Professional Documents

Culture Documents

Carriage of Potatoes

Uploaded by

dassi99Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carriage of Potatoes

Uploaded by

dassi99Copyright:

Available Formats

Carefully to Carry

Carriage of Potatoes

The potato tuber, Solanum tuberosum L., is an annual of the Solanaceae family and originally native to South America. The edible tuber forms at the end of the underground stems or stolons of the plants and within which the starch-rich nutrients are stored. Colour together with other criteria form important characteristics for identifying the numerous varieties of potatoes: Skin colours - brown, russet, white, yellow, pink or red. Skin textures - rough or smooth. Flesh colours - white, cream, yellow, blue/purple/red or striated. Tuber shape - round, oblate, oval, or kidney shaped. Usage - table, processing or seed. Harvest time - early/new or immature, or late/mature. Potatoes are grown throughout the world, except in humid tropical lowland areas. They are one of the worlds most important food crops, and thus are an important commodity of trade. For the purposes of this article we shall refer to three basic types of potato, which are: Early/new or immature. Late/mature. Seed. All of which require special considerations for stowage and carriage. Early or new potatoes have thin, relatively loose, skins that are easily removed and are thus readily liable to damage. Over more recent years, demand for this type of potato has increased and large quantities are shipped from Cyprus, Greece, Israel, Turkey and the Canary Islands during the northern winter and spring seasons. Late/mature potatoes have firm skins and are therefore more resistant to damage and much easier to carry than immature potatoes. Seed potatoes for shipment comprise small whole tubers each with at least one eye to produce the new growth. Seed potatoes are grown under a regulated certification programme to ensure that they are as disease-free as possible.

The carrier shall properly and carefully load, handle, stow, carry, keep, care for and discharge the goods carried. Hague Rules, Articles iii, Rule 2

Carefully to Carry Advisory Committee

This report was produced by the Carefully to Carry Committee the UK P&I Clubs advisory committee on cargo matters. The aim of the Carefully to Carry Committee is to reduce claims through contemporaneous advice to the Clubs Members through the most efcient means available. The committee was established in 1961 and has produced many articles on cargoes that cause claims and other cargo related issues such as hold washing, cargo securing, and ventilation. The quality of advice given has established Carefully to Carry as a key source of guidance for shipowners and ships ofcers. In addition, the articles have frequently been the source of expertise in negotiations over the settlement of claims and have also been relied on in court hearings. In 2002 all articles were revised and published in book form as well as on disk. All articles are also available to Members on the Club website. Visit the Carefully to Carry section in the Loss Prevention area of the Club website www.ukpandi.com for more information, or contact the Loss Prevention Department.

Pre-shipment considerations

Once potatoes have been harvested they must be stored under optimal conditions until released for shipment. However no storage is able to improve the product placed therein, but much can be achieved to minimise losses.

Three basic type of potato, left to right: early/new; late/mature; seed (notice fragile "eyes" which produce new growth)

This can result from mechanical damage, either during harvesting or subsequent handling or, alternatively, can result from other forms of deterioration such as sunscald. It may also result if the tuber is subjected to wetting such that a film of water is present over its surface. Some of the principal diseases found at the time of harvesting may include Phytophthora infestans (potato blight); a dry mealy rot due to species of Fusarium (dry rot); a bacterial soft rot caused by Erwinia ssp. (black leg); or brown rot caused by the bacterium Ralstonia solanacearum and ring rot caused by the bacterium Clavibacter michiganensis subsp. sepedonicus, both of which are notifiable diseases in the UK and other countries. Post-harvest deterioration i.e. storage/stowage deterioration will normally result from the development of bacterial soft rot, usually the result of infection by Erwinia ssp. which causes collapse of the cells of the infected potatoes exuding heavily infected fluid and gives rise, by contact, to soft rot developing in adjacent tubers. Hence over a period of time the contents of whole bags may collapse to a malodorous slime. Another cause of deterioration is infestation by insects, which has been a problem since potatoes have been grown. The two most serious infestants of potato crops are the North American black and yellow striped beetle (Colorado Beetle) and the Potato Tuber Moth (Phthorimaea operculella). It is necessary for shippers or charterers to provide phytosanitary certificates, attached to the bill(s) of lading or other trade documents. These certificates are produced by the Authority of the country of origin indicating that the specified consignment(s) have been inspected or treated according to the importing country's requirements. Recent legislation The Potatoes Originating in Egypt (England) Regulations 2004 came into force on 15 May 2004. Whereas the master should be able to rely upon a valid phyto-sanitary certificate he does have a continuing duty in relation to cargo in his charge. For example, if infestation is noticed during the voyage, the master/owners must take reasonable steps to deal with the situation. Fumigation prior to berthing at an arrived port, or alternatively rejection of a cargo of potatoes as a result of infestation or infection by serious bacterial diseases, not only may cause massive delays to a vessel but also considerable additional problems for the shipowners.

