Professional Documents

Culture Documents

Water Vapor To Be Condensed

Uploaded by

bbmokshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Vapor To Be Condensed

Uploaded by

bbmokshCopyright:

Available Formats

Water Vapor

Water vapor can penetrate virtually any insulation system. Once inside, this vapor will condense to a liquid whenever the dew point is reached, or it will freeze. This results in a system with severely diminished thermal efficiency and a high potential for corrosion. Unfortunately, thin, easily damaged vapor retarders do not provide a satisfactory solution to water vapor migration. But, cellular glass insulation will provide maximum protection with minimum maintenance. PROBLEMS Water vapor is always present in the air, and it can be a threat to both low-temperature and hightemperature insulation systems. It makes up less than 1%, by volume, of our air, but water vapor is the only atmospheric gas that can change to a liquid or a solid under normal, ambient air temperatures. Consequently, it is also the only gas that threatens the thermal efficiency of insulation systems. With low-temperature equipment, water vapor migrates to the cold substrate behind the insulation system. Here, the vapor condenses to liquid water and can even freeze. When this happens, thermal losses increase dramatically. The insulation system may even be physically damaged as it undergoes large, dimensional changes. Vapor Transport The movement of water vapor in an insulation system is dependent upon changes in the relationship of relative humidity, temperature and vapor pressure. The actual weight of vapor per cubic foot of air at a given temperature is the air's absolute humidity. Relative humidity is the actual humidity of the air compared with absolute humidity at saturation for the same temperature. Warm air can hold more water vapor than cold air. And the temperature at which air is saturated is the dew point temperature. All gases in airof which water vapor is just a very small portioncontribute to atmospheric pressure, and the pressure exerted by each is known as its partial pressure. Vapor in unsaturated air exhibits a lower partial pressure than does vapor in saturated air, i.e., vapor pressure is proportional to relative humidity. When vapor in two adjacent bodies of air exhibits a partial pressure difference, the balancing forces of nature cause the vapor to flow from the higher to the lower pressure area. The resistance of a material to the flow of this water vapor is its permeability as measured in perm-inches (1 perm-inch = the passage of 1 grain of vapor through 1 ft. squared of 1 inch-thick material in 1 hour under a pressure difference of 1 inch of mercury). Examples of the permeabilities of some insulation materials are shown in the graph.

Transport Experiments In experiments, plastic foams have been shown to be more permeable to water pressure as the temperature gradient from one side to the other increases. This is because the water vapor pressure driving force is directly related to the temperature gradient. In the case of polyurethane, vapor intrusion reaches 20%, by volume, in 30 days with a 40F (22C) gradient. Obviously, there is a potential for massive water vapor intrusion. Other experiments have shown that the penetration of water vapor is faster and more critical than that of liquid water. For example, with polyurethane after just 20 days, vapor intrusion is >8%, by volume, while liquid penetration has peaked at 1%.

Unreliable Vapor Retarders Vapor "barriers"more correctly vapor checks or retardersonly reduce vapor flow, they cannot eliminate it. And, if damaged, they do not serve even this function. Vapor retarders are placed in direct contact with the thermal insulation, ideally on the warm side of the system. But for outdoor equipment and buildings operating in mild-to-cold environments, the "warm side" can change to the system side from the surrounding environment as the seasons change. Thus, for parts of the year, the vapor retarder is technically on the "wrong" side, retaining water vapor and increasing condensation. Because retarders for cold piping will always be on the outside surface of the insulation, they also are subject to damage by foot traffic, ladders, temperature change and weather. In addition, because retarders are usually adhered directly to insulation, any movement of the insulation also can contribute to retarder damage. Frequently, the elasticity required to maintain retarder integrity is severely compromised by aging and air pollution. Even foils, which are excellent vapor retarders, are very susceptible to puncturing and corrosion. Due to these forces, it is likely that some water vapor will eventually pass through vapor retarders, and as a result, other provisions must be made to protect insulation.

Cellular Plastic Insulations These materials will transmit water vapor in varying degrees depending upon the permeability rating of the material. The reason for any diffusion is a partial pressure difference caused by a difference in temperature or in concentration of water vapor.

