Professional Documents

Culture Documents

CSWIP Test No 1

Uploaded by

stanleyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSWIP Test No 1

Uploaded by

stanleyCopyright:

Available Formats

1-MULTICHOICE PAPER ONE 1.

When hydrogen control is specified for a manual metal arc welding project the electrode would normally be: a. Cellulose b. Iron oxide c. Acid d. Basic You would certainly recognise a hydrogen controlled flux covered electrode from its: a. Colour b. Length c. Trade name d. BS639/AWS code letter When manual metal arc welding is being carried out on an open construction site, which group of welders are most likely to require continuous monitoring? a. Concrete shuttering welding teams b. Pipe welding teams c. Plate welders d. Plant maintenance welders You notice manual metal arc electrodes, stripped of flux, are being used as filler wire for TIG welding. You would object because: a. It is too expensive b. The wire would be too thick c. The metal composition may be wrong d. The wire is too short When open site working, serious porosity in metal arc welds is brought to your attention. What would you investigate? a. Electrode type b. Power plant type c. Electrode storage d. Day temperature The steel composition in a structural contract is changed from 0.15% carbon 0.6% manganese, to 0.2% carbon 1.2% manganese. This might influence the incidence of: a. Porosity b. Cracking in the weld area c. Undercut for fillet welds d. Lack of fusion defects One of the following alloys is non-magnetic - which? a. 4.0% chromium molybdenum b. 12.0% chromium c. Austenitic stainless steel d. 9.0% nickel steel When TIG welding austenitic stainless steel pipe, argon gas backing is called for. This is to: a. Prevent oxidation b. Prevent underbead cracking c. Prevent porosity d. Control the penetration bead shape Pre-heating a carbon steel manual metal arc welding is carried out to minimise the risk of: a. Scattered porosity b. Worm hole porosity c. Parent metal cracking d. Lack of penetration In UK practice, BS499 specifies that the drawing dimension quoted for a fillet weld is the: a. Leg length b. Throat thickness c. Weld width d. Actual throat thickness For open site manual metal welding the following equipment is available. Which would you choose for safe site working? a. Single operator transformer b. Multi operator transformers c. AC/DC composite power unit

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

d. 12.

Diesel engine driven motor generator

If submerged arc welding is used to make butt welds, which would you be most critical of? a. The root gap tolerance b. The angle of preparation c. The root face width d. The gas cut finish During CO2 welding, the arc length is most likely to be affected by: a. The wire diameter b. The current return connections c. The gas flow rate d. The torch to work angle Preheating for arc welding applies to: a. Assembly welding only b. Assembly and tack welding c. Joints over 25 mm thick only d. Cruciform welds only Which one of the following statements is correct? a. Preheating increases hardness b. Preheating increases cooling c. Preheating increases dilution d. Preheating increases shrinkage stress You see a welder using an oxy-acetylene flame with a long feathered inner cone. What would be the effect of this on carbon steel? a. The weld would be hard and brittle b. The weld could be too soft c. There will be no effect on the weld d. The weld will have undercut A welder qualification test is to verify: a. The skill of the welder b. The quality of the materials c. The non-destructive test procedures d. The manufacturing methods A fabricating procedure calls for fillet welds to be 'blended in' by grinding. This influences: a. HAZ. cracking b. Fatigue life c. Residual stress d. Yield strength Bend test specimens have been taken from a 25 mm thick carbon steel butt weld. Which would show lack of inter-run fusion? a. Side bend b. Root bend c. Face bend d. Guided bend Lamellar tearing has occurred in a steel fabrication. BEFORE welding could it have been found by: a. X-ray examination b. Dye penetrant c. Ultrasonic examination d. It would not have been found by any inspection method You are to oversee the arc welding of some machine fittings and find that they are cadmium plated. Would you: a. Permit it to proceed b. Permit it to proceed with fume extraction c. Stop the operation at once d. Advise the welder to drink milk and proceed One of the reasons for excluding hydrogen from the weld metal is to prevent the weld from: a. Cracking b. Cooling slowly c. Cooling quickly d. Expanding

