Professional Documents

Culture Documents

Role of Oxidative Stress and The Activity of Ethylene Biosynthetic Enzymes On The Formation of Spongy Tissue in Alphonso' Mango

Uploaded by

10sgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Role of Oxidative Stress and The Activity of Ethylene Biosynthetic Enzymes On The Formation of Spongy Tissue in Alphonso' Mango

Uploaded by

10sgCopyright:

Available Formats

J Food Food Sci Sci Technol Technol (MayJune (MayJune 2010) 2010) 47(3):295299 47(3):295299 J DOI: 10.

1007/s13197-010-0046-9

295

ORIGINAL ARTICLE

Empowering the Food Professional

Role of oxidative stress and the activity of ethylene biosynthetic enzymes on the formation of spongy tissue in Alphonso mango

Nagamani J. E.

Shivashankara K. S.

Roy T. K.

Revised: 27 July 2009 / Accepted: 2 August 2009 Association of Food Scientists and Technologists (India), Mysore

Abstract Spongy tissue formation in Alphonso mangoes (Mangifera indica L) is a major national problem leading to loss for farmers and traders. Spongy tissue is whitish sponge like tissue formed near the seed with insipid taste and off odour. Lipid peroxidation of membranes as studied by malondialdehyde formation was signicantly higher in spongy tissue. Activities of antioxidative enzymes like superoxide dismutase, catalase, peroxidase and polyphenol oxidase were lower in spongy tissue. Among the antioxidative enzymes, activities of catalase and peroxidases were severely reduced leading to membrane damage in spongy tissue. A signicant reduction in 1-aminocyclopropane1-carboxylic acid (ACC) oxidase and accumulation of ACC was also observed in spongy tissue. However, ACC synthase activity in spongy tissue was more compared to healthy tissue. Results indicate that the membrane peroxidation leading to lower activity of ACC oxidase might lead to the formation of spongy tissue in Alphonso mango.

Introduction Spongy tissue in Alphonso mango is the formation of whitish sponge-like tissue near the stone. The fruit pulp remains unripe due to physiological and biochemical disturbances caused by various factors during ripening of fruits (Katrodia and Seth 1988). External symptoms are not apparent at the time of picking or at the ripe stage. The fruit with spongy tissue exhibits varying degree of tissue breakdown and contains more starch, acid and has off-odour. Numerous factors are known to inuence the incidence and extent of disorder. Some of the probable causes cited are lower calcium content (Gunjate et al. 1979), higher fruit weight (Joshi and Limaye 1986), high soil temperature (Katrodia and Seth 1988), excessive tree vigour (Katrodia and Rane 1981), post-harvest exposure of fruits to sunlight (Gunjate et al. 1982) and lower fruit transpiration rate (Shivashankar and Mathai 1999). Spongy tissue also showed lower activities of -amylase, glutamate dehydrogenase, glutamate oxaloacetate transaminase, peroxidase, catalase, superoxide dismutase, pectin methyl esterase and higher activities of invertase and ascorbic acid oxidase (Gupta et al. 1985, Selvaraj et al. 2000). Higher expression of alcohol dehydrogenase has been reported in spongy tissue indicating the anaerobiasis (Vasanthaiah et al. 2006). Recently, bacterial infection was reported to be a factor responsible for the initiation of spongy tissue (Janave and Sharma 2008). Lower availability of oxygen may alter the antioxidative systems and ethylene biosynthesis in the affected tissues. Even though the lower activities of antioxidative enzymes were reported its relationship with the membrane peroxidation and ethylene biosynthesis was not studied. In mango, a small but notable peak of ethylene is produced during ripening in the cultivars Haden, Kent, Manila and Ataulfo (Cua and Lizada 1990, LopezGomez and Gomez-Lin 1992). The incidence of spongy tissue is considered to be a ripening disorder, which may be due

Keywords Mango . Alphonso . Spongy tissue . Malondialdehyde . Antioxidative enzymes . Aminocyclopropane-1-carboxylic acid oxidase

Nagamani J. E. . Shivashankara K. S. . Roy T. K. Division of Plant Physiology and Biochemistry, Indian Institute of Horticultural Research, Hessaraghatta lake Post, Bangalore - 560 089, India Shivashankara K. S. ( ) E-mail: shiva@iihr.ernet.in

