Professional Documents

Culture Documents

Checklist for manufacturing allopathic drugs layout plan approval

Uploaded by

subirmeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist for manufacturing allopathic drugs layout plan approval

Uploaded by

subirmeCopyright:

Available Formats

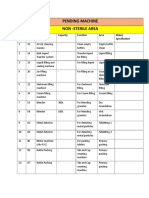

Check List for Lay out Plan Approval for Manufacturing Allopathic Drugs

Sr. No. Manufacturing Section Area Required Provided Area (As per New Sch M Req.) 30 sq.mt + 10 sq. mt Ancillary Area Other Requirement

External Preparation (Ointments, Emulsion , Creams, Lotions, Paste, Dusting Powder etc.) Liquid Orals (Syrups, Elixirs, Suspensions etc.)

Air handling system, Airlock, Air Conditioning & Air Supply through 20 Micron filler & Exhaust system

30 sq. mt + 10 sq. mt Ancillary Area

Oral Powder

Tablets. A. Granulation B. Compression C. Packing D. Coating E. Beta Lactum

Air handling system, Airlock, In primary packaging area 5micron air supply & temp .below 30 degree Celsius. 30 sq. mt Air handling system, Exhaust system, and Separate Section. For Blending. Air handling system, 60 sq. mt Dehumidifier & Air 20 sq. mt Conditioning as Anc. Area required and Suitable Exhaust system 30 sq. mt+ Cubicle for each tablet 10 sq. mt anc. machine. Separate Suitable Measures to manufacturing & avoid cross packing Section contamination, Air Area as required handing System for general tablet section Separate manufacturing & Packing Section Area as required 25 sq. mt +

F. Hypodermic Tablets

Capsule Section A General (Non

Air handling system, Airlock Exhaust

1

Harsha G:\FDA_FINAL\downloads\checklist_allo.doc

Penicillin) E. Beta Lactum Group

9 9a

C. Soft Gelatin Capsule Surgical Dressings A. Surgical Bandages (Excluding Cotton wool) B. Medicated Dressings Opthalmic Preparation (Eye ointments, Eye Lotions etc.) Pesseries & Suppositories (if manufactured by Granulation & compression area required is as per tablet section) Inhalers, Vitroli Metered inhalers Dose

10 sq. mt ancillary. 25 sq. mt + 10 sq. ancillary. 30 sq. mt

Dehumidifier & A/C Air handling system, Provisions to avoid mt Cross contamination Air handling system, A/C, Dehumidifier

30 sq. mt ) Air handling ) System 30 sq. mt 25. sq. mt + 10 sq. mt. anc. 30 sq. mt Sterile, Air conditioned Dehumidifier & Air Lock Other requirement as per Tablet section

20 sq.mt As required

Air handling system Air handling system With following subsections Change room, Container preparation bulk preparation & filling Quarantine spray testing a .Construction above this is not allowed Air handling system 5 micron air supply

10 A

Basic drugs General

30 sq. mt

Sterile

30 sq. mt

All provisions required for manufacture of

Harsha G:\FDA_FINAL\downloads\checklist_allo.doc

sterile formulation 11 Disinfectant / 30 sq. mt Phenyl 30 sq. mt Air lock Powder repacking 12 Liquid repacking 30 sq. mt Air handling system 14 Medicinal gases 30 sq. mt 15 Cotton Wool 100 sq. mt 16 Hard gelatin 75 sq. mt Air handling system capsule 17 Mechanical contraceptives a. Condoms 30 sq. mt Air handling System b. copper T 25 sq. mt Aseptic area c. Tubal rings 25 sq. mt 18 Bottle washing 15 sq. mt Air handing system Cleaning 19 Parenteral Preparations Air handling system ( Following SubEnvironmental sections are Monitoring & other required for Glass Special Provisions as containers ) per Sch M Part l A a Water management 100 sq. mt area ancillary area b Containers & 150 sq. mt for small volume closures prep. parenteral c Solution prep 150 sq.mt. ancillary d Filling capping sealing area e Sterilization f Quarantine g Visual 100 sq. mt for packing inspection material store for large h Packing area volume parietals 20 For parenteral preparation in plastic container Mfgd by FFS/BFS Technology for metered dose required As per Sch M Part I Air handling unit, Water management Environment Area monitoring Solution preparation & Special Provision Area 250 sq. mt Container moulding, 150 Ancillary Area filling & sealing Area 150 Packing material Sterilization Area stores for LVP Quarantine Area

