The RDP formulation works on the

routes by

separately solving (for each vehicle) a relaxation of

the traveling salesman problem. More specically, if

i is a tour associated with a pure truck, then S

i

=S

i

.

The RDP constraints ensure that (1) a tour must start

and nish at the warehouse, and (2) if a tank truck

arrives at a farmer site, it must leave this site (ow

conservation constraints).

If tour i is associated with a complete vehicle, then

the related RDP constraints are split up into two

subsets of constraints, one for S

i

and the other for S

i

.

The rationale for dividing the RDP constraints related

to i into two parts is that a complete vehicle, unlike

a pure truck, must leave the trailer when it serves

farmers belonging to S

.|

; therefore, the correspond-

ing tour must be formed by the proper composition

of subtours with farmers belonging to S

|r

and S

.|

,

respectively.

The RDP objective function is to minimize the total

preparation time and transportation time of all the

tank trucks. The preparation time includes the time

needed for milk analysis, report writing, and pump

connection.

It is important to point out that the RDP for-

mulation might have the following two drawbacks,

which the heuristic functionalities discussed next

address:

1. The minimization of the total tour time might

return a duration for some tours that exceeds the time

T allowed for a working shift.

2. Subtours might be present.

The proposed heuristic has two main blocks,

PHASE I and PHASE II, and is based on the res-

olution of the FRAP and the RDP, respectively. We

refer to a complete execution of both PHASE I and

PHASE II as an iteration of the heuristic.

PHASE I calculates the optimal solution of the FRAP

formulation by obtaining the subset of farmers to be

served by each tank truck, respecting demand and

capacity constraints. However, because this assign-

ment might not be feasible with respect to the max-

imum duration of a tour, PHASE II of the algorithm

veries this by solving the RDP formulation.

Let us examine how the heuristic works depending

on the solution found by the RDP, concentrating on a

generic vehicle i.

1. Vehicle i is a pure truck. If the solution is a unique

tour, then the algorithm terminates; otherwise, the

algorithm tries to dene a feasible solution by execut-

ing an edge-insertion routine. Its goal is to join each

subtour to the warehouse, if necessary, by inserting

the cheapest edges and deleting the heaviest ones.

More formally, this routine, for each subtour i that

does not include the warehouse (node s

0

), inserts the

cheapest edges {s

0

, s] and { s, s], where s is a farmer in

subtour i, s is a neighbor of s, and s is a neighbor of

s

0

. Finally, it deletes edges {s

0

, s] and ( s, s). Figure 3

illustrates a solution of the RDP model.

2. Vehicle i is a complete vehicle. For each tour, the

RDP formulation works with farmers from S

|r

and

S

.|

. A feasible tour for the TTRP requires a main tour

of the CVR and a number of subtours, each starting

from a farmer of the main tour. Therefore, if the solu-

tion to the RDP related to farmers in S

|r

is a unique

tour, this is the main tour of the CVR. Otherwise, to

obtain such a main tour, the algorithm executes the

insertion routine. When the main tour of the CVR

has been dened, the least-cost edge-insertion routine

is invoked again to link each subtour to a farmer in

the main tour, thus obtaining a feasible solution. Such

farmers represent the parking areas of the complete

Warehouse

Warehouse

Figure 3: The schematic illustrates the insertion routine. The left section

shows an RDP model solution with two subtours; one includes the ware-

house, the other does not. The right section shows a solution obtained by

applying the insertion routine.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 135

vehicle tour. It is trivial that, if S

i

= for tour i, the

main tour of the CVR is a feasible solution for i.

In the proposed methodology, we do not permit the

possibility of visiting s S

|r

on the subtours that visit

hard-to-access farmers in S

.|

.

If the solution obtained is such that time limit T is

obeyed for each tour, then the algorithm stops; oth-

erwise, PHASE I is run again with a limitation on

the number of farmers to be serviced by tank trucks.

Formally, if

l

is the subset of tours violating the max-

imum shift duration allowed at the end of iteration l,

at iteration l +1 the FRAP formulation is solved with

the following additional constraints:

sS

z

is

]

i

(l) 1, i

l

, (1)

where ]

i

(l) is the number of farmers assigned to tank

truck i by PHASE I at iteration l, and z

is

is a binary

variable that equals 1 if tank truck i services farmer s

and is zero otherwise.