123

296

J Food Sci Technol (MayJune 2010) 47(3):295299

to lower availability of ethylene due to the lower activities of ethylene forming enzymes. Lower ethylene production may also be due to the membrane damage caused by the generation of reactive oxygen species. In this study we compared the activities of ethylene biosynthetic and antioxidative enzymes in spongy tissue, matured unripe tissue, 3/4th ripened and fully ripened healthy tissues of Alphonso mangoes to identify the role of these enzymes in spongy tissue development. Materials and methods Uniform sized Alphonso mango (Mangifera indica L) fruits were harvested from orchard and the samples from fruits of different ripening stages were collected. Samples from mature unripe tissue, 3/4th ripen tissue, completely ripen healthy tissue, spongy tissue, healthy ripen tissue surrounding the spongy tissue and spongy tissue induced at 40C (mature unripe fruits were ripened at 40C in an oven) were collected. About 500 g of tissue from each of the samples were taken for the preparation of acetone powder, which was used for different enzyme assays. Preparation of acetone powder: The fruit tissue was ground using chilled acetone (10C) in a cold room. The ne paste was ltered and squeezed using muslin cloth. The process was repeated 3 to 4 times until the tissue became a white powder. The powder was air dried to remove traces of acetone, packed in polythene bags and stored at 10C. This acetone powder was used for different enzyme assays. Estimation of malondialdehyde (MDA) content: MDA was extracted following the procedure of Draper and Hadley (1990) by homogenizing 1 g of fruit tissue with 5 ml of 5% aqueous trichloroacetic acid (TCA) solution and 0.5 ml of methanolic butylated hydroxy toluene (BHT). The resulting homogenate was heated for 30 min in a boiling water bath. Then the sample was cooled and centrifuged at 1000g for 10 min. The volume of the resulting supernatant was adjusted to 10 ml with distilled water. The assay mixture consisted of 1 ml aliquot of the supernatant sample and 1 ml of saturated thiobarbituric acid (TBA) solution. The tubes were incubated in boiling water bath for 30 min, cooled and the absorbance of the reaction product was assayed spectrophotometrically at 532 nm against a blank solution. Estimation of superoxide dismutase (SOD) activity: SOD activity was assayed as per the method of Zhanyuan and Bramlage (1994). Acetone powder (0.5 g) was mixed with 10 ml of 50 mM phosphate buffer (pH 7), containing 0.1 ml of 0.3 M MgCl2, and 0.1 ml of 10 mM ethylenediamine tetraacetic acid (EDTA) solution and incubated overnight at 4C. The mixture was homogenized and centrifuged at 15,000g for 15 min and the supernatant was used for enzyme assay. SOD activity was estimated by measuring the ability of SOD to inhibit the photochemical reduction of nitroblue tetrazolium chloride (NBT) in presence of riboavin and methionine and the absorbance of the

assay mixture was read at 560 nm. One unit of SOD activity was dened as the amount of enzyme that inhibited the NBT photoreduction by 50 % under assay conditions. Estimation of catalase activity: Catalase activity was estimated as per the procedure of Masia (1998). Enzyme was extracted from acetone powder using 10 ml of 100 mM chilled sodium phosphate buffer (pH 7) as described earlier by centrifuging at 11,000 g for 20 min at 4C. The resulting supernatant solution was immediately used for enzyme assay. Catalase activity was recorded at 20C according to Aebi (1984). Catalase activity was measured by the reduction in absorbance at 240 nm in a mixture containing 1.5 ml of 50 mM sodium phosphate buffer (pH 7), 0.5 ml of 100 mM H2O2 solution and 0.3 ml of crude enzyme extract and was expressed as units / g fresh weight. Peroxidase: Peroxidase activity was assayed as per the procedure of Chan and Yang (1971). Crude enzyme extract from acetone powder using 10 ml of chilled 0.05 M citrate phosphate buffer (pH 6.4) was used for the estimation of enzyme activity. The assay mixture contained 4.5 ml of 50 mM chilled sodium citrate buffer (pH 6.4), 0.2 ml of 0.3% prechilled H2O2 solution, 0.2 ml of 1% chilled o-phenyldiamine solution and 0.5 ml of crude enzyme extract. Intensity of the colour produced was read at 450 nm at 1 min interval up to 10 min gainst suitable blank. Estimation of polyphenol oxidase (PPO) activity: Polyphenol oxidase activity was assayed following the method described by Selvaraj and Kumar (1989). Crude enzyme from acetone powder was extracted using 10 ml of 0.05 M citrate phosphate buffer (pH 6.8). Oxidation of pyrogallol was read at 450 nm in 0.05 M citrate phosphate buffer (pH 6.8) media. Estimation of Aminocyclopropane-1-carboxylic acid (ACC) content: Estimation was done as per the method of Lizada and Yang (1979). ACC extract was prepared by homogenizing 5 g of fruit tissue with 10 ml of cold 5% sulphosalicylic acid and centrifuged at 10,000g for 10 min. The resulting supernatant solution was taken for ACC estimation and the assay was carried out in 25 ml of Erlenmeyer asks. The assay mixture consisted of 3 ml of crude ACC extract and 0.3 ml of 10 mM HgCl2 solution; the reaction vessels were then sealed with rubber serum stoppers and kept in ice. Again 0.3 ml of cold mixture of 5% sodium hypochlorite saturated NaOH solution was injected through stoppers using 1 ml syringe tted with a 25-gauge needle. Reaction mixtures in asks were agitated on a shaker for 2.5 min after which, 100 l of gas samples were withdrawn for ethylene determination. Ethylene was assayed on a gas chromatograph (HP 5890, USA) equipped with a porapack column and a ame ionization detector. The temperature of the column was maintained at 80C. The amount of ethylene formed corresponds to the quantity of ACC in the tissue and was determined by using internal standards. Estimation of ACC synthase activity: ACC synthase activity was assayed as per the method by Sitrit et al.

123

J Food Sci Technol (MayJune 2010) 47(3):295299

297

(1987). Enzyme extract was prepared by suspending 2.5 g of acetone powder in 50 ml of extraction buffer (50 mM, pH 7.2) and incubated overnight in cold conditions. The extract was homogenized using a prechilled mortar and pestle, ltered through 4 layers of muslin cloth and centrifuged at 10,000g for 10 min at 4C. The resulting supernatant solution was used as crude enzyme extract. All the steps in preparation of the enzyme extract were carried out at 04C. ACC synthase enzyme was precipitated from the supernatant solution by slowly adding ammonium sulphate salt up to 90% saturation, letting the mixture stand for 1 h and centrifuging as above. The supernatant was discarded and the pellet obtained was dissolved in 4 ml of 10 mM potassium phosphate buffer (pH 7.2) containing 0.1 mM dithiothreitol (DTT) and 2 M pyridoxal phosphate and dialysed overnight against the same solution. The dialysate was claried by centrifugation and was used as enzyme extract. The assay mixture contained 3 ml of enzyme extract, 0.25 ml of 40 mM 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (HEPES) buffer (pH 8.2) and 0.25 ml of 200 nM S-adenosyl methionine (SAM) solution in 25 ml of Erlenmeyer asks. The asks were sealed with rubber serum cap and kept for incubation at 30C for 12 h. Then the reaction was stopped by adding 0.3 ml of 10 M HgCl2 solution followed by the addition of 0.3 ml cold 5% NaOH-sodium hypochlorite solution and again incubated for 2 h. The ACC formed was assayed by the method of Lizada and Yang (1979). Enzyme activity is expressed as g of ACC synthesized. Estimation of ACC oxidase activity: ACC oxidase activity was assayed as per the method by Henryk (1989). For the preparation of enzyme extract, 0.5 g of acetone powder was incubated overnight in 20 ml of 25 mM HEPES tris buffer (pH 7.5) in cold condition, and was homogenised using a prechilled mortar and pestle. The extract was ltered through muslin cloth then centrifuged at 10,000g for 10 min. Extraction and subsequent steps were carried out at 4C. The supernatant was used for enzyme assay. ACC oxidase activity was determined by measuring the conversion of administered ACC to ethylene in vivo. The assay

