Professional Documents

Culture Documents

Packinox Catalytic Reforming

Uploaded by

zohaib_farooqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Packinox Catalytic Reforming

Uploaded by

zohaib_farooqCopyright:

Available Formats

Alfa Laval Packinox for catalytic reforming

Standard combined feed/effluent heat exchanger

make-up

Alfa Laval Packinox

Recycled Naphtha

Reformate

Alfa Laval Packinox supplied the first Standard Combined Feed/Effluent Heat Exchanger to a Catalytic Reforming Unit in 1982. Over a decade later, a report from the client congratulated Alfa Laval Packinox on the heat exchangers constant good performance and minimum maintenance requirements. In one piece of equipment, Alfa Laval Packinox large welded plate heat exchangers offer the superior efficiency of plate exchangers together with the resistance to high temperatures and pressures generally associated with Shell & Tubes. Moreover, the compact design of a single Alfa Laval Packinox can replace several tubulars, thus enhancing the impact on capex and opex by cutting installation costs and pressure drop consumption. Alfa Laval Packinox heat exchangers improve the overall economics of greenfield units, and also serve as a low cost retro-

fitting basis for debottlenecking existing units as Alfa Laval Packinox allows higher duty with lower pressure drop. No other change to the units existing equipment (compressors, heaters, etc.) is needed to obtain higher throughput and/or higher H2 production. As a result of general satisfaction with the performance of Alfa Laval Packinox Standard Combined Feed/Effluent Heat Exchangers in catalytic reforming, Alfa Laval Packinox is now considered the industry standard for CRUs and is specified by the main process licensors for both semi-regenerative and CCR units. Typical process conditions: Flow: 5 000 to 70 000 bpd (with one exchanger) Temperatures: from 80C (cold end) to 530C (hot end) Hot approach: as low as 30C or less Operating pressure: 7 to 45 bars depending on process P in exchanger: 2 to 0.7 bar

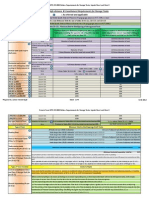

New unit case study 50 000 bpsd Continuous Catalytic Reforming Process Unit Hot End Approach Number of shells Duty Heat recovery Estimated dry weight ALFA LAVAL PACKINOX HEA = 28C 1 130 443.6 7 23.9 150,000.00 S&T HEA = 44C 4 123 419.7

MW MM Btu/h MW MM Btu/h kg

275,000.00

CAPEX Estimated equipment cost Estimated installation cost Estimated installed cost CAPEX Savings on installed heat exchanger CAPEX Savings on other installed equipment (Heater, Cooler) TOTAL CAPEX SAVINGS OPEX ENERGY SAVINGS PER YEAR: CHARGE HEATER,COMPRESSOR, EMISSIONS SAVINGS PER YEAR: Nox, Sox, GHG

$US $US $US $US $US

3,300,000 1,320,000 4,620,000 480,000 500,000 980,000

3,000,000 2,100,000 5,100,000

$US $US

3,150,000 560,000

assuming: 10.5 $US/ MM BTU, 1 Euro = 1,2 $US, GHG = 20 $US/Ton, Nox = 0,5 $US/Lb, Sox = 0,5 $US/Lb

Revamp case study from an actual catalytic reforming revamp Prior to revamp Packinox solution Naptha flow rate 15,000 b/d 20,000 b/d Arrangement 12 (2 x 6) 1 vertical horizontal S&Ts Total weight 236 tons 114 tons Total H.E. duty 82 MW Feed outlet temp. 440 C 475 C Hot approach 60 C 25 C Total pressure drop 4 bar 1.3 bar

(no new compressor needed)

In this case as in others, one Alfa Laval Packinox heat exchanger replaced 12 horizontal tubulars with no changes to the units compressor or furnaces (only new connections were required). Capacity rose by 33% at this unit where a Alfa Laval Packinox exchanger has been in service for over 12 years without major maintenance or repair operations. A report from the client furthermore says Alfa Laval Packinox improved the units energy efficiency, resulting in a reduction of SO2 emissions and a significant drop in total fuel consumption.

