Professional Documents

Culture Documents

MS17825H

Uploaded by

Mark Evan SalutinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS17825H

Uploaded by

Mark Evan SalutinCopyright:

Available Formats

Downloaded from http://www.everyspec.com on 2010-05-18T17:37:49.

INCH-POUND

MS17825H

5 February 2004

SUPERSEDING

MS17825G

30 November 1988

MS SPECIFICATION SHEET

NUT, SELF-LOCKING, CASTELLATED, HEXAGON, .250F

NON-METTALIC INSERT

Reactivate after 5 February 2004 and may be used for new

and existing designs and acquisitions.

This specification is approved for use by all

Department and Agencies of the Department of Defense.

The requirements for acquiring the product described herein shall consist of this MS specification sheet and

NASM25027.

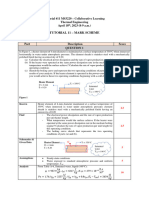

OPPOSITE SLOTS MUST COINCIDE WITHIN

.005 AND SLOT AXIS MUST BE WITHIN

.005 OF THREAD P.D. AXIS

MARK MFG IDENT.

ON THIS SURFACE

K

SHAPE OF TOP

OPTIONAL

R

B

L

A

J

30 5

WASHER FACE, CHAMFER OR RADIUS RELIEF

OPTIONAL WHEN WITHIN THE 30 5

ANGLE AND "M" DIA LIMITATIONS

TABLE I. NUT DIMENSIONS AND STRENGTHS

SIZE

DASH

THREAD

NO.

AS8879

-3

.1900-32 UNJF-3B

-4

.2500-28 UNJF-3B

-5

.3125-24 UNJF-3B

-6

.3750-24 UNJF-3B

-7

.4375-20 UNJF-3B

-8

.5000-20 UNJF-3B

-9

.5625-18 UNJF-3B

-10

.6250-18 UNJF-3B

-12

.7500-16 UNJF-3B

-14

.8750-14 UNJF-3B

-16

1.0000-12 UNJF-3B

-18

1.1250-12 UNJF-3B

-20

1.2500-12 UNJF-3B

AMSC N/A

A

MAX MIN

.265 .235

.296 .266

.343 .313

.421 .391

.468 .438

.578 .548

.624 .594

.734 .704

.828 .798

.921 .891

1.015 .985

1.171 1.141

1.265 1.235

B

MAX

.376

.439

.502

.564

.690

.752

.877

.940

1.064

1.252

1.440

1.627

1.815

MIN

.367

.430

.492

.553

.679

.741

.865

.928

1.052

1.239

1.427

1.614

1.801

MIN

.410

.482

.552

.622

.766

.837

.978

1.051

1.191

1.403

1.615

1.825

2.038

MAX

.215

.275

.338

.400

.463

.525

.587

.650

.795

.900

1.025

1.150

1.275

MAX

.032

.036

.042

MIN

.006

.007

.008

.050

.010

.055

.012

.063

.072

.014

.016

.083

.018

FSC 5310

MAX

.125

.141

.188

.235

.282

.375

.406

.484

.578

.672

.766

.828

.891

MIN

.105

.121

.168

.215

.262

.355

.386

.464

.558

.652

.746

.808

.871

Downloaded from http://www.everyspec.com on 2010-05-18T17:37:49.

MS17825H

TABLE I. (CONTD)

SIZE

DASH

NO.

MAX

-3

-4

-5

-6

-7

-8

-9

-10

-12

-14

-16

-18

-20

MIN

.108

.078

.155

.125

.187

.157

MIN

.110

.125

.172

.218

.265

.359

.390

.468

.562

.656

.750

.844

.938

MAX

.376

.439

.502

.564

.690

.752

.877

.940

1.064

1.252

1.440

1.627

1.815

MIN

.355

.418

.480

.543

.675

.737

.862

.925

1.049

1.237

1.425

1.612

1.800

ULTIMATE

TENSILE

STRENGTH

LB MIN

MAX

.035

.053

.062

1,950

3,500

5,500

9,000

12,200

16,600

21,200

27,400

40,000

54,600

71,000

92,600

118,500

TEST

WRENCHING

TORQUE

(INCH LBS)

MIN

35

80

225

325

575

900

1,100

1,600

2,800

4,600

6,800

10,000

14,000

ASSEMBLY

TORQUE

VIBRATION

(IN. LBS)

MAX

28

65

180

260

460

720

880

1,300

2,200

3,700

5,400

8,000

11,000

WEIGHT

LB/100

MAX

.400

.650

1.000

1.400

2.000

3.900

6.900

11.400

16.900

26.000

38.000

53.500

74.500

REQUIREMENTS:

MATERIALS: Steel, UNS G11370 (AISI 1137) per AMS5024

UNS G11374 (AISI 11L37) per AMS5020

UNS G41300 (AISI 4130) per AMS6348

UNS G87400 (AISI 8740) per AMS6322, 6323, 6325, 6327, and 6358.