mixture consisted of 4 ml of enzyme extract, 0.1 ml of 1.55 mM sorbital solution and 0.25 ml of 1 mM ACC in 25 mL of Erlenmeyer asks. The asks were sealed with rubber serum cap and shaken constantly at 27C for 12 h. The ethylene formed was estimated on a gas chromatograph equipped with a porapack column and a ame ionization detector. The temperature of the column was maintained at 80C. Ethylene was measured every 2 h and the asks were aerated after each sampling and resealed. Statistical analysis: Data were statistically analysed by completely randomized design method using statistical analysis package of Microsoft Ofce Excel. Results and discussion Results are presented in Table 1. Lipid peroxidation was more in spongy tissue (2.32 g of MDA) when compared to articially induced spongy tissue (1.80 g) and healthy tissue (1.44 g). MDA content of mature unripe tissue (0.48 g), 3/4 th ripen tissue (1.16 g) was also lower than the completely ripen healthy tissue (1.44 g) indicating that the lipid peroxidation of cell membrane increases with the increase in ripening. Higher lipid peroxidation of membranes was observed during fruit ripening (Keista et al. 1998, Kumar et al. 1990) due to generation of free radicals. Higher MDA in spongy tissue indicate higher lipid peroxidation of membranes when compared to normal healthy ripe tissue. Activities of antioxidative enzymes: Activities of SOD and catalase were signicantly lower in spongy tissue (23.0 and 1.0 U/g tissue, respectively) when compared to the healthy ones (64.2 and 2.5 U/g tissue). A signicant reduction in the activity of peroxidase was also observed in spongy tissue (0.06 U/g) as compared to healthy tissue (0.30 U/g). Lower activity of PPO was observed in spongy tissue (1.06 U/g) when compared to the healthy tissue (1.66 U/g) but the extent of reduction was less when compared to other enzymes. Activity of all the antioxidative enzymes increased with ripening. The induced spongy tissue showed slightly higher activity PPO when compared to the natural spongy tissue.

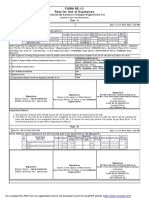

Table 1 Malondialdehyde (MDA) and ACC contents and the activities of antioxidative and ethylene biosynthetic enzymes in six types of tissues from Alphonso mango Tissues MU 3/4 R CR HSS SP ISP

th

SOD, U/g fw 29.92c 63.84 63.68

a

Peroxidase, U/g fw 0.12d 0.40

b

Catalase, U/g fw 0.65e 1.80 3.03

c

PPO, U/ 100g fw 1.06c 1.20 1.19

b

MDA, g /100 g fw 0.48f 1.16

d

ACC content, g /g fw 0.42a 0.14 0.13

d

ACC-OA, l C2H4/h/Kg fw 0.0474e 0.2769 0.1797

a

ACC-SA, g ACC/h/Kg fw 0.0180a 0.0114bc 0.0094d 0.0098d 0.0129b 0.0100cd

64.16a

a

0.30c 0.42

a

2.48b

a

1.66a

b

1.44d 1.55

c

0.12d

d

0.1780b

b

23.01d 37.66b

0.06e 0.03f

1.00d 1.08d

1.06c 1.20b

2.32a 1.80b

0.34b 0.18c

0.0612d 0.0812c

MU = Mature Unripe tissue, 3/4th R = 3/4th Ripen tissue, CR = Completely ripen tissue, HSS = Healthy tissue surrounding spongy tissue, SP = Spongy tissue, ISP = Induced spongy tissue, SOD = Superoxide dismutase, PPO = Polyphenol oxidase, ACC = 1-Aminocylopropane-1 carboxylic acid, ACC-OA = ACC oxidase, ACC-SA = ACC synthase. Values followed by same superscript in a column are not signicantly different at p = 0.01

