Professional Documents

Culture Documents

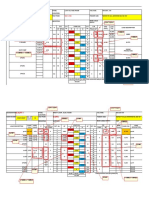

Mesin Larik

Uploaded by

norzaiwanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mesin Larik

Uploaded by

norzaiwanCopyright:

Available Formats

Elaborate the operation in relation to lathe work such as turning boring, facing, drilling,knurling, tread cutting and off-centre

turning.

BORING (menggerek) In machining, boring is the process of enlarging a hole that has already been drilled (or cast), by means of a single-point cutting tool (or of a boring head containing several such tools), for example as in boring a cannon barrel. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters.

FACING (melarik muka) is part of the turning process. It involves moving the cutting tool at right angles to the axis of rotation of the rotating work piece.This can be performed by the operation of the cross-slide, if one is fitted, as distinct from the longitud feed (turning). It is frequently the first operation performed in the production of the work piece, and often the last- hence the phrase "ending up".

DRILLING (menggerudi) Drilling is a cutting process that uses a drill bit to cut or enlarge a hole of circular cross-section in solid materials. The drill bit is a rotary cutting tool, often multipoint. The bit is pressed against the work piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work piece, cutting off chips from what will become the hole being drilled.

Type of drilling Hand drill Protable electric drill Bench drilling machine Biliar drilling machine Column type drilling machine Radial arm drilling machine Gang spindle drilling machine Multi spindle machine

KNURLING (melorek) Knurling is a manufacturing process, typically conducted on a lathe, where by a diamond-shaped (criss-cross) pattern is cut or rolled into metal.

Types : Annular rings Frequently used when the mating part is plastic. Rings allow for easy mating but ridges make it difficult to pull the components apart. Linear knurl Used with mating plastic pieces, the Linear Knurl allows greater torsion between components. Diamond knurl A hybrid of Annular Rings and Linear Knurling in which a diamond shape is formed. It is used to provide better grip on components

Taper turning (melarik tirus) Three methods of producing taper Offsetting tailstock Taper attachment set to proper tpf

Metric by calculating guide bar offset

Adjusting compound rest to angle of taper Method used depends on work length, taper length, taper angle and number of pieces

Three Methods of offsetting the Tailstock By using graduations on end of the tailstock (visual method) By means of the graduated collar and feeler gage By means of a dial indicator Example for taper turning

turning a centre(melarik tak sepusat) There are two methods for turning non-concentric / eccentric turning, using four jaw chuck and method of holding a work piece between centre: For the marking on the side of the work piece surface hold the work piece in the four jaw chuck. Centre bring equipment back to work closely with the material centre midpoint eccentric touches that have been marked. Jaw chuck with soft keys that do not change the position of the work piece. Check and adjust the position of the work piece so long to in diameter eccentric out of the jaws of machined. Lock all with strong jaws . Remove the equipment back. Hold the appropriate tool and adjust its altitude axis machined. Select the appropriate PPM, usually 1/3 of the normal PPM.PPM speeds can be increased when run eccentric nearing completion. Eccentric turning roughly to leave 0.75 mm to run completion. change the tool to do run completion.

Sure long eccentric turning the proper size with a uniform. Remove materials and do finishing work.

turning the eccentric

TOOLS BITS

tool generally made of high carbon steel, alloy steel and castings durable as stellite, terekat carbide and ceramics. properties owned by these materials are different and the use of each depends on the material machined and state machine used. Lathe tool must have the following attributes: a) Hard b) Hold the hard c) Resistant to high temperatures d) Resistant to shock during cutting operations

THE ANGLE OF THE CUTTING SIDE: angle of the cutting edge side in the form of rods of tool. for general use, the angle is from 10 to 20 depending on the material being cut. If the angle is more than 30 vibration will occur.

ANGLE OF THE CUTTING TIP: cutter tip angle is the angle formed at the tip of the tool, usually from 5 to 30 depending on the type of cutting and finishing required. Angle between 5 and 15 sufficient to rough cut and angle of 15 to 30 can be used for general work

ANGLE SIDE RELIEF Side relief angle is the angle that rolled on the surface of the bottom of the cutting geligir, usually between 6 to 10. This angle gives relief to grind with the tool from the workpiece during cutting.

