Professional Documents

Culture Documents

Nuts and Washers Details

Uploaded by

fastenersworld0 ratings0% found this document useful (0 votes)

75 views0 pagesnut and washer details

Original Title

Nuts and Washers details

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentnut and washer details

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views0 pagesNuts and Washers Details

Uploaded by

fastenersworldnut and washer details

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

The primary function of the nut in any threaded assembly is to

act as the instrument through which the tension is induced into

the bolt or screw and to continue to retain that tension and

thus, the clamp load in the assembly.

The vast majority of nuts have hexagon drive faces but they

come with a large variety of other features for a secondary pur-

pose such as thread locking, face seating/location, load spread-

ing, pinning, welding, capping.

Materials include carbon steels, stainless steels, brass, alumini-

um, nylon.

Correct strength combinations of nuts and bolts will ensure that

the nut is capable of tensioning the mating bolt to breaking

point rather than the nut stripping, (a broken bolt is clearly evi-

dent, a stripped nut may not be). To ensure correct combina-

tions, always use bolt and nut products with the same proof

load designations.

Products purchased as a bolt and nut combination will be sup-

plied with the correct nut by the manufacturer.

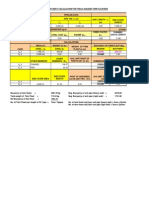

Plain Hexagon

Nut

Hexagon Flange

Serrated Lock Nut

(Whiz Lock)

Hexagon Domed

or Cap Nut

Coupling Nuts

(Joining)

The standard form general purpose nut may be used with vari-

ous washers.

Also available in a thin or lock nut version. (JAM)

Normally supplied double chamfered if cold formed.

May also come with full bearing or washer face when

machined.

Special serrations on the flange face resist loosening in vibration

applications.

Also available as a plain flange to span a large hole or slot or

spread the clamp load.

Either machined with a closed domed end or capped in a sec-

ondary process after tapping.

Used in decorative applications or for protection from protrud-

ing threads.

A plain hexagon nut with increased overall height, giving longer

thread engagement.

Used for connecting lengths of allthread.

Technical Information JAM BUILDING PRODUCTS

Washers come in a wide variety of designs and within those

individual designs are a range of materials, dimensional varia-

tions and finishes. Many can be used either under the head of

the fastener, bolt or screw, or under the nut. Many can be

encapsulated as an assembly on a screw or bolt or occasionally

with a nut. Most washer sizes will be designated by the diame-

ter (size) of the fastener with which they are to be used.

Basic washers are employed to :

- spread the clamp load over a larger surface area

- cover an oversize or elongated hole

- reduce the friction of the rotated component

- protect the work piece surface from damage by the rotated

component

- provide a locking or vibration resistant function

Specialist washers have been designed to perform particular

functions in particular types of applications. These may be lock-

ing, load spreading, decorative, tension indicating, sealing, or a

combination of these functions.

8-4

Sketch Title Comments

Nuts

Washers

PERFECT.HK - Creativity in Fastening

JAM BUILDING PRODUCTS Technical Information

Flat

Spring

Belleville Washer

(Conical)

Internal Tooth

Lock Washer

External Tooth

Lock Washer

Screw Cup (Cup)

Neoprene (Neo)

Structural

Hardened

Load Indicating

Washer

Common general purpose basic washer can come in various

dimensional standards, quality levels, materials, hardness grades

and finishes.

Could also be available square.

Often used in conjunction with a spring washer.

Common locking washer will come in a variety of thicknesses

and sectional ratios.

Available in various materials throughout a wide size range.

Used to resist vibration loosening.

Will damage surface in contact.

For use in high vibration applications where tension must be

maintained if some loosening occurs.

Can be used in stacks or series to increase the axial load or to

increase the possible deflection length.

Used with pan or cheese head machine screws to resist vibra-

tion.

Minimal damage to surface.

Same as above except slightly more damaging to surface.

Also available in countersunk version.

Used under a countersunk screw where a decorative or appeal-

ing finish is required. e.g. Automotive door trims.

Normally would be nickel or chrome plated, or in stainless

steel.

A rubber type material used in roofing screw applications under

washer head screws with sealing washer recess. Designed to cre-

ate a waterproof seal between the screw and sheeting material.

Can also be bonded to aluminium or stainless washers.

A hardened steel washer used in conjunction with structural

bolts in heavy construction applications. The washer reduces

galling between the tightened surfaces and spreads the load.

The three external tabs identify it as structural washer.

Used in the structural industry to provide evidence that the

required tension has been achieved. The raised protrusions will

crush in relation to the load applied, providing a permanent wit-

ness that required tension was achieved.