123

298

J Food Sci Technol (MayJune 2010) 47(3):295299

Increased activities of peroxidase and catalase were observed during the ripening of mango (Keista et al. 1998). This was associated with the climacteric raise in ethylene production (Masia 1998). However, lower activities of peroxidase and catalase (Gupta et al. 1985), higher activities of PPO (Selvaraj et al. 2000) and peroxidase (Lima et al. 1999) were reported in spongy tissue when compared to the healthy tissue. Our results indicated that the activities of antioxidant enzymes increase during fruit ripening. However, in spongy tissue the activity was signicantly reduced indicating that the ripening process was inhibited in the spongy tissue. This could be due to lower ethylene production in the spongy tissue. Lower ethylene forming enzyme activity was reported in spongy tissue (Selvaraj et al. 2000). Our results indicate that, ACC content was more in the unripe stage (0.42 g/g fw) followed by spongy tissue (0.34 g/g fw), heat induced spongy tissue (0.18 g/g fw) and decreased with ripening (0.14 and 0.12 g /g fw at 3/4 th and fully ripen stage respectively). Similar trend was reported by Hoffman and Yang (1980) in avocadoes and banana. They reported that the level of ACC is determined by the rate of ACC synthesis relative to its rate of utilization or degradation. In avocado and banana there was rapid accumulation of ACC during the onset of ripening and also as the fruit becomes overripe. Higher ACC content in spongy tissue shows that the formation of spongy tissue takes place at the initiation of fruit ripening process. ACC oxidase activity increased rapidly from unripe stage (0.0474 l C 2H4 h1 kg1 fw) to the 3/4th ripe stage (0.2769 g C2H4 h1 kg1 fw) indicating the onset of climacteric peak of ethylene production at the initiation of ripening process. As a result of this, ACC content drops from unripe stage to the 3/4th ripe stage. A reduction in the activity was observed from 3/4th ripe stage to completely ripe stage (0.1780 g C2H4 h1 kg1 fw). A reduction in ACC oxidase activity was observed in natural spongy (0.0612 l C 2H4 h1 kg1 fw) and induced spongy tissue (0.0812 l C 2H4 h1 kg1 fw) when compared to healthy tissue. The activity was not affected in the healthy tissue from affected fruit (0.1797 l C 2H4 h1 kg1 fw.). Lower activity of ACC oxidase leads to decreased rate of ethylene production and the accumulation of ACC content in spongy tissue. ACC synthase activity, measured as ACC produced, decreased gradually from mature unripe stage (0.0180 g ACC h1 kg1 fw) to 3/4th ripe stage (0.0114 g ACC h1 kg1 fw) and to completely ripe stage (0.0094 g ACC h1 kg1 fw). ACC synthase activity of spongy tissue (0.0129 g ACC h1 kg1 fw) was in between mature unripe stage to 3/4th ripe stage. After heat treatment ACC synthase activity in induced spongy tissue (0.010 g ACC h1 kg1 fw) was slightly lower than that of natural spongy tissue (0.0129 g ACC h1 kg1 fw). This further indicates that the incidence of spongy tissue occurs during the initiation of ripening process. Results also indicate that ACC synthase was not much affected by the formation of spongy tissue. Similar

results were reported during the heat treatment of mangoes by Keista et al. (1998). A 5 fold increase in protein content during ripening has been reported in mango (Castrillo et al. 1992). Due to increased concentration of protein the activity of ACC oxidase enzyme per unit fruit tissue increased markedly at the 3/4th ripen stage and completely ripen stage. However there was a reduction in the activity of ACC synthase indicating that the climacteric peak in ethylene evolution is probably due to increased activity of ACC oxidase. Therefore the inhibition of ACC oxidase in spongy tissue might result in insufcient ethylene production leading to ripening disorder. Conclusion The spongy tissue formation occurs at the initiation of ripening process and this disorder is mainly due to the lower activity of ACC oxidase leading to lower ethylene production. Higher lipid peroxidation of membranes due to lower activities of antioxidative enzymes has further contributed to the loss of membrane integrity and formation of sponginess in the tissue. Acknowledgement The work was carried as a part of NATP-CGP scheme of ICAR. References

Aebi H (1984) Catalase in vitro. Methods Enzymol 105:121126 Castrillo M, Kruger NJ, Whatley FR (1992) Sucrose metabolism in mango fruit during ripening. Plant Sci 84:4551 Cua AU, Lizada MCC (1990) Ethylene production in the carabao mango fruit during maturation and ripening. Acta Hort 269:69175 Chan HT, Yang HY (1971) Identication and characterization of some oxidizing enzymes of the MC farlin cranberry. J Food Sci 36:169173 Draper HH, Hadley M (1990) Malondialdehyde determination as index of lipid peroxidation. Methods Enzymol 186:421431 Gunjate RT, Tare SJ, Rangawala AD, Limaye VP (1979) Calcium content in Alphonso mango fruits in relation to occurrence of spongy tissue. J Mah Agric Univ 4:159161 Gunjate RT, Walimbe BP, Lad BP, Limaye VP (1982) Development of internal breakdown in Alphonso mango by post harvest exposure of fruits to sunlight. Sci Cult 48:188190 Gupta DN, Lad BL, Chavan AS, Salvi MJ (1985) Enzyme studies on spongy tissue: a physiological ripening disorder in Alphonso mango. J Mah Agric Univ 10:280282 Henryk P (1989) The rate of ethylene production related to 1-aminocyclopropane-1-carboxylic acid formation and ethylene forming enzyme activity in ripening apples. Fruit Sci Rep 16:141154 Hoffman EN, Yang SF (1980) Changes of 1-aminocyclo propane 1-carboxylic acid content in ripening fruits in relation to their ethylene production rates. J Am Soc Hort Sci 105:492495 Janave MT, Sharma A (2008) Spongy tissue development in Alphonso mango: association with Staphylococcus xylosu.s Eur J Plant Pathol 122:335348 Joshi GD, Limaye VP (1986) Effects of tree location and fruit weight on spongy tissue occurence in Alphonso mango. J Mah Agric Univ 11:104109

