Professional Documents

Culture Documents

Article

Uploaded by

Jagannadha ReddyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Article

Uploaded by

Jagannadha ReddyCopyright:

Available Formats

Journal of the Korean Physical Society, Vol. 51, October 2007, pp.

S84S87

Thermal Conductivity of Al2 O3 /Water Nanouids

Dae-Hwang Yoo

Research Center for Dielectric and Advanced Matter Physics, Pusan National University, Busan 609-735

K. S. Hong and T. E. Hong

Busan Center, Korea Basic Science Institute, Busan 609-735

J. A. Eastman

Materials Science Division, Argonne National Laboratory, Argonne, IL 60439, U.S.A.

Ho-Soon Yang

Department of Physics, Pusan National University, Busan 609-735 Nanouids, uids with suspended nanoparticles, are of interest as a novel material for improving heat transfer eciency. The conventional theory of two-component mixtures cannot explain the large enhancement of thermal conductivity of nanouids. It is to be expected that the thermal conductivity of nanouids is related with many factors, such as that eect of surfactants, dispersion of particles, convection or Brownian motion of nanoparticles, etc. but the mechanism is not known. Thermal conductivity of Al2 O3 nanouids is studied in this work and compared with that of Fe nanouids. To study the eect of pH of the base uid on thermal conductivity, we measured the thermal conductivity of Al2 O3 nanouids with dierent pH values. Al2 O3 nanoparticles were dispersed in water of pH values such as 7.0, 9.65 and 10.94. Nanoparticles have a tendency to form clusters, due to van der Waals interaction resulting in reduction of thermal conductivity. It is understood from the variation of thermal conductivity as the pH value of base uids varies that the pH of base uids aects clustering of nanoparticles.

PACS numbers: 66.60.+a Keywords: Nanouid, Thermal conductivity, Hot-wire method

I. INTRODUCTION It has been an important issue to increase the eciency of heat exchange systems. Heat transfer uids such as oil, water, etc., show poor heat conduction properties. Since thermal conductivity of heat transfer uids is critical in determining the eciency of an engine, numerous methods have been adopted to improve thermal conductivity of heat transfer uids. Crystalline solids have much higher thermal conductivity than uids. Therefore, uids containing solid particles have been expected to display signicantly enhanced thermal conductivity, relative to pure uids. Nanosystems have been developed and studied intensively in wide areas, because of their characteristic properties and potential applications [1,2]. As nanotechnology developed, it was proposed that uids containing nanometer-sized particles could be a new class of engineered uids with high thermal conductivity [3]. These

E-mail:

hsyang@pusan.ac.kr

nanoparticle-suspended uids, named nanouids, have been produced as nanotechnology developed rapidly, and many papers have reported enhancement of thermal conductivity of nanouids [47]. Increase of thermal conductivity was observed in a large number of nanouids, such as CuO, Cu, and Al2 O3 nanouids [5]. CuO nanouids showed a 22 % increase of thermal conductivity [4]. Large enhancement of thermal conductivity of nanouids could not be predicted by conventional theories on the eective thermal conductivity of two-component materials [812]. The exact mechanism of thermal transport in nanouids is not known at this moment, even though several potential mechanisms have been suggested to describe experimental results on thermal conductivity of nanouids. Many factors, such as Brownian motion of nanoparticles, particle size, eect of surfactants, dispersion of particles, and thermal properties of dispersed particles, have been expected to inuence the thermal properties of nanouids [13]. Large surface-to-volume ratio of nanoparticles, compared with micro-sized particles, can lead to potential signicant enhancement of thermal con-S84-

Thermal Conductivity of Al2 O3 /Water Nanouids Dae-Hwang Yoo et al.

-S85-

ductivity of uids [14]. In this work, we present the enhancement of thermal conductivity of nanouids containing Fe and Al2 O3 nanoparticles. We also report the enhancement of thermal conductivity of nanouids prepared with base uids of dierent pH values. We also compare the experimental results with those of model calculations.