The restart mechanism diversies the solutions. To

provide counterbalancing, the algorithm tries to build

a new solution at l +1 by not completely varying the

number of farmers assigned to each tour by the FRAP

at iteration l. It accomplishes this as follows: if

l

is

the set of nonempty feasible tours at iteration l, the

FRAP formulation at iteration l +1 is solved with the

additional constraints:

sS

z

is

]

i

(l), i

l

. (2)

To avoid cycling while trying to regain feasibility

i.e., to prevent PHASE I from returning the same solu-

tion on two alternating iterations, e.g., l 1 and l +1

a tabu list in the algorithmis implemented. The assign-

ment of farmers to routes at iterations l 1 and l is

compared, and those farmers on route i at l 1 but not

on route i at iteration l, are marked as tabu to avoid

having a farmer return to route i at an immediate iter-

ation. Therefore, a tabu farmer-tour matrix must be

maintained; its generic entry (s, i) represents the num-

ber of iterations for which farmer s cannot be assigned

to tour i in the optimal solution of the FRAP in PHASE

I. Note that if at iteration l an entry (s, i) of the tabu

matrix is greater than zero, then variable z

is

is forced

to be zero in the solution of the FRAP at iteration l +1.

For example, let us assume that tour i has farm-

ers {1, 2, 5, 10] assigned at iteration 1 and farmers

{1, 2, 3, 4] assigned at iteration 2. Then farmers 5 and

10 are marked as tabu; i.e., they are not allowed to

return to tour i for number of iterations. In our

case study, we notice that must be very small, e.g.,

{2, 3], compared with tenures of tabu search algo-

rithms for other combinatorial optimization problems.

It is worth noting that by imposing constraints (1)

and (2), the solution of PHASE I could become infea-

sible with respect to the capacity constraints. In this

case, the right sides of constraints (1) are increased

by one, the right sides of constraints (2) are decreased

by one, and PHASE I is solved again to retrieve fea-

sibility. This is done iteratively until a feasible solu-

tion is found. We note that the tabu list prevents

cycling among solutions during the search for a fea-

sible solution.

The algorithm is stopped if the last 10 iterations

provide no solution improvement. Table 1 shows the

steps of the proposed algorithm.

Ensure: A set of tours respecting demand, capacity, tour duration, and

milk-type constraints.

Initialization

1: l =1;

2: l

l

=;

3:

l

l

=;

Main loop

4: while not stopping rule do

5: PHASE I: Solve the FRAP mathematical formulation,

adding constraints (1)(2) if l >1;

6: while PHASE I is infeasible do

7: Increase the right sides of constraints (1) by 1, and

decrease the right sides of constraints (2) by 1;

8: Solve the FRAP mathematical formulation,

adding constraints (1)(2);

9: end while

10: PHASE II: Solve the RDP formulation by using for each tour

the farmers assigned by PHASE I;

11: Possibly apply the edge-insertion routine

to retrieve a feasible tour;

12: if the stopping criterion is met then

13: STOP;

14: else

15: Dene sets l

l

and

l

l

;

16: Dene constraints (1) and (2);

17: Update farmer-tour entries of the tabu matrix;

18: Set variables z

is

=0 if farmer s is tabu for tour i.

19: end if

20: end while

Table 1: This table lists the algorithm steps.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

136 Interfaces 40(2), pp. 130143, 2010 INFORMS

Experimental Analysis and

Comparison with Prior Process

In this section, we compare the solution we obtained

using our algorithm with the companys prior opera-

tional process. We implemented our algorithm using

the C language and the mathematical models using

the AMPL language; we also used the solver CPLEX

7.0 (http://www.ilog.com). The C code and the AMPL

implementation were run on a PC Pentium IV with

2.8 GHz and 512 MB of RAM.

Case Study Data

ASSO.LA.C. collects milk from 158 farmers in four

towns in Calabria, a region located in southern Italy.

The towns are Cosenza (80), Catanzaro (8.7), Vibo

Valentia (6.6), and Crotone (4.7) (see Figure 4); the

number following each town represents the per-

centage of the 158 farmers who live in that town.

The companys main warehouse is in the city of

Castrovillari.

Figure 4: This map shows where ASSO.LA.C. collects milk; circles in-

dicate the four towns in which farmers live and the companys main

warehouse.