123

J Food Sci Technol (MayJune 2010) 47(3):295299 Katrodia JS, Rane DA (1981) Effect of tree vigour in relation to spongy tissue development in Alphonso mango fruit. Haryana J Hort Sci 10:151154 Katrodia JS, Sheth IK (1988) Spongy tissue development in mango fruit of cv. Alphonso in relation to temperature and its control. Acta Hort 231:827834 Keista S, Chidtragood S, Klein JD, Wurie S (1998) Ethylene synthesis in mango fruit following heat treatment. Postharvest Biol Technol 15:6572 Kumar S, Patil BC, Sinha SK (1990) Cyanide resistant respiration is involved in temperature rise in ripening mangoes. Biochem Biophys Res Comm 168:818822 Lima LC, Chitarra AB, Chitarra MIF, Silva EB, Michalczuk L (1999) Enzymatic activity changes in spongy tissue: A physiological ripening disorder of Tommy Atkins mango. Acta Hort 485:255258 Lizada MCC, Yang Y (1979) A simple and sensitive assay for 1-Aminocyclo propane-1-carboxylic acid. Anal Biochem 100: 140145 Lopez-Gomez R, Gomez-Lin MA (1992) Changes in mRNA and protein synthesis during ripening in mango fruit. J Plant Physiol 141:8287

299 Masia A (1998) Superoxide dismutase and catalase activities in apple during ripening and post harvest and with special reference to ethylene. Physiol Plant 104:668672 Selvaraj Y, Edward Raja M, Rawal RD (2000) Biochemical studies on internal breakdown-a ripening disorder in mango fruits. Indian J Hort 57:183188 Selvaraj Y, Kumar R (1989) Studies on fruit softening enzyme and polyphenoloxidase in ripening mango (Mangifera indica L) fruit. J Food Sci Technol 26:218222 Shivashankar KS, Mathai CK (1999) Relationship of leaf and fruit transpiration rates to the incidence of spongy tissue disorder in two mango cultivars. Sci Hort 82:317323 Sitrit Y, Blumenfeld A, Riov J (1987) Ethylene biosynthesis in tissues of young and mature avocado fruits. Physiol Plant 69: 504510 Vasanthaiah HKN, Ravishankar KV, Shivashankara KS, Lalitha A, Narayanaswamy P, Prasad TG, Mukunda GK (2006) Cloning and characterization of differentially expressed genes of internal breakdown in mango (Mangifera india L.) cv. Alphonso. J Plant Physiol 163:671679 Zhanyuan D, Brumlage WJ (1994) Superoxide dismutase activities in senescing apple fruit. J Food Sci 59:581584

RENEWAL OF AFST(I) MEMBERSHIP AND SUBSCRIPTION TO JOURNALS

AFST(I) members, who have not renewed their membership/subscription for the year 2009-10 may kindly do so immediately to enable us to give the print order for the required number of copies of the journals viz., Journal of Food Science and Technology/Indian Food Industry.

Address for correspondence: AFST(I), CFTRI Campus, Mysore - 570 020, INDIA

Please update your AFST(I) Membership data to ensure prompt delivery of journals and various communications emanating from AFST(I) headquarters.

123

You might also like

- Duwet PDFDocument9 pagesDuwet PDFYuvitaLiraNo ratings yet

- Article1380180775 - Oyeleke and OduwoleDocument4 pagesArticle1380180775 - Oyeleke and Oduwoleaditi_joshee419No ratings yet

- Cellulolytic Fruits Wastes: A Potential Support For Enzyme Assisted Protein ProductionDocument9 pagesCellulolytic Fruits Wastes: A Potential Support For Enzyme Assisted Protein ProductionkesavarajNo ratings yet

- Investigation On The Antioxidant Activity of Leaves, Peels, Stems Bark, and Kernel of Mango (Mangifera Indica L.)Document4 pagesInvestigation On The Antioxidant Activity of Leaves, Peels, Stems Bark, and Kernel of Mango (Mangifera Indica L.)eliezer999No ratings yet

- Enzyme Synthesis PDFDocument5 pagesEnzyme Synthesis PDFChilaNo ratings yet

- Changes in volatile compounds and properties of snake fruit during maturationDocument7 pagesChanges in volatile compounds and properties of snake fruit during maturationYulis AdrianaNo ratings yet

- Quantitative EstimationDocument4 pagesQuantitative EstimationSarah BODOFIANo ratings yet

- Paper 111Document11 pagesPaper 111IJARBS JOURNALNo ratings yet

- Food Chemistry: Nabasree Dasgupta, Bratati deDocument6 pagesFood Chemistry: Nabasree Dasgupta, Bratati deThuong Lam Huynh HoaiNo ratings yet

- Analysis and identification of phenolic compounds in Dioscorea hispida Dennst tuberDocument14 pagesAnalysis and identification of phenolic compounds in Dioscorea hispida Dennst tuberRainolNo ratings yet

- In Vitro Callus and in Vivo Leaf Extract of Gymnema Sylvestre Stimulate - Cells Regeneration and Anti-Diabetic Activity in Wistar RatsDocument7 pagesIn Vitro Callus and in Vivo Leaf Extract of Gymnema Sylvestre Stimulate - Cells Regeneration and Anti-Diabetic Activity in Wistar Ratsapi-198310771No ratings yet

- Anthocyanins From Eugenia Myrtifolia Sims: Luigia Longo, Anna Scardino, Giuseppe Vasapollo, Federica BlandoDocument4 pagesAnthocyanins From Eugenia Myrtifolia Sims: Luigia Longo, Anna Scardino, Giuseppe Vasapollo, Federica BlandoNithya RNo ratings yet

- s13197 017 2920 1 - BarleyDocument7 pagess13197 017 2920 1 - Barleynelsonmubai1991No ratings yet

- Anti KankerDocument7 pagesAnti KankerRidho Dhe HolmesNo ratings yet

- J LWT 2004 06 004Document8 pagesJ LWT 2004 06 004Nguyễn Thành VinhNo ratings yet

- Huang Et Al 2005 PDFDocument8 pagesHuang Et Al 2005 PDFYoga Bririan JatiNo ratings yet