Harsha G:\FDA_FINAL\downloads\checklist_allo.doc

20 A B C D E F 21 22

Visual inspection Area Packing Area Quality Control Chemical Testing Instrument room Microbiology Pyrogen Testing Sterility testing Animal house Office Workers room

20 sq. mt 10 sq. mt 10 sq. mt 15 sq. mt 10 sq. mt 15 sq. mt 10 sq. mt 8 sq. mt for Gents 8 sq. mt for Ladies

Air conditioned Air Lock Air handling unit LAF Air conditioned Air Lock, Air handing unit LAF Air conditioned

23

Raw material Section One/two section Three/four section More than Four section Receiving bay

a b c d

24 25 a b 26 27 a b c 28

Quarantine Raw Material Finished Goods Store

One section Each additional Section Quarantine for 10 sq. mt finished product Packing & labeling Air handling system for primary packing section one section 20 sq. mt Two section 30 sq. mt Three or more 50 sq. mt Packing Materials 75% of the area Air conditioned or air required for raw handling system as material section required.

A/C for thermolabile drugs Separate sampling 30 sq. mt area 40 sq. mt Separate area for 50 sq. mt Sampling/ As required & Dispensing & covered storing of Betalactum, cytotoxic & sex hormones 10 sq. mt A/C for the thermolabile drugs A/C for the thermolabile drugs 20 sq. mt 10 sq. mt

Harsha G:\FDA_FINAL\downloads\checklist_allo.doc

You might also like

- Mil CoatingDocument250 pagesMil Coatingparimalam100% (1)

- LEED V4 ScorecardDocument1 pageLEED V4 ScorecardsubirmeNo ratings yet

- CEA BangladeshDocument21 pagesCEA Bangladeshsubirme100% (1)

- QC TestsDocument12 pagesQC Testsembermich100% (1)

- IQ Risk AnalysisDocument1 pageIQ Risk AnalysisNadine LilleNo ratings yet

- Proposed Change Room ModificationsDocument4 pagesProposed Change Room ModificationsshdphNo ratings yet

- XYZ Tablet 20mg FCTDocument123 pagesXYZ Tablet 20mg FCTAnonymous jzlKNORNo ratings yet

- Chemical Analysis of Soft WaterDocument4 pagesChemical Analysis of Soft WaterBhawani singhNo ratings yet

- Major Machines As of Jan., 2019Document4 pagesMajor Machines As of Jan., 2019jpmaurya77No ratings yet

- Equipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreDocument1 pageEquipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreMuhammad Rizwan KhanNo ratings yet

- Unilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryDocument92 pagesUnilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryMhike EcoNo ratings yet

- S.NO EQUIPMENTS DESCRIPTION MANUFACTURERS RANGE ACCURACY REQUIREMENTSDocument8 pagesS.NO EQUIPMENTS DESCRIPTION MANUFACTURERS RANGE ACCURACY REQUIREMENTSKrishna ChaitanyaNo ratings yet

- Traveling CardDocument2 pagesTraveling CardKannan Arumugam ANo ratings yet

- Format Ahu ValDocument3 pagesFormat Ahu ValKrishna RajNo ratings yet

- Check List Regarding Documents Submitted For Drug Registration PurposesDocument8 pagesCheck List Regarding Documents Submitted For Drug Registration PurposesMayson Bali100% (1)

- Lovex RegistrDocument64 pagesLovex RegistrbishopshehadehNo ratings yet

- Siphar Bod-03-06-2011Document4 pagesSiphar Bod-03-06-2011Indra NeelNo ratings yet

- Pending Points of EngDocument7 pagesPending Points of EngAbduljabbar SayedNo ratings yet

- Non-Sterile And Sterile Equipment AreasDocument3 pagesNon-Sterile And Sterile Equipment Areasjpmaurya77No ratings yet

- Room Pressure and Airflow Specifications for Pharmaceutical FacilityDocument11 pagesRoom Pressure and Airflow Specifications for Pharmaceutical FacilityAlison LewisNo ratings yet

- Vidyabhari College chemical and equipment orderDocument11 pagesVidyabhari College chemical and equipment orderYogesh BanginwarNo ratings yet

- R.A.K. Pharma Sales Team Induction Training RecordsDocument5 pagesR.A.K. Pharma Sales Team Induction Training Recordsdebaship6529No ratings yet

