Professional Documents

Culture Documents

Comparative Study of FPP vs. CPP for Electric Naval Combatant

Uploaded by

Andre OliveiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Study of FPP vs. CPP for Electric Naval Combatant

Uploaded by

Andre OliveiraCopyright:

Available Formats

Comparative Study of FPP vs.

CPP for an All-Electric Naval Combatant

Mr. Devin Witt & Prof. Y.L. (Julie) Young, Dept. of Naval Architecture & Marine Engineering, University of Michigan

Objectives

-Identify the advantages and disadvantages of fixed pitch propellers (FPP) vs. controllable pitch propellers (CPP) for an all-electric naval combatant. -Compare the performance of a FPP vs. CPP for a notional all-electric naval combatant. -Discuss related total ship architecture and integration issues for an allelectric naval combatant.

FPP and CPP Performance

-Performance and structural analysis was conducted using a 3D coupled boundary element method-finite element method in uniform wake. -Analysis provided evidence that the optimal pitch setting for the CPP was from = 5 to = 0 over the ships operational speed range. Pitch Type Fixed Controllable Optimal 0.7R 40.1 38.7 0,average 0.72 0.73

FPP and CPP Stress Analysis

-A stress analysis was conducted on both the FPP and the CPP over the ships operational range. The stresses are over-estimated at the blade root because the blades are assumed to be cantilevered and the effect of the fillet has been neglected.

Advantages and Disadvantages of FPPs and CPPs

Fixed Pitch Propeller Advantages Disadvantages -Performance degrades rapidly at offdesign conditions, where the vessel (with -Simple construction and less broad operating profile, e.g. naval maintenance than CPPs. combatant) may operate majority of the -No support system needed. time. -Smaller propeller hub leading to -Potential cavitation, strength, & stability increased open water efficiency. issues at highly loaded off-design conditions. Controllable Pitch Propeller Advantages Disadvantages -Pitch schedule can be optimized over operational range. -Ability to mitigate and reduce cavitation and blade stress as well as increase overall efficiency. -Ability to produce forward or reverse thrust while continuing to rotate in the same direction. -Requires a support system to operate properly which will entail more electrical power and maintenance. -More complex and expensive than a FPP. -Larger propeller hub leading to decreased open water efficiency.

Ship Architecture and Integration Issues

Provided Thrust and Power vs Ship Speed

3000 2500 Force (kN) 2000 40 Delivered Power (MW) RPM, Cavitation Volume (10000*Vol./R3) 35

1500

1000 500 0

t = 0.095 w = 0.031 Thrust = RT/[2*(1-t)] Va = Vs*(1-w)

30 25

-There are significant differences between mechanical ships and all-electric ships (AES) that affect the propulsion system and the propeller design. -On mechanical ships, the propellers minimum revolution rate is typically 30 40% of the prime movers maximum speed, while an AES can operate the propeller from zero revolutions to the electric motors maximum rate, and therefore can be more efficient at very low RPMs.

20

15 10 5 0

Ship and Propeller Specifications

-The all-electric naval combatant was based on a modified DTMB 5415 hull: length=162.5m, displ.=15,263 ton, top speed=30 knots, and shaft depth=5m. -The propeller was based on a five-bladed DTMB 5168, which was modified to include a NACA 16A thickness distribution with a zero trail edge thickness, and a NACA a = 0.8 camber distribution. Characteristic Propeller Diameter (m) rhub/R Propeller Material Density (kg/m3) 0.2% Yield Strength (MPa) Fatigue Strength at 108 Cycles (MPa) Value DTMB 5168 5.5 0.282 nickel-aluminum-bronze 7580 205 79.3

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Vs (Knots) Ship Resistance FPP Power FPP Thrust CPP Power CPP Thrust Electric Motor Limit 140

FPP vs. CPP Performance

0.74

Open Water Efficiency, 0 120

0.72

0.70 0.68 0.66 0.64 0.62 0.60

100

80 60 40 20 0

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Vs (kn)