- Phytochemical Constituents and Antioxidant Activity of The Seeds of Cucumeropsis Edulis (Cucurbitaceae) From Momo in Gabon.Document5 pagesPhytochemical Constituents and Antioxidant Activity of The Seeds of Cucumeropsis Edulis (Cucurbitaceae) From Momo in Gabon.IJAR JOURNALNo ratings yet

- 18 505 PDFDocument9 pages18 505 PDFMichaela Marie IlaganNo ratings yet

- Pineapple juice boosts antioxidant activity in corn cob extractDocument7 pagesPineapple juice boosts antioxidant activity in corn cob extractipinseraNo ratings yet

- Tea leaves' radical scavenging activity and effect of additivesDocument5 pagesTea leaves' radical scavenging activity and effect of additivesJibu ThomasNo ratings yet

- Lipid Peroxidation Inhibition and Antiradical Activities of Some Leaf Fractions of Mangifera IndicaDocument7 pagesLipid Peroxidation Inhibition and Antiradical Activities of Some Leaf Fractions of Mangifera IndicaRoy WilsonNo ratings yet

- Organic Phase Synthesis of Ethyl Oleate Using Lipases Produced by Solid-State FermentationDocument9 pagesOrganic Phase Synthesis of Ethyl Oleate Using Lipases Produced by Solid-State FermentationROISYAHNo ratings yet

- Research ArticleDocument4 pagesResearch ArticleMusfeera KhanNo ratings yet

- Jurnal RKL PDFDocument6 pagesJurnal RKL PDFFaishalNo ratings yet

- Jurnal TempeDocument8 pagesJurnal TempeSiti Limbong ChekhoirNo ratings yet

- Antioxidant Flavonoids from Ficus pumila LeavesDocument6 pagesAntioxidant Flavonoids from Ficus pumila LeavesHajrah SuhardiNo ratings yet

- Protease From Courgette (Luffa Acutangula L (Roxb) ) : Isolation, Purification, and Some CharacteristicsDocument8 pagesProtease From Courgette (Luffa Acutangula L (Roxb) ) : Isolation, Purification, and Some CharacteristicsNurlaini NasutionNo ratings yet

- Isolation and partial characterisation of α-amylase components evolved during early wheat germinationDocument13 pagesIsolation and partial characterisation of α-amylase components evolved during early wheat germinationDwi Surya AtmajaNo ratings yet

- Purification and Characterization of Membrane-Bound Peroxidase From Date Palm Leaves (Phoenix Dactylifera L.)Document6 pagesPurification and Characterization of Membrane-Bound Peroxidase From Date Palm Leaves (Phoenix Dactylifera L.)Yetzin RodriguezNo ratings yet

- Paper4 PDFDocument9 pagesPaper4 PDFJaimeParedesNo ratings yet

- Antioxidant Activity of Syzygium polyanthum ExtractsDocument5 pagesAntioxidant Activity of Syzygium polyanthum ExtractsnirdaNo ratings yet

- AzevendoDocument8 pagesAzevendoIndra Muhammad NaufalNo ratings yet

- Etilen Luka, Aktivitas Enzim Peroksidase, Polifenol Oksidase, Dan Fenil Alanin Liase Pada Irisan Mesokarp Labu KuningDocument10 pagesEtilen Luka, Aktivitas Enzim Peroksidase, Polifenol Oksidase, Dan Fenil Alanin Liase Pada Irisan Mesokarp Labu KuningelisabethpriskaNo ratings yet

- Phenolics PDFDocument8 pagesPhenolics PDFFranz MarasiganNo ratings yet

- 1981 Hizukuri, Takjzda, Yasuda 1981Document9 pages1981 Hizukuri, Takjzda, Yasuda 1981Łukasz GraczykNo ratings yet

- 293 DiazDocument6 pages293 DiazSantiago BatallerNo ratings yet

- Structural Features and Antioxidant Activity of Tannin From Persimmon PulpDocument10 pagesStructural Features and Antioxidant Activity of Tannin From Persimmon PulpxchinodanyNo ratings yet

- Essential Oil From Lemon Peels Inhibit Key Enzymes Linked To Neurodegenerative Conditions and Pro-Oxidant Induced Lipid PeroxidationDocument9 pagesEssential Oil From Lemon Peels Inhibit Key Enzymes Linked To Neurodegenerative Conditions and Pro-Oxidant Induced Lipid PeroxidationbabithyNo ratings yet

- Solid State Fermentation Effects On Pistachio Hulls Antioxidant ActivitiesDocument7 pagesSolid State Fermentation Effects On Pistachio Hulls Antioxidant ActivitiesEhsan OskoueianNo ratings yet

- Journal of General MicrobiologyDocument14 pagesJournal of General MicrobiologykadriabdullahNo ratings yet

- IFRJ-2010-038 Nurul HudaDocument12 pagesIFRJ-2010-038 Nurul HudaJeremy GordonNo ratings yet

- Inhibitory Activity of Enzymatically Synthesized Polyphenol Glucosides Against Melanogenesis and MutagenesisDocument6 pagesInhibitory Activity of Enzymatically Synthesized Polyphenol Glucosides Against Melanogenesis and MutagenesisBiodiversitas, etcNo ratings yet

- Draft - Isolation and Radical Scavenging Activity of Resveratrol From Melinjo Bark (Gnetum Gnemon L.)Document12 pagesDraft - Isolation and Radical Scavenging Activity of Resveratrol From Melinjo Bark (Gnetum Gnemon L.)Agung YodhaNo ratings yet

- Protocols For Plant Extract AnalysisDocument6 pagesProtocols For Plant Extract AnalysisKarthikeyan NanjappanNo ratings yet