PPI00202EN 0705

Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval Up-to-date Alfa Laval contact details for all countries are always available on our website at www.alfalaval.com

You might also like

- Long-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryDocument2 pagesLong-Term Reliability: Unipetrol, Refinery Litvínov, Czech Republic Case StoryOsmar DiasNo ratings yet

- Catalytic Reforming: 2011 Refining Processes HandbookDocument3 pagesCatalytic Reforming: 2011 Refining Processes HandbookGaspar BlaserNo ratings yet

- PTQ Enhancing Heat TransferDocument5 pagesPTQ Enhancing Heat TransferkulaspiroNo ratings yet

- 01pa JB 2 6 PDFDocument9 pages01pa JB 2 6 PDFMarcelo Varejão CasarinNo ratings yet

- Management Corner: MILESTONE Heater Fouling ControlDocument6 pagesManagement Corner: MILESTONE Heater Fouling ControlUmer PirachaNo ratings yet

- Buell: Division ofDocument10 pagesBuell: Division ofguptadheerNo ratings yet

- Valero Emerson BlendingDocument3 pagesValero Emerson BlendingGerrard ArchuletaNo ratings yet

- Safety in Operations - Human Aspect - DorcDocument119 pagesSafety in Operations - Human Aspect - DorcAdanenche Daniel Edoh100% (1)

- Vis BreakingDocument21 pagesVis BreakingAhmed Hassan RashedNo ratings yet

- Mina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Document10 pagesMina Abdulla Refinery Experience With Atmospheric Residue Desulfurization (Ards)Owais AhmedNo ratings yet

- Conversion of Isobutylene To Propylene PDFDocument9 pagesConversion of Isobutylene To Propylene PDFtannytranNo ratings yet

- Abelmarle Referencia KF-868 PDFDocument24 pagesAbelmarle Referencia KF-868 PDFEdgar Hector GarciaNo ratings yet

- 6 UOP. Honeywel Egypt - Technologies For Distillate Production - Hydrocracking - E SvenssonDocument17 pages6 UOP. Honeywel Egypt - Technologies For Distillate Production - Hydrocracking - E SvenssonCamilo inversionesNo ratings yet

- Advanced Recycle Paraffin Isomersation TechnologyDocument8 pagesAdvanced Recycle Paraffin Isomersation TechnologytungksnbNo ratings yet

- Hydrotreater Optimization With WpheDocument29 pagesHydrotreater Optimization With Wpheandrei12320003181No ratings yet

- Shell White - VDU UpgradeDocument16 pagesShell White - VDU Upgradesachins1318No ratings yet

- Advances in The OCC Process For Propylene ProductionDocument6 pagesAdvances in The OCC Process For Propylene ProductionAngel Richard MamaniNo ratings yet

- Ethylene Tech Sheet 30M092014Hv4 PDFDocument2 pagesEthylene Tech Sheet 30M092014Hv4 PDFsuhas pawarNo ratings yet

- New Approach To Optimizing Fired HeaterDocument39 pagesNew Approach To Optimizing Fired HeaterSergio IvánNo ratings yet

- Refining CatalystsDocument91 pagesRefining CatalystsOstom Ray100% (1)

- TSPenex ProcessDocument2 pagesTSPenex Processstavros7100% (1)

- Maximise Ethylene Gain PDFDocument4 pagesMaximise Ethylene Gain PDFRaj KumarNo ratings yet

- A Financial Analysis For The Production of HQ Propylene-MustangDocument19 pagesA Financial Analysis For The Production of HQ Propylene-Mustangandrei12320003181No ratings yet

- RusBBTC2015 HALDOR TOPSOE ALEXANDRA KARYAGINA Eng PDFDocument28 pagesRusBBTC2015 HALDOR TOPSOE ALEXANDRA KARYAGINA Eng PDFlaquetengoNo ratings yet

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503No ratings yet

- Applying Chemical Cleaning 2006Document4 pagesApplying Chemical Cleaning 2006rogerh44No ratings yet

- UOP Olefin Production Solutions BrochureDocument2 pagesUOP Olefin Production Solutions BrochureJonas FloresNo ratings yet

- NGLDocument6 pagesNGLAlberto Fonseca UribeNo ratings yet

- What Is DesulfurizationDocument20 pagesWhat Is DesulfurizationYash NandurkarNo ratings yet

- Reforming Process OptimizationDocument23 pagesReforming Process OptimizationSiddharth SharmaNo ratings yet

- Options For Economical Supply of Hydrogen: Special EquipmentDocument4 pagesOptions For Economical Supply of Hydrogen: Special EquipmentsaadashfaqNo ratings yet

- Fischer Tropsch SynthesisDocument18 pagesFischer Tropsch Synthesisdeion29No ratings yet

- PDFDocument6 pagesPDFjamy862004No ratings yet

- Chapter6a Hydrotreating 170106114901 PDFDocument26 pagesChapter6a Hydrotreating 170106114901 PDFMI MNo ratings yet

- Dehydrogenation Catalyst and Reactor SynergiesDocument7 pagesDehydrogenation Catalyst and Reactor Synergiesdiego_daveNo ratings yet

- Upgrade HDK Resid HP 2008-EnglishDocument6 pagesUpgrade HDK Resid HP 2008-Englishsaleh4060No ratings yet

- UOP Maximize Propylene From Your FCC Unit Paper PDFDocument5 pagesUOP Maximize Propylene From Your FCC Unit Paper PDFCarolina GarzónNo ratings yet

