Professional Documents

Culture Documents

TVS 800 Series Cast Iron Trap Valve Station: Reduced Costs

Uploaded by

Gustavo Garces GuerreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TVS 800 Series Cast Iron Trap Valve Station: Reduced Costs

Uploaded by

Gustavo Garces GuerreroCopyright:

Available Formats

TVS 800 Series Cast Iron Trap Valve Station

Steam Trapping and Steam Tracing Equipment

Put the principle of the inverted bucket to work in a tough cast iron package and you have the best of both worldsenergy efficiency and long-lasting reliability. Add the advantages of valves integrated into one compact trap/valve casting, and you extend the benefits into installation, trap testing and maintenance. All the components are concentrated in a single, accessible package and can be dealt with in-line. And if you have existing Armstrong cast iron traps in-line, identical face-to-face dimensions will make retrofitting with the patented* Armstrong Trap Valve Station (TVS) a snap. Youll also reduce your inventory requirements. So youll eliminate what youre paying just to keep parts on hand.

Integral isolation valves

Rugged cast iron package

Reduced costs

TVS saves on these fronts: energy, installationand maintenance.

Integration of trap and valves

Inverted bucket long life and energy efficiency, plus the savings and convenience of components merged into one space-saving package.

A full range of options

TVS will accommodate a test valve, strainer, internal check valve, thermic vent bucket, TrapAlert and SteamEyeremote steam trapmonitoring system for steam traps.

Easy, in-line repairability Elimination of potential leak points Reduced design time

Permits combining products with exact face-to-face dimensions.

Energy-efficient inverted bucket steam trap

Optional integral strainer

*U.S. Patent 5,947,145

138

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

TVS 800 Series Cast Iron Trap Valve Station

Steam Trapping and Steam Tracing Equipment

TVS makes a long storyshort.

Typical Installation Trap Valve Station

Inverted bucket trap with two isolation valves

Inverted bucket trap with two isolation valves and strainer

Inverted bucket trap with two isolation valves, strainer and check valve

The Innovation Is Integration

The Armstrong TVS makes what used to be long, complicated steam installation stories simple and compact. It shortens installations by integrating componentsspecifically an inverted bucket steam trap with two or more valves. For example, heres an old description for a typical installation: valve-nipple-strainer-nipple-trap-nipple-valve. Its a long tale, even for this simple piping arrangement. The Trap Valve Station rewrites this steam story: pipe-TVS-pipe. In other words, the TVS makes itall one, delivering the functions of multiple components in a dramatically smaller unit. It integrates two high-value products inapackage of revolutionary versatility. Look above to see how the Armstrong cast iron Trap Valve Station has rewritten these typical steam installations.

Average Service Life for Different Trap Types 200 psi (14 bar)

0 1 2 3 4 5 6 7 Years

Thermodynamic disc Float and thermostatic Inverted bucket Balanced pressure thermostatic Bimetallic thermostatic

Above data from ICI Engineer January 1993 special issue with permission from ICI Engineering.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

139

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

TVS 800 Series Trap Valve Station

For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr)

Cast Iron for Horizontal Installation, With Integral Piston Valves

Steam Trapping and Steam Tracing Equipment

A F B D B E C 30 F

Model TVS 811

Series TVS 812/813

Series TVS 811/812/813 - Top View

Same principle. Different package. Now the energy-saving performance andreliability of the inverted bucket steam trap are available in a versatile new package. Youll still enjoy all the familiar benefits. And the same efficient condensate drainage from virtually every kind of steam-using equipment. But what youllfind new are all the benefits of a piston valve integrated into the same space-saving package.

Options

Stainless steel internal check valve Thermic vent bucket Stainless steel pop drain Integral strainer Scrub wire Probe connection Blowdown valve (TVS 811 and TVS 812 only)

Maximum Operating Conditions

Maximum allowable pressure (vessel design): Maximum operating pressure: 250 psig @ 450F (17 bar @ 232C) 250 psig (17 bar)

Specification

Connections Materials

Inverted bucket steam trap, type ... in cast iron, with continuous air venting atsteam temperature, free-floating stainless steel mechanism, and discharge orifice at the top of the trap. Integral upstream and downstream shutoff piston style valves in same dimensional space as standard bucket trap.

