Professional Documents

Culture Documents

2010 50

Uploaded by

sabarna1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2010 50

Uploaded by

sabarna1Copyright:

Available Formats

Extraction of Ship Product Design Data

Ernest L S Abbott1, Zhuo Liu2, David K H Chua3, and Chin Lee Lim4

Abstract

Tribon is widely used by ship designers to facilitate product modelling. However, workshop production and on-site construction process could benefit from integrating the use of Tribon design data to achieve effective process planning and production management. Tribon, while providing its own scripting language for data extraction, is not suitable for rapid extraction of data because of its complex internal database structure and of course, it requires licensed access to the Tribon software and hence, its internal database. This paper presents an extraction method to build a relational database of a block's parts and thus enable rapid access to topological data that does not require a Tribon license. Easy and rapid access to a block's topological data, augmented with production data, provides a sound foundation for improvements in productivity and production in a number of areas. Some examples of creating 3D views based on the extracted data are given for illustrative purpose.

Introduction

Tribon is not a single program, but suite of programs that access a common set of databases that contain the design details of ships or semi-submersibles. The databases contain design details, from structural elements to pipe segments to equipment. Tribon is used in 85% of the world's top 20 shipbuilders (AVEVA, 2005b) and clearly plays a significant part in the design and production process or the marine and off-shore industry. Literature review has revealed very little work on the use of Tribon data outside a Tribon environment. Published work has focused on the weaknesses of Tribon as a CAD system in the design stage (Roh & Lee, 2007), the extraction of equipment model digital data from Tribon (Hwang et al., 2004) and the exporting of Tribon model data in Autodesk's DXF format which is then imported to 3DS Max, a commercial software (Li, 2003). Besides, Kim et al. (2005) introduce a PC-based off-line programming method based Tribon interface. Zhang et al. (2009) also extract the hull structure information from Tribon for the further operational use. Li (2010) develops an open framework to integrate Trion and Spar. The use of commercial software to view a 3D model has its limitation because it is just a viewer/updater and does not provide any reasoning capabilities. Further, DXF does not hold useful engineering information such as the weight of the constituent parts or their centre of gravity. There seems to be very few commercial applications extracting data from Tribon; one should be noted, namely, Deltatools (Delta, 2010), which extracts Tribon nesting data for cutting.

Research Engineer, Dept. of Civil Engineering, National University of Singapore, 10 Kent Ridge Crescent, Singapore, 119260, (65) 65164643, FAX (65) 67791635 Email. cveaels@nus.edu.sg 2 Research Fellow, Dept. of Civil Engineering, National University of Singapore, 10 Kent Ridge Crescent, Singapore, 119260, (65) 65164643, FAX (65) 67791635 Email. cveliuz@nus.edu.sg 3 Associate Professor, Dept of Civil Engineering, National University of Singapore, 10 Kent Ridge Crescent, Singapore, 119260, (65) 65162195, FAX (65) 67791635 Email. cvedavid@nus.edu.sg, 4 Assistant Section Manager, Sembcorp Marine Technology Pte Ltd., 29 Tanjong Kling Road, Singapore, 628054 DID: (65) 6262 8010 Email. cllim@smtpl.com.sg

31

Ernest L S Abbott, Zhuo Liu, David K H Chua, and Chin Lee Lim

The purpose of this work is to design a database, which incorporates Tribon's topological data, to support various enhanced engineering functions in the production of blocks for off-shore rigs. The database design will also incorporate production data. The production data, which is clerical in input, is not held in Tribon. Specially written software is used to visualize a b l o c k s topology, using HOOPS, as its rendering engine. The visualization of a block in 3D helps the engineer to clearly identify the various block components. The specially written software is able to identify different block parts, even though they are classified as a single type in Tribon. Tribon has an object called 'Panel'; these naturally come in different sizes and, when used in a block construction, different orientations. Generally, panels, and here we are referring to blocks for offshore rigs used in a horizontal plane, are referred to as panels, by the engineers, but panels which transverse the block are referred to as bulkhead. (Definitions, 2010). Some make a further distinction of panels with flanges along one edge as T-girders. To Tribon, these are all 'panels'. Figure 1, illustrates these differences. To any commercial software that reads DXF files, they are just drawn parts. The specially written software is able to determine the difference and show the difference in a 3D view. The engineer benefits from this distinction by being able to identify the different block parts and to make decisions on the construction sequence of the block.

