Professional Documents

Culture Documents

Count Point and Autocharge Operations in Oracle Bills of Material

Uploaded by

tsurendarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Count Point and Autocharge Operations in Oracle Bills of Material

Uploaded by

tsurendarCopyright:

Available Formats

Count Point and Autocharge When you define operations in Oracle Bills of Material, you can specify whether

an operation is a count point and whether resources at that operation should be automatically charged during a move transaction. You can update this information in Work in Process using the Operations window. Operations that are non-count point/autocharge operations must be defined as backflush operations. You can define which operations in a routing record move transactions (and there by do the backflushing if its enabled) by defining how resources are consumed at that operation. The Count Point and Autocharge check boxes work together. In the following discussion, the Count Point and Autocharge check boxes can be set to either on or off. However, you cannot set Count Point on and Autocharge off. When you move assemblies from an operation with Count Point on / Autocharge on operation to another count point operation set the same way, Work in Process automatically completes all Count Point off / Autocharge on count point operations between them. To transact a Count Point off / Autocharge off count point operation, you must explicitly move assemblies into and out of that operation. Moving assemblies past a Count Point off / Autocharge off count point operation acts as though the operation did not exist in the routing. This is particularly useful for rework or debug operations that are performed on a portion of the assemblies you process. If you issue components with a supply type of Operation pull to an assembly at a Count Point off / Autocharge off count point operation, Work in Process backflushes these components when you move out of the Count Point off / Autocharge off count point operation into a count point operation that allows backflushing. Work in Process never pulls components with a supply type of Assembly pull from Count Point off/ Autocharge off count point operations. However, you must turn Backflush on for Count Point off / Autocharge off count point operations. The Backflush field should always be turned on for the last operation in a routing. Notes 1. If count point is on then auto charge needs to be on. 2. If Both count point and auto charge are off then backflush needs to be on. 3. When count point is on and blackflush is on we dont need to explicitly do the move transaction to and from the operation to do material transaction but if count point is off(and thus autocharge) and balckflush is on then we need to do a move transaction to and from that operation to make the backflush takes place Ex: OP seq Count-Point Autocharge Backflush 10 Y Y Y 20 N N Y 30 N Y Y 40 Y Y Y In the above example if we move from Op 10 to 40(To Move) then resource charges takes place @10,30 & 40 but backflush takes place only @ 10 and 40 though 20 and 30 are also backflush enabled. To make backflush @20 we need to explicitly move to OP20. i.e we need to do move transaction from OP10 to OP20 and then OP20 to OP 40 Again if we need backflush @30 then we need to from OP20 to OP30 and then OP30 to OP40. Effects when Count point is OFF Let consider a routing as shown below 1. When you do the move transaction the system 'll defaule the op 40 as 20 & 30 has no count points. 2. If we select 60 as the To operation then system 'll record only the operation step 40 and all the

resources attached in between operation seq 10 to 60 'll be charged and backflush 'll takes place if its enabled. 3. If we do move transaction directly from 10 to 40 then no backflush takes place @opration 20 and 30 though for both backflush is enabled. But if we do a transactio to either 20 or 30 then we'll force the system to backflush the material at that point. Example Count Point & Auto charge Operations In the following example, the routing has five operations. The second and fourth operations are not count points, and you must explicitly move units in and out of the fourth operation if you want to charge the job or repetitive schedule for the consumed resources. The following table presents an example of count point operations. Operation Sequence Description Count Point Autocharge Backflush Instructions 10 Assembly 1 Yes Yes Yes n/a 20 Assembly 2 No Yes No n/a 30 Painting Yes Yes Yes If color and texture do not meet standards, send to Op 40. If job meets standards, send to Op 50. 40 Painting Rework No Direct charge Yes Sand finish and repaint to meet standards. 50 Packaging Yes Yes Yes Ship directly to customer site when finished with this operation. Count Point off / Autocharge on Assign this count point to operations that you always perform in a routing, but where you do not want to monitor assembly moves into, out of, and through the operation. For example, choose this count point for non-bottleneck operations that are not labor or time-intensive, such as inspection or minor assembly operations. Work in Process automatically completes the operation and charges its WIP move resources to your job or schedule when you record a move transaction through or beyond the operation, as with Count Point on / Autocharge on count point operations. Work in Process does not default the operation, unlike Count Point on / Autocharge on count point operations. You can still record movements into, out of, and through the operation by overriding the default in Work in Process. Count Point off / Autocharge off Assign this count point to operations that you do not typically perform in a routing. For example, a rework operation that you only perform on occasion. If you choose this count point for an operation, Work in Process does not complete the operation and charge its resources to your job or schedule unless you explicitly record a move transaction into and through the operation. Work in Process does not default the operation. You can still record movements into, out of, and through the operation by overriding the default in Work in Process. Count Point on / Autocharge on Assign this count point to operations you want to automatically default as destination operations in the Move Transactions window. You should always assign this count point to the final operation in a routing, to insure that you record move transactions into the operation, and then record completion transactions. You can automatically complete and charge operations in a routing with this count point. Work in Process automatically completes an operation and charges its WIP Move resources to your job or schedule when you record a move transaction through or beyond the operation. For operations that you always perform in a routing, you can also monitor assembly moves into, out of, and through the operation. For example, choose this count point for critical, time-intensive,