Screwed NPT and BSPT

How to Order

ASTM A48 Class 30 All stainless steel304 Hardened chrome steel17-4PH Ductile iron Stainless steel Graphite and stainless steel Stainless steel

Cap and body: Internals: Valve and seat: Handwheel: Internals: Valve sealing rings: Blowdown valve

Specify: Model number Size and type of pipe connection Maximum working pressure that will be encountered or orifice size Any options required For a fully detailed certified drawing, refer to: TVS 811 CD #1099 TVS 812/813 CD #1100

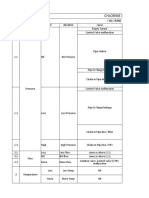

TVS 800 Series Trap Valve Station Model No. Pipe Connections Test Plug A Width Across Handwheels B Outlet Valve Open C Face to Face D Connection C L to Bottom E F Number of Bolts Weight lb (kg)

TVS 811 in mm 1/2, 3/4 15, 20 1/4 6 8-1/4 210 10-1/4 260 5 127 3-11/16 94 7-5/8 194 3 76 6 6 12 (5.4)

TVS 812 in mm 1/2, 3/4 15, 20 1/2 15 13-3/4 349 11-3/4 298 6-1/2 165 4-3/4 121 13 330 4-1/2 114 6 6 25 (11.3)

TVS 813 in mm 3/4, 1 20, 25 3/4 20 15-1/8 384 14-1/4 362 7-3/4 197 7-1/4 184 14-3/8 365 4-7/8 124 6 6 47 (24)

140

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

211/811/881/21-DC/81-DC/TVS-81DC TVS 800 Series Trap Valve Station

For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) Model TVS 811 Capacity

Cast Iron for Horizontal Installation, With Integral Piston Valves

212/812/882/22;82TVS-82

Steam Trapping and Steam Tracing Equipment

Model TVS 812 Capacity

Series 213/813/883/23;83;TVS-83DC

Model TVS 813 Capacity

Options

Internal Check Valves are spring-loaded stainless steel and screw directly into the trap inlet or into an extended inlet tube having a pipe coupling at the top to save fittings, labor and money. Thermic Vent Buckets have a bimetal controlled auxiliary air vent for discharging large amounts of air on start-up. Integral Strainer is made from 20 x 20 stainless steel screen. Probe Connections are available for trapmonitoring. Blowdown Valve for clearing strainers ofdirt and debris. Integral Strainer

Thermic Air Vent in Bucket Internal CheckValve

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

141

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

Next

You might also like

- Amprobe MANUAL Megometro Amb-5kvd PDFDocument32 pagesAmprobe MANUAL Megometro Amb-5kvd PDFSamuel ValleNo ratings yet

- Basic Steam Engineering GuidelinesDocument30 pagesBasic Steam Engineering GuidelinesGustavo Garces GuerreroNo ratings yet

- Manual Lavadora FrigidaireDocument28 pagesManual Lavadora FrigidaireGustavo Garces Guerrero0% (1)

- GB ElectricalDocument54 pagesGB ElectricalGustavo Garces GuerreroNo ratings yet

- Sero7 LT Us S en ManDocument66 pagesSero7 LT Us S en ManGustavo Garces GuerreroNo ratings yet

- CS Series Float & Thermostatic Steam TrapsDocument2 pagesCS Series Float & Thermostatic Steam TrapsGustavo Garces GuerreroNo ratings yet

- Manual Lavadora FrigidaireDocument28 pagesManual Lavadora FrigidaireGustavo Garces Guerrero0% (1)

- Steam15 BenchmarkDocument2 pagesSteam15 BenchmarkGustavo Garces GuerreroNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3KC ATSE Automatic Transfer Switching Equipment: End-To-End Safety For User and SystemsDocument2 pages3KC ATSE Automatic Transfer Switching Equipment: End-To-End Safety For User and SystemssalahNo ratings yet