Figure 1. Panel, Bulkhead and T-Girder This paper describes the extent of the use of Tribon software, the object relationship Tribon exposes for data extraction, how data may be extracted from Tribon and it describes the curved panel used in Tribon. A comparison is made between the number of disk accesses required by Tribon to retrieve data and that required be a relational database to retrieve the same data. The schematic process for extracting Tribon data and creating a relational database together with the database structure is given. Finally, a simple example of the use of the created database is given.

Tribon Software

Tribon M3 software is widely used (AVEVA, 2005a) in the shipbuilding and the offshore industry for the complete process of design and construction of ships and semisubmersibles. It is the de facto standard for construction in the offshore industry. Tribon M3 in the last Tribon version. Tribon M3 is not a single program but a suite of programs that reference a common set of databases that hold the design details of the ship, or semi-submersible. This does not only include the initial design modules, but also outfitting modelling, assembly planning, piping and equipment. User access to Tribon databases and functionality is via its own scripting language, Tribon Vitesse, which is really the platform independent Python language with some additional features. Python libraries may be used along with Tribon Vitesse.

Proceedings of the 2010 International Conference on Engineering, Project, and Production Management 32

Extraction of Ship Product Design Data

Tribon Object Relationship

Tribon major identification of work is by project; within a project, there will be blocks. A block is composed of panels. All construction parts are linked to a panel, or curved panel. Objects that are associated with a panel are brackets, flanges, pillars and stiffeners. Objects that are associated with curved panels are curved stiffeners. Because of the size of the panels, they are sub-divided into plates. Figure 2, illustrates the object relationship between these parts.

Figure 2. Tribon Object Relationship

Extracting Tribon Modeling Data

Using Tribon Vitesse, modelling data may be extracted from Tribon's databases. The access methodology is basic, and unlike Structured Query Language (SQL), Conference on Data System Languages (CODASYL), compliant databases, or even Object Oriented Database Management System (OODBMS). It would probably be fair to say that Tribon database access is at entity level only. Tribon database access does not support CODASYL's currency, or any SQL functionality. It is unable to access more than one entity at a time. For example, to extract the panel weight for a specific block, one Vitesse statement specifying the specific block and panel, together with the entity 'weight', would be required. For every panel, whose weight property is required, such a statement is required. For every entity of the object Panel, such as dimensions, centre of gravity and thickness, similar statements are needed. Clearly, to be efficient in extracting data, focus needs to be on the same Block/Panel's entities, rather than attempt to extract data from different Block/Panels. Tribon does provide access to its database via a COM object and supports C#,VB.Net, VBA, C++, using the Vitesse type commands; however, tests proved that such accessing of the Tribon databases was slow when compared with using Vitesse direct. This is because every access of the Tribon database has to go via the COM object before it goes to the Vitesse process. Topological data is required for each of the objects shown in figure 2. The data consists, inter alia, of the boundary values of the object, which are the high and low values of the x, y, z coordinates of the object, the centre of gravity of the object and the thickness of the steel plate. Pillars and brackets are special cases and are defined by predefined profiles whose parameters, or profile name in the case of brackets are also extracted.

IT Applications 33

Ernest L S Abbott, Zhuo Liu, David K H Chua, and Chin Lee Lim

Tribon's panel boundary data is insufficient to enable the drawing of panels. The boundary values retrieved are simply the boundary box of the panel. The panel boundary returned by Tribon includes all objects that are associated with the panel. To draw panels correctly as panels, plate boundary data is required. There will be one set of coordinates for each point on the plate boundary; a triangular plate has 3 points, a rectangular plate has 4 points etc. Plates with curve profiles have tens of points. The extracted Tribon data is written to comma separated files for later processing.

Curved Panels

Tribon defines two kinds of panels: planar, which have been discussed, and curved panels. Curved panels are an object in their own right. Curved panels are panels that have curves in 3D space. These curves may be simple, following a simple curved profile as in figure 3, left panel, or they can be complex curving in more than one plane at a given point, as in figure 3, right panel. Tribon Vitesse allows the extraction of the curved boundary profile of the panel. Tribon identifies curve paths by name. Tribon Vitesse exposes the names, the paths (a series of coordinates) and the intersection points of the paths. This is sufficient for panels that curve in two planes, but not sufficient for panels that curve in 3 planes. Tribon holds curve data, in ACIS format, in files that are external to the Tribon database. The data in these files are not accessible via Tribon Vitesse. The details of the extraction of this data and integrating it with other Tribon Vitesse extracted data is the subject of current research. The data that Tribon Vitesse exposes allows only the profile of the panel to be drawn but not the curved surfaces.