When water vapor migrates in, nothing happens as long as the dew point is not reached; but water vapor turns into water when this dew point temperature is achieved. While this migration can happen very suddenly and quickly, a very long time is required for dry out. In actual service, however, conditions will probably never permit complete drying to occur. To dry something out, in all practical cases, a flow of nonsaturated air is required, and the amount of water that can be evacuated corresponds to the quantity of water vapor that can still be picked up by the circulating air. While cellular plastics' absorption of water vapor is a slow process compared with fibrous materials, a gradual increase in thermal conductivity is occurring. With polyurethane, for example, permeability to water vapor is 2000 times greater than for air. That's why one manufacturer of urethane foam states that equipment with operating temperatures cycling from below to above ambient requires flawless installation and vigilant maintenance to assure the integrity of the vapor retarder and to guard against insulation failure. In addition, they recommend that the urethane be coated immediately upon installation. Research, however, has shown that vapor permeates most coatings. In an Oakridge National Laboratory study, intermediate low- temperature applications using urethane insulationeven with a vapor retarderdeveloped ice deposits and underwent destruction of insulation integrity at the cold surface, while the warm surface appeared normal. Cellular glass was shown to be superior in this application. Phenolic foams are the most absorptive of the cellular plastics. Tests have shown that water absorption of up to 449%, by weight, can occur after 227 days of exposure. While polystyrene foams exhibit better vapor resistance than other plastic foams, at least one study has shown that extruded polystyrene used as roof insulation picked up nearly 21% moisture, by volume, primarily through vapor diffusion.

The FOAMGLAS Cellular Glass Insulation Solution

FOAMGLAS insulation offers redundant protection to water vapor intrusion, and, in the mastic-sealed joint area, it offers a vapor barrier mastic with a thickness corresponding to the applied FOAMGLAS cellular glass thickness. With FOAMGLAS insulation, virtually the entire outer surface is safe. Accidental mechanical damage to a few FOAMGLAS cells has no influence on the water vapor tightness of the system. The specification of a FOAMGLAS insulation system will provide maximum safety with minimal maintenance.

You might also like

- Rubber LiningDocument16 pagesRubber Liningbbmoksh100% (1)

- CPI MaterialsDocument263 pagesCPI Materialsbbmoksh100% (1)

- Durco® BTV-2000Valve L I N E D C H E M I C A L S E R V I C E V A L V E SDocument12 pagesDurco® BTV-2000Valve L I N E D C H E M I C A L S E R V I C E V A L V E SgullenariNo ratings yet

- Materials Selection Guide Final VersionDocument77 pagesMaterials Selection Guide Final VersionRahul ManeNo ratings yet

- Sure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsDocument8 pagesSure Seal LBF Series Lined Butterfly Valves for Demanding ApplicationsbbmokshNo ratings yet

- Modern PumpingDocument68 pagesModern Pumpingbbmoksh100% (1)

- Handling of Hydrochloric AcidDocument30 pagesHandling of Hydrochloric AcidbbmokshNo ratings yet

- Teflon LiningDocument4 pagesTeflon LiningbbmokshNo ratings yet

- Seal Selection GuideDocument89 pagesSeal Selection GuidebbmokshNo ratings yet

- Corrosion Resistant Alloys.Document8 pagesCorrosion Resistant Alloys.bbmokshNo ratings yet

- Material Selection GuideDocument0 pagesMaterial Selection GuidebbmokshNo ratings yet

- ACHE ManualDocument129 pagesACHE ManualbbmokshNo ratings yet

- Nickel Base Alloys: Aci/Astm DIN Afnor UNS OthersDocument3 pagesNickel Base Alloys: Aci/Astm DIN Afnor UNS OthersbbmokshNo ratings yet

- Valve Chemical ResistanceDocument0 pagesValve Chemical ResistancebbmokshNo ratings yet

- Material SelectionDocument4 pagesMaterial SelectionbbmokshNo ratings yet

- Sodium Hydroxide BookletDocument24 pagesSodium Hydroxide BookletbbmokshNo ratings yet

- GD ToursDocument52 pagesGD ToursbbmokshNo ratings yet

- Challenges API-Safety Relief ValvesDocument5 pagesChallenges API-Safety Relief ValvesheitorgmsNo ratings yet

- Acids HandlingDocument8 pagesAcids Handlingminhphuongpham0% (1)

- US Chemical Resistance ChartDocument18 pagesUS Chemical Resistance ChartCarlos Esaú López GómezNo ratings yet

- 10019Document12 pages10019Emir MujićNo ratings yet

- Material SelectionDocument4 pagesMaterial SelectionbbmokshNo ratings yet

- RD Combo With Relief ValvesDocument11 pagesRD Combo With Relief ValvesbbmokshNo ratings yet

- Caustic Soda ManualDocument63 pagesCaustic Soda ManualFarhan Zafar Khan100% (1)

- Safe Handling of Caustic Soda PDFDocument1 pageSafe Handling of Caustic Soda PDFStephen OgunladeNo ratings yet

- MSDS Sodium Hydroxide (50 Solution)Document11 pagesMSDS Sodium Hydroxide (50 Solution)bbmokshNo ratings yet

- APPDS Zirconium in Hydrochloric Acid ApplicationsDocument5 pagesAPPDS Zirconium in Hydrochloric Acid ApplicationsbbmokshNo ratings yet