INSERT MATERIAL: Nylon.

FINISH: Cadmium plating in accordance with SAE-AMS-QQ-P-416, Type II, Class 2.

Break all sharp edges and remove burrs.

SURFACE TEXTURE: 125 in accordance with ASME B46.1.

DIMENSIONS: All dimensions are in inches unless otherwise specified.

DESIGN INFORMATION: These nuts may be used at temperatures 250 F and below in those types of applications for

which slotted or castellated nuts are approved for use, and if such applications conflict with

any limitation on the use of self-locking nuts, as cited by NASM33588, this standard takes

precedence. Nuts are to be installed in accordance with NASM33540.

EXAMPLE OF PART NUMBER: MS17825-4 = .2500-28 nut, cadmium plated, non-metallic insert.

PERFORMANCE: Per NASM25027 except for:

1 Tabulated ultimate tensile strength values.

2 Vibration per NASM1312-7, (30,000 cycles) using assembly torques listed in Table I for one seated

cycle.

3 Locking torque valves applicable for one cycle at room temperature only.

Certain provisions (limits for across flat dimension) of this standard are the subject of International Standardization ABC

STD 17/2. When revision or cancellation of this standard is proposed which will affect or violate the international agreement

concerned. The preparing activity will take appropriate reconciliation action through international standardization channels,

including departmental standardization officer, if required.

For design feature purposes, this standard takes precedence over procurement documents referenced herein. Referenced

documents shall be of the issue in effect on date of invitations for bids, or request for proposal.

Changes from previous issue. Marginal notations are not used in this revision to identify changes with respect to the previous

issue due to the extent of the changes.

Custodians:

Navy AS

Air Force 99

Preparing Activity

DLA-IS

(Project 5310- 2710)

You might also like

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- Wing in Ground Effect Craft Review ADA361836Document88 pagesWing in Ground Effect Craft Review ADA361836Mark Evan SalutinNo ratings yet

- Permatex Form A GasketDocument3 pagesPermatex Form A GasketMark Evan SalutinNo ratings yet

- Aluminum in AircraftDocument117 pagesAluminum in AircraftMark Evan Salutin91% (11)

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurNo ratings yet

- Petroleum JellyDocument6 pagesPetroleum JellyMark Evan SalutinNo ratings yet

- Agard 406351 Ground Effect MachinesDocument169 pagesAgard 406351 Ground Effect MachinesMark Evan SalutinNo ratings yet

- Poly FIber BR-8600 Blush RetarderDocument2 pagesPoly FIber BR-8600 Blush RetarderMark Evan SalutinNo ratings yet

- Poly Fiber Poly-TakDocument2 pagesPoly Fiber Poly-TakMark Evan SalutinNo ratings yet

- Poly Fiber Reducer R65-75Document2 pagesPoly Fiber Reducer R65-75Mark Evan SalutinNo ratings yet

- PolyFLex Evercoat.Document7 pagesPolyFLex Evercoat.Mark Evan SalutinNo ratings yet

- Simple GreenDocument4 pagesSimple GreenMark Evan SalutinNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument10 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinNo ratings yet

- Poly-Spray MSDS Paint CoatingsDocument2 pagesPoly-Spray MSDS Paint CoatingsMark Evan SalutinNo ratings yet

- Superior Graphite Tube o LubeDocument3 pagesSuperior Graphite Tube o LubeMark Evan SalutinNo ratings yet

- Rundolph Spray VarnishDocument7 pagesRundolph Spray VarnishMark Evan SalutinNo ratings yet

- Poly-Spray MSDS Paint CoatingsDocument2 pagesPoly-Spray MSDS Paint CoatingsMark Evan SalutinNo ratings yet

- Power CleanDocument2 pagesPower CleanMark Evan SalutinNo ratings yet

- Sting-X II, Aerosol Certified LabsDocument4 pagesSting-X II, Aerosol Certified LabsMark Evan SalutinNo ratings yet

- Sonnen Honing OilDocument5 pagesSonnen Honing OilMark Evan SalutinNo ratings yet

