Professional Documents

Culture Documents

4807

Uploaded by

Komol KabirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4807

Uploaded by

Komol KabirCopyright:

Available Formats

www.fibre2fashion.

com

www.fibre2fashion.com

Wicking of woven fabrics

By: Valsang R.K. & Patil L.G.

Abstract: Textile fabrics play an important role in the daily life of every human mankind. They are used in various applications. There application is mainly governed by liquid transport property (wicking).The type weave and one type of warp & weft interaction to another interaction significantly affects the wicking property of clothing. The main aim of this research article is to study the interaction and weaves effect on wicking, absorbency, air permeability values. Key words: - Wicking, Absorbency, Air permeability Introduction Textile fabrics play an important role in the daily life of every human mankind. Their applications for many end users are governed by their liquid transport properties (wicking property). . The characterization of liquid flow of textile fabrics are useful to decide the flow of spin finish, dyeing behavior, transport of water through the textile, comfort of under clothing, and absorbency of towels(3). The phenomenon of liquid transport during sorption from one weave to another weave and one type of warp & weft interaction to another interaction is often overlooked even though its believed to be an important part of the absorption process in the fabric. Therefore the main goal of this research is to understand the effect of fabric structure and interaction effect on the overall liquid transport behavior of fabrics (1).

www.fibre2fashion.com

2. Experimental work 2.1-Materials Throughout this study, 12 woven fabric samples were produced. The details of the fabric samples were listed in table I. The modified polyester weft yarn was purchase from market with count of 160 denier. The combed cotton warp yarns were purchased from market with count of 30 Ne .The warp and weft density per inch for all the samples were same. All woven fabric samples were produced on rapier weaving machine with the following particulars: - Warp density: 125 ends / inch. - Weft density: 60 picks / inch - Fabric Width: 160 cm. - Number of Harness Frames: 6 - Weave structure: 1/1 plain, 2/1 twill, and 6-satin weaves - Machine speed: 400 ppm Table I. Warp mateial x Weft Weave Plain(G1) X 100% Twill(G2) A1 A2 A7 A8 Satin(G3) A5 A6 A3 A4

material 100% polyester

100 % Cotton X 100% polyester A9 polyester 100 % Cotton X 100 % Cotton A10

100% polyester X 100 % Cotton A11 A12

2.2 Method The air permeability test were conducted by air permeability tester according to ASTM slandered D73796.The conditioned test sample were centrally placed between adaptor disc and lower grip. The sufficient tension is applied over the fabric to eliminate the creases. The equipment and vacuum pump was switched on and the flow adjusting value

www.fibre2fashion.com

is slowly opened and readjusted till desired level of pressure drop was obtained in monometer. Record the air flow in cm3/cm2/sec under the pressure drop of 10 mm head of water. The strip test was employed to measure the wicking. The wicking height of water in accordance with DIN 53924 standards (1). The fabric samples (250 mm in length and 30 mm in width) were cut along the warp and weft direction & vertically immersed in reservoir of distill water so that the lower end will contact the water (15 mm from the lower end). The height attain by water in fabric above water level in the reservoir was measured at each 5 min time interval. Record the height of water at 20 min and remove the sample from reservoir. The absorbency of sample was determined by the drop absorbency method according to AATCC/ASTM test method TS-18. 3.Result and Discussion:All the measurements were made under standard atmospheric conditions. The results were evaluated statistically according to two-way variance analysis (ANOVA). The means were compared with each other by using a statistical package program separately for every test. 3.1 Wicking The wicking property of fabric is mainly depend on the fabric charaterstics of fibre and structure of component yarns and the fabric.Table III shows the wicking height of sample fabrics in warp and weft direction for different time intreval.The fabric sample woven with satin interlacement order with interaction of warp cotton & weft polyester exibits higher wicking height in warp direction compare to plain and twill interlacement order fabric samples woven with interaction of warp cotton & weft polyester.The statistical graph shown in fig 1. The fabric woven with plain weave with interaction of polyester warp and cotton weft shows lower wicking height in warp direction compare to