or bottleneck operations. Backflush Indicate whether to backflush components on shop floor moves at this operation. A backflush transaction automatically pulls Operation pull components from inventory. Work in Process also pulls all Operation pull components at non-backflush operations preceding this operation (through the previous completed backflush operation.) Minimum transfer quantity Enter the minimum transfer quantity of assemblies to move from this operation to the next. Work in Process will warn you if you attempt to move a number less than this value. If you used a standard operation, this value defaults to minimum transfer quantity defined for the standard operation. Otherwise the default is 0.

You might also like

- What Is BackflushDocument4 pagesWhat Is BackflushSachin IngleNo ratings yet

- Over CompletionsDocument12 pagesOver Completionslucky76No ratings yet

- Fulfillment in Oracle Order ManagementDocument9 pagesFulfillment in Oracle Order ManagementAlok Kumar100% (2)

- Creating A WIP JOBDocument49 pagesCreating A WIP JOBNaveed MohammadNo ratings yet

- Oracle Work in Process - Backflush Processing: An Oracle White Paper January 2011Document41 pagesOracle Work in Process - Backflush Processing: An Oracle White Paper January 2011malelbolgiaNo ratings yet

- BOM-Bill Resource CreationDocument4 pagesBOM-Bill Resource Creationpiks_ban83No ratings yet

- WIP Parameters: 11. What Are The Required Setups Need To Be Done in Inventory?Document3 pagesWIP Parameters: 11. What Are The Required Setups Need To Be Done in Inventory?sankarshan deNo ratings yet

- ASCP and Safety Stock PeggingDocument2 pagesASCP and Safety Stock PeggingRamakrishna Reddy GorantlaNo ratings yet

- Oracle Field Service Data SheetDocument4 pagesOracle Field Service Data SheetBhanu PratapNo ratings yet

- How To Use Attribute Mapping in Oracle Advanced PricingDocument4 pagesHow To Use Attribute Mapping in Oracle Advanced PricingBabu ChalamalasettiNo ratings yet

- SM7 - Oracle Production SchedullingDocument4 pagesSM7 - Oracle Production SchedullingRakha Setyoadi Dwi LeksonoNo ratings yet

- WIP VarianceDocument34 pagesWIP Varianceanchauhan30610% (1)

- LCM Accounting in P2PDocument4 pagesLCM Accounting in P2Pramthilak2007gmailcomNo ratings yet

- Forecast Explosion Consumption Setup StepsDocument5 pagesForecast Explosion Consumption Setup StepsGops989No ratings yet

- Oracle Demantra model codes used in MDP_MATRIXDocument3 pagesOracle Demantra model codes used in MDP_MATRIXVictor MillanNo ratings yet

- Global & Local Causal Factors in DemantraDocument9 pagesGlobal & Local Causal Factors in DemantraGaurav SinghNo ratings yet

- WebADI Whitepaper - Updated Sept2017Document31 pagesWebADI Whitepaper - Updated Sept2017ShriNo ratings yet

- WIP Create A Discrete Job TrainingDocument17 pagesWIP Create A Discrete Job TrainingSureshAvaldarNo ratings yet

- Oracle Demantra Demand ManagementDocument29 pagesOracle Demantra Demand Managementeuge_prime2001No ratings yet

- Cost ManagementDocument78 pagesCost ManagementSudheer SanagalaNo ratings yet

- ASCP and OM SetupsDocument5 pagesASCP and OM SetupsVikram JanardhanamNo ratings yet