FPP Efficiency CPP RPM CPP Efficiency FPP Cav. Volume FPP RPM CPP Cav. Volume

-Development is still needed to enhance variable speed drives which control the revolution rate and torque output of the large electric propulsion motors for pairing with CPPs. -Other integration issues is the control of the pitch setting on the propeller to keep the blades at optimal pitch settings while at specific ship speeds. -Due to losses associated with all-electric systems, further work is needed on total fuel consumption and maintenance requirements for both propeller systems. -An investigation of off-design conditions (crashback, crashforward, etc.) is needed to ensure the safety, effectiveness, and efficiency of both systems. -Maintenance and reliability issues of the two propeller types is a major concern when determining which propeller to integrate. FPPs are relatively low maintenance, while its not uncommon to have an expensive systems overhaul of a hydraulically actuated CPP every couple of years requiring dry docking.

You might also like

- All-Electric Naval CombatantDocument1 pageAll-Electric Naval CombatantChakma NhikiNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Matching Propulsion Engine With PropulsorDocument9 pagesMatching Propulsion Engine With PropulsorAnonymous gxAd4liNo ratings yet

- Ship Electrical Load and Power Generation OptimizationDocument7 pagesShip Electrical Load and Power Generation OptimizationmahmudNo ratings yet

- Dtic Ada489739Document63 pagesDtic Ada489739GunjanNo ratings yet

- Scherer Evolution ASNE 2011 PDFDocument25 pagesScherer Evolution ASNE 2011 PDFio75No ratings yet

- Survey of Naval Surface Ship Propulsion and Auxiliary System DevelopmentsDocument90 pagesSurvey of Naval Surface Ship Propulsion and Auxiliary System DevelopmentsAn NgocSonNo ratings yet

- Electromagnetic Aircraft Launch SystemDocument8 pagesElectromagnetic Aircraft Launch SystemRikhil Yalamanchi100% (1)

- Electic MotorsDocument22 pagesElectic MotorsAshutosh ShuklaNo ratings yet

- Motors and DrivesDocument27 pagesMotors and DrivessifuszNo ratings yet

- BMTDSL Caimen FLC Confpaper RINAWarship Jun10Document9 pagesBMTDSL Caimen FLC Confpaper RINAWarship Jun10DUNCAN0420No ratings yet

- Prius Gen IV 1.8L SimulationDocument14 pagesPrius Gen IV 1.8L SimulationseyyidMubeenNo ratings yet

- 5 Propeller DesignDocument50 pages5 Propeller DesignAnca GeaninaNo ratings yet

- Ungrounded Shipboard Electrical SystemDocument5 pagesUngrounded Shipboard Electrical SystemDaniel VaideanuNo ratings yet

- MAN Marine Propulsion SystemsDocument3 pagesMAN Marine Propulsion SystemsJereszNo ratings yet

- Preliminary Design of A Multi Column TLP Foundation For A 5 MW Offshore Wind Turbine PDFDocument18 pagesPreliminary Design of A Multi Column TLP Foundation For A 5 MW Offshore Wind Turbine PDFhrsimtyzNo ratings yet

- Australian Naval Architect MagazineDocument64 pagesAustralian Naval Architect MagazineMaurizio BernasconiNo ratings yet

- Specifications of A Naval ShipDocument13 pagesSpecifications of A Naval ShipSiddharth Narayanan ChidambareswaranNo ratings yet

- ABS Rules For Integrated Power Systems (IPS)Document17 pagesABS Rules For Integrated Power Systems (IPS)Andreas MattheouNo ratings yet

- Busbar AdaptersDocument20 pagesBusbar AdaptersGayan Buddhika AlahendraNo ratings yet

- c1 PDFDocument43 pagesc1 PDFMadhushan DassanayakeNo ratings yet

- AC Drives MSc2016Document21 pagesAC Drives MSc2016Mohamed Elsaid El ShallNo ratings yet

- DB&A Project at NAVSEADocument4 pagesDB&A Project at NAVSEAFred AppleNo ratings yet

