Professional Documents

Culture Documents

Handout3 UMM RAP Coal

Uploaded by

Putoy ItoyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handout3 UMM RAP Coal

Uploaded by

Putoy ItoyCopyright:

Available Formats

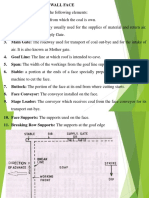

MIN 454: Underground Mining Methods Handout 3 MIN 454 The next stage in mine development is to actually open

n the mine. Typically, coal is mined by one of two methods, room-and-pillar (or bord and pillar, in British terminology) mining and longwall mining. The method of mining is chosen based on several factors (to be discussed in the next few handouts). We begin with room-and-pillar mining. The first part of this handout presents the nomenclature. Room-and-pillar mining involves opening a series of tunnels in parallel (called entries) with tunnels going across them (called crosscuts) at regular intervals leaving solids blocks of coal in between (Figure 1). The crosscuts can be perpendicular to the entries or be at an angle. The tunnels themselves (be it the entries or the crosscuts) are called rooms (locally, i.e. in a give spot) while the solid blocks of coal are called pillars. Pillars are left to support the rooms. During mining, these entries are extended all the way up to the end of the deposit after which, the pillars are removed in retreat. Removal of the pillars (called pillaring) from an area concludes mining in the area (the roof collapses very quickly after a pillar is removed, thereby reducing the stress).

entry #1 r entry #2 s entry #3 c u entry #4 entry #5 t A o s

Direction of advance

Figure 1. Basic geometry of room-and-pillar workings. Entries are generally named from left to right, facing inby. Inby and outby are terms frequently used in mining to describe location relative to the observer. Inby is towards the direction of advance, while outby is in the opposite direction (generally towards the exit). In Figure 1, A is inby of B, while B is outby of A. Mine Plan Format: If you are seeing a room-and-pillar mine plan for the first time, you will notice that in the mine plan given to you, rooms are depicted as lines, unlike in Figure 1. To help you make the transition to mine plans, Figure 1 has been redrawn in a typical mine plan format in Figure 2 (not in the same scale, however).

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods

Figure 2. Figure 1 redrawn in mine plan format. Before opening a mine, few parameters need to be decided on. These are presented next. Number of entries: The example mine plan that was given to you uses a 7 entry system (ask me if you do not have the mine plan). This is evident from the 7 entries for mains, sub-mains and panels. Mains, as the name suggests, are an important part of the mine. They form the skeleton or backbone for the mine, allowing access to various parts of the mine. Every ton of mined coal passes through the mains. Due to their long life and pivotal role in coal hauling, mains usually have pillars larger in size than in other areas of the mine. Sometimes, the same is true for sub-mains also. Sub-mains are the system of entries that branch off mains, giving access to various portions of the mine. Sub-mains may be absent in small mines. Panels are entries that branch off the sub-mains. Mining is generally done off the panels. However, mine geometry may sometimes necessitate driving panels off mains. Also, the distinction between mains and sub-mains, and sub-mains and panels may not always be clear. The decision to drive a certain number of entries in a panel should consider the following: The purpose of the panel. For longwall development, typically 3 or 4 entries suffice. It is difficult driving anything lower than three entries since belts, air-return and track/human transportation each (typically) require a separate entry. Additionally, congestion can be an issue for fewer entries; for example, even with three entries, there is very little room for equipment parking (for repairs or routine daily maintenance). Figure 3 shows a 4 entry longwall development section. Note how congested it is. When the number of entries are small, there are only a few available working faces. This usually results in delays. This is because mining is cyclical (including continuous mining). Cutting is followed by bolting and servicing (clearing the floor, advancing ventilation and rock dusting), and therefore, any delay in any of the activities affects the others. When there are many working faces available, an activity can be shifted to another location without any interruption. For example, if the bolter is down in entry#1, the miner could work in entry #2 rather than wait for the bolter to be repaired. More entries mean more space. Therefore, machines can maneuver easily and quickly, saving time. In case of shuttle car sections, more entries may mean different routes for loaded and empty cars, thereby reducing travel times.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods

Roof bolter (bolting #3) Miner (cutting #4) Shuttle Cars (moving) Miner (cutting #2) Trickle dusters (left and right) Roof bolter (parked) Feeder + crusher D C D Run thru drops + line curtain Line curtain Power Center Welder Safety sled