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

When a metal regains its original shape when a stress acting upon it is removed, the metal is said to have: a. Ductility b. Plasticity c. Malleability d. Elasticity Proof stress is used when non-ferrous metals are undergoing tensile tests to determine the equivalent: a. Tenacity b. Elasticity c. Yield strength d. Tensile strength To test a component for vibrational loading, a suitable mechanical test would be: a. Impact b. Tensile c. Compressive d. Fatigue The main reason for pre-heating medium and high carbon steels before cutting by oxy-fuel gas technique is to: a. Improve the quality of the cut b. Increase the cutting speed c. Refine the grain structure d. Prevent hardening and cracking One purpose of a microscopic examination of a weld is to establish the: a. Strength of the weld b. Number of alloying elements c. Grain size d. Number of runs used The predominant structure of an hyper-eutectoid steel that has been quenched at above its upper critical point will be: a. Austenite b. Martensite c. Troostite d. Sorbite When weld metal refinement takes place in a multi-run deposit, it is known by the term: a. Weld annealing b. Weld refining c. Weld normalising d. Weld recrystallisation One advantage of metal gas arc shielded welding is: a. Can be used in draughty locations without protection b. Produces a deposit low in hydrogen content c. Any welding position can be welded with spray transfer d. Fine spatter at nozzle restricting gas flow

24.

25.

26.

27.

28.

29.

30.

You might also like

- Cswip 3.1 Difficul - Multichoice QuesDocument11 pagesCswip 3.1 Difficul - Multichoice QuesLuan Nguyen0% (1)

- General 3Document5 pagesGeneral 3AnandNo ratings yet

- B. The Amount of Time The Electrode Is Being UsedDocument4 pagesB. The Amount of Time The Electrode Is Being UsedSolomon AttaNo ratings yet

- CSWIP 3.1 Welding Inspector MCQDocument35 pagesCSWIP 3.1 Welding Inspector MCQJadam UchihaNo ratings yet

- Cswip QbankDocument23 pagesCswip QbankFownoon100% (1)

- General 6Document4 pagesGeneral 6Solomon AttaNo ratings yet

- General All SolvedDocument25 pagesGeneral All SolvedAndiappan Pillai100% (2)

- Cswip Paper 3.1Document5 pagesCswip Paper 3.1Fran Bakkara100% (1)

- Sample Questions On CSWIP 3.1Document16 pagesSample Questions On CSWIP 3.1mushruff100% (2)

- GENERAL4 Solve Answer-1Document4 pagesGENERAL4 Solve Answer-1JlkKumar100% (1)

- WISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014Document5 pagesWISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014rinhycra100% (1)

- MFY Multiple Choice 001Document6 pagesMFY Multiple Choice 001Danu KautsarNo ratings yet

- WISS CSWIP Technology Multiple Choice Exam 1Document10 pagesWISS CSWIP Technology Multiple Choice Exam 1rinhycraNo ratings yet

- Welding Assessment QuizDocument8 pagesWelding Assessment QuizLe Tuan100% (1)

- Technology Multi Choice Exam 4Document9 pagesTechnology Multi Choice Exam 4Alex Kulleh100% (1)

- Questions CswipDocument63 pagesQuestions CswipMohamed ElsayedNo ratings yet

- Cswip 3.1 QU MSR WI 4 05Document8 pagesCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- Welding questions document titleDocument5 pagesWelding questions document titleKani Al Bazir100% (1)

- CSWIP 3.1 (Updates-2016) : General - 1Document9 pagesCSWIP 3.1 (Updates-2016) : General - 1PradeepNo ratings yet

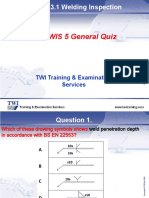

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument63 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23No ratings yet

- GENERAL5 Answer-1Document4 pagesGENERAL5 Answer-1JlkKumarNo ratings yet

- TECHNOLOGY3 AnswerDocument7 pagesTECHNOLOGY3 Answerابومحمد الكنانيNo ratings yet

- Welding Institute Multi-Choice Exam on Steels and InspectionDocument8 pagesWelding Institute Multi-Choice Exam on Steels and InspectionLuan Nguyen100% (1)