- A560861development of Second Generation Intact Stability CriteriaDocument175 pagesA560861development of Second Generation Intact Stability CriteriaWee WeeNo ratings yet

- CPV757Document1 pageCPV757Richard Leonel Vasquez MezaNo ratings yet

- Marine Propulsion Systems GuideDocument63 pagesMarine Propulsion Systems GuidetoshugoNo ratings yet

- Modelling of LithiumDocument18 pagesModelling of LithiumSaumya SinhaNo ratings yet

- Unified Power Quality ConditionerDocument19 pagesUnified Power Quality ConditionerShameer Sr S RNo ratings yet

- Basic Ship Hull StructureDocument51 pagesBasic Ship Hull Structuresyamsidar100% (1)

- EEE381B Aerospace Systems & Avionics: RadarDocument39 pagesEEE381B Aerospace Systems & Avionics: RadarMohammad AhmedNo ratings yet

- Power Control of DC Microgrid With Variable Generation and Energy StorageDocument5 pagesPower Control of DC Microgrid With Variable Generation and Energy StorageSEP-PublisherNo ratings yet

- Engineering For Ship ProductionDocument489 pagesEngineering For Ship Productionharsha nwn100% (1)

- STD 1622 BDocument64 pagesSTD 1622 BDynamicSystemsIncNo ratings yet

- 001 V 0 R 43Document36 pages001 V 0 R 43wvwinters0% (1)

- Electric Power Load Analysis: Technical ArticleDocument4 pagesElectric Power Load Analysis: Technical ArticleDony SaputraNo ratings yet

- Zonal Ship Design (Paper)Document16 pagesZonal Ship Design (Paper)pal_malayNo ratings yet

- Specifications and Standards for Electric WarshipsDocument8 pagesSpecifications and Standards for Electric WarshipsTian TianNo ratings yet

- Navships 0900-002-3000 1964Document861 pagesNavships 0900-002-3000 1964Exequiel MedinaNo ratings yet

- Electric Motor in Ship PropulsionDocument13 pagesElectric Motor in Ship PropulsionConcept of ReasoningNo ratings yet

- T9640 Ac DSP 010 - HabDocument176 pagesT9640 Ac DSP 010 - HabjmScriNo ratings yet

- Professional Integrity and Disobedience in The Military PDFDocument15 pagesProfessional Integrity and Disobedience in The Military PDFLeo BiadnesNo ratings yet

- Planing Craft: The Editor Dr. Daniel SavitskyDocument29 pagesPlaning Craft: The Editor Dr. Daniel SavitskyAkbar Adi WijayaNo ratings yet

- A Bulbous Bow Design Methodology For High-Speed Ships PDFDocument26 pagesA Bulbous Bow Design Methodology For High-Speed Ships PDFali trrafNo ratings yet

- Propellers PDFDocument61 pagesPropellers PDFfaridNo ratings yet

- How To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFDocument9 pagesHow To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFoszemNo ratings yet

- Simulink Model of A Lithium-Ion Battery For TheDocument8 pagesSimulink Model of A Lithium-Ion Battery For Theyassserdiab75No ratings yet

- Marine Electrical Power Analysis PDFDocument4 pagesMarine Electrical Power Analysis PDFinfraNo ratings yet

- A Cyber-Physical Threat Analysis For MicrogridsDocument7 pagesA Cyber-Physical Threat Analysis For MicrogridsjmescalanteNo ratings yet

- Threat Identification and Avoidance SystemDocument10 pagesThreat Identification and Avoidance SystemSanket BansalNo ratings yet

- The Load As An Energy Asset in A Distributed DC MGDocument8 pagesThe Load As An Energy Asset in A Distributed DC MGAakanksha DugarNo ratings yet

- Resistance Sname ArticleDocument13 pagesResistance Sname ArticleAnish MohanNo ratings yet

- MATLAB-Introduction To ApplicationsDocument62 pagesMATLAB-Introduction To Applicationsnavz143No ratings yet