8-5

Sketch Title Comments

PERFECT.HK - Creativity in Fastening

You might also like

- 3.2 Design of Welded JointsDocument41 pages3.2 Design of Welded Jointsssn MLNo ratings yet

- Flexible Screw ConveyorDocument3 pagesFlexible Screw ConveyorjohandbdNo ratings yet

- Basics of A ScaffoldDocument8 pagesBasics of A ScaffoldAhmed IsahNo ratings yet

- Piping FabricationDocument3 pagesPiping FabricationNa100% (2)

- Manufacturing Processes Lab WeldingDocument8 pagesManufacturing Processes Lab WeldingKhalid EwigNo ratings yet

- Mechanicl EngineeringDocument981 pagesMechanicl EngineeringBobby WaltersNo ratings yet

- Butterfly Valve PrincipleDocument2 pagesButterfly Valve PrincipleDevendra Bangar100% (1)

- Field Service Manual: Title: Tightening Torque For Cap ScrewsDocument3 pagesField Service Manual: Title: Tightening Torque For Cap ScrewsPuchit Spk100% (1)

- Febolt: Hexagon Covernut Type "Febolt"Document1 pageFebolt: Hexagon Covernut Type "Febolt"Tuntun TatNo ratings yet

- Bending Test.Document21 pagesBending Test.julio padronNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- Pipes FittingsDocument7 pagesPipes FittingsTushar ArekarNo ratings yet

- Welded Connection Weld DesignDocument12 pagesWelded Connection Weld Designlram70No ratings yet

- CHAPTER Four: Torque Transmitting Joints: Keys, Spline Joints Pin Joints Interference FitDocument33 pagesCHAPTER Four: Torque Transmitting Joints: Keys, Spline Joints Pin Joints Interference Fitkibromgidey12No ratings yet

- Gland Packing For Centrifugal PumpsDocument4 pagesGland Packing For Centrifugal Pumpsnoelaroboi100% (1)

- Single V WeldDocument4 pagesSingle V WeldkoyahassanNo ratings yet

- 4DMechanical VesselDocument26 pages4DMechanical VesselBowo Edhi WibowoNo ratings yet

- Impacts Tests (Astm E23) : Impact Test Is Performed To Study The Behavior of MaterialsDocument7 pagesImpacts Tests (Astm E23) : Impact Test Is Performed To Study The Behavior of Materialsjayhuacat7743No ratings yet

- Shaft Components and Design FactorsDocument25 pagesShaft Components and Design FactorsHüseyinYılmazNo ratings yet

- Filletweld 1Document4 pagesFilletweld 1Prakash RajNo ratings yet

- Spring TestingDocument4 pagesSpring Testingunam123No ratings yet

- Through Conduit Gate Valves Slab & ExpandingDocument7 pagesThrough Conduit Gate Valves Slab & ExpandingRockny310No ratings yet

- Rubber in ShearDocument18 pagesRubber in ShearHassan BhinderNo ratings yet

- Maximum Shear Stress Theory-DerivationDocument21 pagesMaximum Shear Stress Theory-DerivationMaria Elisa Lara50% (2)

- Hardness Test SubmitDocument8 pagesHardness Test Submitonkod1No ratings yet

- American Standard Steel Pipe Sizes and Wall ThicknessesDocument3 pagesAmerican Standard Steel Pipe Sizes and Wall ThicknessesFelipa ShanNo ratings yet

- Load Calculation of ShedDocument5 pagesLoad Calculation of ShedvaideehNo ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- JMT Welding Positioner CatalogDocument8 pagesJMT Welding Positioner Catalogazeez basha100% (1)

- Torsion LabDocument22 pagesTorsion LabNeoXana01No ratings yet

- Torsion of Circular ShaftsDocument26 pagesTorsion of Circular ShaftsNaveen Kumar0% (1)

- Gas Injection Well X-Mas Tree OnshoreDocument1 pageGas Injection Well X-Mas Tree OnshoreHosseinNo ratings yet

- Mechanical Strengthening of Al Alloys Under Cold ForgingDocument19 pagesMechanical Strengthening of Al Alloys Under Cold ForgingSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- Study & Analysis of Transportation SkidDocument10 pagesStudy & Analysis of Transportation SkidJay PNo ratings yet

- Neral Notes On Engineering Hardware - FastenersDocument45 pagesNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- Press Working Operations - Sheet MetalDocument16 pagesPress Working Operations - Sheet MetalIrwan Rony100% (2)

- Friction in PipesDocument15 pagesFriction in PipesShivesh SohawanNo ratings yet

- SC Screw Conveyor Torque PDFDocument3 pagesSC Screw Conveyor Torque PDFQuality Tech AccessoriesNo ratings yet