- PRPC NoteDocument61 pagesPRPC NoteRohan MehtaNo ratings yet

- Catalytic Isomerization Process OptimizationDocument7 pagesCatalytic Isomerization Process Optimizationanasaie20% (1)

- Catalysts PTQ GastroH2Document4 pagesCatalysts PTQ GastroH2Wäśü RāđNo ratings yet

- RefineryWide Sim HEMag March PDFDocument3 pagesRefineryWide Sim HEMag March PDFnaraNJORNo ratings yet

- 2010 Catalysis PDFDocument60 pages2010 Catalysis PDFKevinNo ratings yet

- Towards A Zero Gasoline Refinery PTQ Parts 1 2Document15 pagesTowards A Zero Gasoline Refinery PTQ Parts 1 2Anil UpadhyaNo ratings yet

- DRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEODocument7 pagesDRI Plant Flowsheet Options: By: Gerard B. Hawkins Managing Director, CEOMohsen ArdestaniNo ratings yet

- FCC Profitability Assessment Via Advanced ModelingDocument10 pagesFCC Profitability Assessment Via Advanced Modelingsaleh4060No ratings yet

- PETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONDocument6 pagesPETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONMilan MoradiyaNo ratings yet

- Shot CokeDocument9 pagesShot CokeaminNo ratings yet

- Coking and Thermal ProcessesDocument8 pagesCoking and Thermal ProcessesWulandariNo ratings yet

- Advanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsDocument12 pagesAdvanced Catalytic Olefins ACO First Commercial Demonstration Unit Begins OperationsmakhadermfNo ratings yet

- UOP ParaxyleneDocument2 pagesUOP ParaxyleneAiza CabolesNo ratings yet

- Achieve Success in Gasoline HydrotreatingDocument6 pagesAchieve Success in Gasoline Hydrotreatingdonald55555No ratings yet

- Sintering The Main Cause of DeactivationDocument2 pagesSintering The Main Cause of DeactivationCai ZiminNo ratings yet

- Waste Incineration Heat Recovery at Roche IrelandDocument12 pagesWaste Incineration Heat Recovery at Roche IrelandidrieshamidiNo ratings yet

- Uop Unisar Process For Saturation of Aromatics: H. W. GowdyDocument8 pagesUop Unisar Process For Saturation of Aromatics: H. W. GowdyBharavi K SNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Alfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat ExchangerDocument3 pagesAlfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat Exchangerrizwan khan100% (1)

- Packinox Hydrotreating PDFDocument4 pagesPackinox Hydrotreating PDFzubair195No ratings yet

- Sr. Risk Engineer Job DescriptionDocument3 pagesSr. Risk Engineer Job Descriptionzohaib_farooqNo ratings yet

- Pig Trap SizingDocument1 pagePig Trap Sizingzohaib_farooqNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- The Galaxy Industries Production Problem - A Prototype ExampleDocument25 pagesThe Galaxy Industries Production Problem - A Prototype Examplezohaib_farooqNo ratings yet

- Election MenifestoDocument1 pageElection Menifestozohaib_farooqNo ratings yet

- HSC Frame WorkDocument5 pagesHSC Frame Workzohaib_farooqNo ratings yet

- Intro To HAZID of PipelinesDocument30 pagesIntro To HAZID of Pipelineszohaib_farooq100% (3)

- NamazDocument55 pagesNamazzohaib_farooqNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- Solving Linear Programs: The Simplex MethodDocument10 pagesSolving Linear Programs: The Simplex MethodKhalid MalikNo ratings yet

- E GN 000Document90 pagesE GN 000أصلان أصلانNo ratings yet

- HAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONDocument9 pagesHAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONzohaib_farooqNo ratings yet

- Datasheet of Monitor (Sample)Document4 pagesDatasheet of Monitor (Sample)zohaib_farooqNo ratings yet

- NFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIDocument4 pagesNFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIzohaib_farooqNo ratings yet

- Sharjeel HassanDocument2 pagesSharjeel Hassanzohaib_farooqNo ratings yet

- Mechanics of AirDocument4 pagesMechanics of Airzohaib_farooqNo ratings yet

- Ehsan Rashid InstrumentDocument1 pageEhsan Rashid Instrumentzohaib_farooqNo ratings yet

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- CryogenicDocument19 pagesCryogeniczohaib_farooq100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Factor de UnidadesDocument81 pagesFactor de Unidadesyoly10No ratings yet

- Pages From Selection and Sizing of Pressure Relief ValvesDocument1 pagePages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNo ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- ProfileDocument68 pagesProfilezohaib_farooqNo ratings yet

- Number Name Description Halal StatusDocument16 pagesNumber Name Description Halal Statuszohaib_farooqNo ratings yet