Truck Trailer No. of Capacity of

ID vehicle Capacity capacity capacity compartments compartments

0l

1

150 75 75 4 37.5/37.5/37.5/37.5

0l

2

150 75 75 4 37.5/37.5/37.5/37.5

0l

3

310 140 170 5 80/60/50/60/60

0l

4

310 130 180 3 130/130/50

0l

5

150 75 75 4 37.5/37.5/37.5/37.5

Table 2: This complete vehicle characteristics table shows capacities

expressed in quintals.

The milk types are denoted as high-quality,

standard-quality, sanitary-prescription, and origin-

protected milk. The eet comprises complete vehicles

and pure trucks. Table 2 shows complete vehi-

cle characteristics, and Table 3 shows pure truck

characteristics.

Tables 47 show the case studys main demand

nodes; note that to decrease the problem size to

improve tractability, we aggregated farmers closer

than two kilometers in a single node with a demand

equal to the sum of the demands of the clus-

tered nodes. The Complete vehicle column indi-

cates whether a complete vehicle can access the farm,

thereby indicating hard-to-access farms.

Finally, we assume that the preparation time |

s

is

known a priori for each farmer s and that the work

shift for drivers is eight hours.

Case Study Computational Results

The computational results demonstrate that the pro-

posed algorithm can provide tours such that the tank

trucks start their tours from Castrovillari and come

back to Castrovillari within the work shift. We used

No. of Capacity of

ID vehicle Capacity compartments compartments

F!

1

140 3 46.7/46.7/46.7

F!

2

140 3 46.7/46.7/46.7

F!

3

130 3 43.5/43.5/43.5

F!

4

105 3 37.37/31

F!

5

60 3 20/20/20

F!

6

60 3 20/20/20

F!

7

40 3 13.35/13.35/13.35

F!

8

110 3 37/37/36

Table 3: This pure vehicle characteristics table shows capacities

expressed in quintals.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 137

Node City Complete vehicle High quality Standard quality Sanitary prescription Origin protected

1 Castrovillari (1) Yes 20.94 8

2 Castrovillari (2) Yes 8.55

3 Francavilla Marittima Yes 2.8

4 Spezzano Albanese Yes 7.03

5 San Lorenzo (1) No 12.61 22.43

6 San Lorenzo (2) No 5.8 7.87

7 Terranova da Sibari (1) No 5.05 4

8 Terranova da Sibari (2) No 2.62 1.6

9 Cassano allo Ionio Yes 2.6 33.48

10 Tarsia (1) Yes 10.77

11 Tarsia (2) No 3.75 2.4

12 Altomonte No 4.35 2.9

13 San Sosti No 8.4

14 Malvito No 3.76

15 Roggiano Gravina No 13.53

16 San Marco Argentano Yes 10.4

17 Cerzeto No 58.33

18 Santa Soa DEpiro No 2.5

19 Bisignano No 20 1.2

20 Luzzi (1) No 26.3 12.72

21 Luzzi (2) No 8.6

22 Lattarico No 8.2 6.62

23 San Vincenzo la Costa No 1.75

24 Montalto (1) No 12.2 1.6 12.67 6.45

25 Montalto (2) No 8.1 8.9

26 Castiglione Cosentino No 7.2

27 Rende (1) Yes 12.04 23.9

28 Rende (2) Yes 15.87 12.8

29 Cosenza (1) Yes 19.36

30 Cosenza (2) Yes 52.6 11.9

31 Carolei No 4.7 3

32 Celico (1) No 3.89 6.1

33 Celico (2) No 14.65

34 Spezzano Sila No 11 3.8 2.4

35 San Giovanni in Fiore Yes 20.9

36 Corigliano Yes 71.93

37 Rossano Yes 62.5

38 Paludi No 39.28

39 Crosia No 2

40 Calopezzati No 6.46

Table 4: The demand data for Cosenza are shown.

three complete vehicles, CV

1

, CV

2

, and CV

4

, to serve

farmers in Crotone, Vibo Valentia, and Catanzaro

areas that provide easy access to farmers. CV

1

and

CV

2

serve Crotone and Vibo Valentia. CV

4

is the

only vehicle that can be used to serve farmers in

Catanzaro to ensure that the working-shift duration

is not exceeded.

The algorithm uses all eight pure trucks to collect

milk from farmers in Cosenza. Note that the average

lling ratio, i.e., the average ratio between the load of

a truck and its capacity, is 95 percent.

To complete the study, we computed the distance

that each vehicle travelled and the transportation

cost (Table 8). ASSO.LA.C. provided both direct and

indirect transportation costs. We used 1,189 seconds

and 20 iterations to nd the solution.