High temperatures cause the tuber respiration rate to increase, whereby oxygen and food reserves are used, potentially resulting in excessive shrinkage. Freezing or chilling temperatures can damage and kill tuber cells. If the air surrounding the tubers has a low humidity then water will move from the tubers to the air, resulting in weight loss. Should the oxygen content of the air fall to a low level, cells within the tubers die and 'blackheart' forms. Sprouting is a natural function of the tuber, however, during shipment it is not desirable as, in the event, quality and condition will suffer. Sprout suppressant chemicals or other methods may be used prior to shipment to preclude sprouting but control in stowage can only be maintained by application of the correct temperature(s). Potato tuber diseases may be the result of micro-organisms or adverse preshipment storage conditions. They may also be the result of improper stowage and conditions of carriage. Potatoes are grown under the soil and, as such, when harvested will always contain on their surfaces spores of invading micro-organisms, which will attack the tubers if the natural defence mechanism is ruptured.

Signs of infestation by the Potato Tuber Moth

Potato tubers infested with Colorado Beetle

Greening may occur in any part of a tuber exposed to light. Exposure to bright light during post harvest handling, or longer periods (7 to 14 days) of low light, can result in the development of chlorophyll (greening) and bitter, toxic glycoalkaloids, such as solanine. Experts advise that whereas in cultivated varieties green discolour of the flesh does not cause substantive harm to health, it undoubtedly will, depending upon extent, result in a loss of value of consignments. Green flesh of potatoes tastes bitter and must be cut away before cooking. When presented for shipment, consignments should be inspected for external condition of the packaging. Evidence of wet patch staining of the bags, or any associated malodours, should alert crewmembers to likely problems and the vessel's P&I association should be requested to appoint an expert surveyor to investigate and ensure only healthy and undamaged potatoes are shipped. Since potatoes have been shipped in woven polypropylene bags of varying dark colours it has become extremely difficult to recognise wet patches from superficial examinations; close inspections are thus recommended. Mechanical damage is one of the most important factors affecting potato condition, since it is largely preventable. Special care is therefore essential during handling to and from the vessel, especially when immature/new potatoes are being shipped. Bags of potatoes should not be walked over or handled roughly, with special care taken if palletised units of bags are over-stowed by a second tier of pallets. In light rain, snow, or damp weather cargo must be protected from moisture to preclude the onset of premature spoilage by bacterial soft rot. Do not load or discharge potatoes during heavy rain.

Potatoes packed in large open-top lift bags

Packaging

Potatoes may be packed in hessian bags, woven polypropylene bags, sacks lined with an internal perforated polyethylene bag and sometimes cartons or crates. Various sizes of bags are utilised, however the bags will usually contain about 25 kg of tubers. A more recent innovation is to pack potatoes in large opentop lift bags weighing some two to three tonnes. New potatoes are frequently packed in moist or dry peat moss. The main purpose for including moist peat moss within the bags is to protect the 'new' tubers and to preclude skin-set and thus maintaining their value. However, excess free water or release of water from the peat moss during carriage can cause problems leading to bacterial soft rot of the tubers.