- Spotcheck Reg Cleaner Remover SKC-HFDocument3 pagesSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinNo ratings yet

- Sulfuric Acid Electrolyte 5-05Document5 pagesSulfuric Acid Electrolyte 5-05Mark Evan SalutinNo ratings yet

- Soldering Flux PasteDocument9 pagesSoldering Flux PasteMark Evan SalutinNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Small Volume Prover Manual 005 To 025Document136 pagesSmall Volume Prover Manual 005 To 025anafadoNo ratings yet

- Jot Brochure 2021-22Document60 pagesJot Brochure 2021-22Darshan MakwanaNo ratings yet

- UDOT Seismic Design Manual SectionDocument82 pagesUDOT Seismic Design Manual Sectionyoungc71No ratings yet

- Tico S PDFDocument4 pagesTico S PDFjittshong8072No ratings yet

- Asme B18.2.1 PDFDocument37 pagesAsme B18.2.1 PDFJUAN C100% (1)

- Cooling Methods of A Transformer: For Dry Type Transformers For Oil Immersed TranformersDocument2 pagesCooling Methods of A Transformer: For Dry Type Transformers For Oil Immersed TranformerskashifNo ratings yet

- System ConfigurationDocument64 pagesSystem ConfigurationMuhamad Sayid Akil MhsAkilNo ratings yet

- Models - Mbd.washing Machine Vibration PDFDocument36 pagesModels - Mbd.washing Machine Vibration PDFgf-antaresNo ratings yet

- Week 2 - Physical Science Q2Document2 pagesWeek 2 - Physical Science Q2Gemma Quiocho-CardenasNo ratings yet

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Document6 pagesTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsNo ratings yet

- (20200922) Theo Doi AW RFQ 1-5Document29 pages(20200922) Theo Doi AW RFQ 1-5Tuấn PhạmNo ratings yet

- 1014 BKTNG ME SP 0017 - Rev0 Specification For EDG PackageDocument1 page1014 BKTNG ME SP 0017 - Rev0 Specification For EDG Packagesondk2No ratings yet

- Bladedesign CalcDocument55 pagesBladedesign CalcMeiring PretoriusNo ratings yet

- Tarea 4Document13 pagesTarea 4Isidro MedranoNo ratings yet

- 40mm StepperDocument1 page40mm StepperRAFAEL DA COSTA BONOTTONo ratings yet

- 2-Vle Part 2Document22 pages2-Vle Part 2Arfa Zulkifli01No ratings yet

- Guide to Optimizing Low Load Operation of Mitsui-MAN B&W EnginesDocument7 pagesGuide to Optimizing Low Load Operation of Mitsui-MAN B&W EnginesLagon AinNo ratings yet

- Hdpe Pipe Price List 2017Document2 pagesHdpe Pipe Price List 2017sukiraj100% (2)

- ME 188 - Combined Brayton & Rankine CyclesDocument44 pagesME 188 - Combined Brayton & Rankine CyclesAzherRoiFerrerNo ratings yet

- 05 2013 1072 Sredanovic 04 PDFDocument7 pages05 2013 1072 Sredanovic 04 PDFOcta RioNo ratings yet

- Steady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Document24 pagesSteady Heat Transfer AND Thermal Resistance Networks: Dr. Şaziye Balku 1Pankaj KumarNo ratings yet

- ARTICLE - Destructive Testing Basics (2012)Document4 pagesARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNo ratings yet

- CST Solutions for Carel Standard ApplicationsDocument4 pagesCST Solutions for Carel Standard Applicationselshan_asgarovNo ratings yet

- Pin MillingDocument16 pagesPin MillingBhavik NagdaNo ratings yet

- GATE 2007 CHEMICAL ENGINEERING EXAM REVIEWDocument23 pagesGATE 2007 CHEMICAL ENGINEERING EXAM REVIEWVammsy Manikanta SaiNo ratings yet

- Ag machineryDocument4 pagesAg machineryvinzyyNo ratings yet

- C5 Gearbox Design AnalysisDocument151 pagesC5 Gearbox Design AnalysisaakashtrivediNo ratings yet

- Finite Element Method: Mechanical Engineering DepartmentDocument27 pagesFinite Element Method: Mechanical Engineering DepartmentmNo ratings yet

- Heat Load-KitchenDocument1 pageHeat Load-Kitchenrinko447459No ratings yet

- WishboneDocument14 pagesWishboneSapana Kudake SK0% (1)