Professional Documents

Culture Documents

MIP Thickener Design

Uploaded by

Hatem SalahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIP Thickener Design

Uploaded by

Hatem SalahCopyright:

Available Formats

MIP Thickener Design The following is a short cut to designing your own thickener: (a) Size of Thickener As a first

stab we can either use the thickener flux (m2/tpd) or the rise rate, depending if solids loading is the dominant (eg. Platinum Tailings) or feed flow rate (e.g. Clarification or low feed solids). Say, we have a coal tailings application and testwork shows a rise rate of 2 m/h with a pulp feed flow rate of 100 m3/h. Thus, Rise Rate = Pulp Flow Rate Area 4 D2 Pulp Flow Rate Rise Rate

Thus, Area

= = 11.3

Use 12m diameter (b) Torque requirement In order to select the drive we need to calculate the torque required. A factor (Z-Factor) is used based on the following: Material type Particle size distribution Size range Thickener type Underflow density required Rheology

So, you need to check with clever process guys at MIP before using a value!! Now, T = Torque Where T D = = = Z x D2 Max operating torque in ft. lbs Thickener diameter in feet

Typical Z Factors are: Light duty: Medium duty: Heavy duty: Extra heavy duty: 5 - 10 10 - 20 20 - 35 > 35

Therefore for a 12m diameter high rate thickener with the coal tailings duty,we can use medium duty (Z-Factor of 15) Note: T orque = = = 15 x (12 x 3.281)2 23 252 x 1.35 Nm 31 390 Nm 1m = 3.281ft. 1ft.lb = 1.35 Nm

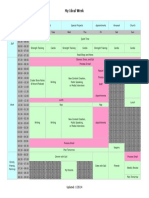

From the MIP range of gearboxes, (below), we would select a RR2500, with a maximum Torque value of 36 000 Nm. MIP PROCESS TECHNOLOGIES THICKENER GEARBOX TABLE

Gearbox Type

RR70 RR120 RR220 RR320 RR520 RR620 RR820 RR1200 RR1800 RR2500 RR3200 RR5200 RR6500 RR8000 RR15000 RR20000 RR25000 RR30000 RR40000 RR55000 RR65000 Thus, actual K-factor = 17.1

Installed Torque (Nm)

1 200 2 000 2 500 5 500 7 000 8 500 14 500 17 500 24 000 36 000 45 000 62 000 105 000 155 000 300 000 330 000 420 000 460 000 720 000 900 000 1 300 000

(c) Gearbox output speed We generally operate at a thickener rake speed of 8 to 12m/min Thus gearbox output rpm = = rake tip speed (m/min) x diameter (m) 8 X 12

0.21 rpm

(d) Electric motor sizing To size an electric motor, we would use the following calculation;

2NT 60 x E x 1000

N = Actual Gearbox output speed rpm T = Trip torque (Nm) E = Overall efficiency = 0.5 P = Power (kW)

Therefore, for our 10m thickener, P = = = 2 x TT x 0.21 x 36 000 60 x 0.5 x 1 000 1.6 kW Use 2.2 kW

We would not recommend being tight in motor selection since the price difference of being conservative in electric motor selection is minimal.

You might also like

- MIP Thickener Design-02Document3 pagesMIP Thickener Design-02Bellary SreedharNo ratings yet

- MIP Thickener Design-02Document3 pagesMIP Thickener Design-02Vedat AxNo ratings yet

- Thickener Presentation ScreenDocument10 pagesThickener Presentation ScreenArdian20100% (1)

- Design of A ThickenerDocument3 pagesDesign of A ThickenerHelenette Joy Vergara Cane100% (6)

- ThickenersDocument4 pagesThickenersmacross086No ratings yet

- 20 Years of AMIRA P266 "Improving Thickener TechnologyDocument10 pages20 Years of AMIRA P266 "Improving Thickener TechnologyKirill ZatulovskiyNo ratings yet

- Thickener Calc r2Document45 pagesThickener Calc r2Ardian20100% (1)

- Current Theory and Thickener Design PDFDocument11 pagesCurrent Theory and Thickener Design PDFMabel Ginestar100% (1)

- Sludge ThickenerDocument15 pagesSludge ThickenerDavid LambertNo ratings yet

- ChuteDesignFormulas Paper43Document11 pagesChuteDesignFormulas Paper43Martin LarochelleNo ratings yet

- 2.4m Thickener Preliminary Report Rev0Document42 pages2.4m Thickener Preliminary Report Rev0fran_osorio123No ratings yet

- Final Report - On Thickener DesigningDocument7 pagesFinal Report - On Thickener Designingaman singh50% (2)

- 4 NewThickener PDFDocument3 pages4 NewThickener PDFRogerio CannoniNo ratings yet

- MPE Chute DesignDocument24 pagesMPE Chute DesignGareth Blakey100% (2)

- Sidewinder ManualDocument162 pagesSidewinder Manualoscarjofk0% (1)

- Froth Pump Power EstimationDocument40 pagesFroth Pump Power EstimationJuan Pablo Apaza100% (3)