- ''Technology Examination Questions (Multi-Cohice Exam - 1)Document4 pages''Technology Examination Questions (Multi-Cohice Exam - 1)Vijaya BaraniNo ratings yet

- Cswip Multi Choice Questions With AnswersDocument19 pagesCswip Multi Choice Questions With AnswersNeel Mukherjee0% (1)

- Paper 10Document8 pagesPaper 10Kani Al BazirNo ratings yet

- Technology 1Document9 pagesTechnology 1Prabhu KalpakkamNo ratings yet

- Section 16 QuestionsDocument5 pagesSection 16 QuestionsSameer MohammadNo ratings yet

- Soalan Cswip 3.1 Set 3 GeneralDocument3 pagesSoalan Cswip 3.1 Set 3 GeneralShamsul Affendi25% (4)

- Technology Multiple Choice 3Document10 pagesTechnology Multiple Choice 3Alex KullehNo ratings yet

- CSWIP 3.1 Multichoice With AnswerDocument18 pagesCSWIP 3.1 Multichoice With AnswerBassamOmarFarghl100% (2)

- General3 AnswerDocument4 pagesGeneral3 AnswerAnonymous 8bH7sXpcEHNo ratings yet

- GENERAL2 Solve AnswerDocument3 pagesGENERAL2 Solve AnswerJlkKumar80% (5)

- Heat Treatments, Welding Processes, and Carbon Steel PropertiesDocument10 pagesHeat Treatments, Welding Processes, and Carbon Steel PropertiesAhmed Ben Nouma100% (1)

- Technology Multiple Choice Exam Få Fò - HWPDocument39 pagesTechnology Multiple Choice Exam Få Fò - HWPMark Darrel Aranas100% (3)

- Question ShopDocument112 pagesQuestion ShopThân Kha100% (3)

- CSWIP 3 New Update QuestionDocument81 pagesCSWIP 3 New Update QuestionrezaNo ratings yet

- CSWIPDocument3 pagesCSWIPBox Empty100% (2)

- Practice 7 Questions - CSWIPDocument12 pagesPractice 7 Questions - CSWIPravichandran0506100% (1)

- Wis 5 Eoca AnswersDocument34 pagesWis 5 Eoca AnswersAli ClubistNo ratings yet

- CSWIP QuizDocument12 pagesCSWIP Quizmushruff100% (1)

- Questions Cswip 3.11.1Document11 pagesQuestions Cswip 3.11.1Ralph Laurence Parungao100% (1)

- Welding QuizDocument3 pagesWelding QuizKarthiNo ratings yet

- NDT Methods and Weld Defects Identification QuizDocument8 pagesNDT Methods and Weld Defects Identification QuizMyak OkuokuNo ratings yet

- CSWIP 3.1 QuestionsDocument43 pagesCSWIP 3.1 QuestionsMichael AlbuquerqueNo ratings yet

- Welding Questions and AnswersDocument10 pagesWelding Questions and AnswersUmaibalan100% (2)

- Appendix English 2016Document180 pagesAppendix English 2016Adil Hasanov100% (1)

- CSWIP 3.1 Question and AnswerDocument31 pagesCSWIP 3.1 Question and AnswerDevendran Marappan92% (51)

- MMA Welding Paper Exam QuestionsDocument31 pagesMMA Welding Paper Exam QuestionsNeo80% (5)

- Multichoice Paper OneDocument4 pagesMultichoice Paper OneAhmed ShakirNo ratings yet

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- Cswip 3.2 MCQ-001Document5 pagesCswip 3.2 MCQ-001Moses_JakkalaNo ratings yet

- General 5Document3 pagesGeneral 5Sobia KalsoomNo ratings yet

- Welding Questions 1Document26 pagesWelding Questions 1dselvakuuNo ratings yet

- Question Excerpt From CSWIP 3Document4 pagesQuestion Excerpt From CSWIP 3Ekor JohnNo ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- CSWIP Test No 2Document3 pagesCSWIP Test No 2stanley100% (2)