Table 9 shows details of the proposed algorithms

performance. To show the effectiveness of constraints

(1) and (2) in the proposed method, we report the

results we achieved using three implementations of

the algorithm. The rst implementation (Both in

Table 9) considers constraints (1) and (2), the second

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

138 Interfaces 40(2), pp. 130143, 2010 INFORMS

Complete High Standard Sanitary Origin

Node City vehicle quality quality prescription protected

1 Catanzaro Yes 4.65

2 Lamezia Terme Yes 76.72 43.2

Table 5: The demand data for Catanzaro are shown.

Complete High Standard Sanitary Origin

Node City vehicle quality quality prescription protected

3 Crotone Yes 15.45

4 Crucoli No 15.11

5 Cutro Yes 4.76

6 Isola Capo Rizzuto Yes 30.58

7 Roccabernarda No 32.21

8 Scandale No 12.39

Table 6: The demand data for Crotone are shown.

Complete High Standard Sanitary Origin

Node City vehicle quality quality prescription protected

9 Vibo Valentia Yes 115.31 2

10 Cir Marina Yes 15.1

Table 7: The demand data for Vibo Valentia are shown.

(None) does not implement constraints (1) or (2),

and the third (Only (1)) uses only constraints (1).

For each iteration l in Table 9, we list (1) the num-

ber of tours obtained from PHASE I, (2) the total

tour length from PHASE II, (3) the fullment of the

maximum shift duration for each tour (yes means

that all the tours respect the maximum shift duration

allowed and no means that at least one tour has

a length greater than T ), and (4) the average tight-

ness of constraints (1) and (2), computed, respectively,

as

i

l

sluc|

i

,

l

and

i

l

surplus

i

,

l

, where sluc|

i

is the slack variable of constraint i

l

and surplus

i

is the surplus variable of constraint i

l

. The algo-

rithm takes advantage of both constraints to produce

a better-quality solution.

Figure 5 shows the cost trend (j axis indicates the

cost of the solution in euros) over different values

(x axis). As we mentioned in the previous section,

the algorithm reaches its best solution when the value

of is very small; e.g., = 2 ( is the number of

iterations within which a given farmer cannot belong

to a given tour).

Distance travelled Transportation cost

ID vehicle (km/day) (euro/day)

0l

1

275 103

0l

2

282 106

0l

4

274 114

F!

1

186 84

F!

2

198 86

F!

3

176 83

F!

4

166 81

F!

5

135 77

F!

6

135 76

F!

7

141 79

F!

8

158 81

Total 2,126 667

Table 8: The data in this table illustrate case study results for our opti-

mized solution.

To show the improvements that the proposed

method produced, Table 10 reports how ASSO.LA.C.

operated prior to implementing our optimization

method; it uses the same parameters as Table 8 to

provide a fair comparison.

Note that the prior solution used 12 vehicles; our

optimized solution used 11 vehicles (it did not use

complete vehicle CV

3

), thus implying that the FRAP

objective function makes a difference. In the prior

solution, the daily transportation cost was 1,100 euros

and the trucks travelled 2,484 km.

Comparing values in Tables 8 and 10, we see that

the dairy company attained a reduction of about

14.4 percent in the total distance that the tank trucks

600

700

800

900

1 2 3 4 5 6

Figure 5: The graph illustrates solution cost varying , values. The y axis

indicates the cost in euros of the solution over different , values reported

in the x axis; , is the number of iterations within which a given farmer

cannot belong to a given tour.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 139

Constraints No. of tours Total tour length Fullment of the maximum Average tightness Average tightness

Iterations (1) and (2) in PHASE I in PHASE II (km) shift duration for each tour of constraints (1) of constraints (2)