Fuel Cell (diesel, hydraulic oil, transmission oil etc)

Scoop battery charging station

End of track

Return Air Stopping

Intake Air Section Belt

Check curtain Point Feed

D Door

Figure 3. Congestion in a four entry longwall development section.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods The more the entries, less is the air resistance. Therefore, volume of air flow is higher than with fewer entries. However, with too many entries, section ventilation may be difficult and prone to leakages (too many curtains). One disadvantage of many entries is that it slows down development and therefore, pillaring. Hence, cash flow may be small for a long time. Too many entries can also be cumbersome and uneconomical. Section ventilation and management becomes difficult in a very spread-out section.

The number of entries in a panel is usually 3 to 7; with 3-4 entry systems being primarily for longwall development. In the mine plan given to you, it was decided to use bridge sections and, therefore, the mine was planned with 5 entries (since any less number of entries causes congestion with bridges). Many times, when the number of entries is large, two sets of equipments (i.e. two sets of miner-bolter-car combinations) are used. These sections are termed super-sections. Angle between entries and crosscuts: The angle between crosscuts and entries depends on the machinery. Bridges and ramcars, for example, require oblique angles, while shuttle cars require perpendicular angles. The angle between the panel entries and main/sub-main entries in the mine plan given to you is oblique to reduce spillage in conveyor transfer points. Conveyor spillage is high when the direction of flow takes a sharp turn (Figure 4). Therefore, one must plan oblique angles wherever the conveyor flow direction is expected to change.

Higher spillage

Lower spillage

Figure 4. Spillage at transfer points. Entry/crosscut height and width: The mining height is dependent on geology (seam heights) and panel requirements. Typically, as long as it can be economically justified, a height comfortable for humans, is preferred. However, many times heights are also justified based on current equipment and personnel. For example, I have known mines to drive certain entries higher to accommodate longwall shields. Sometimes, entry height is determined by roof control; for example, a thin layer of slate is better mined down instead of being supported. The width is primarily dependent on equipment needs. Most entries are 16-20 feet wide. Pillar sizes: These are determined by ground control and systems engineering. The ground control aspects are discussed at length in the next handout. As far as the systems aspect go, as pillars become longer, travel times from one crosscut to another becomes longer. It impacts the haulage cycle times (shuttle or ram car) since when one car is in an entry, others have to wait until the entry is cleared. For larger pillars, such idle waiting times can be long. While driving longwall panels, there is always a conflict between driving longer pillars (reduces total amount of cutting) and reducing idle waiting times by reducing pillar lengths.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Mining Progression: Figures 5 through 8 show the progression in mining activity during the life of a mine. This discussion assumes a pure room and pillar mine (i.e. no longwall panels). The first stage (Figure 5), development, involves driving the mains all the way to the end of the property. The second stage may involve further development, especially in large deposits. In Figure 6, panels are being developed on the flank, while small sections are being developed off of the mains. In the next stage (Figure 7), the sections off of the main are extracted or pillared, while panels continue to being developed. At this point, the production levels in the mine are very high due to the presence of pillaring sections. Mines like to have few pillaring sections as they are very productive. Most mines remain at this stage for a long time, i.e. most mines have both pillaring sections and development sections for a majority of their lifetime. Mining progresses this way (Figure 8) till the deposit is completely mined.

Figure 5. Stage 1: Development Driving the mains to the end of the deposit

Figure 6. Stage 2: Further Development i. ii. Panels developed on the flanks Sections developed off of the mains Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks PANEL SECTION

MIN 454: Underground Mining Methods

Pillar extraction (sections developed earlier being extracted)

Figure 7. Stage 3: Development and Extraction Development around a panel i. Extraction in some areas (dashed lines indicate pillaring or extraction) ii. Development in others

Figure 8. Stage 4: Repeat of Stage 3 Mining slowly retreats to the portal

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Caveats: Many times, however, due to financial reasons, a mine may start developing panels as soon a possible, without waiting to drive to the end of the property. This is especially true of longwall panels, that take about a year to develop. In Figure 9, advance of the mains is delayed, while the longwall panel is developed. The main reason for doing this would be to start the revenue stream quicker.