Summary

Subsequent to harvesting and prior to packing for shipment: Early or new potato tubers should be graded and sorted: without mechanical damage; sound, without disease; dry; without greening; free from adherent soil and stones; and stored at optimum temperatures. Late or mature potato tubers should, in addition to the above: be fully mature and firm skinned; have been stored for a specific post harvest period of 10 to 14 days (wound healing and curing). Seed potato tubers may, in addition to those points noted under 'early potatoes': consist of unwashed tubers and may contain loose soil and foreign material but should generally be free of caked soil.

Stowage

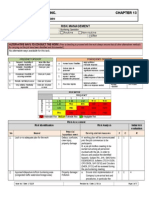

As for any product which may enter the human food chain, preparation of stowages will include ensuring that the cargo spaces are clean and dry. Potatoes are highly sensitive to odours and readily absorb foreign smells from chemicals, mineral oils, and some fruits, etc. All compartments destined for stowage of potatoes must be free from malodours and volatile substances. Potato tubers are living organisms that consume oxygen and evolve carbon dioxide, water and heat. The principal problem as far as stowage and carriage is concerned is the heat produced, and therefore good climate control is required to maintain the condition of tubers. Condensation in the form of ship or cargo sweat should not be allowed to develop during a voyage. Long voyages therefore demand more critical control than short-term voyages. An example of the heat produced by cargoes of potatoes is noted in the following table.

From these figures it is evident that new/immature potatoes produce considerably more heat per 1000 kg than late/ mature potatoes and are commensurately more difficult to carry. When potatoes are presented for loading in bags, stow heights of up to eight tiers are preferable. To ensure adequate ventilation of cargo blocks, maximum stow heights of twelve to thirteen bags should never be exceeded. The stowage must be so arranged to ensure a free flow of air throughout the compartments. Bags shipped on pallets are usually stacked to a height of eight/nine bags and are often secured to the pallet baseboards by means of nylon netting. Care must be taken, (especially when the bags are constructed of woven polyethylene) to ensure that the contents of pallets are fully and properly secured. The frictionless nature of this type of outer bag frequently results in the pallet loads becoming deformed and, in some cases, detached from the base-boards. This slippage can result in additional stevedoring costs for re-making the pallets. Slippage of woven polyethylene bags from pallets, and also when loose stowed, into ventilation channels will cause restrictions of air flow and must be prevented by the use of timber dunnage or dunnage nets.

flesh temperatures should be maintained throughout the transit period. At the time of discharge from refrigerated stowages, the cargo should ideally be landed to stores at similar temperatures to that of carriage. If cold cargoes are discharged into ambient warm humid conditions then a risk of condensation forming on the tubers may exist and bacterial soft rot will ensue. Some shippers/consignees will request the vessel to undertake a dual temperature regime during transit and require the vessel to slowly raise the temperature of the cargo, to above the anticipated ambient dew point at the discharge port, commencing some two to three days before discharge is due to commence.

Stowages in mechanically ventilated general cargo spaces

The usual system adopted is to use block stowage with air channels around each cargo block. This system relies on convection cooling. The cargo is stowed clear of the deck either by placing it on double dunnage or alternatively on pallet boards. Cargo blocks should normally not exceed 3 metres by 3 metres square. Smaller blocks may be preferred under certain circumstances; however stability of each block is critical and when loose stowed, bags must be key-stacked to construct a locking stow precluding slippage or collapse of bags into the air channels potentially causing a breakdown in the air circulation. High stows may not only cause compression damage/ bruising to the potatoes (especially new/immature tubers) but may also result in excessive heating due to metabolic processes. Bags should be stowed ideally to eight tiers in height, but never more than twelve to thirteen. The width of the air channels around the cargo blocks should be in the order of 20 to 30 cms. constructed using dunnage and/ or the locking stow noted above. Cargo should be stowed clear of transverse bulkheads and ship's sides to promote air circulation with exposed steel work protected by paper mats or other sheeting to preclude condensation damage. Potato cargoes should be kept well clear of engine room bulkheads and any other local heat source situated on the vessel. The stowage on any vessel should be designed to suit the type of permanent ventilation system fitted. Potato cargoes make heavy demands on ships' ventilation systems and a capacity of at least fifteen air changes per hour in each empty hold is required. At these rates the ventilation system