1 Both 10 2,268 No

None 10 2,268 No

Only (1) 10 2,268 No

2 Both 11 2,156 No 1.00 0.00

None 11 2,212 No

Only (1) 11 2,178 No 0.25

3 Both 12 2,148 Yes 0.67 0.00

None 11 2,178 No

Only (1) 12 2,154 Yes 0.33

4 Both 13 2,132 Yes 0.00

None 11 2,184 No

Only (1) 12 2,144 Yes

5 Both 11

2,209 No 0.00

None 12 2,144 Yes

Only (1) 11 2,182 No

6 Both 11 2,198 No 0.33 0.00

None 12 2,154 Yes

Only (1) 11 2,192 No 0.00

7 Both 11 2,172 No 0.00 0.00

None 11 2,182 No

Only (1) 12

2,158 Yes 0.33

8 Both 12 2,154 Yes 0.33 0.00

None 11 2,192 No

Only (1) 12 2,148 Yes

9 Both 13 2,132 Yes 0.00

None 11 2,209 No

Only (1) 11 2,160 No

10 Both 11

2,126 Yes 0.00

None 12 2,172 Yes

Only (1) 11 2,178 No 0.00

11 Both 12 2,138 Yes 0.00

None 12 2,174 Yes

Only (1) 11 2,202 No 0.00

12 Both 11 2,146 No 0.67

None 11 2,178 No

Only (1) 12 2,172 Yes 0.33

13 Both 12 2,178 Yes 0.25 0.00

None 11 2,186 No

Only (1) 12 2,162 Yes

14 Both 12 2,198 No 0.00

None 11 2,192 No

Only (1) 12 2,158 Yes

15 Both 12 2,176 No 0.25 0.00

None 11 2,184 No

Only (1)

16 Both 12 2,174 Yes 0.25 0.00

None

Only (1)

Table 9: The data in this table show behavior of different implementations of the proposed algorithm. Note that

the asterisk means that at least one infeasibility in PHASE I has been met; i.e., the algorithm entered into the

while cycle at Step 6 (Table 1).

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

140 Interfaces 40(2), pp. 130143, 2010 INFORMS

Constraints No. of tours Total tour length Fullment of the maximum Average tightness Average tightness

Iterations (1) and (2) in PHASE I in PHASE II (km) shift duration for each tour of constraints (1) of constraints (2)

17 Both 11 2,248 No 0.70

None

Only (1)

18 Both 11 2,202 No 0.50 0.57

None

Only (1)

19 Both 11 2,189 No 0.50 0.57

None

Only (1)

20 Both 12 2,152 Yes 0.75 0.00

None

Only (1)

Table 9: Continued.

covered. Furthermore, the average lling ratio of the

tank trucks, which represented 85 percent in the com-

panys prior solution, was 95 percent for our opti-

mized solution.

These costs imply that our proposed approach

produces a yearly transportation cost savings of

156,000 euros and an additional cost reduction of

about 10,000 euros (because of using one less truck

and its constituent devices installed to monitor the

temperature of the milk during transport). Reduc-

ing transportation cost by 166,000 euros in our 158-

farmer case study is proportional to the cost savings

described by Butler et al. (2005), in which an Irish

Distance travelled Transp. cost

ID vehicle (km/day) (euro/day)

0l

1

260 100

0l

2

334 118

0l

3

260 112

0l

4

245 100

F!

1

192 86

F!

2

210 89

F!

3

180 84

F!

4

163 80

F!

5

155 82

F!

6

153 80

F!

7

155 82

F!

8

177 87

Total 2, 484 1, 100

Table 10: The data in this table illustrate case study results for the prior

solution.

dairy company with about 800 farmers reduced its

annual costs by 635,000 euros.

Summary

This paper studies a problem faced by an Italian dairy

company that collects milk from farmers. We mod-

eled the problem as a generalization of the TTRP and

show how OR techniques improved the companys

performance.

The problem has specic constraintsfarmers pro-

duce different types of milk, and each tank truck

must have different compartments to hold these dif-

ferent milk types; this imposes the limitation that

at most one milk type can be assigned to a tank-truck

compartment. We propose an optimization approach

based on the joint use of mathematical programming

and local search, present experiments we performed

as part of the case study, and compare the perfor-

mance of our proposed method with the process that

the company used prior to implementing our pro-

posal. The results show that our process results in cost

savings of approximately 166,000 euros per year.

Appendix A. The Farmer Route

Assignment Problem Formulation

Let

i be tank truck i in eet ;

eet =

1

2

, where

1

is the set of complete

vehicles and

2

is the set of pure trucks;

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 141

) be milk type in the milk-type set ) ;

s, s

S, be farmers s and s

in the set S of

farmers;

set S of farmers be split into S

|r

and S

.|

, with S

|r

as the set of farmers reachable by complete vehicles

and S

.|

reachable by pure trucks only;

| K

i

be compartment | in tank truck i;

K

i

=K

i

K

i

, where K

i

is the set of compartments

on the truck component of complete vehicle i and K

i

is the set of compartments on the trailer component

of complete vehicle i;

Q

s

, be the amount of milk type associated with

farmer s; and

c

i|

, be the capacity of compartment | in tank

truck i.

