Professional Documents

Culture Documents

DEHA V Sulfite - 100809

Uploaded by

babis1980Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DEHA V Sulfite - 100809

Uploaded by

babis1980Copyright:

Available Formats

NORTH METAL & CHEMICAL COMPANY

World Class Molybdenum & Tungsten Compounds

Since 1921 Web: www.nmc-nic.com email: north@nmc-nic.com

Technical Services Bulletin

Oxygen Scavengers in Boiler Systems:

DEHA vs. Sodium Sulfite

DEHA: DEHA was introduced as an alternative oxygen scavenger to hydrazine, offering the advantages of very low toxicity, metal passivating capabilities and the volatility of a neutralizing amine to provide complete system protection. The fact that DEHA is volatile represents an enormous advantage in condensate Distribution Ratio Comparison system treatment because most of it DEHA 1.3 is transported and Hydrazine 0.1 absorbed in the condensate sys Sodium sulfite 0.0 tem. Why Use DEHA?

DEHA is recommended for use in medium and highpressure steam boilers. DEHA protects condensate loops as well as boilers DEHA leaves no residue in boiler systems DEHA provides good efficiency (use 3:1 ratio DEHA:Oxygen) Increased blowdown rates/costs with sulfite to remove accumulated solids

or industrial and commercial boilers, it is critical to minimize corrosion and deposits in boiler systems in order to maximize their energy efficiency and life expectancy. Typically, dissolved gases in water such as oxygen and carbon dioxide lead to corrosionoxygen causes pitting and rusting, while carbon dioxide causes acid corrosion. These radical scavengers include a) inorgainic compounds such as sodium sulfite and hydrazine, and b) organic chemicals such as carbohydrazide, Diethylhydroxylamine (DEHA), methyl ethyl ketoxime (MEKO) and hydroquinone. Sodium Sulfite

Sodium sulfite has been widely used as an oxygen scavenger in low pressure boiler systems due to its low cost. It is non-toxic and relatively easy to apply. It can be used in either solid or liquid (sodium bisulfite dissolved in water) form. In low pressure systems it is generally recommended that sodium sulfite be maintained in an operating boiler at an excess of 20-40 mg/L. However, use of sodium sulfite adds considerable solids (sulfate salts) to the boiler water, which limits its use in systems utilizing high purity boiler feedwater. Sodium sulfite is limited to about 900 psi, beyond which it could decompose to sulfur dioxide and hydrogen sulfide. It does not promote passivation in feedwater or boiler water systems and its ability to minimize corrosion comes solely from its capability to remove oxygen from water. Sodium sulfite is also not volatile enough to protect the condensate loop and cannot be used to protect the steam condensate system.

The Economics of DEHA vs Sulfite

The average cost of DEHA is ~ $2.80/lb. and sodium sulfite is ~ $0.48/lb. Typical boiler systems require about 6 times the amount of sulfite compared to DEHA

DEHA: 0.36 ppm in feedwater x $2.80 DEHA = $1.00 per 1,000,000 gallons SODIUM SULFITE: 1.8 ppm in feedwater x $0.48 = $0.86 per 1,000,000 gallons

Cost Differential:

$0.14/lb. per 1,000,000 gals

6 0 9

E a s t

K i n g

S t .

P . O .

B o x

1 9 0 4

Y o r k ,

P A

1 7 4 0 5

P h : : 7 1 7 - 8 4 5 - 8 6 4 6

F a x :

7 1 7 - 8 4 6 - 7 3 5 0

Rev. _100809

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- FUSION MANUAL - Rev IllustrationsDocument36 pagesFUSION MANUAL - Rev IllustrationsMehmet SoysalNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Document2 pages1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Ati 317Document13 pagesAti 317babis1980No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Orifice Plate Flow MetersDocument8 pagesOrifice Plate Flow MetersGaurav Dhiman100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- FRL SIF 618 CompressedAirDryingDocument36 pagesFRL SIF 618 CompressedAirDryingbabis1980No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GF Type 546 BallDocument10 pagesGF Type 546 Ballbabis1980No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 pagesThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- White Paper RBIDocument12 pagesWhite Paper RBImahesh070No ratings yet

- Sa 312Document1 pageSa 312babis1980No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Non-Circular Pressure Vessels SquareDocument27 pagesNon-Circular Pressure Vessels SquareAbhilash Kurian100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- StainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerDocument14 pagesStainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerbabis1980No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PPG Minimizing The Effects of CorrosionDocument9 pagesPPG Minimizing The Effects of Corrosionbabis1980No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Brochure ACCDocument8 pagesBrochure ACCbabis1980No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionkeronsNo ratings yet

- Veizades Gas Removal Systems Liquid Ring VPDocument3 pagesVeizades Gas Removal Systems Liquid Ring VPVenkatespatange RaoNo ratings yet

- Fundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Document199 pagesFundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Anshul JainNo ratings yet

- Tech Manual Electrical Power Plant DesignDocument135 pagesTech Manual Electrical Power Plant Designd_kabulpuriaNo ratings yet