Stowages in refrigerated cargo vessels

As previously noted, not only do growing and harvesting conditions influence the post harvest/pre-shipment behaviour of potatoes but, additionally, post-harvest storage conditions are also critical to the optimum temperature requirements for their carriage. Therefore written instructions for the carriage temperature regime should always be obtained from the shippers and should be complied with throughout the voyage. Transport temperatures must be such that respiration and weight losses due to evaporation are maintained to a minimum. The approximate lowest safe temperature for the carriage of potatoes is plus 4 Celsius (39 Fahrenheit) and carriage is usually recommended at plus 4 to 5 Celsius (39 to 41 Fahrenheit) at a relative humidity of between 90 and 95%. However potatoes destined for cases, it is thus essential for shippers to provide detailed instructions and for those instructions to be rigorously followed. The exact stowage patterns adopted for potatoes will depend upon the permanent air circulation systems incorporated in a vessel. Strict supervision of cargo stowage must ensure that airflow will be evenly distributed throughout the compartments for maintenance of optimal temperature control. Detailed records of cargo compartment/

Blackheart is formed when the oxygen content of the air falls to a low level. should be run continuously except when weather and climatic conditions prevent e.g. risk of shipping water through the weatherdeck ventilators or condensation forming on the cargo or internal ship's structures. At higher rates of air changes per hour consideration should be given, especially on longer voyages, to either run the fans on lesser power (reduction of speed) or for lesser times (ventilate intermittently) in order to maintain humidity and preclude water loss from the tubers (desiccation). Details of ambient air wet and dry bulb temperatures, hold wet and dry bulb air temperatures/flesh temperatures and the ventilation regime undertaken according to the acquired data regularly obtained must be recorded in a dedicated ventilation logbook or alternatively the deck log book.

Greening occurs when tubers are exposed to brght light or long periods of low light

Transport of potatoes in ISO containers

Cargoes of potatoes may be carried in fan assisted ventilated containers, open sided containers, insulated refrigerated containers and 'port-hole' insulated containers. For voyages of a short Carriage of potatoes continued duration, closed cargo containers may be used but doors should remain open when ever possible to promote ventilation. Stowage on deck must include provisions to protect the cargo from rain, sea-spray and sunlight. Flat racks are also used for below deck stowages in wellventilated compar, provisions should be made to afford exposed bags protection against rain and sunlight prior to loading and subsequent to discharge.

Seed potatoes

Seed potatoes are usually shipped around the world in smaller consignments than those of new or mature potatoes. The value of seed potatoes is much greater than potatoes destined for consumption and special care should be taken as any loss in quality or condition will potentially result in substantial claims. They may be carried in a mechanically ventilated stowage but for longer voyages involving any prolonged period in warm climatic conditions, say in excess of 20 Celsius, they should be carried under refrigeration at a temperature of 2 to 4 Celsius.

Ro-Ro vessels

Cargoes of new/immature potatoes have for some time been shipped from Eastern Mediterranean ports in the holds of Ro-Ro vessels. Packed in woven polypropylene bags, shipped on pallet boards with bags secured by nylon nets, losses and/or additional costs have been experienced due to the displacement of bags from the pallet boards. Bearing in mind the practice of keeping the Ro-Ro deck lights illuminated throughout the voyage the problem of tuber greening has been experienced. Attempts to prevent this have included covering stowages with polythene sheets, which unfortunately reduce the effectiveness of the hold ventilation system. Hold lights should never remain continuously illuminated throughout a voyage, even of short duration.

Safety

Inadequate, or failure of, ventilation in spaces containing cargoes of potatoes can cause life threatening concentrations of carbon dioxide (CO2) or oxygen (O2) depletion to arise. Thus under these or suspected conditions the compartment(s) must be fully ventilated and a gas measurement conducted. The threshold limit value (TLV) for CO2 concentrations is 0.49 % by volume.