Figure 9. Driving panels early on (not to scale)

A possible problem with the above is that in the future when panels are developed farther from the mouth of the mine, travel to these panels require that one pass by the older sealed off panels (Figure 10). While sealed off panels are generally safe, they can prove hazardous as seen in the Sago mine accident in 2006.

SEALED PANELS

SEALED PANELS

Figure 10. Traveling by sealed panels. Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Production Cycle: There are two types of production methods in room-and-pillar mining, continuous mining and cyclical mining. Cyclical mining consists of drilling, blasting, mucking or loading and supporting. As these actions occur in sequence or cycles, this type of production is called cyclical. As drilling and blasting is becoming rare in coal mines, and due to time constraints, only continuous mining will be discussed in this course. Continuous mining assumes non-cyclical production. This is attained by the use of a continuous miner that cuts the coal while simultaneously loading it into a conveyor or a shuttle car, thereby, eliminating the need for drilling, blasting and mucking cycles. However, in reality the term continuous mining is a misnomer. Given the continuous miner, and assuming a good haulage system, one can theoretically mine continuously. However, mining is not continuous. This is because mining laws require ground control and ventilation measures to be undertaken after each cut. For example, no opening can be unsupported for more than 40 feet. This means that any time the depth of the cut reaches 40 feet, one must stop cutting and allow roof supports to be installed. Therefore, cutting is only one aspect of a cycle of activities. The cycle usual consists of: cutting coal install roof supports, usually roof bolts extend ventilation using ventilation devices such as brattices or tubes service the face (scoop it) including rock dusting pump water, if necessary survey, to ensure advance in the proper direction periodically one must re-locate the power center so that the machines can advance also periodically, one must advance the static conveyor.

The last two need not interfere with the production cycle when a mine only has two shifts of production per day and one shift of maintenance. These can then be accomplished during the maintenance shift. Any backlogs in roof support is generally also accomplished in the maintenance shift. Surveying is not necessary after each cut though foremen measure the advance from each cut using a tape. Note that miner-bolters are equipment that allow bolting, while cutting coal, thereby not requiring that mining be stopped for roof bolting. Additionally, these machines also have a built-in rock duster. Therefore, when using miner-bolters, coal mining can be very close to continuous mining. Equipment: The typical equipment requirements for room-and-pillar mining are (per section): continuous miner roof bolter haulage machinery such as shuttle cars and bridges utility equipment a scoop and a lo-trac conveyors

The various types of continuous miners, roof bolters, haulage machinery such as shuttle cars and bridges, and conveyors are described in the textbook. The capacities of the machines, however, are a little outdated.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Some recent numbers (these change constantly) on machine output are: Miner loading rate : Shuttle car payload for 6ft seam: Shuttle car speed : Discharge capacity : Panel belt size : Bolting capabilities : Bolting per row : 9-18 tons/min 8.2 tons 91-114 m/min 810 tons/hr 1.07 1-1.5 mins/bolt 5-6 mins

Using these numbers, let us compute the average time to make a cut. Let us assume a 12 m long cut, 6 m wide and 2 m high. The density of r.o.m. coal is: 1.342 tons/m3 i.e. 1.342/0.91 short tons per cubic meter. Tons/cut Time for the miner to cut Car loads/cut = 12x6x2x(1.342/0.91) = 212.4/9 = 212.4/8.2 = 212.4 tons = 24 mins (from miner loading rate) = 26 = 13 = 1.5 mins (assume given) = 1 min (from miner loading rate) = 2.5 mins = 32.5

Assuming 2 cars, trips/car Travel time for car Loading time for the car Cycle time for the car Total time required by each car

= 2.5 x 13

From the above, it becomes clear that the miner will have a wait of about 8.5 minutes (32.5 24). If another car is added: Trips per car Cycle Time Total time = 26/3 =2.5x9 =9 = 2.5 mins = 22.5 mins

If the above time estimates were accurate, we have a good miner-car match. No miner wait time (due to cars) is expected. However, addition of another car will probably add to the car cycle time due to congestion and higher utilization of resources such as feeder (discharge hopper) or miner. The miner-bolter match should also be examined. If the bolting requirements are 4 bolts per row and rows 1.5 m apart: # of rows/cut = cut length/dist. betw. rows = 12/1.5 = 2x1.25 Time per row = Tram time from row to row Total time for row = 2.5+0.5 Time to bolt a cut =8 = 2.5 mins = 0.5 mins = 3 mins = 24 mins

Therefore, the miner and the bolter are perfectly matched. In real life, however, one would design it so that the bolter had a cycle time much less than the miner. This would insure there were no delays due to bolter.