- Chapter IIIDocument19 pagesChapter IIIghostamirNo ratings yet

- Energy Saving in Steam Systems.Document34 pagesEnergy Saving in Steam Systems.babis1980No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- What's New in API 610 11th EditionDocument4 pagesWhat's New in API 610 11th Editionshyam_anupNo ratings yet

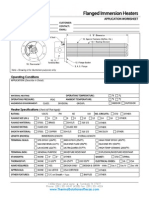

- Flanged Immersion Heaters: Operating ConditionsDocument1 pageFlanged Immersion Heaters: Operating Conditionsbabis1980No ratings yet

- Advanced GE CCPPDocument20 pagesAdvanced GE CCPPR Krishna KumarNo ratings yet

- Ideal Bearing Temp LimitsDocument1 pageIdeal Bearing Temp Limitsbabis1980No ratings yet

- ATEX Reference GuideDocument2 pagesATEX Reference Guidebabis1980No ratings yet

- Introduction To Gas Turbines For Non-EngineersDocument9 pagesIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaNo ratings yet

- 4.24 Drains Systems Design PhilosophyDocument8 pages4.24 Drains Systems Design Philosophybabis1980No ratings yet

- Demographically Similar EntriesDocument1 pageDemographically Similar EntriesTahsildar MydukurNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Acsomega 9b01541Document9 pagesAcsomega 9b01541Benedictus EduardoNo ratings yet

- NTP35N15 Power MOSFET Features and SpecificationsDocument7 pagesNTP35N15 Power MOSFET Features and SpecificationsChristine GomezNo ratings yet

- Beumer - Pipeconveyor TechnologyDocument51 pagesBeumer - Pipeconveyor TechnologyAli AlatasNo ratings yet

- Operator Interface Hmi Touch Screen Cmore - 10Document54 pagesOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- Stress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionDocument16 pagesStress-Strain Behaviour of Steel-Fibre-Reinforced Recycled Aggregate Concrete Under Axial TensionAndrucruz CruzNo ratings yet

- Installing RegCM4.3rc Training Session IDocument11 pagesInstalling RegCM4.3rc Training Session Ijmatias765428100% (1)

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocument12 pages83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraNo ratings yet

- Woodson Property Group's Conditional Use Permit ApplicationDocument108 pagesWoodson Property Group's Conditional Use Permit ApplicationShannon GeisenNo ratings yet

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Conventional and Non-Conventional Energy Resources of India: Present and FutureDocument8 pagesConventional and Non-Conventional Energy Resources of India: Present and FutureAnkit SharmaNo ratings yet

- Tabla 1 Engine ControlDocument2 pagesTabla 1 Engine Controljulio montenegroNo ratings yet

- Physics Lab ReportDocument2 pagesPhysics Lab ReportFelix SonsunNo ratings yet

- Power Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesDocument29 pagesPower Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesPhD EENo ratings yet

- JDA SCE Standard Release NotesDocument3 pagesJDA SCE Standard Release Notesgolcha_edu532No ratings yet

- Stressman Engineering - Brochure Norway 2018-6Document8 pagesStressman Engineering - Brochure Norway 2018-6FelipeNo ratings yet

- CAD1 AssignmentDocument11 pagesCAD1 AssignmentJohn2jNo ratings yet

- Customer Targeted E-CommerceDocument4 pagesCustomer Targeted E-CommercepriyaNo ratings yet

- Permeability: The Key to ProductionDocument30 pagesPermeability: The Key to ProductionDarshak Sakhreliya100% (1)

- Sample Purchase Specification For ClariflocculatorDocument1 pageSample Purchase Specification For Clariflocculatorcontactdevansh1174No ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

- Models - Rf.bowtie Antenna OptimizationDocument14 pagesModels - Rf.bowtie Antenna OptimizationbkmmizanNo ratings yet

- Java Topics To Cover in InterviewsDocument5 pagesJava Topics To Cover in InterviewsHemanth KumarNo ratings yet

- Symfony 2 The BookDocument354 pagesSymfony 2 The BookYamuna ChowdaryNo ratings yet

- TMC 421 PDFDocument82 pagesTMC 421 PDFJamie MooreNo ratings yet

- Smarter and Safer: Cordless Endodontic HandpieceDocument2 pagesSmarter and Safer: Cordless Endodontic Handpiecesonu1296No ratings yet

- Master Opp GaveDocument84 pagesMaster Opp GaveRizki Al AyyubiNo ratings yet

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Service Menu - SamyGODocument5 pagesService Menu - SamyGOVenkatesh SubramanyaNo ratings yet

- AMS Thread Size ChartDocument4 pagesAMS Thread Size Chartarunvelu_1250% (2)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (3)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 3.5 out of 5 stars3.5/5 (2)

- This Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyFrom EverandThis Is Your Brain On Parasites: How Tiny Creatures Manipulate Our Behavior and Shape SocietyRating: 3.5 out of 5 stars3.5/5 (31)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (4)