We dene a (real) variable j

i|s

0, which is asso-

ciated with the quantity of milk type loaded in

compartment | of tank truck i from farmer s. Vari-

able j

i|s

> 0 means that tank truck i had to load a

certain quantity of milk type from farmer s. We

then dene a binary variable z

is

to keep track of this

farmer; i.e.,

z

is

=

1 if tank truck i serves farmer s,

0 otherwise.

In addition, x

i|

and

i

denote two binary variables

such that

x

i|

=

1 if milk type is assigned to

compartment | of tank truck i,

0 otherwise,

i

=

1 if tank truck i is used,

0 otherwise.

Therefore, the overall formulation of the FRAP is

min

|K

i

j

i|s

=Q

s

) , s S, (A1)

sS

j

i|s

c

i|

x

i|

i , ) , | K

i

, (A2)

i

z

is

1 s S, (A3)

sS

|r

z

is

i

i

1

, (A4)

j

i|s

z

is

c

i|

i , | K

i

, ) , s S, (A5)

sS

z

is

i

S i , (A6)

)

x

i|

1 i , | K

i

, (A7)

j

i|s

=0 i

1

, | K

i

, ) , s S

.|

(A8)

x

i|

{0, 1] i , | K

i

, )

j

i|s

+

i , | K

i

, ) , s S

i

{0, 1] i .

Constraints (A1) say that for farmer s and milk

type , demand Q

s

must be satised. Constraints (A2)

impose the restriction that if a positive amount of

milk type is loaded in compartment | of tank truck

i, then x

i|

= 1; i.e., milk type is assigned to com-

partment | of tank truck i, and this quantity must

not be larger than the capacity c

i|

of compartment |

of tank truck i. Constraints (A3) mean that at least

one truck must serve each farmer. Constraints (A4)

state that complete vehicles (if utilized) must visit

at least one farmer in S

|r

. Constraints (A5) establish

that if a certain quantity of a milk type is loaded from

farmer s in a tank truck i (i.e., j

i|s

0), then tank

truck i serves farmer s; i.e., z

is

= 1. Inequalities (A6)

are strictly related to the objective function. Indeed,

when at least one customer is assigned to vehicle i,

then

i

must equal one and contributes to the value

of the objective. Constraints (A7) are the milk-type

incompatibility constraints. Recall that by constraints

(A2), if the quantity

sS

j

i|s

of milk type loaded

in compartment | of tank truck i is greater than zero,

the binary variable x

i|

is forced to assume a value

equal to one. The FRAP formulation is completed by

constraints (A8), which ascertain that milk cannot be

transferred between the truck and trailer because of

the existence of varying milk types.

Appendix B. The Route Denition

Problem Formulation

Let .

iss

be a binary variable, which is dened for each

tank truck i and for each farmer s and s

. We have

.

iss

=

1 if tank truck i travels from s to s

,

0 otherwise.

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

142 Interfaces 40(2), pp. 130143, 2010 INFORMS

Let Succ(s) and Prcd(s) be the set of successors and

predecessors, respectively, of farmer s. Starting from

the denitions of S

i

and S

i

, we can dene the RDP

constraints separately for each tour i. In particular, if

i is a tour associated with a pure truck, then the RDP

constraints are

sSucc(s

0

)S

i

.

is

0

s

=1 i , (B1)

sPrcd(s

0

)S

i

.

iss

0

=1 i , (B2)

Succ(s)S

i

.

iss

=1 i , s S

i

, (B3)

Prcd(s)S

i

.

is

s

=1 i , s S

i

. (B4)

Constraints (B1) and (B2) say that a tour must start

and nish at warehouse s

0

. Constraints (B3) and (B4)

are ow-conservation laws; i.e., if a tank truck arrives

at a farmer site, it must leave this site.

As we discussed in the Milk Collection with Incom-

patibility Constraints section, if tour i is associated with

a complete vehicle, then the RDP constraints split up

into two subsets, one related to S

i

obtained by replac-

ing S

i

with S

i

in constraints (B1)(B4) and the other

related to S

i

dened by constraints (B3)(B4) in which

S

i

is replaced by S

i

.

The objective function of RDP takes the following

form:

min

sS

z

is

|

s

+

sS

S

d

ss

.

iss

.