Twin boom ATRS has two drilling booms. Therefore, each operator drills half the required number of holes in parallel to the other operator. Therefore, in the example, time is accounted for only 2 holes.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Note: In the above example, we did not take into account the tram time between cuts or the time to service the face. We are assuming that the miner and the bolter have the same tram time and that there is an additional face that the scoop services, while the bolter is bolting the fresh cut. In a four entry system, typically only one free face is available and, therefore, bolting and servicing have to be completed, while the miner is cutting the face. The ventilation also determines cycle time. A four entry longwall development section is presented next, where it becomes clear that miner-shuttle car-bolter times are not the only factors that determine cycle time. Figure 11 presents a 4 entry longwall development section. As in most modern mines, the section has two miners (one for each side, left and right) and two bolters (one for each side, left and right) in addition to four shuttle/ram cars. Note the section ventilation. In the left side, the intake air travels from #2 entry to #1 entry before returning, while in the right side, it travels from #3 entry to #4 entry before returning. Since miners cannot work downstream of a continuous miner (due to high dust levels), it precludes #4 entry being bolted or serviced, while #3 entry is being mined. Similarly, when #2 is being mined, #1 entry has to be idled (as shown in Figure 11, where the bolter is simply parked). When the miner is in #1 entry, #2 can be bolted and serviced (except, when #2 is being rock dusted, the miner in #1 would have to be briefly stopped). Same applies to #3 and 4 entries. Miner (cutting #2) Miner cutting #4

Roof bolter (parked)

D C

Roof bolter pinning #3

Figure 11. Factors affecting cycle time.

1 Return Air Stopping

2 Intake Air Section Belt

4 C Check curtain Point Feed

D Door

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

MIN 454: Underground Mining Methods Therefore, as far as equipment utilization goes, only the miner is being utilized on one side when the inside entries (#2 or 3) are being mined. The bolter is effectively idled since space limitations require it to be parked in the outside entries (#1 or #4 entry), which gets dusted out. The scoop can hopefully be kept active doing other work. Lets look at a longer cycle to see how the actual run might be. Considering only the right side (the analysis applies to right side since its a mirror image), when the miner is done cutting #3, it moves to #4. While it is cutting #4, #3 gets bolted and serviced. If everything works perfectly, #3 will be ready when the miner gets done with #4. But so what? Can the miner go to #3? No, because #4 now needs to be bolted and serviced, which means, you cannot dust out #4. Therefore, the miner will have to wait, so that #4 can be bolter and serviced. Hopefully, during this idle time, some maintenance is done on the miner (oil and bits changed, general cleaning done besides other routine maintenance). In any case, these issues are not taken into account in computations done previously. Therefore, one must take into account the entire cycle when estimating section productivity. In my experience, I have seen management very often over-estimate section advance rates since idle times such as from moving the return up, or those due to belt and power moves, or inbuilt cycle delay time (like the one presented earlier) are not incorporated into time studies.

References and Recommended Reading Special on Appalachian Coal, 1995, Mining Engineering, SME Publication, December. Ganguli, R, 1997, Multiseam Mine Design for Buffalo Creek and Winifrede Seams, Report submitted to Arch of Kentucky, July. Stefanko, R., 1983, Coal Mining Technology, Theory and Practice, SME Publication.