For further information please contact: Loss Prevention Department, Thomas Miller P&I Ltd Tel: +44 20 7204 2307. Fax +44 20 7283 6517. Email: lossprevention.ukclub@thomasmiller.com

You might also like

- New Nekima CrewDocument20 pagesNew Nekima CrewMarco AntonelliNo ratings yet

- RA 002 - BunkeringDocument5 pagesRA 002 - Bunkeringdassi99No ratings yet

- DOT TANK INSPECTION RISK ASSESSMENTDocument6 pagesDOT TANK INSPECTION RISK ASSESSMENTdassi99100% (1)

- GrowingPotato PDFDocument25 pagesGrowingPotato PDFThura Teq100% (1)

- Sweet Potato Production GuideDocument11 pagesSweet Potato Production GuideArn CruzNo ratings yet

- Food Losses During Food Processing As Food WasteDocument20 pagesFood Losses During Food Processing As Food WasteJyoti JhaNo ratings yet

- Recipe Book 1.Zp210082Document27 pagesRecipe Book 1.Zp210082tomevoNo ratings yet

- Unit II Plant Tissue CultureDocument43 pagesUnit II Plant Tissue CultureabhinavNo ratings yet

- RA 002 - HFO Line Pressure TestDocument4 pagesRA 002 - HFO Line Pressure Testdassi99100% (1)

- Bourke Street Bakery Cakes and BiscuitsDocument74 pagesBourke Street Bakery Cakes and Biscuitsbhavna100% (1)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99No ratings yet

- Postharvest Handling Definition of TermsDocument8 pagesPostharvest Handling Definition of TermsApril Ervas100% (1)

- Risk Assessment for LPSG Steam Pipe Hot Work in ERDocument6 pagesRisk Assessment for LPSG Steam Pipe Hot Work in ERdassi99No ratings yet

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Document16 pages06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- Oyster MushroomDocument8 pagesOyster MushroomJessi MysNo ratings yet

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99No ratings yet

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractDocument3 pagesThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99No ratings yet

- WISE Cargo User Manual - Ver 6 (A4)Document36 pagesWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- Vegetable Forcing - Containing Information on Greenhouse Construction, Management and Frame CultureFrom EverandVegetable Forcing - Containing Information on Greenhouse Construction, Management and Frame CultureNo ratings yet

- PG SweetPotatoDocument28 pagesPG SweetPotatoBebo Gomez BruNo ratings yet

- Practical TestDocument4 pagesPractical Testdassi99100% (1)

- Past Simple WorksheetDocument3 pagesPast Simple WorksheetBibi Petkoska100% (1)

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusDocument1 page4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- Vegetative PropagationDocument23 pagesVegetative PropagationAaron DizonNo ratings yet

- Fresh Fruit PackagingDocument19 pagesFresh Fruit PackagingjihedwardNo ratings yet

- Aflatoxins in Corn: How To Sample Corn For Aflatoxin TestingDocument4 pagesAflatoxins in Corn: How To Sample Corn For Aflatoxin TestingAnonymous t5TDwdNo ratings yet

- West of England Loss Prevention Bulletin The Carriage of Soya Beans in BulkDocument4 pagesWest of England Loss Prevention Bulletin The Carriage of Soya Beans in BulkCenk Çoban100% (1)

- Region I La Union Schools Division Office CABA NATIONAL HIGH SCHOOL Second Quarter Assessment TLE-COOKERY 9Document8 pagesRegion I La Union Schools Division Office CABA NATIONAL HIGH SCHOOL Second Quarter Assessment TLE-COOKERY 9Lordy B. PicarNo ratings yet

- All About ECDISDocument12 pagesAll About ECDISdassi99No ratings yet

- Dominos Mock Meeting ScriptDocument8 pagesDominos Mock Meeting ScriptLaiba KhanNo ratings yet

- The Potato - With Information on Varieties, Seed Selection, Cultivation and Diseases of the PotatoFrom EverandThe Potato - With Information on Varieties, Seed Selection, Cultivation and Diseases of the PotatoNo ratings yet

- Post Harvest Handling of Fruits and VegetablesDocument21 pagesPost Harvest Handling of Fruits and VegetablesGerman Antonio Aviles OrellanaNo ratings yet

- FST 505 Fruit and Vegetable ProcessingDocument43 pagesFST 505 Fruit and Vegetable Processingfadijidavid3No ratings yet

- Quality and Safety of Crops IIDocument3 pagesQuality and Safety of Crops IIMadhumita VenkateswaranNo ratings yet