www.fibre2fashion.com

sample of satin and twill interlacement order with interaction of polyester warp and cotton weft.This may due to dominacy of hygroscopic material in warp direction as well as minumum number of binding point in satin weave which leads higher wicking in warp direction. The woven fabric sample with satin weave interlacement order with combination of polyester warp and cotton weft shows heigher wicking height in weft direction.The sample with twill and plain weave respectively shows less wicking height in weft direction compare to privious interlacement order.The woven fabric interlace with polyester warp and polyester weft shows lower wicking height in weft direction.This may due to avilability of cotton fibres in weft direction and less number of binding points per weave repeat.The statistical graph shown in fig.2. The wicking height increaes with time for all the samples which shows from table.III

Table III. sample No A12 A10 A11 A9 A8 A2 A7 A1 A4 A6 A3 A5 vertical wicking height( cm) warp way 5 10 15 20 min min min min 5.34 6.94 7.74 8.52 4.54 5.88 6.7 7.34 3.5 4.4 4.8 5.1 7.14 9.04 10.32 11.04 7.32 9.46 10.46 11.62 4.98 6.2 7.8 8.98 5.5 7.3 8.6 9.3 8.22 10.52 12.04 12.54 9.16 11.88 13.78 15.2 7.1 9 10.76 11.4 6.84 9.22 10.7 11.76 10.62 13.94 15.98 17.18 weft way 5 10 min min 4.42 5.8 3.6 4.88 5.5 7.3 5.32 6.66 6.06 7.58 3.06 4.22 6.8 8.5 5.82 7.22 8.04 9.94 5.52 7.32 9.8 12.14 7.42 9.72

15 min 6.56 5.74 8.6 7.62 8.48 5.22 10 8.32 11.54 8.8 14.12 11.22

20 min 7.18 6.56 9.3 8.28 9.12 5.94 10.6 9.16 12.3 9.68 14.76 12.38

Fig.1.1 Warp way wicking ( Plain )

www.fibre2fashion.com

Fig.1.2.Warp way wicking ( twill )

Fig.1.3.Warp way wicking ( satin )

www.fibre2fashion.com

Fig.1: warpway wicking effect

Fig.2.1. Weft way wicking (plain)

www.fibre2fashion.com

Fig.2.2. weftway wicking (twill)

Fig.2.3.weftway wicking (satin) Fig:-2:- weft way wicking effect 3.2 Absorbency Absorbency of fabric is mainly depend on the fabric structure,type of yarn structure,surface tension of water.The absorbency value of plain,twill and satin weaves for various interaction is shown in Figure 3 and 4.The fabric woven with intraction of

www.fibre2fashion.com

warp polyester and weft polyester with twill weave shows higher value of absorbency.The fabric woven with same interactions but with different interlacement order (satin & plain) exibits lower absorbency value.The sample with high absorbency value requires maximum time to absorb the water particle from the surface.This may due to warp float percentage is high than the weft floats with hydrophilic yarn.The satin weave sample with cotton warp & weft interaction shown lower absorbency value among all the samples.The satin weave shows lower absorbency value with all interactions.The reasons for this is percentage of cotton and majority of hydrophilic yarn exposed on fabric.

Fig. 3. Effect of interaction on absorbency

www.fibre2fashion.com

Fig.4. Effect of weaves on absobency 3.3 Air permeability The average results of air permeability measurements of woven fabrics are given in Table IV and Figure 5. Table: IV weave Sample no A12 Plain A10 A11 A9 A8 twill A2 A7 A1 A4 satin A6 A3 A5 Air permeability (cm3/cm2/sec) 14.04 11.12 14.19 9.10 15.37 14.55 22.08 13.74 18.67 19.03 24.94 12.02