II. EXPERIMENTAL WORK Fe and Al2 O3 nanouids used in this work were prepared by a two-step procedure. Nanoparticles were synthesized by a chemical vapor condensation process and the average sizes of Fe and Al2 O3 particles are 10 nm and 50 nm, respectively. Ethylene glycol (EG) was used for Fe nanouids as a base uid, and water was used for Al2 O3 nanouids. Nanoparticles form clusters in nanouids, which leads to poor dispersion [18]. In order to improve the dispersion of particles in the uid, we used an ultrasonic cell disrupter (Jeiotech, ULH-700S) generating ultrasonic pulses of 700 W at 20 kHz. Sonicating time was dierent for dierent volume fractions of nanoparticles: 50 min. for 0.3 and 0.5 vol.% nanouids, 70 min. for 0.7 vol.% nanouid, and 90 min. for 1.0 and 1.5 vol.% nanouids. Al2 O3 nanouids were prepared with base uids having dierent pH values. NaOH solution was used to change the pH values of the nanouids. Properties of nanouids and the volume fractions used in the experiments are shown in Table 1. Thermal conductivity of nanouids was measured with a transient hot-wire (THW) method, which is one of the most accurate methods for determining thermal conductivity of uids [15, 16]. A Teon-coated pure (99.9 %) platinum wire was used in the measurement. The wire was used as both heater and thermometer. We measured the thermal conductivity of the nanouids as a function of volume fraction of particles after sonication.

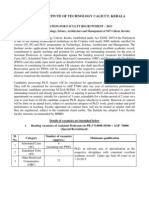

Fig. 1. XRD and TEM of Al2 O3 nanoparticles. (a) XRD data; (b) TEM.

III. RESULTS AND DISCUSSION Figure 1(a) and (b) present an X-ray diraction (XRD) pattern and a TEM image of Al2 O3 nanoparticles, respectively. The XRD result shows that Al2 O3 nanoparticles are formed in a structure. From the TEM image, we nd that the nanoparticles are spheres and have a broad size distribution. Figure 2 represents thermal conductivity of Fe nanouids and Al2 O3 nanouids as a function of volume fraction of nanoparticles. The y -axis represents the ratio of thermal conductivity of nanouid to that of base uid. The thermal conductivity increases as the volume fraction increases. 0.55 vol.% Fe nanouid shows 18 % enhancement of thermal

conductivity, and 1.0 vol.% Al2 O3 exhibits about 4 % enhancement. We are not able to explain the further enhancement of thermal conductivity of Fe nanouids without knowing the exact mechanism of thermal transport in nanouids. Suspending smaller particles is more eective to improve thermal conductivity of nanouids, because the surface-to-volume ratio of particles increases as particle size decreases. The intrinsic thermal conductivity of Fe (80 W/m-K) is much higher than that of Al2 O3 (30 W/m-K). We understand that thermal conductivity of Fe nanouids is enhanced more than that of Al2 O3 nanouids, due to the smaller size and also higher intrinsic thermal conductivity of the particles. Figure 3 shows thermal conductivity of Al2 O3 /pH nanouid prepared with water of dierent pH values. The nanouid of pH 10.94 exhibits higher thermal conductivity than the others. This result implies that controlling the pH of uids can lead to an increase of thermal conductivity of nanouids. In general, nanoparticles form clusters due to van der Waals interaction. We presume that the surface charge of nanoparticles in high-pH

-S86Table 1. Properties of nanouids used in experiments. Sample Base uid Average particle size Volume fraction Notation

Journal of the Korean Physical Society, Vol. 51, October 2007

Al2 O3 water, pH solution 50 nm 0.3, 0.5, 0.7, 1.0, 1.5 Al2 O3 /water, Al2 O3 /pH

Fe ethylene glycol (EG) 10 nm 0.2, 0.3, 0.4, 0.55 Fe/EG

Fig. 2. Thermal conductivity of Fe and Al2 O3 nanouids as a function of volume fraction of nanoparticles.