- Corrosion Performance and Fabric Ability of The New Generation of Highly Corrosion Resistant NiCrMo AlloysDocument12 pagesCorrosion Performance and Fabric Ability of The New Generation of Highly Corrosion Resistant NiCrMo AlloysbrkmechNo ratings yet

- Valve Material Selection GuideDocument5 pagesValve Material Selection GuidekamiloktayNo ratings yet

- Castings Stainless Steel and Nickel Base 11022Document0 pagesCastings Stainless Steel and Nickel Base 11022DavindRa SoniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- K45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedDocument2 pagesK45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedCAT MINING SHOVELNo ratings yet

- Process Control FundamentalsDocument151 pagesProcess Control FundamentalsKzenette Anne RoblesNo ratings yet

- IJEDR1701019Document13 pagesIJEDR1701019ShivSagarNo ratings yet

- Baby Mait PDFDocument2 pagesBaby Mait PDFChris LuNo ratings yet

- Vibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ADocument14 pagesVibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ALiciu CiprianNo ratings yet

- Paper Machine Handbook 10580EN - TCM - 12-125114 PDFDocument214 pagesPaper Machine Handbook 10580EN - TCM - 12-125114 PDFJeffry KarundengNo ratings yet

- Aircon - Schedule of Maintenance ServiceDocument3 pagesAircon - Schedule of Maintenance ServiceesagcojrNo ratings yet

- Small Volume Prover Manual 005 To 025Document136 pagesSmall Volume Prover Manual 005 To 025anafadoNo ratings yet

- Finite Element Method: Mechanical Engineering DepartmentDocument27 pagesFinite Element Method: Mechanical Engineering DepartmentmNo ratings yet

- Mechanical SectionDocument16 pagesMechanical SectionFrancis DimeNo ratings yet

- Gad 20406510 10 En-00 PDFDocument1 pageGad 20406510 10 En-00 PDFErikikoNo ratings yet

- VENTURIMETERDocument10 pagesVENTURIMETERKrishan PrajapatiNo ratings yet

- Sumitomo HSMDocument68 pagesSumitomo HSMEdisson Yanqui VivancoNo ratings yet

- Astm Material Specifications: Group 1 MaterialsDocument4 pagesAstm Material Specifications: Group 1 Materialsabdelkader benabdallahNo ratings yet

- Flexural Strength Enhancement of Confined Reinforced Concrete ColumnsDocument8 pagesFlexural Strength Enhancement of Confined Reinforced Concrete ColumnsKunalNo ratings yet

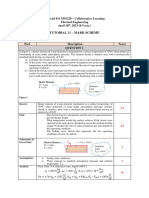

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Document6 pagesTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsNo ratings yet

- Repair Instructions - Off Vehicle: A/Trans Case AssemblyDocument94 pagesRepair Instructions - Off Vehicle: A/Trans Case AssemblyHidromaticos RNo ratings yet

- Part Number Per 1 Maret 13Document266 pagesPart Number Per 1 Maret 13Muhammad FaridNo ratings yet

- Gas Leak Detectors - RegulationsDocument1 pageGas Leak Detectors - Regulationsaneeshm91No ratings yet

- PUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Document10 pagesPUNCHING STRESS CHECK COMPARISON OF ECP203 AND ACI318Abdelhamid MaymonNo ratings yet

- Diagnositc Trouble Codes and Possible CausesDocument6 pagesDiagnositc Trouble Codes and Possible CausesJuan Carlos Sequeira Robles100% (1)

- Necchi Manuel de Service Bu-Bf Nova-Mira PDFDocument93 pagesNecchi Manuel de Service Bu-Bf Nova-Mira PDFSissyNo ratings yet

- Darshan BLDC Market Anaylsysic PDFDocument48 pagesDarshan BLDC Market Anaylsysic PDFPatidar Darshan PatelNo ratings yet

- 30/40 Models SpecificationsDocument333 pages30/40 Models SpecificationsDouglas Duarte100% (2)

- Eurotech Multiflex 545-735-835 SeriesDocument4 pagesEurotech Multiflex 545-735-835 SeriesCNC SYSTEMSNo ratings yet

- Training On Dry Fog Dust Suppression SystemDocument10 pagesTraining On Dry Fog Dust Suppression SystemPriyatham GangapatnamNo ratings yet

- W201 Wiring DiagramDocument290 pagesW201 Wiring Diagramilikemyfishbigandblue86% (44)

- Ag machineryDocument4 pagesAg machineryvinzyyNo ratings yet

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocument7 pagesA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNo ratings yet

- Edexcel GCE: Tuesday 7 June 2005 Afternoon Time: 1 Hour 30 MinutesDocument4 pagesEdexcel GCE: Tuesday 7 June 2005 Afternoon Time: 1 Hour 30 MinutesMargarita SatrakiNo ratings yet