- 555 560 (P)Document6 pages555 560 (P)Mahdi SantosoNo ratings yet

- Article1380128362 Al HashimiDocument6 pagesArticle1380128362 Al HashimiCherif Abdourahmane DiopNo ratings yet

- IFRJ-2011-161 MandanaDocument6 pagesIFRJ-2011-161 MandanakdsrianiNo ratings yet

- In Vitro Antioxidant Activity of Guibourtia TessmanniiDocument8 pagesIn Vitro Antioxidant Activity of Guibourtia TessmanniiClaudio Luis VenturiniNo ratings yet

- Activity Enzymes Associated With The Enzymatic Browning of Minimally Processed PotatoesDocument8 pagesActivity Enzymes Associated With The Enzymatic Browning of Minimally Processed PotatoesWendy TorresNo ratings yet

- IOP Conference: Antioxidant Activity of Kecapi Leaf ExtractDocument9 pagesIOP Conference: Antioxidant Activity of Kecapi Leaf ExtractEllymar DuqueNo ratings yet

- JF 0210019Document4 pagesJF 0210019Nguyễn Thành VinhNo ratings yet

- Jurnal Acara 1Document6 pagesJurnal Acara 1dinaserevinaNo ratings yet

- Pectinase Production and Clarification TreatmentsDocument6 pagesPectinase Production and Clarification TreatmentscarolasbdNo ratings yet

- Mulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)Document7 pagesMulberry Jelly (2019 - 12 - 27 16 - 04 - 56 UTC)tayyaba mehmoodNo ratings yet

- Purification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257Document7 pagesPurification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257ayauNo ratings yet

- Partial Purification and Characterisation of CytosDocument8 pagesPartial Purification and Characterisation of CytosRaksha MukhiaNo ratings yet

- WWW Ajol Infoindex Phpajbarticledownload4311326661Document5 pagesWWW Ajol Infoindex Phpajbarticledownload4311326661Sitti Rafiah AminullahNo ratings yet

- Phy TaseDocument6 pagesPhy Taseduverney.gaviriaNo ratings yet

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterFrom EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNo ratings yet

- 1Document7 pages110sgNo ratings yet

- The Genomic Impact of Social Evolution in Seven Ant SpeciesDocument16 pagesThe Genomic Impact of Social Evolution in Seven Ant Species10sgNo ratings yet

- A Research Agenda For Helminth Diseases of Humans: Modelling For Control and EliminationDocument11 pagesA Research Agenda For Helminth Diseases of Humans: Modelling For Control and Elimination10sgNo ratings yet

- A Research Agenda For Helminth Diseases of Humans: Social Ecology, Environmental Determinants, and Health SystemsDocument11 pagesA Research Agenda For Helminth Diseases of Humans: Social Ecology, Environmental Determinants, and Health Systems10sgNo ratings yet

- Field Attractants For Pachnoda Interrupta Selected by Means of GC-EAD and Single Sensillum ScreeningDocument14 pagesField Attractants For Pachnoda Interrupta Selected by Means of GC-EAD and Single Sensillum Screening10sgNo ratings yet

- Prunus PersicaeDocument6 pagesPrunus Persicae10sgNo ratings yet

- 1Document6 pages110sgNo ratings yet

- 1Document14 pages110sgNo ratings yet

- 1Document3 pages110sgNo ratings yet

- 1Document8 pages110sgNo ratings yet

- 1Document13 pages110sgNo ratings yet

- Analysis of Volatile Aroma Constituents of Wine Produced From Indian Mango (Mangifera Indica L.) by GC-MSDocument9 pagesAnalysis of Volatile Aroma Constituents of Wine Produced From Indian Mango (Mangifera Indica L.) by GC-MS10sgNo ratings yet

- 1Document8 pages110sgNo ratings yet

- Characterization of Three-Dimensional Spatial Aggregation and Association Patterns of Brown Rot Symptoms Within Intensively Mapped Sour Cherry TreesDocument8 pagesCharacterization of Three-Dimensional Spatial Aggregation and Association Patterns of Brown Rot Symptoms Within Intensively Mapped Sour Cherry Trees10sgNo ratings yet

- Sex-Dependent Novelty Response in Neurexin-1 A Mutant MiceDocument6 pagesSex-Dependent Novelty Response in Neurexin-1 A Mutant Mice10sgNo ratings yet

- NIH Public Access: p21 Protects "Super p53" Mice From The Radiation-Induced Gastrointestinal SyndromeDocument7 pagesNIH Public Access: p21 Protects "Super p53" Mice From The Radiation-Induced Gastrointestinal Syndrome10sgNo ratings yet

- Optimization of Serine Protease Purification From Mango (Mangifera Indica Cv. Chokanan) Peel in Polyethylene Glycol/Dextran Aqueous Two Phase SystemDocument14 pagesOptimization of Serine Protease Purification From Mango (Mangifera Indica Cv. Chokanan) Peel in Polyethylene Glycol/Dextran Aqueous Two Phase System10sgNo ratings yet

- Is Axis Position Within Tree Architecture A Determinant of Axis Morphology, Branching, Flowering and Fruiting? An Essay in MangoDocument12 pagesIs Axis Position Within Tree Architecture A Determinant of Axis Morphology, Branching, Flowering and Fruiting? An Essay in Mango10sgNo ratings yet

- Activation of Ethylene-Responsive P-Hydroxyphenylpyruvate Dioxygenase Leads To Increased Tocopherol Levels During Ripening in MangoDocument11 pagesActivation of Ethylene-Responsive P-Hydroxyphenylpyruvate Dioxygenase Leads To Increased Tocopherol Levels During Ripening in Mango10sgNo ratings yet