Figure 3. Curve Panel in 2 Planes and 3 Planes

Comparison of Tribon Database Extracts and Relational Database Extract

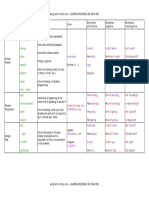

It was mentioned earlier that Tribon extracts by entity. This clearly is a slow process. To demonstrate the superiority of using a relational database approach, a comparison of database retrievals (accesses) is shown in the following tables. Each object is shown with the number of entities extracted for this research. Following this, 4 projects were chosen for their mixed nature and the number of Tribon database extracts used to retrieve the data is shown.

Proceedings of the 2010 International Conference on Engineering, Project, and Production Management 34

Extraction of Ship Product Design Data

Table 1. Number of Extracted Entities For Each Object Type

Block Panel Plate Plate Boundar y Stiffener Flange Pillar Plate Name Curve Panel Curve Panel Limits Curve Stiffener

12

14

15

11

14

Table 2. Sample Database Retrievals

Block Panel Plate Plate Boundary Stiffener Flange Pillar Plate Name Curve Panel Curve Panel Limits 3 0 0 0 Curve Stiffener Total Accesses

Entities Objects Tribon Accesses Relational Accesses

1 74 74 74

12 4137 49644 4137

9 5783 42047 5783

1 97234 97234 5738

14 8608 120512 8608

Project A 15 1830 27450 1830

11 294 3234 294

1 5783 5783 0

7 0 0 0

14 0 0 0

355978 26417

Entities Objects Tribon Accesses Relational Accesses

1 101 101 101

12 5759 69108 5759

9 8188 73692 8188

1 113819 113189 8188

14 13757 192598 13757

Project B 15 3132 46980 3132

11 119 1309 119

1 8188 8188 0

7 1928 13496 1928

3 3465 10935 3645

14 1095 15330 1095

545556 45812

Entities Objects Tribon Accesses Relational Accesses

1 64 64 64

12 2236 26832 2236

9 3033 27297 3033

1 75193 75193 3033

14 8543 119602 8543

Project C 15 1964 29460 1964

11 23 253 23

1 3033 3033 0

7 5707 39949 5707

3 7578 22734 7578

14 15053 210742 15053

555159 47234

Entities Objects Tribon Accesses Relational Accesses

1 32 32 32

12 1316 15792 1316

9 1637 14733 1637

1 33546 33546 1637

14 4229 59206 4229

Project D 15 980 14700 980

11 4 44 4

1 1637 1637 0

7 1227 8589 1227

3 2058 6174 2058

14 3445 48230 3445

202683 16565

Project Tribon Accesses/Block Relational Accesses/Block % Reduction in Accesses

Table 3. Summary of Database Accesses Sample A Sample B Sample C 4810.5 5401.5 8674.3 357.6 92.6% 454.6 91.6% 738.0 91.5%

Sample D 6333.8 517.7 91.8%

Clearly, using a tailor-made relational database reduces the number of database accesses between 91.5% and 92.6%. This is important for the engineer to have a rapid response to his enquiry experience. Tests showed that retrieving block information using Tribon and

IT Applications 35

Ernest L S Abbott, Zhuo Liu, David K H Chua, and Chin Lee Lim

writing the data to a comma separated file, averaged 1 minute a block. Times varied depending on the network load and the speed of the CPU being used.

Creating an External Database

Once data has been extracted from Tribon, it is loaded into a Microsoft Access Database, which is a relational database, see figure 4 for schematic. MS Access has been used for this research, but the system will work on any SQL compliant database.

Figure 4. Tribon Data Extraction and External Database Creation

Figure 5. Key Structure of External Database Figure 5 gives the relational database structure with the keys. The relationship is very similar to Tribon's object relationship, but it differs in that the data is organized in tables

Proceedings of the 2010 International Conference on Engineering, Project, and Production Management 36