- DriveMotorBasics01 PDFDocument11 pagesDriveMotorBasics01 PDFSundar Kumar Vasantha GovindarajuluNo ratings yet

- Resistnace Lab Full ReportDocument25 pagesResistnace Lab Full ReportMahmoudYasserOrabyNo ratings yet

- Evaluation of High Power Energy Storage Devices For Use in Compact Pulsed Power SystemsDocument19 pagesEvaluation of High Power Energy Storage Devices For Use in Compact Pulsed Power SystemsbijushresthNo ratings yet

- Modelling System Reliability Using Continuous-Time Markov ChainDocument4 pagesModelling System Reliability Using Continuous-Time Markov ChainjoyopsonNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

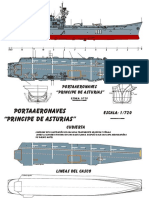

- Principe de AsturiasDocument2 pagesPrincipe de AsturiasAndre OliveiraNo ratings yet

- E03ENGDocument12 pagesE03ENGAndre OliveiraNo ratings yet

- Autodyn Theory ManualDocument235 pagesAutodyn Theory ManualAndre OliveiraNo ratings yet

- ANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityDocument56 pagesANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityGz2239No ratings yet

- T03ENGDocument128 pagesT03ENGAndre OliveiraNo ratings yet

- Example 21Document14 pagesExample 21Andre OliveiraNo ratings yet

- Seismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADocument16 pagesSeismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ACamv VenturaNo ratings yet

- E10ENGDocument41 pagesE10ENGAndre OliveiraNo ratings yet

- T11BENGDocument159 pagesT11BENGAndre OliveiraNo ratings yet

- Example 7Document11 pagesExample 7Andre OliveiraNo ratings yet

- T08ENGDocument32 pagesT08ENGAndre OliveiraNo ratings yet

- Non Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADocument12 pagesNon Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.AAndre OliveiraNo ratings yet

- DM DeletFaceThicknesses ACT Extension Description v160 v1Document1 pageDM DeletFaceThicknesses ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- Example #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Document14 pagesExample #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Andre OliveiraNo ratings yet

- Example 13Document10 pagesExample 13Andre OliveiraNo ratings yet

- Example 2Document16 pagesExample 2Andre OliveiraNo ratings yet

- Example 8Document11 pagesExample 8Andre OliveiraNo ratings yet

- Example 5Document23 pagesExample 5Andre OliveiraNo ratings yet

- Push-Over Analysis: Problem DescriptionDocument51 pagesPush-Over Analysis: Problem DescriptionAndre OliveiraNo ratings yet

- DM Cross Section Lib ACT Extension Description v160 v1Document1 pageDM Cross Section Lib ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- Mech-UCO 120 WS-07 FilterDocument32 pagesMech-UCO 120 WS-07 FilterAndre OliveiraNo ratings yet

- 4 Polyflow - 12.1 Polyflow BDocument17 pages4 Polyflow - 12.1 Polyflow BAndre OliveiraNo ratings yet

- TDAS ACT Extension Description v160 v1Document1 pageTDAS ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- ReadmeDocument1 pageReadmeAndre OliveiraNo ratings yet

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDocument112 pagesCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- Example 5Document23 pagesExample 5Andre OliveiraNo ratings yet

- Tut 16Document36 pagesTut 16Andre OliveiraNo ratings yet

- Tutorial For Ansys Fluent Porous MediaDocument30 pagesTutorial For Ansys Fluent Porous MediaLykaios Schultz DohrnNo ratings yet

- 42 M Bow String Girder-10408-6-R PDFDocument1 page42 M Bow String Girder-10408-6-R PDFPhanindra MajetiNo ratings yet

- Catalogo Weichai 2020Document106 pagesCatalogo Weichai 2020Jose AntonioNo ratings yet

- Decoding The Teenage Brain (In 3 Charts) - Edutopia PDFDocument6 pagesDecoding The Teenage Brain (In 3 Charts) - Edutopia PDFVirgínia Chaves de LimaNo ratings yet