- Inspection QueriesDocument3 pagesInspection Queriesmuhammad qasimNo ratings yet

- DOEH Pesticide FilesDocument20 pagesDOEH Pesticide FilesMichael_Lee_RobertsNo ratings yet

- B-Block B Iii Area Clean Room Entry & Exit Pictorial DisplayDocument24 pagesB-Block B Iii Area Clean Room Entry & Exit Pictorial DisplaySanathNo ratings yet

- Flow Chart Neozep F Exp TabletDocument4 pagesFlow Chart Neozep F Exp TabletRio FebriansyahNo ratings yet

- Bhaluka Equipment, Utilities and QC Instrument DetailsDocument15 pagesBhaluka Equipment, Utilities and QC Instrument DetailsRamboNo ratings yet

- Purified Water User PointDocument1 pagePurified Water User PointMuhammadAmdadulHoqueNo ratings yet

- 2nd Floor Ceph Area Hilton PharmaDocument1 page2nd Floor Ceph Area Hilton PharmamhmaharNo ratings yet

- Annexure - VIDocument19 pagesAnnexure - VIKiran KumarNo ratings yet

- Summary Caldece 112.8 KG NewDocument23 pagesSummary Caldece 112.8 KG NewfajarRS69No ratings yet

- GMP AyurvedaDocument3 pagesGMP AyurvedaMrprambaNo ratings yet

- Calibration of ExperimentsDocument48 pagesCalibration of ExperimentsNgocThuc LeNo ratings yet

- Related Substances of Cefipime IPDocument4 pagesRelated Substances of Cefipime IPBhawani singhNo ratings yet

- Annexure-Ii: White Film Coated Hormonal Tablet Active IngredientsDocument14 pagesAnnexure-Ii: White Film Coated Hormonal Tablet Active IngredientsGaFf ArNo ratings yet

- List of Licenses / Certificates: As Per List Attached Here WithDocument2 pagesList of Licenses / Certificates: As Per List Attached Here Withkanji63No ratings yet

- Biopharma Ltd. Product Wise COGS Report for January 2016Document406 pagesBiopharma Ltd. Product Wise COGS Report for January 2016EmranNo ratings yet

- Monthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthDocument31 pagesMonthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthFajarRachmadiNo ratings yet

- Filter IDsDocument4 pagesFilter IDsopd pharmacyNo ratings yet

- TENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletDocument2 pagesTENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletGaFf ArNo ratings yet

- Attachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)Document6 pagesAttachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)PAWAN KUMARNo ratings yet

- Change Control Form: Giva Olviana YudhistaDocument4 pagesChange Control Form: Giva Olviana YudhistaFajarRachmadiNo ratings yet

- Acene CreamDocument2 pagesAcene CreamJai MurugeshNo ratings yet

- 161 ListDocument8 pages161 ListAnnie KhanNo ratings yet

- Lab Ledger PhyDocument287 pagesLab Ledger PhyMumtazAhmadNo ratings yet

- Cefepime For Injection USP (Dossier) PDFDocument66 pagesCefepime For Injection USP (Dossier) PDFsofiaNo ratings yet

- Creating Own Distributor Company SWOT AnalysisDocument7 pagesCreating Own Distributor Company SWOT AnalysisdesurkarbNo ratings yet

- Siddhi Vinayak Batch Manufacturing RecordsDocument11 pagesSiddhi Vinayak Batch Manufacturing RecordsPANKAJNo ratings yet

- Concentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfateDocument6 pagesConcentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfatesajidNo ratings yet

- Paracetamol Syrup IPDocument2 pagesParacetamol Syrup IPamebadhaNo ratings yet

- प्रधानमंत्री जन औषधि केंद्र रेट लिस्टDocument29 pagesप्रधानमंत्री जन औषधि केंद्र रेट लिस्टbrijeshcocoNo ratings yet

- Carbohydrate Analysis by HPLC I Intro-ADocument1 pageCarbohydrate Analysis by HPLC I Intro-AYan XunNo ratings yet

- Calibration Curve: Tartaric Acid: Peak AreaDocument10 pagesCalibration Curve: Tartaric Acid: Peak Areajanesalazar3369No ratings yet

- ListDocument18 pagesListits4krishna3776No ratings yet

- Sop ZetasizerDocument3 pagesSop ZetasizerP SWETHANo ratings yet

- Assay Determination: General IndexDocument10 pagesAssay Determination: General IndexDavid SanabriaNo ratings yet