- 1Z0-511 Exam DumpsDocument6 pages1Z0-511 Exam DumpsExamDumpsNo ratings yet

- Mfg WIP Advisor Webcast 2013 1030Understanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureDocument50 pagesMfg WIP Advisor Webcast 2013 1030Understanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosureUnderstanding Discrete Job ClosuresryallaNo ratings yet

- SS InvDocument32 pagesSS InvvishuoracleNo ratings yet

- E ATP - 11 V D D: Nabling ON A WEB Enabled Item IN THE I Ision EMO AtabaseDocument10 pagesE ATP - 11 V D D: Nabling ON A WEB Enabled Item IN THE I Ision EMO AtabasePJ1902100% (2)

- Gen SetupDocument113 pagesGen Setupkiran_shri1No ratings yet

- P2P 3Document8 pagesP2P 3nahlaNo ratings yet

- Issues On Purchasing & OMDocument4 pagesIssues On Purchasing & OMThammineni Vishwanath NaiduNo ratings yet

- Auto Invoice FAQDocument11 pagesAuto Invoice FAQblshinde88No ratings yet

- Manage Outside Assembly with Chargeable SubcontractingDocument23 pagesManage Outside Assembly with Chargeable SubcontractingArun MinnasandranNo ratings yet

- Oracle - White Paper - Demand-Driven Retail Planning & Store Replenishment (Retail-planning-And-store-replenishment-white-paper)Document5 pagesOracle - White Paper - Demand-Driven Retail Planning & Store Replenishment (Retail-planning-And-store-replenishment-white-paper)Victor MillanNo ratings yet

- ASCP IO Safety Stock Calc Lead TimeDocument13 pagesASCP IO Safety Stock Calc Lead TimeMohan Srireddy100% (1)

- Oracle Advanced Planning and Scheduling: Implementation and User's Guide, Volumes 1 & 2Document908 pagesOracle Advanced Planning and Scheduling: Implementation and User's Guide, Volumes 1 & 2priyaNo ratings yet

- EAM Schedular WorkbenchDocument99 pagesEAM Schedular Workbenchvenvimal1No ratings yet

- Cyccle CountingDocument64 pagesCyccle CountingAshish MalviyaNo ratings yet

- DemantraDocument30 pagesDemantraRavi P HunachannavarNo ratings yet

- On Time in Full (OTIF) KPI Guide: Definition, Formulas, Tips, Practical ApplicationsDocument17 pagesOn Time in Full (OTIF) KPI Guide: Definition, Formulas, Tips, Practical ApplicationsBernardo RiveroNo ratings yet

- Oracle Quality: Manufacturing Functional FoundationDocument23 pagesOracle Quality: Manufacturing Functional FoundationJose DuqueNo ratings yet

- INV, Costing Period CloseDocument9 pagesINV, Costing Period CloseMd MuzaffarNo ratings yet

- SCP DemandPlanningScalability R13Document20 pagesSCP DemandPlanningScalability R13javierNo ratings yet

- How To Cancel/ Restart The Cost Manager:: More Create Blog Sign inDocument4 pagesHow To Cancel/ Restart The Cost Manager:: More Create Blog Sign inRahul AgarwalNo ratings yet

- Beginners Guide to Implementing Oracle ASCPDocument21 pagesBeginners Guide to Implementing Oracle ASCPNavin SidanaNo ratings yet

- Set up consigned inventory in Oracle EBSDocument14 pagesSet up consigned inventory in Oracle EBSfarhanahmed01No ratings yet

- Cycle CountDocument58 pagesCycle CountPJ190275% (4)

- OSP Setup and ProcessingDocument3 pagesOSP Setup and ProcessingLarry Sherrod100% (2)

- Consigned Orders in PurchasingDocument28 pagesConsigned Orders in PurchasingOmer ShahzadNo ratings yet

- Approved Supplier Sourcing Rules PresentationDocument31 pagesApproved Supplier Sourcing Rules PresentationMaulikNo ratings yet

- ATO WorkflowDocument7 pagesATO WorkflowtsurendarNo ratings yet

- Shipping Ship Method Freight Charges Oracle AppsDocument12 pagesShipping Ship Method Freight Charges Oracle AppsRamesh GarikapatiNo ratings yet

- CH 15 Demand Manmagement & Forecasting-HKDocument20 pagesCH 15 Demand Manmagement & Forecasting-HKShashank GuptaNo ratings yet