Instructor: Dr. Rajive Ganguli, University of Alaska Fairbanks

You might also like

- Handout 3 - MIN 454Document13 pagesHandout 3 - MIN 454rajganguliNo ratings yet

- Sublevel Stoping Method: (Orblastholestoping)Document11 pagesSublevel Stoping Method: (Orblastholestoping)Jóse AntonioNo ratings yet

- 4underground Coal Mining MethodsDocument14 pages4underground Coal Mining MethodsAkhil Sai KrishnaNo ratings yet

- Reading Material On TunnelingDocument35 pagesReading Material On Tunnelingisithkesara23No ratings yet

- Chapter 3 - HeadingDocument18 pagesChapter 3 - Headingrozana luqmanNo ratings yet

- Pete424 Chapter3Document20 pagesPete424 Chapter3Milton Saul Cruz YucraNo ratings yet

- Multilateral Well Technology OverviewDocument18 pagesMultilateral Well Technology OverviewKaouachi Ahmed LouayNo ratings yet

- Chapter 11. Cost Calculations For Highly Mechanized Cut-and-Fill StopingDocument50 pagesChapter 11. Cost Calculations For Highly Mechanized Cut-and-Fill StopingEdward RmzNo ratings yet

- Supported Method1Document19 pagesSupported Method1Kanishka DilshanNo ratings yet

- Multilateral Well (Mohsin)Document10 pagesMultilateral Well (Mohsin)Mohsin ZiaNo ratings yet

- 1mining Through Adit, Incline, Decline and ShaftDocument11 pages1mining Through Adit, Incline, Decline and ShaftAkhil Sai KrishnaNo ratings yet

- 16.shortwall Mining-D M Gokhale, WCLDocument6 pages16.shortwall Mining-D M Gokhale, WCLkatta_sridharNo ratings yet

- Case Studies Kohat TunnelDocument17 pagesCase Studies Kohat TunnelMustafa Zahid100% (1)

- DRLG 6035pDocument24 pagesDRLG 6035pJorge Jiménez100% (2)

- Mining Magazine - Sinking SkilfullyDocument14 pagesMining Magazine - Sinking SkilfullyLehlohonolo MoqekelaNo ratings yet

- Vertical Crater RetreatDocument3 pagesVertical Crater RetreatvinothkhannaNo ratings yet

- Introduction of Directional Drilling in Oil & Gas Indutry - WikipediaDocument5 pagesIntroduction of Directional Drilling in Oil & Gas Indutry - WikipediaFaiz AhmadNo ratings yet

- Shafts DesignDocument14 pagesShafts DesignIslam AhmedNo ratings yet

- A Longwall Face Comprises The Following ElementsDocument20 pagesA Longwall Face Comprises The Following ElementsUnknownNo ratings yet

- Subway Construction Using Tripled-Faced Shield Method and RC Seg-Ments in Soft GroundDocument7 pagesSubway Construction Using Tripled-Faced Shield Method and RC Seg-Ments in Soft GroundHarold TaylorNo ratings yet

- Chapter 2: Literature ReviewDocument14 pagesChapter 2: Literature ReviewShahadat HossainNo ratings yet

- Prevent Surface Subsidence with Pillar DesignDocument6 pagesPrevent Surface Subsidence with Pillar DesignDaniel SantanaNo ratings yet

- Examples of Good and Bad Chute DesignDocument7 pagesExamples of Good and Bad Chute DesignAmit BhaduriNo ratings yet

- Drilling and Technology5Document11 pagesDrilling and Technology5Aryan el-BerwarîNo ratings yet

- OPENCAST MINE PLANNING AND DRAGLINE OPTIMIZATIONDocument21 pagesOPENCAST MINE PLANNING AND DRAGLINE OPTIMIZATIONMadhu GovindanNo ratings yet

- Free-Samples - Amie - Chapters - Pillar Mining Methods-Sec-B-EmdDocument31 pagesFree-Samples - Amie - Chapters - Pillar Mining Methods-Sec-B-EmdSouvik RayNo ratings yet

- Bord and Pillar Method of WorkingDocument20 pagesBord and Pillar Method of WorkingSheshu Babu50% (2)

- Shrinkage StopingDocument14 pagesShrinkage StopingWilliam WatersNo ratings yet

- New Tunnel Boring MachineDocument7 pagesNew Tunnel Boring Machinealvaroaac4100% (1)

- Modern Drilling Equipment For Underground ApplicationsDocument5 pagesModern Drilling Equipment For Underground ApplicationsAnkur MandawatNo ratings yet

- Pillar Mining MethodsDocument32 pagesPillar Mining Methodsbongisisa9No ratings yet

- Enlargement of Live Line Tunnel by Drilling and BlastingDocument6 pagesEnlargement of Live Line Tunnel by Drilling and BlastingHarold TaylorNo ratings yet