tures, and compared those values with the experimental results [9]. Figure 4 represents a comparison of the calculations and experimental results as a function of particle volume fraction. The lines in Figure 4(b) represent linear tted results for the data. In the case of the Fe nanouid, the experimental results show higher thermal conductivity than those of the H-C model calculation by more than 10 %. In the case of the Al2 O3 /water nanouid, the result of the model calculation diers from that for the Fe nanouid. The experimental values are nearly the same as those of the model calculation, which means that the thermal conduction behavior of the Al2 O3 /water nanouid follows the classical theory in this volume fraction region. Other researchers reported that Al2 O3 nanouid showed larger enhancement of thermal conductivity in the higher volume fraction region [17]. However, as we expected, nanouids synthesized by controlling the pH of the solution show a tendency of an increase with larger enhancement compared to the result of the H-C model calculation, and the degree of enhancement increases with volume fraction. At 1.5 % volume fraction, Al2 O3 /pH nanouid shows about 7 % increase of thermal conductivity relative to the model calculation result. This implies that controlling the pH of the nanouid can lead to enhancement of thermal conductivity.

IV. CONCLUSIONS The thermal conductivity of Al2 O3 nanouids was studied and compared with that of Fe nanouids. Al2 O3 nanouids show thermal conductivity close to the value predicted by the H-C model, while the thermal conductivity of Fe nanouids is improved more than as predicted by the H-C model. To study the eect of pH of base uid on thermal conductivity, we measured the thermal conductivity of Al2 O3 nanouids with dierent pH values and observed that thermal conductivity is improved by controlling the pH value of the nanouids. It is thus found that thermal conductivity of nanouids is improved by controlling pH values of nanouids. In order to understand the pH-dependent thermal conductivity, we need further study. This work will contribute to understanding a mechanism of thermal transport, which will facilitate eective enhancement of thermal conductivity of nanouids.

Fig. 3. Thermal conductivity of Al2 O3 /water and Al2 O3 / pH nanouids, related to volume fraction and pH values.

nanouids hinders clustering of nanoparticles, which results in smaller clusters. The change of cluster size of nanoparticles can be observed by means of light scattering, and such measurements will be made in our next work. We calculated thermal conductivity for Fe and Al2 O3 nanouids by using the Hamilton-Crosser (H-C) model which is a conventional model for two-component mix-

Thermal Conductivity of Al2 O3 /Water Nanouids Dae-Hwang Yoo et al.

-S87-

tion Grants KRF-2003-015-C00227 and KRF-2004-005C00065.

REFERENCES

[1] S. M. Kim, K. Kyhm, H.-S. Yang and K. S. Hong, J. Korean Phys. Soc. 49, S688 (2006). [2] N. Chevalier, M. J. Nasse, M. Stark, J. F. Motte, J. C. Woehl, S. Huant, P. Reiss, J. Bleuse and F. Chandezon, J. Korean Phys. Soc. 47, 126 (2005). [3] S. U. S. Choi, in Developments and Applications of NonNewtonian Flows (The ASME, New York, 1995). [4] S. Lee, S. U. S. Choi, S. Li and J. A. Eastman, J. Heat Transfer 121, 280 (1999). [5] H. Q. Xie, J. C. Wang, T. G. Xi, Y. Liu and F. Ai, J. Appl. Phys. 91, 4568 (2002). [6] S. U. S. Choi, Z. G. Zhang, W. Yu, F. E. Lockwood and E. A. Grulke, Appl. Phys. Lett. 79, 2252 (2001). [7] X. W. Wang, X. F. Xu and S. U. S. Choi, J. Thermophys. Heat Transfer 13, 474 (1999). [8] J. C. Maxwell, A Treatise on Electricity and Magnetism, 2nd ed. (Oxford University Press, oxford, 1904). [9] R. L. Hamilton and O. K. Crosser, Ind. Eng. Chem. Fundam. 1, 187 (1962). [10] A. Tobitani and T. Tanaka, Can. J. Chem. Eng. 65, 321 (1987). [11] D. H. Yoo, K. S. Hong, J. H. Park and H. S. Yang, submitted in J. Korean Phys. Soc. [12] T. K. Hong and H. S. Yang, J. Korean Phys. Soc. 47, 321 (2005). [13] S. P. Jang and S. U. S. Choi, Appl. Phys. Lett. 84, 4316 (2004). [14] Y. Xuan and Q. Li, Int. J. Heat Fluid Fl. 21, 58 (2000). [15] Y. Nagasaka and A. Nagashima, J. Phys. E 14, 1435 (1981). [16] E. Yamasue and A. Nagashima, J. Cryst. Growth 234, 121 (2002). [17] J. A. Eastman, S. U. S. Choi, S. Li, W. Yu and L. J. Thompson, Appl. Phys. Lett. 78, 718 (2001). [18] K. S. Hong, T. K. Hong and H.-S. Yang, Appl. Phys. Lett. 88, 30901 (2006).