www.fibre2fashion.com

Fig.5 Effect of interaction on air permeability

Fig.6 Effect of weave on air permeability The fabrics woven with warp polyester & weft cotton with Satin weave shows higher air permeability value followed by fabrics of polyester by polyester, cotton by cotton, cotton by polyester interactions figure 6.The fabric woven with warp cotton and weft polyester with plain weave shows lower air permeability values followed by fabrics of polyester by

www.fibre2fashion.com

polyester, polyester by cotton, polyester by polyester interactions. This is particularly so because polyester yarn having more wraps/cm, less hairiness, and more space available in fabric structure which means that they offer less resistance to air. The woven fabric with c x p exhibits high air resistance in all weaves because of cotton yarns having more hairs, less tendency to slip in structure, compact yarn structure.

Conclusion:-

The fabrics woven with warp polyester & weft cotton with Satin weave shows higher air permeability value followed by fabrics of polyester by polyester, cotton by cotton, cotton by polyester interactions figure 6.The fabric woven with warp cotton and weft polyester with plain weave shows lower air permeability values followed by fabrics of polyester by polyester, polyester by cotton, polyester by polyester interactions. This is particularly so because polyester yarn having more wraps/cm, less hairiness, and more space available in fabric structure which means that they offer less resistance to air. The woven fabric with c x p exhibits high air resistance in all weaves because of cotton yarns having more hairs, less tendency to slip in structure, compact yarn structure.

References :1) A.das and s. m ishetqua , comfort charchetrstics of fabric containing twistless and hollow fibre in weft,JTATM,volume 3,issu 4,winter 2004. 2) A Das,A jain,study on the liquid flow behavior of cotton wick, fibers & polymer 2008,vol 9,no 2,176-186 3) K.V.P Singh and A. Das, Study on physiological comfort comfort of fabrics made up of structurally modified friction spun yarns: part I- vapour transmission, IJFTR, vol 35,March 2010, pp. 31-37. 4) B.K.V.P Singh and A. Das, Study on physiological comfort comfort of fabrics made up of structurally modified friction spun yarns: part II - Liquid transmission, IJFTR ,vol 35 , June 2010 ,pp. 134-138. 5) G.K.Taygi, G.Krishana, P.Kumar, Comfort aspects of finished polyester cotton and polyester viscose ring and MJS yarn fabrics, IJFTR, vol 34, June 2009, pp.137-143.

www.fibre2fashion.com

6) T. Ramchandran ,Thermal behavior of ring and compact spun yarns single jersey ,rib and interlock knitted fabrics by, IJFTR ,vol 35, Sept 2010 ,pp 250-257.

Image Courtsey: 1. ptfegraphite.com 2. nma.gov.au

Valsang R.K. and

Patil L.G. are profesor at D.K.T.E.S. Textile &

Engineering Institute, Ichalkaranji, India

You might also like

- Messrs: National Denim LimitedDocument5 pagesMessrs: National Denim LimitedKomol KabirNo ratings yet

- Messrs: National Denim LimitedDocument5 pagesMessrs: National Denim LimitedKomol KabirNo ratings yet

- Latest Commonly Used ConstructionsDocument1 pageLatest Commonly Used ConstructionsKomol KabirNo ratings yet

- Acostingofwovenfabrics 150317095839 Conversion Gate01Document105 pagesAcostingofwovenfabrics 150317095839 Conversion Gate01Komol KabirNo ratings yet

- TEST BABT NEW Production & Log Report March-2017Document416 pagesTEST BABT NEW Production & Log Report March-2017Komol KabirNo ratings yet

- Noman Local Party Costing For Solid Dyed 1Document4 pagesNoman Local Party Costing For Solid Dyed 1Komol KabirNo ratings yet

- TEST BABT NEW Production & Log Report March-2017Document416 pagesTEST BABT NEW Production & Log Report March-2017Komol KabirNo ratings yet

- Sizing Chemicals InformationsDocument19 pagesSizing Chemicals InformationsKomol KabirNo ratings yet

- Swiss Textile Machinery Export StrengthDocument20 pagesSwiss Textile Machinery Export StrengthKomol KabirNo ratings yet