- Drilling and Technology8Document11 pagesDrilling and Technology8Aryan el-BerwarîNo ratings yet

- ESSENTIAL UNIT OPERATIONS IN MININGDocument10 pagesESSENTIAL UNIT OPERATIONS IN MININGNaveenNo ratings yet

- Lecture Note PPT Lecture Eight Prepared by Zzigwa MarvinDocument22 pagesLecture Note PPT Lecture Eight Prepared by Zzigwa MarvinAthiyo Martin100% (1)

- 14v144g Ok SubterraneoDocument10 pages14v144g Ok SubterraneoMINEXPONNo ratings yet

- Drilling and Technology7Document11 pagesDrilling and Technology7Aryan el-BerwarîNo ratings yet

- D Martin Et Al - Borehole Hoisting SystemsDocument14 pagesD Martin Et Al - Borehole Hoisting SystemsalunpjNo ratings yet

- Pit OptimisationDocument6 pagesPit OptimisationJuan Pablo Henríquez ValenciaNo ratings yet

- Design of Large Diameter Microtunnelling Shafts in Soft GroDocument9 pagesDesign of Large Diameter Microtunnelling Shafts in Soft Grojenshid100% (2)

- Disadvantages and Benefits of Horizontal Wells: T.K. Akhmedzhanov, I. B. Igembaev, D.K. Baiseit, A. S. Abd ElmaksoudDocument4 pagesDisadvantages and Benefits of Horizontal Wells: T.K. Akhmedzhanov, I. B. Igembaev, D.K. Baiseit, A. S. Abd Elmaksoudbagus1313No ratings yet

- 14 Geomechanical Issues in Longwall Mining-An IntroductionDocument22 pages14 Geomechanical Issues in Longwall Mining-An IntroductionRogerio DiasNo ratings yet

- Pique o Rampa 6Document10 pagesPique o Rampa 6Yery SantanderNo ratings yet

- Cut-and-Fill Stoping Cost CalculationsDocument21 pagesCut-and-Fill Stoping Cost CalculationsHubertZenonQuentaCondoriNo ratings yet

- Week2 GEM314e-2012Document36 pagesWeek2 GEM314e-2012Kendal YeltekinNo ratings yet

- Unsupported MethodsDocument21 pagesUnsupported MethodsOgina Lamenta-AbuanNo ratings yet

- SHRINKAGE STOPING MINING METHODDocument6 pagesSHRINKAGE STOPING MINING METHODRiuRiversNo ratings yet

- LONGWALL MINING METHODSDocument22 pagesLONGWALL MINING METHODSUnknownNo ratings yet

- Horizontal Drilling - M. EconomideDocument36 pagesHorizontal Drilling - M. EconomideRosa K Chang HNo ratings yet

- Pit to Plant Trends in In-Pit Crushing and ConveyingDocument6 pagesPit to Plant Trends in In-Pit Crushing and Conveyingretrospect1000No ratings yet

- Drilling and Technology6Document11 pagesDrilling and Technology6Aryan el-BerwarîNo ratings yet

- Block CavingDocument23 pagesBlock CavingNatália AraújoNo ratings yet

- Rump Jalan TambangDocument9 pagesRump Jalan TambangAndre AlistinNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- A Practical Course in Wooden Boat and Ship BuildingFrom EverandA Practical Course in Wooden Boat and Ship BuildingRating: 4 out of 5 stars4/5 (1)

- Permeability of Sandstone and Coal Samples Subjected To ConfiningDocument101 pagesPermeability of Sandstone and Coal Samples Subjected To Confiningkatta_sridharNo ratings yet

- Bridges & StructuresDocument24 pagesBridges & Structureskatta_sridharNo ratings yet

- 25th International Conference On Ground Control in MiningDocument6 pages25th International Conference On Ground Control in Miningkatta_sridharNo ratings yet

- LW Face Supports in Germal Coal Mining CompanyDocument24 pagesLW Face Supports in Germal Coal Mining Companykatta_sridharNo ratings yet

- Experience in Longwall Mining at Coalbrook CollieriesDocument15 pagesExperience in Longwall Mining at Coalbrook Collierieskatta_sridharNo ratings yet