This equation comprises two parts; the rst is

the total preparation time, i.e., the time needed for

the milk analysis, writing the report, and connect-

ing pumps to tanks. For this rst part, we must con-

sider which tank truck serves which farmer. If tank

truck i serves farmer s, then z

is

is equal to one. When

this happens, we consider the contribution given by

the preparation time |

s

of farmer s. Summing up the

total number of farmers, we have the total prepa-

ration time. Note that this contribution depends on

the number of tank trucks that services a certain

client.

The second part refers to the transportation time.

When .

iss

=1, then tank truck i serves both farmers

s and s

. Summing all the farmers, multiplying by the

distance d

ss

between s and s

, and dividing by the

average truck speed ., we obtain the total transporta-

tion time.

Acknowledgments

We thank the anonymous referees for their valuable sug-

gestions and the ASSO.LA.C. Dairy Company for its kind

collaboration in this research project.

References

Baldacci, R., M. Battarra, D. Vigo. 2008. Routing a heterogeneous

eet of vehicles. B. Golden, S. Raghavan, E. Wasil, eds. The

Vehicle Routing Problem: Latest Advances and New Challenges.

Springer, Heidelberg, Germany, 328.

Basnet, C., L. R. Foulds, J. M. Wilson. 1999. An exact algorithm for

a milk tanker scheduling and sequencing problem. Ann. Oper.

Res. 86 559568.

Butler, M., P. Herlihy, P. B. Keenan. 2005. Integrating information

technology and operational research in the management of

milk collection. J. Food Engrg. 70(3) 341349.

Butler, M., H. P. Williams, L.-A. Yarrow. 1997. The two-period trav-

elling salesman problem applied to milk collection. Comput.

Optim. Appl. 7(3) 291306.

Chao, I.-M. 2002. A tabu search method for the truck and trailer

routing problem. Comput. Oper. Res. 29(1) 3351.

Chao, I. M., B. L. Golden, E. A. Wasil. 1995. An improved heuristic

for the period vehicle routing. Networks 26(1) 2544.

Claassen, G. D. H., T. Hendriks. 2007. An application of special

ordered sets to a periodic milk collection problem. Eur. J. Oper.

Res. 180(2) 754769.

Cordeau, J. F., M. Gendreau, G. Laporte, J. Y. Potvin, F. Semet. 2000.

Classical and modern heuristics for the vehicle routing prob-

lem. Internat. Trans. Oper. Res. 7 285300.

Cordeau, J. F., M. Gendreau, G. Laporte, J. Y. Potvin, F. Semet. 2002.

A guide to vehicle routing heuristics. J. Oper. Res. Soc. 53(5)

512522.

Fisher, M. L., R. Jaikumar. 1981. A generalized assignment heuristic

for vehicle routing. Networks 11(2) 109124.

Hoff, A., A. Lkketangen. 2007. A tabu search approach for

milk collection in western Norway using trucks and trailers.

Proc. Sixth Triennial Sympos. Transportation Anal. (TRISTAN VI),

Phuket Island, Thailand.

Sankaran, J. K, R. R. Ubgade. 1994. Routing tankers for dairy milk

pickup. Interfaces 24(5) 5966.

Scheuerer, S. 2006. A tabu search heuristic for the truck and trailer

routing problem. Comput. Oper. Res. 33(4) 894909.

Tan, K. C., Y. H. Chew, L. H. Lee. 2006. A hybrid multi-objective

evolutionary algorithm for solving truck and trailer vehicle

routing problems. Eur. J. Oper. Res. 172(3) 855885.

Toth, P., D. Vigo, eds. 2002. The Vehicle Routing Problem. SIAM

Monographs on Discrete Mathematics and Applications,

Philadelphia.

Camillo Nola, Chief Executive Ofcer, ASSO.LA.C.

Societ Cooperativa Agricola, Contrada Ciparsia,

87012 Castrovillari (CS), Italy, writes: I certify that

Caramia and Guerriero: Milk Collection Problem with Incompatibility Constraints

Interfaces 40(2), pp. 130143, 2010 INFORMS 143

in 2005, the ASSOLAC dairy company, Castrovil-

lari (CS) Italy, in collaboration with the Faculty of

Engineering, University of Calabria, Italy, initiated a

project to minimize routing costs deriving from milk

collection while also improving the number of cus-

tomers to be serviced: it is well known that optimiz-

ing transport cost can allow the company to pay a

higher milk price to farmers, thus attracting higher vol-

umes. The method based on mathematical program-

ming and local search heuristic proposed has signif-

icantly improved the overall transportation cost and

also the number of vehicles employed in servicing the

current clients; therefore, this clearly enables the sec-

ond objective of enlarging the set of customers.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Library System Case StudyDocument55 pagesLibrary System Case StudyUmakanth Nune50% (6)