- Pump Calculation - SlurryDocument1 pagePump Calculation - SlurryBilly Brikz YanisNo ratings yet

- Theory and Application of Thickener Design PDFDocument7 pagesTheory and Application of Thickener Design PDFajitkk79100% (1)

- MinPro Thickening TechnologiesDocument12 pagesMinPro Thickening TechnologiescecilinauNo ratings yet

- A Filter PressDocument0 pagesA Filter Pressraneshkumar1992No ratings yet

- Chapter 13 D1 CEMA Bucket Elevator HP and CalculationsDocument4 pagesChapter 13 D1 CEMA Bucket Elevator HP and Calculationshafidh naufaldiNo ratings yet

- Engineering Design Process DevelopmentDocument4 pagesEngineering Design Process DevelopmentpixulinoNo ratings yet

- Thickeners DesignDocument28 pagesThickeners DesignhazimraadNo ratings yet

- Apron FeederDocument10 pagesApron FeederKenny Ruiz100% (1)

- Apron Feeder Power Calculations PDFDocument4 pagesApron Feeder Power Calculations PDFtuba25% (4)

- Agitator DesignDocument6 pagesAgitator Designप्रमोद रणपिसेNo ratings yet

- ScreeningDocument17 pagesScreeningGerald Lim100% (1)

- Tank Baffles Design CalcDocument8 pagesTank Baffles Design CalcJorge Alberto Martinez Ortiz100% (1)

- Beginners Guide To Thickeners - OutotecDocument7 pagesBeginners Guide To Thickeners - OutotecMauricio ToledoNo ratings yet

- The Secret To Thickener PerformanceDocument23 pagesThe Secret To Thickener PerformanceGustavNo ratings yet

- Plate and Frambhhe LAB REPORTDocument10 pagesPlate and Frambhhe LAB REPORTrossangel35No ratings yet

- Slurry Viscocity CalculationDocument3 pagesSlurry Viscocity CalculationVijay PatelNo ratings yet

- THICKENER Mechanism - Center Pier Type ManualDocument35 pagesTHICKENER Mechanism - Center Pier Type ManualAnonymous PWrmAKNo ratings yet

- Agitator Guide for Mixing and Stirring Tank ProductsDocument10 pagesAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591No ratings yet

- Apron FeederDocument12 pagesApron FeederMidDeL'OrmeNo ratings yet

- GRAVITY THICKENER OPERATIONDocument4 pagesGRAVITY THICKENER OPERATIONEllie Jane MapaNo ratings yet

- Science Raking in Gravity Thickeners PDFDocument17 pagesScience Raking in Gravity Thickeners PDFJuan Alberto Giglio FernándezNo ratings yet

- Mechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期Document1 pageMechanical Model of Scraper Rake Torque in Deep-cone Thickener - 《Journal of Central South University (Science and Technology) 》2012年04期saidNo ratings yet

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiNo ratings yet

- Hydrocyclone Data SheetDocument4 pagesHydrocyclone Data SheetHimmahSekarEagNo ratings yet

- High Rate Thickener (ENG)Document4 pagesHigh Rate Thickener (ENG)Nikhil Takbhate100% (1)

- gMAX CapacityCurves3Document1 pagegMAX CapacityCurves3kcontreras_79309No ratings yet

- Slurry Pump Sizing1Document4 pagesSlurry Pump Sizing1chennaimechNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- Screw ConveyorsDocument4 pagesScrew ConveyorsAshish SharmaNo ratings yet

- Power Requirement (Agitator and High-Torque Stirrer)Document8 pagesPower Requirement (Agitator and High-Torque Stirrer)DozdiNo ratings yet

- Slurry Piping DesignDocument11 pagesSlurry Piping DesignDipanjan ChakrabartiNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculationmpshah29860% (5)

- Shaft diameter calculation for stainless steelDocument1 pageShaft diameter calculation for stainless steelAhmad Ashshiddieqy60% (5)

- Operation Manuals of Filter PressDocument7 pagesOperation Manuals of Filter PressmichaelspivakNo ratings yet

- Agitation: Introduction To Principles and PracticeDocument44 pagesAgitation: Introduction To Principles and Practicearun89000100% (9)

- Clarifiers & ThickenersDocument8 pagesClarifiers & ThickenersIstifiarti MandasariNo ratings yet

- TutorialDocument5 pagesTutorialAbdul Razak RahmatNo ratings yet

- 3.2 Design SystemDocument48 pages3.2 Design SystemMahmoud RababahNo ratings yet

- CalculationDocument10 pagesCalculationNur SurizzaNo ratings yet

- 2 CAD Connecting Rod ForgingDocument56 pages2 CAD Connecting Rod ForgingIsrar EqubalNo ratings yet

- Date: Experiment No Beaker Decantation AIM: ρ - Density of fluidDocument66 pagesDate: Experiment No Beaker Decantation AIM: ρ - Density of fluidHEMANT RAJNo ratings yet