- Pressure Arch Theory (Longwall) : Prepared by P. Vinay CharyDocument23 pagesPressure Arch Theory (Longwall) : Prepared by P. Vinay Charykatta_sridharNo ratings yet

- WATER PROBLEMS ASSOCIATED With Undersea LWDocument20 pagesWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharNo ratings yet

- Investigation of Rib Pillar Stability at Ömerler Underground Mine byDocument8 pagesInvestigation of Rib Pillar Stability at Ömerler Underground Mine bykatta_sridharNo ratings yet

- A Study of The Behaviour of Overlying Strata in Longwall Mining and Its Application To Strata Contro 141111171916 Conversion Gate02Document5 pagesA Study of The Behaviour of Overlying Strata in Longwall Mining and Its Application To Strata Contro 141111171916 Conversion Gate02katta_sridharNo ratings yet

- Mine-scale numerical modelling compares longwall extraction methodsDocument11 pagesMine-scale numerical modelling compares longwall extraction methodskatta_sridharNo ratings yet

- NUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWDocument12 pagesNUMERICAL MODELLING OF SURFACE SUBSIDENCE Due To LWkatta_sridharNo ratings yet

- Automation in LongwallDocument116 pagesAutomation in Longwallkatta_sridharNo ratings yet

- Manage Ground Risks Gold MineDocument8 pagesManage Ground Risks Gold Minekatta_sridharNo ratings yet

- Pillar in Coal MinesDocument8 pagesPillar in Coal MinesSujit KumarNo ratings yet

- Design of Rib Pillars in LW MiningDocument16 pagesDesign of Rib Pillars in LW Miningkatta_sridharNo ratings yet

- Tiwari InnovationDocument1 pageTiwari Innovationkatta_sridharNo ratings yet

- Export - 2015-09-03 09-05-55Document1 pageExport - 2015-09-03 09-05-55katta_sridharNo ratings yet

- 14EE MiningTechnology-CavingSlopeInteractionModellingDocument9 pages14EE MiningTechnology-CavingSlopeInteractionModellingMezamMohammedCherifNo ratings yet

- 13.hydraulic Mining With Automation - Suresh D. Gharde, WCL HQDocument6 pages13.hydraulic Mining With Automation - Suresh D. Gharde, WCL HQkatta_sridharNo ratings yet

- WATER PROBLEMS ASSOCIATED With Undersea LWDocument20 pagesWATER PROBLEMS ASSOCIATED With Undersea LWkatta_sridharNo ratings yet

- Stress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual PillarsDocument7 pagesStress Evolution and Induced Accidents Mechanism in Shallow Coal Seam in Proximity Underlying The Room Mining Residual Pillarskatta_sridharNo ratings yet

- Thick Seam Longwall MiningDocument10 pagesThick Seam Longwall Miningkatta_sridharNo ratings yet

- 15.production and Productivity Improvement Measures at MOIL-MOILDocument8 pages15.production and Productivity Improvement Measures at MOIL-MOILkatta_sridharNo ratings yet

- 14.an Overview of Ug Coal mining-WCL HQDocument30 pages14.an Overview of Ug Coal mining-WCL HQkatta_sridharNo ratings yet

- 16.shortwall Mining-D M Gokhale, WCLDocument6 pages16.shortwall Mining-D M Gokhale, WCLkatta_sridharNo ratings yet

- Deformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering GeologyDocument12 pagesDeformation Failure and Permeability of Coal Bearing Strata During Longwall Mining 2016 Engineering Geologykatta_sridharNo ratings yet

- 12.challenges in UG Coal mining-CMPDI RanchiDocument7 pages12.challenges in UG Coal mining-CMPDI Ranchikatta_sridharNo ratings yet

- Caving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining SciencesDocument11 pagesCaving Mechanisms of Loose Top Coal in Longwall Top Coal Caving Mining Method 2014 International Journal of Rock Mechanics and Mining Scienceskatta_sridharNo ratings yet

- 19 Ratnesh Mine ClosureDocument12 pages19 Ratnesh Mine Closurekatta_sridharNo ratings yet

- Strata Behaviors in Extra-Thick Coal SeamsDocument10 pagesStrata Behaviors in Extra-Thick Coal Seamskatta_sridharNo ratings yet