Extraction of Ship Product Design Data

and retrieved by rows. This is the reason why a relational database significantly reduces the number of disk accesses when compared with Tribon to retrieve the same data. Unlike Tribon, different tables may be accessed simultaneously without loss of the position in a table. For example, reading the Bracket table is independent of reading the Pillar table. In Tribon, there is only one read mechanism through which all data reading is carried out. This clearly makes the relational database more flexible and easier and provides a firmer foundation for building other requirements. A few examples of research, whose details are beyond the scope of this paper, will demonstrate the usefulness of an external relational database. First, relationships between various components, such as T-girders, bulkheads, panels and stiffeners can be inferred quickly. This is useful when locating crossover points of some parts, which is required for the sighting of lifting lugs. Second, the data can be used to produce 3D views of ship's blocks, which, in itself, can has been used to show what parts are used in a block's construction in a workshop. Using the relational database gives a quick response to an engineer's enquiry. Third, it is possible to see the effects of removing sections from a construction on the block's weight and centre of gravity. Fourth, it would be possible with the addition of production data to view the status of a block construction progress. Having a relational database which is external to Tribon frees the engineer from needing a Tribon license to view block information. If, the viewing of block data was by directly using Tribon data via its COM object, that would require a license and would further put an unnecessary loading on the Tribon database. Having the external database allows unlimited access to the Tribon extracted data without any impact on Tribon's performance.

An Example of Creating and Using 3D Drawings

By way of example, figure 6 shows a block with all parts being displayed while figure 7 shows the same block without the pillars being displayed. These 3D images were produced after reading the data from the external database, intelligently identifying the various types of parts and using the HOOPS (Techsoft, 2010) rendering package, to render the result. Sometimes, for operational reasons, some parts, as in case of this example, pillars, will not be constructed with the block in the workshop. In such cases, the non-construction of some parts will have an effect on the centre of gravity and weight; it will no longer be the same as the full block. Engineers will need to calculate the new weight and centre of gravity. This may prove cumbersome as they may not always have to hand the required details, which are held in the Tribon databases. In figure 5, the centre of gravity is shown as X=1543mm, Y=1705mm, Z=1702mm; this is relative to the origin of the block. The block's local origin is determined by the lowest corner coordinates of the block. The weight of the block is shown to be 5.76 tonnes. Figure 6 shows the same block with the 2 pillars removed. As the details of weight and centre of gravity of all parts are known, a new centre of gravity and weight can be calculated. The updated centre of gravity is X=1301mm, Y=1705mm, Z=1634mm and the weight is 4.74 tonnes. The calculation of the updated centre gravity is calculated from all the shown mi ri , where R is the centre of gravity, component parts and their respective weight. R mi mi is mass of a component part and ri is its position

IT Applications 37

Ernest L S Abbott, Zhuo Liu, David K H Chua, and Chin Lee Lim

Figure 6. Block Showing All Objects

Figure 7. Block Showing Pillars Removed

Conclusion

Tribon for all its wide use as a design package for the shipping and off-shore industry does not provide reasoning capabilities per se. In order to extend the capabilities of Tribon, it is necessary to either interface with Tribon directly, but this proves to be cumbersome, too slow in terms of response time, uses additional Tribon database resources and requires a

Proceedings of the 2010 International Conference on Engineering, Project, and Production Management 38

Extraction of Ship Product Design Data

license. Two options remain, either to export data directly from Tribon in a format that is usable by other packages, e.g. export in a DXF format for use in commercial software that supports reading of files in DXF format, or to extract data and create an external database for use on tailor-made software. The option chosen here, as it supports the production of blocks and enhances the engineer's productivity, is to extract the data by directly interacting with Tribon using Vitesse and finally creating a relational database. The database becomes the foundation for intelligent use of the topological data and thus, enables suitable software support to be created that supports the engineer in his decision making.

References

AVEVA, 2005(a), http://www.aveva.com/news_content.php?_id=55 [Accessed 3 June 2010] AVEVA, 2005(b), http://www.aveva.com/news_content.php?_id=80 [Accessed 3 June 2010] Definitions. http://www.marineterms.com/cgi-bin/insearchdictionary.pl [Accessed 3 June 2010] Delta. http://www.kolumbus.fi/granbrott/luukku/index.html. [Accessed 3 June 2010] Hwang, H.J., and Lee, H.M., 2004. Digital exchange of design models between marine equipment libraries using hybrid neutral formats. Journal of Marine Science Technology 9, 182 189. Kim, C., Hong, K and Han, Y., 2005. PC-based off-line programming in the shipbuilding industry: open architecture. Advanced Robotics, 19(4), 435-458. Li, J., 2010. Framework and realization of ship product data exchange. Proceedings of the 2010 IEEE International Conference on information and Automation, Harbin, China. Li, Q., 2003. Transferring the Hull Model between TRIBON and 3DS MAX. Journal of East China Shipbuilding Institute(Natural Science Edition) 1(17), 1-4. Roh, M.I., and Lee, K.Y,, 2007. Generation of production material information for building block and simulation of block erection for process planning and scheduling in shipbuilding. International Journal of Production Research, 45(20), 4653 4683 TechSoft. 2010 http://www.techsoft3d.com/ [Accessed 3 June 2010]. Zhang, H.Q., Yang, S.L., An, Y.C., Zhao, J.J. and He, W.X., 2009. Information processing of the hull structure oriented to ship structure knowledge-type military specification. The 2nd International Conference on Interaction Sciences: Information Technology, Culture and Human, Korean.