- EscalatorDocument10 pagesEscalatorbernabasNo ratings yet

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- Dimension and Specification Analysis of a Pedal-Powered Washing MachineDocument17 pagesDimension and Specification Analysis of a Pedal-Powered Washing MachineErwin Morales HangorNo ratings yet

- Chapter 4. CyclonesDocument17 pagesChapter 4. CyclonesHatem SalahNo ratings yet

- Chapter 4. CyclonesDocument38 pagesChapter 4. CyclonesUzair Wahid100% (1)

- Cementing Loss Circulatio SolutionsDocument32 pagesCementing Loss Circulatio SolutionsHatem SalahNo ratings yet

- H2O2 Manufacturing ProcessDocument6 pagesH2O2 Manufacturing ProcessJames YatesNo ratings yet

- Chapter 1Document19 pagesChapter 1Hatem SalahNo ratings yet

- PDF Ebook Pickle Things by Marc Brown Download BookDocument5 pagesPDF Ebook Pickle Things by Marc Brown Download BookCorissNo ratings yet

- Acha Teff ThresherDocument62 pagesAcha Teff ThresherTANKO BAKO100% (2)

- SM-800.11 TypeM Plus ValvesDocument13 pagesSM-800.11 TypeM Plus ValvesAdel AhmedNo ratings yet

- Guide to Rubber Expansion JointsDocument7 pagesGuide to Rubber Expansion JointsHu HenryNo ratings yet

- IT Act 2000 overview objectives featuresDocument3 pagesIT Act 2000 overview objectives featuresalpanshiNo ratings yet

- Project Management Book PDFDocument55 pagesProject Management Book PDFSerigne Mbaye Diop94% (16)

- Communication in AfricaDocument5 pagesCommunication in AfricaJaque TornneNo ratings yet

- 24C02BN Su18Document26 pages24C02BN Su18Dwp BhaskaranNo ratings yet

- My Ideal Week PDFDocument1 pageMy Ideal Week PDFAnonymous QE45TVC9e3No ratings yet

- OTC13998Document15 pagesOTC13998Raifel MoralesNo ratings yet

- QUICK GUIDE To Installing Oracle Database 11gR2 - PART1Document7 pagesQUICK GUIDE To Installing Oracle Database 11gR2 - PART1Peter AsanNo ratings yet

- Huffman & ShannonDocument30 pagesHuffman & ShannonDhamodharan SrinivasanNo ratings yet

- Axial Piston Pump Variable Displacement Bosch Rexroth A4VSO-1421347275Document60 pagesAxial Piston Pump Variable Displacement Bosch Rexroth A4VSO-1421347275LIVIANo ratings yet

- PBV20N2 Service Manual PDFDocument244 pagesPBV20N2 Service Manual PDFJack Norhy100% (1)

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- Gold Series Dust Collector: Installation, Operation and MaintenanceDocument85 pagesGold Series Dust Collector: Installation, Operation and MaintenanceDAVID ALFONSO CARABALLO PATIÑONo ratings yet

- Clarion Technologies: at A GlanceDocument7 pagesClarion Technologies: at A GlanceChetan PrasadNo ratings yet

- BK - Scrum and CMMIDocument132 pagesBK - Scrum and CMMIcoolgoroNo ratings yet

- Converting Urban Waste To EnergyDocument11 pagesConverting Urban Waste To EnergyDéépákNo ratings yet

- Unit 8 #10 Doppler - Effect - PPTDocument13 pagesUnit 8 #10 Doppler - Effect - PPTPrasanta NaskarNo ratings yet

- Workman GTX: Utility VehicleDocument36 pagesWorkman GTX: Utility VehicleDaniel Carrillo BarriosNo ratings yet

- Definitions of CEC2017 Benchmark Suite Final Version UpdatedDocument34 pagesDefinitions of CEC2017 Benchmark Suite Final Version Updatedpc100% (1)

- F. M. 1Document3 pagesF. M. 1Aashish PardeshiNo ratings yet

- Look at The Picture Carefully. Rearrange The Words To Form Correct SentencesDocument6 pagesLook at The Picture Carefully. Rearrange The Words To Form Correct SentencesAdy PutraNo ratings yet

- Oracle Service Procurement Advisory & ConsultingDocument22 pagesOracle Service Procurement Advisory & ConsultingPrakashNo ratings yet

- L .. Eee - .: Distribution Voltage RegulatorsDocument11 pagesL .. Eee - .: Distribution Voltage RegulatorsSirajulNo ratings yet

- Range and Angle Tracking Techniques for Moving Target EstimationDocument34 pagesRange and Angle Tracking Techniques for Moving Target Estimationmykingboody2156No ratings yet

- Torque ValuesDocument1 pageTorque ValuesfadhlidzilNo ratings yet

- Rfid Based Attendance SystemDocument16 pagesRfid Based Attendance Systemhim chauNo ratings yet

- Object-Oriented Programming Lab Manual RDocument63 pagesObject-Oriented Programming Lab Manual RKLR CETNo ratings yet