- Kadija Sem. Write UpDocument13 pagesKadija Sem. Write Upbasiru abubakarNo ratings yet

- Post - Harvest Management of Mushrooms With Special Reference To Himachal PradeshDocument13 pagesPost - Harvest Management of Mushrooms With Special Reference To Himachal PradeshVinay RanaNo ratings yet

- Seed Potatoes-2024 - RevisedDocument14 pagesSeed Potatoes-2024 - Revisedapi-248973401No ratings yet

- Farm To Fork TransportDocument2 pagesFarm To Fork TransportPaula MontanariNo ratings yet

- Post-harvest losses of fruits and vegetablesDocument2 pagesPost-harvest losses of fruits and vegetablesMaan MirallesNo ratings yet

- Post Harvest Losses HorticultureDocument42 pagesPost Harvest Losses HorticultureDaguale Melaku AyeleNo ratings yet

- Agricultural Sciences Mushroom Cultivation (AGA - 453) B.Sc. (Hons.), B.Sc. Integrated MBADocument6 pagesAgricultural Sciences Mushroom Cultivation (AGA - 453) B.Sc. (Hons.), B.Sc. Integrated MBAMahendra paudel PaudelNo ratings yet

- Abiotic Factors Moisture Content: Stored Grain Deterioration by Biotic and Abiotic FactorsDocument5 pagesAbiotic Factors Moisture Content: Stored Grain Deterioration by Biotic and Abiotic FactorsMd IrfanNo ratings yet

- 2011-Microbiological Hazards and MelonsDocument33 pages2011-Microbiological Hazards and MelonsstefNo ratings yet

- Cropproductionprotocol Sugarloafpineapple EngDocument28 pagesCropproductionprotocol Sugarloafpineapple EngSeyha L. AgriFoodNo ratings yet

- Commercial Postharvest Handling of Fresh Market ApplesDocument11 pagesCommercial Postharvest Handling of Fresh Market ApplesAmira NatasyaNo ratings yet

- Grape (Table) : Scientific Name and IntroductionDocument7 pagesGrape (Table) : Scientific Name and IntroductionIonescuTeodoraNo ratings yet

- Handling Florida Vegetables - TomatoDocument6 pagesHandling Florida Vegetables - TomatoGerman Antonio Aviles OrellanaNo ratings yet

- Causes of Food Spoilage and Their PreventionDocument6 pagesCauses of Food Spoilage and Their PreventionBlack MaestroNo ratings yet

- Kentucky Pest News, May 7, 2013Document8 pagesKentucky Pest News, May 7, 2013awpmaintNo ratings yet

- Banana: Bananas Are One of The Most Widely Consumed Fruits in The World For Good ReasonDocument3 pagesBanana: Bananas Are One of The Most Widely Consumed Fruits in The World For Good ReasonSharleen MichaelaNo ratings yet

- EPP 7652webDocument2 pagesEPP 7652webmarusikamaruNo ratings yet

- Code of Practice For The Prevention and Reduction of Patulin Contamination in Apple Juice and Apple Juice Ingredients in Other BeveragesDocument6 pagesCode of Practice For The Prevention and Reduction of Patulin Contamination in Apple Juice and Apple Juice Ingredients in Other BeveragesAhmedAmer1No ratings yet

- Banana & Its ExportDocument8 pagesBanana & Its ExportsahakaranagarNo ratings yet

- Chapter 11 - Fruit Growth, Ripening and Post-Harvest PhysiologyDocument50 pagesChapter 11 - Fruit Growth, Ripening and Post-Harvest PhysiologyTikTok ZappingNo ratings yet

- Iftah PPT1Document17 pagesIftah PPT1stevenfadhiliNo ratings yet

- Philip ProjejworkDocument47 pagesPhilip ProjejworkcreedapiliNo ratings yet

- Factors Affecting Quality of Fresh ProduceDocument36 pagesFactors Affecting Quality of Fresh ProduceSuhrita ChakrabartyNo ratings yet

- Post-Harvest Handling of OrangeDocument9 pagesPost-Harvest Handling of OrangeChu BagunuNo ratings yet