IT Applications 39

Ernest L S Abbott, Zhuo Liu, David K H Chua, and Chin Lee Lim

Proceedings of the 2010 International Conference on Engineering, Project, and Production Management 40

You might also like

- Tutorials Page1.HtmDocument1 pageTutorials Page1.Htmsabarna1No ratings yet

- Run /nhaspx - Exe. Be Sure That "Sim Type Hasp" Is Selected 7. Run /haspx - Exe. Be Sure That Hasp Is Found 8. Enjoy 8. EnjoyDocument1 pageRun /nhaspx - Exe. Be Sure That "Sim Type Hasp" Is Selected 7. Run /haspx - Exe. Be Sure That Hasp Is Found 8. Enjoy 8. Enjoysabarna1No ratings yet

- Eng Nupas Cadmatic Modules Overview RU WEB - Ru.enDocument40 pagesEng Nupas Cadmatic Modules Overview RU WEB - Ru.ensabarna1No ratings yet

- CADMATIC Hull Structure Basic DesignDocument4 pagesCADMATIC Hull Structure Basic Designsabarna1No ratings yet

- Sto CADDocument2 pagesSto CADsabarna1No ratings yet

- SDesign ProcessDocument16 pagesSDesign ProcessYl WongNo ratings yet

- Cadmatic Hull - 01Document1 pageCadmatic Hull - 01sabarna1No ratings yet

- 06 Vedam-Animation 3D & Interior Design Services PDFDocument1 page06 Vedam-Animation 3D & Interior Design Services PDFsabarna1No ratings yet

- Aveva Marine Administration-Tips PDFDocument1 pageAveva Marine Administration-Tips PDFsabarna1No ratings yet

- Offshore Structures - Analysis and Design by Dr.S.nallayarasuDocument115 pagesOffshore Structures - Analysis and Design by Dr.S.nallayarasumariusz19781103100% (9)

- ProNest 2012 Quick Start GuideDocument5 pagesProNest 2012 Quick Start Guidesabarna1100% (1)

- TM-2107 Hull Detailed Design - Plate Nesting-Rev4.1Document75 pagesTM-2107 Hull Detailed Design - Plate Nesting-Rev4.1sabarna1No ratings yet

- GymsDocument4 pagesGymssabarna1No ratings yet

- Nestix Ship EsiteDocument4 pagesNestix Ship Esitesabarna1No ratings yet

- Dulux Colours and YouDocument52 pagesDulux Colours and Yousabarna1No ratings yet

- TEBMA KnowledgePortJune2009Document12 pagesTEBMA KnowledgePortJune2009sabarna1No ratings yet

- Aja Ship DesignDocument13 pagesAja Ship Designsabarna1No ratings yet

- Use Body Constraints and Model DimensionsDocument7 pagesUse Body Constraints and Model Dimensionssabarna1No ratings yet

- Panel 3 AVEVA Warship 2010 Robert AdamsDocument21 pagesPanel 3 AVEVA Warship 2010 Robert Adamssabarna1No ratings yet

- v1 AC5836 AllenDocument16 pagesv1 AC5836 Allensabarna1No ratings yet

- AVEVA Marine DraftingDocument2 pagesAVEVA Marine Draftingsabarna1100% (2)

- SCDocument13 pagesSCsabarna1No ratings yet

- Antiphospholipid Syndrome and Pregnancy Loss Jan 20111Document8 pagesAntiphospholipid Syndrome and Pregnancy Loss Jan 20111sabarna1No ratings yet

- Tenses Table PDFDocument5 pagesTenses Table PDFAlejandra Neira GonzálezNo ratings yet