- As Statistics Mechanics 1Document240 pagesAs Statistics Mechanics 1claire zhouNo ratings yet

- SQL Injection Attack Detection and Preve PDFDocument12 pagesSQL Injection Attack Detection and Preve PDFPramono PramonoNo ratings yet

- MOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doDocument2 pagesMOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doĐặng Trung AnhNo ratings yet

- Model SRX-101A: Operation ManualDocument31 pagesModel SRX-101A: Operation ManualSebastian SamolewskiNo ratings yet

- SSC JE Mechanical Study Material Strength of Materials PDFDocument13 pagesSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahNo ratings yet

- Drum RudimentsDocument4 pagesDrum Rudimentsmaame nyarkoaNo ratings yet

- Astrology, Believe It or Not - OCRDocument155 pagesAstrology, Believe It or Not - OCRShashwat Singh Pokharel100% (2)

- Basic Research Approaches and Designs - An Overview - Amoud - 2020Document18 pagesBasic Research Approaches and Designs - An Overview - Amoud - 2020Haaji CommandoNo ratings yet

- Criteria Cogni+Ve Ap+Tude Style Free Test: AssessmentdayDocument15 pagesCriteria Cogni+Ve Ap+Tude Style Free Test: AssessmentdayRahul SharmaNo ratings yet

- Chemistry Investigatory File Handmade NewDocument17 pagesChemistry Investigatory File Handmade NewMadhusudan PeriwalNo ratings yet

- Nob Tool CatalogueDocument2 pagesNob Tool CatalogueFoton y JacNo ratings yet

- A Review On Promethee and Analytic Hierarchy Process With Its ApplicationDocument7 pagesA Review On Promethee and Analytic Hierarchy Process With Its Applicationkherrouf YOUNESNo ratings yet

- CS250 LCD Keypad User Manual: GE InterlogixDocument32 pagesCS250 LCD Keypad User Manual: GE InterlogixpttnpttnNo ratings yet

- CRC Csharp and Game Programming 2nd Edition 1138428108Document530 pagesCRC Csharp and Game Programming 2nd Edition 1138428108harimotoNo ratings yet

- Module 6 The HypothesisDocument14 pagesModule 6 The HypothesisJester Guballa de LeonNo ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- Grundfosliterature 5439390Document108 pagesGrundfosliterature 5439390ptlNo ratings yet

- Study of Types of Storage and Handling Methods of HydrogenDocument82 pagesStudy of Types of Storage and Handling Methods of Hydrogens9kktqnvb9No ratings yet

- Carbon FibreDocument25 pagesCarbon Fibrejagadish.kvNo ratings yet

- Qualcomm Snapdragon 660 Mobile Platform Product BriefDocument2 pagesQualcomm Snapdragon 660 Mobile Platform Product BriefTuxInfoNo ratings yet

- Math Let Reviewer 44 Analytic GeometryDocument3 pagesMath Let Reviewer 44 Analytic Geometryjohn johnNo ratings yet

- Data Communication & Computer NetworksDocument32 pagesData Communication & Computer NetworksMuhammad NadeemNo ratings yet

- Grade 4 Maths 1Document4 pagesGrade 4 Maths 1tmunyonho18No ratings yet

- Endothermic Reactions Absorb HeatDocument2 pagesEndothermic Reactions Absorb HeatRista WaniNo ratings yet

- CB Climbing Bracket PERIDocument52 pagesCB Climbing Bracket PERINathan FryerNo ratings yet

- Indigenous Microorganisms Production and The Effect On Composting ProcessDocument5 pagesIndigenous Microorganisms Production and The Effect On Composting ProcessAldrin Baquilid FernandezNo ratings yet

- Emphatic Struct and InversionDocument11 pagesEmphatic Struct and InversionMaria Veronica BustosNo ratings yet

- Alili M S PDFDocument20 pagesAlili M S PDFStatsitika ITNo ratings yet

- EEE415 Digital Image Processing: Frequency Domain FilteringDocument50 pagesEEE415 Digital Image Processing: Frequency Domain FilteringFAISAL NAWABNo ratings yet