FRONT CLEARANCE ANGLE Front clearance angle is the angle that rolled under the nose of the tool allows the tool is fed into the workpiece. for a general-purpose tool angle is between 10 and 15. SIDE HAS A RAKE ANGLE The back has a rake angle is the angle steep back from the nozzle surface of the tool. Usually angled 14, allows the scroll runs out quickly. For soft materials, has a rake angle increases side.

THE BACK HAS A RAKE ANGLE (TOP) The back has a rake angle is the angle steep back from the top surface of the tool nose, usually the back has a rake angle allows the scroll 20.Sudut flowing out from the point of cutting 3 types of Positive has a rake back has a rake angle(top)

positive has a rake angle used to cut soft materials such as aluminum and mild steel

Neutral has a rake angle neutral has a rake angle for cutting hard materials such as hard steel and cast iron Negative has a rake angle Negative has a rake angle is used for cutting materials such as gun metal and brass

BRASS DESIGN TOOL DESIGN TOOL AND ROLLED ANGLES DEPENDING ON 1. TYPE OF WORK TO BE DONE 2. MATERIAL TO BE MACHINED 3. POWER AND MACHINE INFORMATION 4. A LOT OF METAL TO BE REMOVED 5. QUALITY OF FINISH REQUIRED

You might also like

- CHAPTER 3 - Lathe MachineDocument27 pagesCHAPTER 3 - Lathe MachineYJ SiowNo ratings yet

- JJ 104 Workshop Technology 1 MillingDocument44 pagesJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Fitting Workshop ReportDocument17 pagesFitting Workshop ReportAkshay kumarNo ratings yet

- Surface GrindingDocument14 pagesSurface GrindingariefNo ratings yet

- JJ 103 Fitting ReportDocument11 pagesJJ 103 Fitting Reportrafiah bazlaaNo ratings yet

- TURNING LAB EXPERIMENTDocument12 pagesTURNING LAB EXPERIMENTLuqman HakimNo ratings yet

- Case Study Lathe.....Document16 pagesCase Study Lathe.....Zul AimanNo ratings yet

- Machining 2 ReportDocument11 pagesMachining 2 ReportTan Jun ZheNo ratings yet

- Lab Sheet Djj5113Document27 pagesLab Sheet Djj5113Munisprasad MuniandyNo ratings yet

- Mechatronic Workshop Practice 1Document15 pagesMechatronic Workshop Practice 1Khairul AminNo ratings yet

- A Lab Report On Fitting Workshop Practice PDFDocument6 pagesA Lab Report On Fitting Workshop Practice PDFSorna Kailash50% (4)

- LatheDocument4 pagesLatheAnees Calicut100% (1)

- Name of The Experiment:: Study and Operation Bench Drilling MachineDocument5 pagesName of The Experiment:: Study and Operation Bench Drilling MachinemadNo ratings yet

- Production Technology Lab FileDocument45 pagesProduction Technology Lab FileSakshi RoyNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- Lab Session Introduction To Lathe MachineDocument5 pagesLab Session Introduction To Lathe MachineAqib ZamanNo ratings yet

- Case Study Djj50203 (GRP Sethu)Document14 pagesCase Study Djj50203 (GRP Sethu)Roysilva SilvaNo ratings yet

- TIG Workshop ReportDocument9 pagesTIG Workshop ReportKee Zhenyuan100% (1)

- Lathe Workholding and Operations GuideDocument4 pagesLathe Workholding and Operations GuideBOT-X GAMING100% (1)

- Fitting Shop: 1.2.1 Bench ViceDocument3 pagesFitting Shop: 1.2.1 Bench ViceMRINAL GAUTAM100% (1)

- Grinding OperationsDocument25 pagesGrinding OperationsSundaram Jegatheesan100% (2)

- Bench Work ProceduresDocument7 pagesBench Work ProceduresAniz Farznor SariffuddinNo ratings yet

- Bench WorkingDocument11 pagesBench WorkingMonica MagdyNo ratings yet

- Fitting ToolsDocument14 pagesFitting ToolsManoj Lohumi100% (2)

- Grinding Lab 2Document9 pagesGrinding Lab 2Ming QuanNo ratings yet

- Drilling Machine and TypesDocument15 pagesDrilling Machine and TypesNaveen luckyNo ratings yet

- Velocity and Acceleration Lab Result (Car Ramp)Document3 pagesVelocity and Acceleration Lab Result (Car Ramp)Ugur ASİT60% (5)