- Microorganism and Food 160821Document9 pagesMicroorganism and Food 160821Fadil RezaNo ratings yet

- Demerara Brown Sugar - Farm To TableDocument10 pagesDemerara Brown Sugar - Farm To Tableakayla adolphusNo ratings yet

- Thesis On Potato DiseasesDocument6 pagesThesis On Potato Diseasessjfgexgig100% (2)

- Smo ChinDocument84 pagesSmo ChinBaracMNo ratings yet

- HRT 302 MannualDocument62 pagesHRT 302 MannualDR V S PATILNo ratings yet

- POSTHARVEST: CucumberDocument9 pagesPOSTHARVEST: CucumberChayyNo ratings yet

- Paper No.: 12 Paper Title: Food Packaging Technology Module - 14: Packaging of Food Grains and Their FloursDocument8 pagesPaper No.: 12 Paper Title: Food Packaging Technology Module - 14: Packaging of Food Grains and Their FloursM SNo ratings yet

- Factors Affecting Vegetables: Seed Storage LifeDocument19 pagesFactors Affecting Vegetables: Seed Storage Lifeism100% (2)

- Lecture Notes Handling & Transportation of F&V 1Document11 pagesLecture Notes Handling & Transportation of F&V 1Jasvir Mann100% (2)

- Lab ReportDocument4 pagesLab ReportAwais ChaudharyNo ratings yet

- Introduction to the history and importance of food packagingDocument2 pagesIntroduction to the history and importance of food packagingPatricia Belen CarrilloNo ratings yet

- 13 HRT 3002-POST HARVEST PhysiologyDocument34 pages13 HRT 3002-POST HARVEST PhysiologyGuru temp id-04 for Sekolah-8252 MoeNo ratings yet

- History of CanningDocument2 pagesHistory of CanningUjangNo ratings yet

- Packing House Operations Fruits and VegetablesDocument16 pagesPacking House Operations Fruits and Vegetablesronalit malintad0% (1)

- Potatoes: Nutritional Recommendations ForDocument44 pagesPotatoes: Nutritional Recommendations ForNik NikNo ratings yet

- Post-harvest profile and losses of Sweet potatoDocument25 pagesPost-harvest profile and losses of Sweet potatoAngelo DinNo ratings yet

- Growing Blackcurrants - With Information on Planting, Pruning, Watering, Picking and Other Aspects of Blackcurrant CultivationFrom EverandGrowing Blackcurrants - With Information on Planting, Pruning, Watering, Picking and Other Aspects of Blackcurrant CultivationNo ratings yet

- Qual 001 Supplier-Subcontractor Quality HistoryDocument1 pageQual 001 Supplier-Subcontractor Quality Historydassi99No ratings yet

- Quick Reference - EnglishDocument44 pagesQuick Reference - Englishdassi99No ratings yet

- Qual 002 Evaluation of Supplier - SubcontractorDocument1 pageQual 002 Evaluation of Supplier - Subcontractordassi99No ratings yet

- Installation Guide EnglishDocument11 pagesInstallation Guide Englishdassi99No ratings yet

- E1 - Purging & Gas Leakage Test SequencesDocument6 pagesE1 - Purging & Gas Leakage Test Sequencesdassi99No ratings yet

- Final Impa Pilot Ladder PosterDocument1 pageFinal Impa Pilot Ladder Posterdassi99No ratings yet

- Cause and Effect Diagram - HHISHI (01-LIST - 1040438Document2 pagesCause and Effect Diagram - HHISHI (01-LIST - 1040438dassi99No ratings yet

- JAN 701B HandoutsDocument22 pagesJAN 701B Handoutsdassi990% (1)

- Piezoelectricity:: Principle Knock SensorsDocument1 pagePiezoelectricity:: Principle Knock Sensorsdassi99No ratings yet

- LMAA Spring Seminar Owners' Damages for Repudiation Without Available MarketDocument16 pagesLMAA Spring Seminar Owners' Damages for Repudiation Without Available Marketdassi99No ratings yet

- Point Fortin - Umm Bab Port OptimoorDocument7 pagesPoint Fortin - Umm Bab Port Optimoordassi99No ratings yet