- SERIES: Parts ManualDocument30 pagesSERIES: Parts ManualДенис ЧерныйNo ratings yet

- Generators Acapp 2nd1718 4Document19 pagesGenerators Acapp 2nd1718 4Anonymous uCjM4Q0% (2)

- Delhi Directory 2022 EvDocument30 pagesDelhi Directory 2022 EvVipul Khandelwal100% (1)

- Renovation cost analysis for Pocket Bell HouseDocument1 pageRenovation cost analysis for Pocket Bell HouseRayley Daven SusiNo ratings yet

- Skid-Steer Loader: Left Side Standard Instrument PanelDocument2 pagesSkid-Steer Loader: Left Side Standard Instrument PanelMario AguirreNo ratings yet

- Electronic Projects: 18W Audio AmplifierDocument2 pagesElectronic Projects: 18W Audio AmplifierLaurentiu DraganNo ratings yet

- Vec 104 KDocument17 pagesVec 104 Kyu3za0% (1)

- GS 5390 - Parts ManualDocument278 pagesGS 5390 - Parts Manualgermain.floresNo ratings yet

- Radio News 1938 01 RDocument68 pagesRadio News 1938 01 RRoberto Vitor100% (1)

- CVS Controls Sample Heater July 09Document2 pagesCVS Controls Sample Heater July 09alexmontellNo ratings yet

- FS-l6S: Instruction ManualDocument25 pagesFS-l6S: Instruction ManualFazrulNo ratings yet

- Danfoss FC102 Parameter RegistersDocument89 pagesDanfoss FC102 Parameter RegistersErwin SusantoNo ratings yet

- Elmasonic - S Manual Support.Document67 pagesElmasonic - S Manual Support.Mustafa SariNo ratings yet

- Compact Conductor CalculationDocument3 pagesCompact Conductor CalculationGautama Chandra PradiptaNo ratings yet

- Harmony Easy Xa2 Xa2evm4lcDocument5 pagesHarmony Easy Xa2 Xa2evm4lcBNCHNo ratings yet

- 025 Daily Lorry Crane Inspection ChecklistDocument1 page025 Daily Lorry Crane Inspection Checklisthaslinda Abdul SahakNo ratings yet

- EPB With Preload: Ep B 20 05 - 6 QZ RR G0 +650L C3Document2 pagesEPB With Preload: Ep B 20 05 - 6 QZ RR G0 +650L C3Radinal Fernandez SimanjuntakNo ratings yet

- JTM RDocument129 pagesJTM Rwira subrataNo ratings yet

- Senarai Kod Barang Stor Baru Tahun 2019Document6 pagesSenarai Kod Barang Stor Baru Tahun 2019Syikin SharifNo ratings yet

- tl431 PDFDocument81 pagestl431 PDFAngga JuliantaraNo ratings yet

- Disassembly & Reassembly PDFDocument7 pagesDisassembly & Reassembly PDFKiris SantacruzNo ratings yet

- AIS-008-Installation of Lighting and SignallingDocument80 pagesAIS-008-Installation of Lighting and SignallingElam Paruthi MNo ratings yet

- Worm & Worm GearsDocument23 pagesWorm & Worm GearsHopedejene DejeneNo ratings yet

- Install Gabion GuideDocument2 pagesInstall Gabion Guidesgm6911No ratings yet

- 2001 FORD: Texas BuyerDocument3 pages2001 FORD: Texas Buyerjunior50% (2)

- HSFG Bolt PDFDocument6 pagesHSFG Bolt PDFSatish PawarNo ratings yet

- Rec Alphα Series 380 wp 20 year 25 Year Power product warranty power output warranty α recgroup.com/alphaDocument2 pagesRec Alphα Series 380 wp 20 year 25 Year Power product warranty power output warranty α recgroup.com/alphaASHLESHNo ratings yet

- Chlorine Dosing System: Chlorine Tonner To PRVDocument4 pagesChlorine Dosing System: Chlorine Tonner To PRVN KannanNo ratings yet

- Vision™ OPLC™: General DescriptionDocument13 pagesVision™ OPLC™: General DescriptionDenson Prima UtamaNo ratings yet