- Company Profile NecarrDocument10 pagesCompany Profile Necarranescobar0001No ratings yet

- CP SanitaryDocument2 pagesCP SanitaryMuthu ManiNo ratings yet

- AGBT05-18 Guide To Bridge Technology Part 5 Structural DraftingDocument73 pagesAGBT05-18 Guide To Bridge Technology Part 5 Structural DraftingyasNo ratings yet

- FET Static CharacteristicDocument4 pagesFET Static CharacteristicAzim Kamal0% (1)

- Toyota TVIP System ProgrammingDocument11 pagesToyota TVIP System Programmingcheerios353No ratings yet

- LTE eNB L1 API DefinitionDocument106 pagesLTE eNB L1 API Definitioneng_alshimaaNo ratings yet

- Scepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtDocument31 pagesScepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtNicolás Antonio Rojas CortésNo ratings yet

- Angle of Incidence and Reflection Intensity Through a PolarizerDocument23 pagesAngle of Incidence and Reflection Intensity Through a PolarizerSatyam GuptaNo ratings yet

- Impact of Using A Bilingual Model On Kazakh-Russian Code-Switching Speech RecognitionDocument6 pagesImpact of Using A Bilingual Model On Kazakh-Russian Code-Switching Speech RecognitionOnsamak MachineryNo ratings yet

- A Right Unexercised Is A Right Lost?: Abolishing Antidumping in Regional Trade AgreementsDocument38 pagesA Right Unexercised Is A Right Lost?: Abolishing Antidumping in Regional Trade AgreementshappyjourneygatewayNo ratings yet

- Articulator Selection For Restorative DentistryDocument9 pagesArticulator Selection For Restorative DentistryAayushi VaidyaNo ratings yet

- RecitationDocument3 pagesRecitationViola NguyenNo ratings yet

- Wall-Mounted King Shell Temperature and Humidity Transmitter User ManualDocument6 pagesWall-Mounted King Shell Temperature and Humidity Transmitter User ManualTrung Trần HữuNo ratings yet

- 09931017A Clarus SQ8 MS Hardware GuideDocument162 pages09931017A Clarus SQ8 MS Hardware GuidePaola Cardozo100% (2)

- Cooling Fan Motor (Spin-on Element) (Square Solenoid Coil) Parts ListDocument2 pagesCooling Fan Motor (Spin-on Element) (Square Solenoid Coil) Parts ListEdgar SanchezNo ratings yet

- Gambar Tata Ruang Landscape PDFDocument11 pagesGambar Tata Ruang Landscape PDFmhaiqalNo ratings yet

- Karen Horney Abduls PDFDocument31 pagesKaren Horney Abduls PDFlala123No ratings yet

- (Franziska Bieri) From Blood Diamonds To The KimbeDocument226 pages(Franziska Bieri) From Blood Diamonds To The KimbeMona SaidNo ratings yet

- Alcohol-Related DiseaseDocument18 pagesAlcohol-Related DiseaseSNo ratings yet

- Flexfiled Oracle FaqDocument14 pagesFlexfiled Oracle Faq$!@#$%!@#$%No ratings yet

- Chap 011 NotesDocument10 pagesChap 011 Notesfree50No ratings yet

- Compare and Contrast RubricDocument1 pageCompare and Contrast RubricBrian BorkowskiNo ratings yet

- Hse Plan Rev01Document71 pagesHse Plan Rev01Lovedeep SinghNo ratings yet

- Mdu 1Document3 pagesMdu 1Gaurang Agrawal0% (1)

- MCT-MST Summative Teaching Placement Assessment Rubric - EPC 4406 - 17 PagesDocument17 pagesMCT-MST Summative Teaching Placement Assessment Rubric - EPC 4406 - 17 PagesHuda HamadNo ratings yet

- Infections PDFDocument29 pagesInfections PDFLoudry ElfaNo ratings yet

- Luccon PflegehinweisEDocument2 pagesLuccon PflegehinweisEDejana Lazarus Lufkin MarosNo ratings yet