- InstallDocument5 pagesInstallsabarna1No ratings yet

- Ts 301Document185 pagesTs 301yapsguanNo ratings yet

- Use Body Constraints and Model DimensionsDocument7 pagesUse Body Constraints and Model Dimensionssabarna1No ratings yet

- GoaDocument2 pagesGoasabarna1No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- English Grammar CohesionDocument1 pageEnglish Grammar Cohesionbutterball100% (1)

- Be The Best You. Be The Best For Your StudentsDocument16 pagesBe The Best You. Be The Best For Your StudentsPrithviraj ThakurNo ratings yet

- Thirukural (TamilEnglish)Document167 pagesThirukural (TamilEnglish)arunprasad.vit100% (5)

- openFoamUserManual PFMDocument300 pagesopenFoamUserManual PFMLuis BorrazNo ratings yet

- English 10 2nd Quarter Module 7Document24 pagesEnglish 10 2nd Quarter Module 7Jocarl CarinanNo ratings yet

- Notes On Barrier of CommunicationDocument14 pagesNotes On Barrier of Communicationteenu2783% (6)

- Assessing Learning 1 DocumentDocument19 pagesAssessing Learning 1 Documentmark Jayson marinasNo ratings yet

- Small Talk PresentationDocument14 pagesSmall Talk PresentationpratikshaNo ratings yet

- Grammar Test 1-2 TestDocument4 pagesGrammar Test 1-2 TestSimeon StaykovNo ratings yet

- Tense and TimeDocument6 pagesTense and TimeSatarupa SenNo ratings yet

- Critical Analysis of 'Two WordsDocument3 pagesCritical Analysis of 'Two Wordskay kayNo ratings yet

- NameDocument2 pagesNameenyong123123No ratings yet

- Descriptive Text About PeterDocument5 pagesDescriptive Text About PetersaraaaahNo ratings yet

- Daily Lesson Plan English Language Year 3: Click Here To Enter A DateDocument32 pagesDaily Lesson Plan English Language Year 3: Click Here To Enter A DateSITI NOR SARRAH BINTI RAMLY MoeNo ratings yet

- Rainbow of Translation: A Semiotic Approach To Intercultural Transfer of Colors in Children's Picture BooksDocument19 pagesRainbow of Translation: A Semiotic Approach To Intercultural Transfer of Colors in Children's Picture BooksMony AlmalechNo ratings yet

- Preliminary Test - Purposive Communication - 2022 2023Document8 pagesPreliminary Test - Purposive Communication - 2022 2023Sherwin Buenavente SulitNo ratings yet

- English Language Collection MandalayDocument103 pagesEnglish Language Collection MandalayNyan Lin ThetNo ratings yet

- English HL P3 Nov 2020 MemoDocument9 pagesEnglish HL P3 Nov 2020 MemoSquishy MellowNo ratings yet

- Materi Lapangan Bahasa InggrisDocument2 pagesMateri Lapangan Bahasa InggrisYogi PutraaNo ratings yet

- Organizing Professional ActivityDocument6 pagesOrganizing Professional ActivityAdrian AlîmovNo ratings yet

- CelebritiesDocument6 pagesCelebritiesmihaela165No ratings yet

- Grammar Lessons - Aleph With BethDocument106 pagesGrammar Lessons - Aleph With BethDeShaunNo ratings yet

- Amanda Landa Mechanized Bodies of AdolescenceDocument18 pagesAmanda Landa Mechanized Bodies of Adolescenceleroi77No ratings yet

- BS en Iso Iec 19788-3-2013Document40 pagesBS en Iso Iec 19788-3-2013MstefNo ratings yet

- Order of AdjectivesDocument5 pagesOrder of Adjectivestworivers100% (1)

- 40 Rohani Ilaj PDFDocument12 pages40 Rohani Ilaj PDFMuhammad TalhaNo ratings yet

- The 1,2,3,4 and Names With and Without The 1.Document2 pagesThe 1,2,3,4 and Names With and Without The 1.Maria del CarmenNo ratings yet

- Designing A CLIL Unit © Isabel Pérez Torres: - de - Bloom - PDF 985846Document2 pagesDesigning A CLIL Unit © Isabel Pérez Torres: - de - Bloom - PDF 985846angelaNo ratings yet

- INTERROGATIVE WORDS QUIZDocument12 pagesINTERROGATIVE WORDS QUIZcarmenbergsancNo ratings yet

- Marketing Resort Hotel in MauritiusDocument54 pagesMarketing Resort Hotel in MauritiusAsh Vin100% (1)