- Costing of Woven FabricsDocument38 pagesCosting of Woven Fabricsbfaabgctub67% (6)

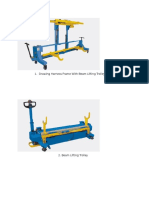

- Drawing Harness Frame With Beam Lifting TrolleyDocument3 pagesDrawing Harness Frame With Beam Lifting TrolleyKomol KabirNo ratings yet

- BABT TrolleyDocument3 pagesBABT TrolleyKomol KabirNo ratings yet

- Costing of Woven FabricsDocument38 pagesCosting of Woven Fabricsbfaabgctub67% (6)

- Babt Manpower Update March-2017Document1 pageBabt Manpower Update March-2017Komol KabirNo ratings yet

- Name of Supplier, Buyers& CompetitorDocument1 pageName of Supplier, Buyers& CompetitorKomol KabirNo ratings yet

- WIS Inventory January 2017 (Shed - 02)Document8 pagesWIS Inventory January 2017 (Shed - 02)Komol KabirNo ratings yet

- NOMAN COMPOSITE TEXTILE LTD Weft Yarn Lot Tracking DocumentDocument34 pagesNOMAN COMPOSITE TEXTILE LTD Weft Yarn Lot Tracking DocumentKomol KabirNo ratings yet

- Blacks & Blues Textile TrolleyDocument1 pageBlacks & Blues Textile TrolleyKomol KabirNo ratings yet

- Blank Excel File For Bulk Upload NewDocument134 pagesBlank Excel File For Bulk Upload NewKomol KabirNo ratings yet

- Sizing MachineDocument21 pagesSizing MachineKomol Kabir100% (2)

- SFPDocument89 pagesSFPKomol Kabir100% (1)

- Double Weave Workshop NotesDocument6 pagesDouble Weave Workshop NotesKomol KabirNo ratings yet

- Sizing MachineDocument21 pagesSizing MachineKomol Kabir100% (2)

- Size LubrificationDocument12 pagesSize LubrificationfernandolimaNo ratings yet

- Knitting CalculationsDocument14 pagesKnitting CalculationsAzhar Ali67% (3)

- What Is MerchandizingDocument2 pagesWhat Is MerchandizingKomol KabirNo ratings yet

- Presentation On The Monthly Production ReportDocument17 pagesPresentation On The Monthly Production ReportKomol Kabir100% (1)

- Grey Departmen & Weaving FinishingtDocument60 pagesGrey Departmen & Weaving FinishingtKomol KabirNo ratings yet

- 1 Complete Weaving MillDocument6 pages1 Complete Weaving MillKomol KabirNo ratings yet

- Costing of WeavingDocument1 pageCosting of WeavingSadah LokNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Deleted Portion Physics - 042 Class XiDocument3 pagesDeleted Portion Physics - 042 Class XiRounak SahaNo ratings yet

- Activity 3 Hardy Magsino BHTTEQDocument21 pagesActivity 3 Hardy Magsino BHTTEQrc cortezNo ratings yet

- Physics exam specifications tableDocument5 pagesPhysics exam specifications tableShekaina Faith Cuizon LozadaNo ratings yet

- Steel DesignDocument62 pagesSteel DesignDexter DoteNo ratings yet

- Electronics Activity 4Document5 pagesElectronics Activity 4Christian AlbosNo ratings yet

- Primary and Secondary TreatmentDocument8 pagesPrimary and Secondary TreatmentJohn Rhey Almojallas BenedictoNo ratings yet

- 01 - Solar Photovoltaic - SolutionsDocument12 pages01 - Solar Photovoltaic - SolutionsPhaniNo ratings yet

- Hierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeDocument17 pagesHierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeSyed Anas HussaniNo ratings yet

- BQ 25713Document90 pagesBQ 25713Ngọc Hưng TạNo ratings yet

- Technical Specification 11 KV Indoor Switchgear SCADA Controlled PDFDocument59 pagesTechnical Specification 11 KV Indoor Switchgear SCADA Controlled PDFIMRAN TUMANGGORNo ratings yet