- Checklist Audits Production FacilityDocument20 pagesChecklist Audits Production FacilityTahir IbrahimNo ratings yet

- OQ Raw Materials Sample TentDocument18 pagesOQ Raw Materials Sample TentAnup BajracharyaNo ratings yet

- Docs h06 FM 018Document2 pagesDocs h06 FM 018ArchanNo ratings yet

- Master Listof Watertreatment PlantDocument2 pagesMaster Listof Watertreatment PlantHarpal SainiNo ratings yet

- Medical Gases CalculationsDocument14 pagesMedical Gases Calculationssitehab67% (3)

- Microsoft PowerPoint - Environmemtal Monitoring of Clean Rooms WEB PAGEDocument44 pagesMicrosoft PowerPoint - Environmemtal Monitoring of Clean Rooms WEB PAGEmadosb5133No ratings yet

- Environmentalmonitoring 170510154126Document33 pagesEnvironmentalmonitoring 170510154126amar prasadNo ratings yet

- BPC Tender Section 3 (Page 36-53)Document18 pagesBPC Tender Section 3 (Page 36-53)subirmeNo ratings yet

- Designing for inherent safetyDocument68 pagesDesigning for inherent safetysubirme100% (1)

- BPC Tender Section 5 (Page 60-76)Document17 pagesBPC Tender Section 5 (Page 60-76)subirmeNo ratings yet

- BPC Tender Section 4 (Page 54-59)Document6 pagesBPC Tender Section 4 (Page 54-59)subirmeNo ratings yet

- Fire Extinguisher Training PDFDocument29 pagesFire Extinguisher Training PDFsubirmeNo ratings yet

- LPG VRS PDFDocument1 pageLPG VRS PDFsubirmeNo ratings yet

- ISO 9606-1 Welder Qualification Download LinkDocument1 pageISO 9606-1 Welder Qualification Download LinksubirmeNo ratings yet

- BPC Tender Section 2 (Page 30-35)Document6 pagesBPC Tender Section 2 (Page 30-35)subirmeNo ratings yet

- BPC Tender Section 1 (Page 1-29)Document29 pagesBPC Tender Section 1 (Page 1-29)subirmeNo ratings yet

- LPG VRSDocument1 pageLPG VRSsubirmeNo ratings yet

- LPG Vapour Liquefication SystemDocument1 pageLPG Vapour Liquefication SystemsubirmeNo ratings yet

- ASHRAE 100 - Energy Conservation in Existing BuildingDocument1 pageASHRAE 100 - Energy Conservation in Existing BuildingsubirmeNo ratings yet

- LPG Vapour Recovery System PDFDocument1 pageLPG Vapour Recovery System PDFsubirmeNo ratings yet

- Double Ball Valve With ESRDocument1 pageDouble Ball Valve With ESRsubirmeNo ratings yet

- Sectional View of Turnnion Mounted Ball ValveDocument1 pageSectional View of Turnnion Mounted Ball ValvesubirmeNo ratings yet

- Motor Star Delta ConnectionDocument11 pagesMotor Star Delta ConnectionsubirmeNo ratings yet

- Factory Safety Checking Instrument ListDocument1 pageFactory Safety Checking Instrument ListsubirmeNo ratings yet

- List of Parts of Boiler BurnerDocument1 pageList of Parts of Boiler BurnersubirmeNo ratings yet

- How Boilers WorkDocument18 pagesHow Boilers Workhozipek5599100% (1)

- Green in BrochurDocument1 pageGreen in BrochursubirmeNo ratings yet

- Boiler Short GuideDocument6 pagesBoiler Short GuidesubirmeNo ratings yet

- Soyabean Casein Digest Medium (Tryptone Soya Broth) : CompositionDocument3 pagesSoyabean Casein Digest Medium (Tryptone Soya Broth) : CompositionsubirmeNo ratings yet

- Guidebook For The Preparation of HACCP PlansDocument74 pagesGuidebook For The Preparation of HACCP Planslatog13No ratings yet

- WHO Non Sterile Process ValidationDocument15 pagesWHO Non Sterile Process Validationsubirme100% (1)

- Pharma WasteDocument1 pagePharma WastesubirmeNo ratings yet

- Solar Energy FundamentalsDocument11 pagesSolar Energy FundamentalsMitul KhandhadiaNo ratings yet