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 pagesLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNo ratings yet

- Presentation of Drilling Machine by Anil Dahiya SirDocument72 pagesPresentation of Drilling Machine by Anil Dahiya SirRAMAKANT RANA100% (1)

- Planer MachineDocument46 pagesPlaner Machinepoohru puru100% (15)

- Machine Shop GuideDocument6 pagesMachine Shop GuideZain MirzaNo ratings yet

- Thread Cutting and Its MethodsDocument24 pagesThread Cutting and Its MethodsMr.N.S. NateshNo ratings yet

- Shaping Machine Operations GuideDocument25 pagesShaping Machine Operations Guidekatakamharish100% (1)

- Introduction To Fitting Shop.Document11 pagesIntroduction To Fitting Shop.Mahmood AliNo ratings yet

- CNC Turning Machining GuideDocument11 pagesCNC Turning Machining GuideMorearemad RozaidiNo ratings yet

- Workshop Practice II (MEng4191)Document35 pagesWorkshop Practice II (MEng4191)Tesema TeshomeNo ratings yet

- Operations in TurningDocument8 pagesOperations in Turningcanavarsanayok100% (1)

- Sheetmetal IntroductionDocument9 pagesSheetmetal IntroductionVinay BalineniNo ratings yet

- Features of A Milling CutterDocument8 pagesFeatures of A Milling CutterAnuj KrNo ratings yet

- Lathe MachineDocument16 pagesLathe MachineVanamali Thirumalai100% (4)

- Shot Blasting Is A Rapid, Environment Friendly, CostDocument10 pagesShot Blasting Is A Rapid, Environment Friendly, CostSulfikar SalimNo ratings yet

- Machine Tools Guide in 40 CharactersDocument16 pagesMachine Tools Guide in 40 CharactersKarNo ratings yet

- Gas Welding ReportDocument18 pagesGas Welding ReportAkmal AzaliNo ratings yet

- Drilling MachineDocument9 pagesDrilling MachineAqib ZamanNo ratings yet

- Heat Treatment and Tooling DesignDocument28 pagesHeat Treatment and Tooling DesignAfzan Noor HisyamNo ratings yet

- Date: ............................................................(Assistant’s SignatureDocument8 pagesDate: ............................................................(Assistant’s SignatureThaneswaran BaluNo ratings yet

- Non Chip FormingDocument33 pagesNon Chip FormingNur AmirahNo ratings yet

- GRINDING PROCESS GUIDEDocument44 pagesGRINDING PROCESS GUIDEPrashant Rao MeshramNo ratings yet

- Fitting LabDocument8 pagesFitting LabArun kumar rouniyarNo ratings yet

- Drilling SRM UniviersityDocument27 pagesDrilling SRM UniviersityBhavin Desai100% (2)

- Introduction Metrology Lab ReportDocument2 pagesIntroduction Metrology Lab ReportMuhamad Hafiz100% (1)

- Milling: Prepared By: Dinbandhu Singh 1Document23 pagesMilling: Prepared By: Dinbandhu Singh 1Dino SinghNo ratings yet

- Lathe Machine: Description and Function of Lathe PartsDocument16 pagesLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (1)

- WinCNC - V1.12 - V8 Operating Manual PDFDocument48 pagesWinCNC - V1.12 - V8 Operating Manual PDFMilko Migneco100% (1)

- LatheDocument74 pagesLatheChandrakantha K100% (1)

- Milling MachineDocument14 pagesMilling MachineAqib ZamanNo ratings yet

- Edm Wire Cut LabDocument6 pagesEdm Wire Cut LabJieMan BahRom100% (1)

- Milling Tool DesignDocument18 pagesMilling Tool DesignSiddharth DubeyNo ratings yet

- Light Intensity Control Using Diac and TriacDocument12 pagesLight Intensity Control Using Diac and TriacPrathamesh KaleNo ratings yet

- Automatic Cutting SystemDocument25 pagesAutomatic Cutting SystemDebdeep GhoshNo ratings yet

- Valves DatasheetDocument1 pageValves DatasheetLuis Acevedo AyalaNo ratings yet

- Epson Stylus NX400 Service PartsDocument7 pagesEpson Stylus NX400 Service Partsnelson_223No ratings yet