- Euler’s disc finite-time singularity theoryDocument6 pagesEuler’s disc finite-time singularity theoryTanmay MathurNo ratings yet

- STUDY ABOUT 641-212 AIRFOIL PROPERTIES - Fillipe OliveiraDocument15 pagesSTUDY ABOUT 641-212 AIRFOIL PROPERTIES - Fillipe OliveiraFillipe OliveiraNo ratings yet

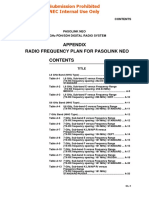

- Radio Frequency Plan for NEC Pasolink NEO Digital Radio SystemDocument90 pagesRadio Frequency Plan for NEC Pasolink NEO Digital Radio Systemlibo gomezNo ratings yet

- To Find Current Flowing Through Load Resistor by Using Thevenin's TheoremDocument1 pageTo Find Current Flowing Through Load Resistor by Using Thevenin's TheoremmohsinsafiNo ratings yet

- STD 11 Consolidated Test 1 Units & Errors, Straight Line Motion 1 and 2, NLM1 and VectorsDocument31 pagesSTD 11 Consolidated Test 1 Units & Errors, Straight Line Motion 1 and 2, NLM1 and VectorsRAVI ANANTHAKRISHNANNo ratings yet

- Design and Assembly of 100KVA Transformer: A Practicum Report OnDocument53 pagesDesign and Assembly of 100KVA Transformer: A Practicum Report Ondip bormanNo ratings yet

- Strain Gauges: Mark ColtonDocument15 pagesStrain Gauges: Mark ColtonGATE FACULTYNo ratings yet

- Multiple Choice Questionnaire: Phiếu Đề Thi Trắc NghiệmDocument2 pagesMultiple Choice Questionnaire: Phiếu Đề Thi Trắc NghiệmTrung SơnNo ratings yet

- Ionic and Covalent BondDocument27 pagesIonic and Covalent Bondsharina NNo ratings yet

- 50156637-B-Thermo Scientific Sorvall Legend XF - XFR-EnDocument57 pages50156637-B-Thermo Scientific Sorvall Legend XF - XFR-EnManuel Alejandro Navarro SalgadoNo ratings yet

- Garde 11 Stem General Chemistry Module PrelimDocument51 pagesGarde 11 Stem General Chemistry Module PrelimYza S.No ratings yet

- Wbjee2021 Physics Chemistry Answer KeyDocument1 pageWbjee2021 Physics Chemistry Answer KeyShahriar Rijman asifNo ratings yet

- S1, S2 - S3 - S4 - MergedDocument4 pagesS1, S2 - S3 - S4 - Mergedselvakumar sNo ratings yet

- (Asce) 0733 9445 (1990) 116:10 (2671) PDFDocument20 pages(Asce) 0733 9445 (1990) 116:10 (2671) PDFS LNo ratings yet

- Civil & Civil (Rural) Eng. 3rd SemDocument23 pagesCivil & Civil (Rural) Eng. 3rd SemArman RajNo ratings yet

- Bioplasm NLS User ManualDocument136 pagesBioplasm NLS User ManualSun100% (1)

- AC Sharp AH-A9UCYDocument2 pagesAC Sharp AH-A9UCYBee NETNo ratings yet

- Electromagnetic FormingDocument7 pagesElectromagnetic Formingrushikesh huleNo ratings yet

- Schematic Diagram: Model: MZ-1246MG FCC Id: Bejx1241XgDocument2 pagesSchematic Diagram: Model: MZ-1246MG FCC Id: Bejx1241XgJacky NplNo ratings yet

- RTN Lighting OnOff Module 2-Gang - Product SpecificationDocument4 pagesRTN Lighting OnOff Module 2-Gang - Product SpecificationAditya Wahyu PerdanaNo ratings yet