- Mfy 003Document4 pagesMfy 003Le TuanNo ratings yet

- Cswip QA/answerDocument6 pagesCswip QA/answerJoseph PeterNo ratings yet

- Weld QuestionsDocument9 pagesWeld QuestionsdselvakuuNo ratings yet

- Answer Key To Set I Question No. Answer: Professional Training and ConsultationDocument1 pageAnswer Key To Set I Question No. Answer: Professional Training and ConsultationstanleyNo ratings yet

- 510 Answer Key JDocument2 pages510 Answer Key JstanleyNo ratings yet

- Income Tax Rules 1962 SummaryDocument2 pagesIncome Tax Rules 1962 Summaryajitjoshi950No ratings yet

- WTIA Sample Questions and Answers For Iwp ExaminationsDocument15 pagesWTIA Sample Questions and Answers For Iwp ExaminationssusanwebNo ratings yet

- PF - Tax On WithdrawalDocument9 pagesPF - Tax On WithdrawalstanleyNo ratings yet

- CF Flowers of Destiny Font - Read MeDocument1 pageCF Flowers of Destiny Font - Read MestanleyNo ratings yet

- ReadmeDocument1 pageReadmestanleyNo ratings yet

- Answer Key To Set A: Professional Training and ConsultationDocument1 pageAnswer Key To Set A: Professional Training and ConsultationstanleyNo ratings yet

- 510 Sample Questions Rev 061815Document3 pages510 Sample Questions Rev 061815stanleyNo ratings yet

- RPFC NoticeDocument12 pagesRPFC NoticestanleyNo ratings yet

- Guidline For Form 15GDocument1 pageGuidline For Form 15GstanleyNo ratings yet

- FLBOEA Course Notes Welding MEM05026B-Sections 13-18Document111 pagesFLBOEA Course Notes Welding MEM05026B-Sections 13-18stanleyNo ratings yet

- WJ 1992 12 s461Document12 pagesWJ 1992 12 s461stanleyNo ratings yet

- Oracle HRMS FundamentalsDocument398 pagesOracle HRMS FundamentalssourabhparandeNo ratings yet

- Form 15G With InstructionDocument2 pagesForm 15G With InstructionstanleyNo ratings yet

- Introduction To Valves ISO 5208Document5 pagesIntroduction To Valves ISO 5208stanley100% (1)

- Form 15GDocument2 pagesForm 15GkandurimaruthiNo ratings yet

- Form 10C With Instruction With HightlightedDocument4 pagesForm 10C With Instruction With HightlightedstanleyNo ratings yet

- Piping InspectionDocument5 pagesPiping InspectionstanleyNo ratings yet

- Article - Welding Stainless Steels To Other SteelsDocument2 pagesArticle - Welding Stainless Steels To Other SteelsstanleyNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- Manali Honeymoon Package 4N 5DDocument4 pagesManali Honeymoon Package 4N 5DstanleyNo ratings yet

- VesselDocument66 pagesVesselG100% (3)

- Inconel Alloy 625Document20 pagesInconel Alloy 625cmpatel_00No ratings yet

- Preheat and Interpass TempDocument2 pagesPreheat and Interpass TempUche UrchNo ratings yet

- Presentation 1Document21 pagesPresentation 1stanleyNo ratings yet

- Medicine: External SignsDocument1 pageMedicine: External SignsstanleyNo ratings yet

- Madam Bonaparte Key of A MajorDocument1 pageMadam Bonaparte Key of A MajorstanleyNo ratings yet

- !!34¿tttttttttt !! T TTTT T T T !! T TTTT T TTTT !!TTTTT ¿ T T T !! ¿ T TTTT T T T !! T T T T T T !! T T T T TT TT !!TTTTTT ¿ TTTTDocument1 page!!34¿tttttttttt !! T TTTT T T T !! T TTTT T TTTT !!TTTTT ¿ T T T !! ¿ T TTTT T T T !! T T T T T T !! T T T T TT TT !!TTTTTT ¿ TTTTstanleyNo ratings yet

- Chapter 17 - Spontaneity, Entropy, and Free Energy: Answer: CDocument34 pagesChapter 17 - Spontaneity, Entropy, and Free Energy: Answer: C鄭子玄No ratings yet