Fig. 4. Comparison of experimental results with H-C model calculation. (a) Fe; (b) Al2 O3 .

ACKNOWLEDGMENTS This work was supported by Korean Research Founda-

You might also like

- 329 1881 2 PBDocument11 pages329 1881 2 PBAshwin SheriefNo ratings yet

- 409 1926 2 PB PDFDocument11 pages409 1926 2 PB PDFAshwin SheriefNo ratings yet

- 10 4 4 PDFDocument12 pages10 4 4 PDFAshwin SheriefNo ratings yet

- OSPV Preprint PDFDocument23 pagesOSPV Preprint PDFAshwin SheriefNo ratings yet

- Wiseannounce PDFDocument4 pagesWiseannounce PDFAshwin SheriefNo ratings yet

- Ebeling Thesis2 PDFDocument105 pagesEbeling Thesis2 PDFAshwin SheriefNo ratings yet

- Online RTI application status trackerDocument1 pageOnline RTI application status trackerAshwin SheriefNo ratings yet

- SN Bose Scholars Program 2013 - Flyer PDFDocument1 pageSN Bose Scholars Program 2013 - Flyer PDFAshwin SheriefNo ratings yet

- Detailed NotificationDocument4 pagesDetailed NotificationbuddysmbdNo ratings yet

- Conditions For Award of Specialisations - Aug13 PDFDocument8 pagesConditions For Award of Specialisations - Aug13 PDFAshwin SheriefNo ratings yet

- WinternshipDocument1 pageWinternshipMohit KulkarniNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Join CED Students' Membership Drive & Learn EntrepreneurshipDocument1 pageJoin CED Students' Membership Drive & Learn EntrepreneurshipAshwin SheriefNo ratings yet

- Batch3brochure PDFDocument5 pagesBatch3brochure PDFAshwin SheriefNo ratings yet

- Call For Proposals Students Innovative Project (CTDT) PDFDocument7 pagesCall For Proposals Students Innovative Project (CTDT) PDFAshwin SheriefNo ratings yet

- S.N. Bose Scholars Program Application GuidelinesDocument1 pageS.N. Bose Scholars Program Application GuidelinesAshwin SheriefNo ratings yet

- Effect of Axial Conduction and Variable Properties On Two-Dimensional Conjugate Heat Transfer of Al O - EG/Water Mixture Nanofluid in MicrochannelDocument9 pagesEffect of Axial Conduction and Variable Properties On Two-Dimensional Conjugate Heat Transfer of Al O - EG/Water Mixture Nanofluid in MicrochannelAshwin SheriefNo ratings yet

- Apply Online for Police Special Branch Assistant VacancyDocument2 pagesApply Online for Police Special Branch Assistant VacancyAshwin SheriefNo ratings yet

- JRF IgcarDocument8 pagesJRF IgcarJ WilliamsNo ratings yet

- Angercircular PDFDocument1 pageAngercircular PDFAshwin SheriefNo ratings yet

- Appeal Under RI Act PDFDocument1 pageAppeal Under RI Act PDFAshwin SheriefNo ratings yet

- PDFDocument9 pagesPDFAshwin SheriefNo ratings yet

- 36brochure PDFDocument2 pages36brochure PDFAshwin SheriefNo ratings yet

- Mass Flow Versus Volumetric FlowDocument4 pagesMass Flow Versus Volumetric FlowIAabbasiNo ratings yet

- National Institute of Technology Calicut, KeralaDocument4 pagesNational Institute of Technology Calicut, KeralaAshwin SheriefNo ratings yet

- PDFDocument15 pagesPDFAshwin SheriefNo ratings yet

- PDFDocument15 pagesPDFAshwin SheriefNo ratings yet

- 9-Convection - Internal Flow PDFDocument0 pages9-Convection - Internal Flow PDFAshwin SheriefNo ratings yet