- Datasheet VertexS+ NEG9RC.27 EN 2023 Aus BDocument2 pagesDatasheet VertexS+ NEG9RC.27 EN 2023 Aus B9fytyksqfyNo ratings yet

- Ingersoll-Rand R37-45 - Manual de PecasDocument216 pagesIngersoll-Rand R37-45 - Manual de PecasRuanita Veiga50% (6)

- Automatic Transfer Switch (Ats) 1600-3000 AMP ZTSCTL Series With Mx200 Microprocessor-Based Control PanelDocument7 pagesAutomatic Transfer Switch (Ats) 1600-3000 AMP ZTSCTL Series With Mx200 Microprocessor-Based Control Panelanoop13No ratings yet

- Yanagiba Sharpening: Everything You Need To KnowDocument16 pagesYanagiba Sharpening: Everything You Need To KnowT ChenNo ratings yet

- Mini-Split Maintenance: Best PracticesDocument16 pagesMini-Split Maintenance: Best PracticesFrancisco Sanchez RNo ratings yet

- Parts Catalogue for ECO 125 Cylinder HeadDocument72 pagesParts Catalogue for ECO 125 Cylinder HeadMichaell KingsNo ratings yet

- ARCTURUS User Manual PDFDocument1 pageARCTURUS User Manual PDFStefan IstrateNo ratings yet

- 580 Manual MMC-153 RV5-9-98Document40 pages580 Manual MMC-153 RV5-9-98Ashly JosephNo ratings yet

- 03 - Screwcutting in The LatheDocument172 pages03 - Screwcutting in The Lathej43951048No ratings yet

- Activity 2: The Microscope: ObjectivesDocument6 pagesActivity 2: The Microscope: ObjectivesKhim BalcitaNo ratings yet

- Maintenance Parts List: Service DocumentsDocument104 pagesMaintenance Parts List: Service DocumentsCristian GuevaraNo ratings yet

- 2888 450CLCDocument589 pages2888 450CLCAlfredo ZablahNo ratings yet

- All Elect Panel Moc Dated 15-03-20Document17 pagesAll Elect Panel Moc Dated 15-03-20nadeem UddinNo ratings yet

- Cycletrol 240 ManualDocument21 pagesCycletrol 240 ManualeloyNo ratings yet

- Cajas Raco-Fichas TecnicasDocument1 pageCajas Raco-Fichas Tecnicasjimg05No ratings yet

- Muratec F-300 Illustrated Parts CatalogDocument48 pagesMuratec F-300 Illustrated Parts CatalogCHRISNo ratings yet

- Tech Tip Mc521 Pro Controller Slide Door Installation and Operation ManualDocument40 pagesTech Tip Mc521 Pro Controller Slide Door Installation and Operation ManualRubén Pérez ArmasNo ratings yet

- Top 10 Workbench Accessories PDFDocument4 pagesTop 10 Workbench Accessories PDFfallenlordNo ratings yet

- Magnetron ListDocument1 pageMagnetron ListEslem DoğanNo ratings yet

- Bajaj Gem Catalogue - 8 X 8 Inch All Pages - 25th AugustDocument36 pagesBajaj Gem Catalogue - 8 X 8 Inch All Pages - 25th Augustp.rohidas1606No ratings yet

- Introduction To Electronics: Electronic Devices Lesson 0.0Document16 pagesIntroduction To Electronics: Electronic Devices Lesson 0.0Yves CaraangNo ratings yet

- Elevator wiring diagramDocument12 pagesElevator wiring diagramWissam RgailyNo ratings yet

- Usb 2 Axis CNC Motion Controller Stepping Motor Controller 150khz With LCD Display For CNC Lathe System #Sm655 @SD - Motor Controller - AliExpressDocument12 pagesUsb 2 Axis CNC Motion Controller Stepping Motor Controller 150khz With LCD Display For CNC Lathe System #Sm655 @SD - Motor Controller - AliExpressSyed Hassan TariqNo ratings yet

- 360 Degree Drilling MachineDocument22 pages360 Degree Drilling MachineVishalNo ratings yet

- Surge Protection (SPD) & Power Conditioning ProductsDocument44 pagesSurge Protection (SPD) & Power Conditioning ProductsAyman SaberNo ratings yet

- Switching Module LTB Compact Rated 123-170 kVDocument4 pagesSwitching Module LTB Compact Rated 123-170 kVThangco HutNo ratings yet