- FREIGHT ChargesDocument36 pagesFREIGHT Chargesmayankpant1No ratings yet

- Oracle Bills of Material and EngineeringDocument35 pagesOracle Bills of Material and EngineeringjovellloyNo ratings yet

- Destination Type-Oracle AppsDocument1 pageDestination Type-Oracle AppsPritesh MoganeNo ratings yet

- Demantra End 2 End Sol GooDDocument16 pagesDemantra End 2 End Sol GooDRamesh PoshalaNo ratings yet

- Oracle WIPDocument195 pagesOracle WIPgauravbokariaNo ratings yet

- Short Notes On Oracle WIP User GuideDocument22 pagesShort Notes On Oracle WIP User Guidetsurendar0% (1)

- How To Use A Pulse Oximeter at Home: Home Isolation & Care For COVID-19Document1 pageHow To Use A Pulse Oximeter at Home: Home Isolation & Care For COVID-19Deepi DasNo ratings yet

- Iproc R12 Imp & User GuideDocument308 pagesIproc R12 Imp & User GuideManmohan KulkarniNo ratings yet

- Waste To Wealth & Organic Farming-A Way Forward To Employment GenerationDocument8 pagesWaste To Wealth & Organic Farming-A Way Forward To Employment GenerationtsurendarNo ratings yet

- Soil Organic Carbon Sequestration in Agriculture Issues and PrioritiesDocument16 pagesSoil Organic Carbon Sequestration in Agriculture Issues and PrioritiestsurendarNo ratings yet

- Vasthu - Sleep - StudyDocument3 pagesVasthu - Sleep - StudytsurendarNo ratings yet

- Why Use Oracle Services Procurement.Document3 pagesWhy Use Oracle Services Procurement.tsurendarNo ratings yet

- Home Remedies For DiabetesDocument1 pageHome Remedies For DiabetestsurendarNo ratings yet

- Iproc R12 Imp & User GuideDocument308 pagesIproc R12 Imp & User GuideManmohan KulkarniNo ratings yet

- Blah Blah Blah InstructionsDocument3 pagesBlah Blah Blah InstructionstsurendarNo ratings yet

- Aim & OumDocument4 pagesAim & Oumtsurendar100% (1)

- Oracle Process Manufacturing - Costing: Key FeaturesDocument3 pagesOracle Process Manufacturing - Costing: Key FeaturesRam PrabuNo ratings yet

- E TRMDocument7 pagesE TRMtsurendarNo ratings yet

- Oracle Internal Requistions 11i Explanation and Complete ExerciseDocument11 pagesOracle Internal Requistions 11i Explanation and Complete ExercisetsurendarNo ratings yet

- How To Create And Demonstrate The Contingent Worker Flow In PurchasingDocument52 pagesHow To Create And Demonstrate The Contingent Worker Flow In PurchasingtsurendarNo ratings yet

- Oracle AlertsDocument3 pagesOracle AlertstsurendarNo ratings yet

- Oracle FlexfieldsDocument75 pagesOracle FlexfieldstsurendarNo ratings yet

- 11i Vs R12Document1 page11i Vs R12tsurendarNo ratings yet

- Oracle CRM ProfilesDocument1 pageOracle CRM ProfilestsurendarNo ratings yet

- Aim & OumDocument4 pagesAim & Oumtsurendar100% (1)

- Oracle CRM Teleservice & Marketing ManagementDocument124 pagesOracle CRM Teleservice & Marketing ManagementtsurendarNo ratings yet

- Oracle INV Profile OptionsDocument10 pagesOracle INV Profile OptionstsurendarNo ratings yet

- Mobile Apps Server GuideDocument30 pagesMobile Apps Server GuidetsurendarNo ratings yet

- Inventory - Setup - PlannerDocument1 pageInventory - Setup - PlannertsurendarNo ratings yet

- Cost Rollup BasicsDocument9 pagesCost Rollup BasicssdhrubuNo ratings yet

- I ExpensesDocument38 pagesI ExpensestsurendarNo ratings yet

- Ebs Financial Integration.Document35 pagesEbs Financial Integration.tsurendarNo ratings yet

- Workday CalendarDocument3 pagesWorkday Calendartsurendar100% (1)

- Oracle Key Flexfields Security Tips and TricksDocument9 pagesOracle Key Flexfields Security Tips and TricksAnuradhatagoreNo ratings yet

- A2Z Oracle 11i Tip SheetDocument2 pagesA2Z Oracle 11i Tip SheetManoranjan RathNo ratings yet