- Di-Octyl Phthalate Carcinogen ExposureDocument2 pagesDi-Octyl Phthalate Carcinogen ExposuresubirmeNo ratings yet

- Dokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexDocument40 pagesDokumen - Tips Raphex 2001 Cloud Object Storage Store Retrieve Data s3 2012-04-30raphexRuan MouraNo ratings yet

- Aluminum Alloy Sand Casting SpecDocument2 pagesAluminum Alloy Sand Casting SpecGanesh SonawaneNo ratings yet

- Test Bank For Anatomy and Physiology 1st Edition Michael MckinleyDocument37 pagesTest Bank For Anatomy and Physiology 1st Edition Michael Mckinleyreidelsebirew100% (12)

- MSDS 419 BulkDocument3 pagesMSDS 419 BulkEliasNo ratings yet

- Sample Paper-01 Chemistry (Theory) Class – XIDocument4 pagesSample Paper-01 Chemistry (Theory) Class – XISarthakNo ratings yet

- Sikaflex®-400 Fire: Product Data SheetDocument4 pagesSikaflex®-400 Fire: Product Data SheetLA BoiserNo ratings yet

- Aqua SilencerDocument18 pagesAqua SilencerManideep AlluNo ratings yet

- CEMENT LECTURE SUMMARYDocument22 pagesCEMENT LECTURE SUMMARYYusf ari jerjisNo ratings yet

- Chemicals Zetag MSDS Powder Zetag 8190S - 0710Document6 pagesChemicals Zetag MSDS Powder Zetag 8190S - 0710PromagEnviro.comNo ratings yet

- Calculating percentage of oxygen in air after evaporating liquid nitrogenDocument2 pagesCalculating percentage of oxygen in air after evaporating liquid nitrogenlutfi awnNo ratings yet

- T1 1 E Automotive 072Document15 pagesT1 1 E Automotive 072Marian OstrowskiNo ratings yet

- Pressure Vessel Manual-M.asgaRZADEGANDocument79 pagesPressure Vessel Manual-M.asgaRZADEGANH BNo ratings yet

- KS3 Science 2009 Paper 2 Level 3-6Document32 pagesKS3 Science 2009 Paper 2 Level 3-6Macwise IngabireNo ratings yet

- Superabsorbent PolymerDocument21 pagesSuperabsorbent PolymerIsha MeshramNo ratings yet

- Applied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurDocument19 pagesApplied Thermodynamics For Marine Systems Prof. P. K. Das Department of Mechanical Engineering Indian Institute of Technology, KharagpurTommyVercettiNo ratings yet

- NFPA 10 - Selection of Fire Extinguishers PDFDocument9 pagesNFPA 10 - Selection of Fire Extinguishers PDFHSE nest100% (1)

- Laminar and Turbulent FlowDocument16 pagesLaminar and Turbulent FlowMariya ZolotarNo ratings yet

- Non Linear PharmacokineticsDocument64 pagesNon Linear PharmacokineticsMoganaa LakshmiNo ratings yet

- Membrane - FunctionDocument4 pagesMembrane - Functionphuong anhNo ratings yet

- Absorption of Carbon Dioxide Into Aqueous Blends of Diethanolamine and MethyldiethanolamineDocument11 pagesAbsorption of Carbon Dioxide Into Aqueous Blends of Diethanolamine and MethyldiethanolamineAnkit KumarNo ratings yet

- DURALITEDocument7 pagesDURALITEEri FebriantoNo ratings yet

- Welding Defect PhotoDocument14 pagesWelding Defect Photo0502raviNo ratings yet

- PPTDocument13 pagesPPTAJINKYANo ratings yet

- Theory Guide Multiphase Flow - ANSYS Fluent 16Document136 pagesTheory Guide Multiphase Flow - ANSYS Fluent 16Verenia Shania100% (1)

- Stoichiometry Notes - 2014 KEYDocument10 pagesStoichiometry Notes - 2014 KEY5020NitinNo ratings yet

- Electrostatic PrecipitatorDocument12 pagesElectrostatic PrecipitatorchandraNo ratings yet

- MethanizerDocument1 pageMethanizerDaniv NguyenNo ratings yet

- Shell and tube heat exchanger designDocument32 pagesShell and tube heat exchanger designdesignselvaNo ratings yet

- Ruggedness and Robustness-Robustez y SólidezDocument4 pagesRuggedness and Robustness-Robustez y SólidezRafael100% (2)