- DNV CertificateDocument1 pageDNV Certificatedassi99No ratings yet

- RTCM Auto Acquisition Vs Manual Guard Ring ARPADocument10 pagesRTCM Auto Acquisition Vs Manual Guard Ring ARPAdassi99No ratings yet

- Shipping Law Handbook - Part E CollisionDocument21 pagesShipping Law Handbook - Part E Collisiondassi99No ratings yet

- Gas System Double WallDocument1 pageGas System Double Walldassi99No ratings yet

- Calculating Damages by Clive AstonDocument10 pagesCalculating Damages by Clive Astondassi99100% (1)

- Winch Drum SpoolingDocument2 pagesWinch Drum Spoolingdassi99No ratings yet

- Tugas BING FDocument7 pagesTugas BING FEmilyNo ratings yet

- Patrik 1Document342 pagesPatrik 1NanoCellNo ratings yet

- Beef Supply EffortsDocument12 pagesBeef Supply EffortssucianiNo ratings yet

- Milling Catalogue - RevisedDocument20 pagesMilling Catalogue - Revisedpurchase Core CarbNo ratings yet

- Entrees MenuDocument3 pagesEntrees MenueatlocalmenusNo ratings yet

- Deskripsi Dillenia Indica LDocument17 pagesDeskripsi Dillenia Indica LEly SavitriNo ratings yet

- TillageDocument21 pagesTillageAbhilash DwivedyNo ratings yet

- Easy Baked Chicken Tacos (HOW TO VIDEO) - The Cookie RookieDocument2 pagesEasy Baked Chicken Tacos (HOW TO VIDEO) - The Cookie RookieSvetlanaNo ratings yet

- Poultry Waste Management Techniques and Environmental ImpactsDocument12 pagesPoultry Waste Management Techniques and Environmental ImpactsMahammed HasimNo ratings yet

- AGRICULTUREDocument8 pagesAGRICULTUREANKIT RAJNo ratings yet

- IkeaDocument8 pagesIkeaNirnay Prakhar100% (2)

- Fern Frond : Leaf FernsDocument2 pagesFern Frond : Leaf FernsKristine AlegradoNo ratings yet

- NUR 200 Week 4 Practice Case StudyDocument1 pageNUR 200 Week 4 Practice Case StudyHannah MarieNo ratings yet

- Experimental Studies On Drying Characteristics of Tomato in A Solar Tunnel Greenhouse DryerDocument6 pagesExperimental Studies On Drying Characteristics of Tomato in A Solar Tunnel Greenhouse DryerYared AssefaNo ratings yet

- Chippiparai Breed of Dogs in Tamil Nadu: An Assessment of Physical and Performance CharacteristicsDocument6 pagesChippiparai Breed of Dogs in Tamil Nadu: An Assessment of Physical and Performance CharacteristicsDrRameem BlochNo ratings yet

- Readin EnglishDocument15 pagesReadin EnglishlhouieNo ratings yet

- Sandpoint Residents - Sheet1Document2 pagesSandpoint Residents - Sheet1Joseph NietubiczNo ratings yet

- 676 - 22 Aloe VeraDocument5 pages676 - 22 Aloe VeraZairi ZakariaNo ratings yet

- Umbi GembiliDocument8 pagesUmbi GembiliZakaria SandyNo ratings yet

- Historic Bridge To Be Replaced: by The Rag Investigation UnitDocument20 pagesHistoric Bridge To Be Replaced: by The Rag Investigation UnitHamraki RagNo ratings yet

- K01299 - 20211018160945 - SBF3043 Chapter 3 - Digestive SystemDocument52 pagesK01299 - 20211018160945 - SBF3043 Chapter 3 - Digestive SystemChimChim UrkNo ratings yet

- 6to MODULO DE APRENDIZAJE SECOND GRADEDocument5 pages6to MODULO DE APRENDIZAJE SECOND GRADEthaily quijadaNo ratings yet

- The pros and cons of aquaponics for home food productionDocument3 pagesThe pros and cons of aquaponics for home food productionNarayanan MadhavanNo ratings yet