- VA Financial Services: Virtual CFO Support for GrowthDocument18 pagesVA Financial Services: Virtual CFO Support for Growthlanka saravanNo ratings yet

- Human Resource Management Final - QuizletDocument23 pagesHuman Resource Management Final - QuizletReem BouZeineddineNo ratings yet

- Human Resource ManagementDocument3 pagesHuman Resource ManagementQuestTutorials BmsNo ratings yet

- IRLW - QB - 2016 RegulationsDocument20 pagesIRLW - QB - 2016 RegulationsmanikaNo ratings yet

- Akzonobel: Submitted To Dr. Syed JalilDocument26 pagesAkzonobel: Submitted To Dr. Syed JalilSHARON TESS JoseNo ratings yet

- NIVEADocument11 pagesNIVEAShobhit Dixit50% (2)

- 1.1 Electronic Commerce:: Definition of E-CommerceDocument8 pages1.1 Electronic Commerce:: Definition of E-Commercesyed hussainNo ratings yet

- Bahr 323Document5 pagesBahr 323Tessia EralithNo ratings yet

- HR at Descon Etmaad SlidesDocument18 pagesHR at Descon Etmaad SlidesUsama ShahNo ratings yet

- Chapter 6 PlanningDocument31 pagesChapter 6 PlanningMuhammad Haris100% (1)

- Resources. Service Actions: SVC Activities SVC ActivitiesDocument15 pagesResources. Service Actions: SVC Activities SVC Activitiesmanoja GorrepatiNo ratings yet

- Prepare for GM role by developing HR skillsDocument2 pagesPrepare for GM role by developing HR skillsAboi BoboiNo ratings yet

- Power System Analysis and Design 5th Edition by J. Duncan GloverDocument4 pagesPower System Analysis and Design 5th Edition by J. Duncan Gloversiegfred sicatNo ratings yet

- SIF Planning QuestionsDocument6 pagesSIF Planning QuestionsKamarul KhalidNo ratings yet

- SAP SD Awareness Session on Sales & Distribution OverviewDocument14 pagesSAP SD Awareness Session on Sales & Distribution OverviewShahnawaz BaigNo ratings yet

- Top Management Responsibilities and Strategic Planning RoleDocument13 pagesTop Management Responsibilities and Strategic Planning Rolessaini67144No ratings yet

- Project Management and Quality Control Quality Control: Yarmouk University Yarmouk UniversityDocument62 pagesProject Management and Quality Control Quality Control: Yarmouk University Yarmouk UniversityLola NurungNo ratings yet

- Korn Ferry Work Redesigning Action PlanDocument6 pagesKorn Ferry Work Redesigning Action PlanNitikaNo ratings yet

- Unscoped DCT Report on Maintenance Special RequirementsDocument5 pagesUnscoped DCT Report on Maintenance Special RequirementsshaggipcNo ratings yet

- Assignment On Mid-Term ExamDocument11 pagesAssignment On Mid-Term ExamTwasin WaresNo ratings yet

- BUSINESS AS and A Level NOTES CIE SYLLAB PDFDocument29 pagesBUSINESS AS and A Level NOTES CIE SYLLAB PDFPrashant Joshi50% (2)

- Seven Principles of QMS 9001 - 2015Document11 pagesSeven Principles of QMS 9001 - 2015caesar bintangNo ratings yet

- Mcdonald'S: Training & DevelopmentDocument4 pagesMcdonald'S: Training & DevelopmentHammad TariqNo ratings yet

- CA Abdul Muthalif - OriginalDocument2 pagesCA Abdul Muthalif - Originalayesha siddiquiNo ratings yet

- Eaton Global Supplier Excellence ManualDocument30 pagesEaton Global Supplier Excellence Manualfdsa01100% (1)

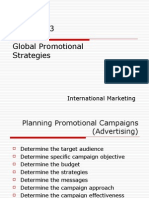

- Global Promotional StrategiesDocument10 pagesGlobal Promotional Strategiesginz2008100% (4)

- Swot AnalysisDocument34 pagesSwot Analysisbonnyme.00No ratings yet

- 14 HiringDocument5 pages14 HiringMoeez100% (1)

- ISO 9001 - HutchinsonDocument2 pagesISO 9001 - HutchinsonUğurNo ratings yet

- Chapter 7 - No Voice OverDocument19 pagesChapter 7 - No Voice OverAli BaradaNo ratings yet