- 1 s2.0 S0038092X08002880 Main PDFDocument15 pages1 s2.0 S0038092X08002880 Main PDFAshwin SheriefNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Afrah Summer ProjectDocument11 pagesAfrah Summer Projectاشفاق احمدNo ratings yet

- Hilton 5-29 Case SolutionDocument4 pagesHilton 5-29 Case SolutionPebbles RobblesNo ratings yet

- Complex Numbers GuideDocument17 pagesComplex Numbers GuideGus EdiNo ratings yet

- Evolution BrochureDocument4 pagesEvolution Brochurelucas28031978No ratings yet

- JTIL Purchase Requisition for Plasma Machine SparesDocument3 pagesJTIL Purchase Requisition for Plasma Machine Sparesshivam soniNo ratings yet

- Clinical Indications, Treatment and Current PracticeDocument14 pagesClinical Indications, Treatment and Current PracticefadmayulianiNo ratings yet

- Exercise C: Cocurrent and Countercurrent FlowDocument6 pagesExercise C: Cocurrent and Countercurrent FlowJuniorNo ratings yet

- Mono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Document25 pagesMono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Farhan aliNo ratings yet

- Control Systems Engineering by S C Goyal U A Bakshi PDFDocument3 pagesControl Systems Engineering by S C Goyal U A Bakshi PDFShubham SinghNo ratings yet

- APTARE IT Analytics: Presenter NameDocument16 pagesAPTARE IT Analytics: Presenter NameCCIE DetectNo ratings yet

- MP & MC Module-4Document72 pagesMP & MC Module-4jeezNo ratings yet

- Country Profile - NigerDocument1 pageCountry Profile - Nigernana kayNo ratings yet

- Lay Out New PL Press QltyDocument68 pagesLay Out New PL Press QltyDadan Hendra KurniawanNo ratings yet

- Foundry Technology GuideDocument34 pagesFoundry Technology GuidePranav Pandey100% (1)

- Yardi Commercial SuiteDocument52 pagesYardi Commercial SuiteSpicyNo ratings yet

- Online Music Courses With NifaDocument5 pagesOnline Music Courses With NifagksamuraiNo ratings yet

- Impression Techniques in Complete Denture Patients: A ReviewDocument6 pagesImpression Techniques in Complete Denture Patients: A ReviewRoja AllampallyNo ratings yet

- Galley cleaning hazards and controlsDocument9 pagesGalley cleaning hazards and controlsRosalie RosalesNo ratings yet

- Carbapenamses in Antibiotic ResistanceDocument53 pagesCarbapenamses in Antibiotic Resistancetummalapalli venkateswara raoNo ratings yet

- Wargames Illustrated #115Document64 pagesWargames Illustrated #115Анатолий Золотухин100% (1)

- Shell Omala S2 G150 DatasheetDocument3 pagesShell Omala S2 G150 Datasheetphankhoa83-1No ratings yet

- Bargaining Power of SuppliersDocument9 pagesBargaining Power of SuppliersPiyumi VitharanaNo ratings yet

- Technical CommunicationDocument35 pagesTechnical CommunicationPrecious Tinashe NyakabauNo ratings yet

- 2020 - Audcap1 - 2.3 RCCM - BunagDocument1 page2020 - Audcap1 - 2.3 RCCM - BunagSherilyn BunagNo ratings yet

- Popular Tools CatalogDocument24 pagesPopular Tools CatalogCarbide Processors IncNo ratings yet

- John Williams - WikipediaDocument2 pagesJohn Williams - Wikipedia三木和代No ratings yet

- Audi A3 Quick Reference Guide: Adjusting Front SeatsDocument4 pagesAudi A3 Quick Reference Guide: Adjusting Front SeatsgordonjairoNo ratings yet

- Dwarf Boas of The Caribbean PDFDocument5 pagesDwarf Boas of The Caribbean PDFJohn GamesbyNo ratings yet

- UFO Midwest Magazine April2011Document16 pagesUFO Midwest Magazine April2011Jimi HughesNo ratings yet

- TSGE - TLGE - TTGE - Reduce Moment High Performance CouplingDocument6 pagesTSGE - TLGE - TTGE - Reduce Moment High Performance CouplingazayfathirNo ratings yet