- MT-1 (English) - N SchemeDocument288 pagesMT-1 (English) - N SchemeKumar Subramanian100% (1)

- Title: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolDocument2 pagesTitle: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolEfraínNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- The Effective Removal of FeCO3 Deposits From Critical Process Heat Exchangers Used in Ammonia Production Using A Proprietary Ultrasonic Chemical Cleaning MethodDocument3 pagesThe Effective Removal of FeCO3 Deposits From Critical Process Heat Exchangers Used in Ammonia Production Using A Proprietary Ultrasonic Chemical Cleaning MethodjordanNo ratings yet

- EG0800300 UV-protection of Natural and Synthetic Fabrics by Surface Treatment Under The Effect of Gamma IrradiationDocument9 pagesEG0800300 UV-protection of Natural and Synthetic Fabrics by Surface Treatment Under The Effect of Gamma IrradiationariefNo ratings yet

- Chemistry File Xii 2Document24 pagesChemistry File Xii 2AzkkNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- ABRASIVESDocument5 pagesABRASIVES147No ratings yet

- A-Dec Self-Contained Water System: Instructions For UseDocument8 pagesA-Dec Self-Contained Water System: Instructions For UseIliasNo ratings yet

- Stress Rupture Behavior of Post-Weld Heat Treated 2-1/4Cr-1Mo Steel Weld MetalDocument56 pagesStress Rupture Behavior of Post-Weld Heat Treated 2-1/4Cr-1Mo Steel Weld Metalclaude.bouillot3566No ratings yet

- Pompe À Eun Honda WMP20XDocument100 pagesPompe À Eun Honda WMP20XLaure GarnierNo ratings yet

- LED Flashlight Design for Circular EconomyDocument12 pagesLED Flashlight Design for Circular EconomyAlexander GhidellaNo ratings yet

- Black 2Document14 pagesBlack 2KashyapNo ratings yet

- Iodine Value - WikipediaDocument39 pagesIodine Value - WikipediaMuhammad HussainNo ratings yet

- Bhartiyam Report 1Document58 pagesBhartiyam Report 1Bhartiyam Sushil0% (1)

- Order For SDIDocument18 pagesOrder For SDIحسن علي فالح حسنNo ratings yet

- Thermal Insulation Barrier Providing Corrosion Protection With "Cool-To-Touch" PropertiesDocument2 pagesThermal Insulation Barrier Providing Corrosion Protection With "Cool-To-Touch" PropertiesnarmathaNo ratings yet

- Appendix B Matl PropsDocument20 pagesAppendix B Matl PropsLindi NewmanNo ratings yet

- Answers To Mixed Stoichiometry Practice Review Problems-2Document2 pagesAnswers To Mixed Stoichiometry Practice Review Problems-2Jacqueline GomezNo ratings yet

- Dental CeramicsDocument62 pagesDental CeramicsAnamika Thakur Rana100% (2)

- Flourokem - Sherwin WilliamsDocument2 pagesFlourokem - Sherwin WilliamsOgbedande Awo OrunmilaNo ratings yet

- Molecular Polarity ExplainedDocument4 pagesMolecular Polarity ExplainedTea RadicNo ratings yet

- Topic 10 Paper 1Document30 pagesTopic 10 Paper 1RawanMazen SharifNo ratings yet

- BlongDocument11 pagesBlongMeriza SagaNo ratings yet

- CH 6Document10 pagesCH 6abdulrehmantofiqNo ratings yet

- Exxsol DSP 80 110 Product Safety SummarypdfDocument3 pagesExxsol DSP 80 110 Product Safety SummarypdfNatdanai LimprasertNo ratings yet

- SDS-PAGE of Protein: BT 510 Analytical Biotechnology LabDocument6 pagesSDS-PAGE of Protein: BT 510 Analytical Biotechnology LabBarish RoyNo ratings yet

- PMET 292 Nano AlloyDocument1 pagePMET 292 Nano Alloy.xNo ratings yet

- The Chemistry of COSDocument20 pagesThe Chemistry of COSsharkkingkingNo ratings yet