- Optimization of Freeze Drying Conditions For Purified Pectinase From Mango (Mangifera Indica Cv. Chokanan) PeelDocument12 pagesOptimization of Freeze Drying Conditions For Purified Pectinase From Mango (Mangifera Indica Cv. Chokanan) Peel10sgNo ratings yet

- 1Document5 pages110sgNo ratings yet

- Allergy: Hypersensitivity Manifestations To The Fruit MangoDocument7 pagesAllergy: Hypersensitivity Manifestations To The Fruit Mango10sgNo ratings yet

- Extraction of DNA Suitable For PCR Applications From Mature Leaves of Mangifera Indica LDocument5 pagesExtraction of DNA Suitable For PCR Applications From Mature Leaves of Mangifera Indica L10sgNo ratings yet

- 1joi0i 0ritknDocument14 pages1joi0i 0ritkn10sgNo ratings yet

- Contrasting Diversity Patterns of Crenarchaeal, Bacterial and Fungal Soil Communities in An Alpine LandscapeDocument7 pagesContrasting Diversity Patterns of Crenarchaeal, Bacterial and Fungal Soil Communities in An Alpine Landscape10sgNo ratings yet

- Comparative Genome Analysis of Filamentous Fungi Reveals Gene Family Expansions Associated With Fungal PathogenesisDocument15 pagesComparative Genome Analysis of Filamentous Fungi Reveals Gene Family Expansions Associated With Fungal Pathogenesis10sgNo ratings yet

- Limits of Nuclear Ribosomal DNA Internal Transcribed Spacer (ITS) Sequences As Species Barcodes For FungiDocument1 pageLimits of Nuclear Ribosomal DNA Internal Transcribed Spacer (ITS) Sequences As Species Barcodes For Fungi10sgNo ratings yet

- Marine Drugs: Immense Essence of Excellence: Marine Microbial Bioactive CompoundsDocument29 pagesMarine Drugs: Immense Essence of Excellence: Marine Microbial Bioactive Compounds10sgNo ratings yet

- Vaccines and Immunotherapy Against Fungi: The New Frontier: Joshua D. Nosanchuk Carlos P. TabordaDocument2 pagesVaccines and Immunotherapy Against Fungi: The New Frontier: Joshua D. Nosanchuk Carlos P. Taborda10sgNo ratings yet

- FranklinDocument4 pagesFranklinapi-291282463No ratings yet

- MID TERM Question Paper SETTLEMENT PLANNING - SEC CDocument1 pageMID TERM Question Paper SETTLEMENT PLANNING - SEC CSHASHWAT GUPTANo ratings yet

- Portfolio Artifact Entry Form - Ostp Standard 3Document1 pagePortfolio Artifact Entry Form - Ostp Standard 3api-253007574No ratings yet

- #### # ## E232 0010 Qba - 0Document9 pages#### # ## E232 0010 Qba - 0MARCONo ratings yet

- Personalised MedicineDocument25 pagesPersonalised MedicineRevanti MukherjeeNo ratings yet

- International Certificate in WealthDocument388 pagesInternational Certificate in Wealthabhishek210585100% (2)

- 2nd Pornhub Awards - WikipediaaDocument13 pages2nd Pornhub Awards - WikipediaaParam SinghNo ratings yet

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Document76 pagesGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- PESO Online Explosives-Returns SystemDocument1 pagePESO Online Explosives-Returns Systemgirinandini0% (1)

- SCA ALKO Case Study ReportDocument4 pagesSCA ALKO Case Study ReportRavidas KRNo ratings yet

- 5511Document29 pages5511Ckaal74No ratings yet

- Axe Case Study - Call Me NowDocument6 pagesAxe Case Study - Call Me NowvirgoashishNo ratings yet

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47No ratings yet

- GLF550 Normal ChecklistDocument5 pagesGLF550 Normal ChecklistPetar RadovićNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- HenyaDocument6 pagesHenyaKunnithi Sameunjai100% (1)

- Whisper Flo XF 3 PhaseDocument16 pagesWhisper Flo XF 3 Phasehargote_2No ratings yet

- 5054 w11 QP 11Document20 pages5054 w11 QP 11mstudy123456No ratings yet

- GATE ECE 2006 Actual PaperDocument33 pagesGATE ECE 2006 Actual Paperkibrom atsbhaNo ratings yet

- DIN Flange Dimensions PDFDocument1 pageDIN Flange Dimensions PDFrasel.sheikh5000158No ratings yet

- Electronics Project Automatic Bike Controller Using Infrared RaysDocument16 pagesElectronics Project Automatic Bike Controller Using Infrared RaysragajeevaNo ratings yet

- Zelev 1Document2 pagesZelev 1evansparrowNo ratings yet

- Merchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaDocument29 pagesMerchandising Calender: By: Harsha Siddham Sanghamitra Kalita Sayantani SahaSanghamitra KalitaNo ratings yet

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocument12 pagesMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNo ratings yet

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDocument6 pagesLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0No ratings yet

- DLL - The Firm and Its EnvironmentDocument5 pagesDLL - The Firm and Its Environmentfrances_peña_7100% (2)

- TheEconomist 2023 04 01Document297 pagesTheEconomist 2023 04 01Sh FNo ratings yet

- Game Rules PDFDocument12 pagesGame Rules PDFEric WaddellNo ratings yet

- Software Requirements Specification: Chaitanya Bharathi Institute of TechnologyDocument20 pagesSoftware Requirements Specification: Chaitanya Bharathi Institute of TechnologyHima Bindhu BusireddyNo ratings yet

- Last Clean ExceptionDocument24 pagesLast Clean Exceptionbeom choiNo ratings yet