- Umm Shaif - Ppef881cDocument26 pagesUmm Shaif - Ppef881czohaib_farooqNo ratings yet

- Study Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent ReactDocument1 pageStudy Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent Reactzohaib_farooqNo ratings yet

- A Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFDocument20 pagesA Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFtiara arlettaNo ratings yet

- Refinery Process Design Notes - For IITGDocument193 pagesRefinery Process Design Notes - For IITGLakshmi Devineni100% (3)

- Prikljucci COADIS LINE PDFDocument2 pagesPrikljucci COADIS LINE PDFSlobodan BanicNo ratings yet

- TPW5 TRAINING MANUALDocument68 pagesTPW5 TRAINING MANUALClaudio Cocio JaimeNo ratings yet

- Understanding Heat PumpsDocument5 pagesUnderstanding Heat PumpsSyamim HamizanNo ratings yet

- 01 EU VRF V5X Series PDFDocument9 pages01 EU VRF V5X Series PDFMiraNo ratings yet

- Topic No. 4 CompressorsDocument13 pagesTopic No. 4 CompressorsSamarth SNo ratings yet

- Design of Atmospheric Gas BurnersDocument55 pagesDesign of Atmospheric Gas BurnersTanya BoseNo ratings yet

- STG SiemensDocument2 pagesSTG SiemensjoncperezNo ratings yet

- 3.3.2 Boiler DraughtDocument27 pages3.3.2 Boiler DraughtTitus RNo ratings yet

- Ihp w22 Model Answer Paper 22655Document15 pagesIhp w22 Model Answer Paper 22655abhishek Shinde71% (7)

- Ee2428j - Question - Part 1 - Epo622 - Feb2022Document10 pagesEe2428j - Question - Part 1 - Epo622 - Feb2022MOHD ENDRA SHAFIQNo ratings yet

- Generator performance log analysisDocument1 pageGenerator performance log analysissanjayNo ratings yet

- Turbo Generator & Exciter BHEL Haridwar: A PresentationonDocument15 pagesTurbo Generator & Exciter BHEL Haridwar: A Presentationonraspberry piNo ratings yet

- Eei Catalogue PDFDocument30 pagesEei Catalogue PDFMadhur SherawatNo ratings yet

- PH 45 ES CI Peripheral Pump: Features ApplicationDocument2 pagesPH 45 ES CI Peripheral Pump: Features ApplicationMohammad ZeeshanNo ratings yet

- Course Syllabus of Hydropower and Renewal EnergyDocument3 pagesCourse Syllabus of Hydropower and Renewal Energydrbhatta100% (1)

- IGV-Operation: Rev.: A Page: 1 / 8 Operation and Maintenance ManualDocument7 pagesIGV-Operation: Rev.: A Page: 1 / 8 Operation and Maintenance ManualredwaneNo ratings yet

- Renewable Energy and Smart Grid for Region IVDocument9 pagesRenewable Energy and Smart Grid for Region IVJaycee SimonNo ratings yet

- General Electric Systems Technology Manual Reactor Water Cleanup SystemDocument18 pagesGeneral Electric Systems Technology Manual Reactor Water Cleanup SystemZeeshan MianNo ratings yet

- Differences Between String Inverter and Central InverterDocument1 pageDifferences Between String Inverter and Central Inverterparlin71No ratings yet

- Chapter 1 - Engine Components and ClassificationDocument42 pagesChapter 1 - Engine Components and ClassificationAdib MaharunNo ratings yet

- Energy Storage For A High Penetration of RenewablesDocument10 pagesEnergy Storage For A High Penetration of RenewablesRosalind CardenasNo ratings yet

- Solar Pumping Inverter: Operation ManualDocument25 pagesSolar Pumping Inverter: Operation ManualdiegoNo ratings yet

- Seminar On Solar Power GenerationDocument17 pagesSeminar On Solar Power GenerationJasvir Singh100% (2)

- Electrical Submersible PumpDocument15 pagesElectrical Submersible PumpHussam AgabNo ratings yet

- Hisense Residential Air Conditioner 2020/2021Document11 pagesHisense Residential Air Conditioner 2020/2021Quang nguyen duyNo ratings yet

- Motor DetailsDocument2 pagesMotor DetailsDurgadatta RayNo ratings yet

- L3 Gas Power CyclesDocument78 pagesL3 Gas Power CyclesYang Woo SeongNo ratings yet

- Power Protection RelaysDocument14 pagesPower Protection RelaysRidham Patel0% (2)

- No. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Document32 pagesNo. 2 UAS Mekanika Fluida Perorangan (Hilmi Haidar Alif)Hilmi Haidar AlifNo ratings yet

- Poster A1 SGEM2018 WebDocument1 pagePoster A1 SGEM2018 Webihp4romaniaNo ratings yet