- Unit 4steamturbine 160705174835Document48 pagesUnit 4steamturbine 160705174835Ruby ShajiNo ratings yet

- Texsteam-Ñ Bomba QuímicaDocument8 pagesTexsteam-Ñ Bomba QuímicarivomarNo ratings yet

- Is 12735 Wire Rope SlingsDocument14 pagesIs 12735 Wire Rope SlingsMD ParthiNo ratings yet

- Flange DimensionsDocument30 pagesFlange DimensionshibhavuNo ratings yet

- Shop Fabrication Inspection: 1 Material Receiving Inspection ReportDocument7 pagesShop Fabrication Inspection: 1 Material Receiving Inspection ReportManoj PrabakaranNo ratings yet

- Torsion of A Spiral SpringDocument5 pagesTorsion of A Spiral Springawe_em100% (2)

- Shaft Design On Strength BasisDocument2 pagesShaft Design On Strength Basisparthajit11No ratings yet

- Dissimilar Metal Weldability Concepts Alber SadekDocument45 pagesDissimilar Metal Weldability Concepts Alber SadekMohammad AliNo ratings yet

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 pagesCalculation Sheet For 700mm SQ Metal FloatersAdagharaNo ratings yet

- Bolt Torque ValuesDocument1 pageBolt Torque ValuesFrancois-No ratings yet

- 31 1 Static Equipment Vertical ErectionDocument2 pages31 1 Static Equipment Vertical Erectionpunitg_2No ratings yet

- Drilling MC ManualDocument3 pagesDrilling MC ManualKS Rajawat100% (1)

- Anchor Force CalculationsDocument40 pagesAnchor Force CalculationsImmanuel SNo ratings yet

- Labyrinth WeirsDocument223 pagesLabyrinth WeirsMaria PanagouNo ratings yet

- Maximum Bolt Torque For FlangesDocument1 pageMaximum Bolt Torque For FlangesmohdNo ratings yet

- Finite Element Analysis - Pressure Vessel and PipeDocument2 pagesFinite Element Analysis - Pressure Vessel and PipevamcodongNo ratings yet

- Experiment Name: Study and Operation of Bench Drilling MachineDocument13 pagesExperiment Name: Study and Operation of Bench Drilling MachineHashim Al-mahdliNo ratings yet

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 pagesTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenNo ratings yet

- Fitter ToolsDocument7 pagesFitter ToolsSainadhReddy100% (1)

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- DIN 934 Metric Hex Nuts SpecificationDocument1 pageDIN 934 Metric Hex Nuts SpecificationfastenersworldNo ratings yet

- Din 933-87 PDFDocument9 pagesDin 933-87 PDFEdson.Serejo100% (4)

- Logistic GoalDocument1 pageLogistic GoalfastenersworldNo ratings yet

- 2315155054Document2 pages2315155054fastenersworldNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotofastenersworldNo ratings yet

- Iso TS 16949 2009Document30 pagesIso TS 16949 2009AndroidFlaghipNo ratings yet

- Di Gi Tal Si Gnature Certi Fi Cate Subscri Pti On FormDocument3 pagesDi Gi Tal Si Gnature Certi Fi Cate Subscri Pti On FormfastenersworldNo ratings yet

- Time TAbleDocument3 pagesTime TAblefastenersworldNo ratings yet

- Hardened Flat Washers for Industrial ApplicationsDocument1 pageHardened Flat Washers for Industrial Applicationsbabis1980No ratings yet

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroNo ratings yet

- 16 - 1 - 1 - Health Advt. 2015Document10 pages16 - 1 - 1 - Health Advt. 2015Manu KhodNo ratings yet

- viewNitPdf 1136048Document2 pagesviewNitPdf 1136048fastenersworldNo ratings yet

- VacanciesDocument6 pagesVacanciesfastenersworldNo ratings yet

- Automotive CompaniesDocument12 pagesAutomotive CompaniesfastenersworldNo ratings yet

- Trivalent Chromates FAQDocument3 pagesTrivalent Chromates FAQfastenersworldNo ratings yet

- List of Companies PDFDocument106 pagesList of Companies PDFfastenersworldNo ratings yet

- Abacus: Mystery of The BeadDocument37 pagesAbacus: Mystery of The BeadUsama AlsoofiNo ratings yet

- Guide to HSFG bolts for Indian railway bridgesDocument16 pagesGuide to HSFG bolts for Indian railway bridgesUpaliFernando100% (1)

- Bolt Flange Selection Guide for Metric SizesDocument1 pageBolt Flange Selection Guide for Metric Sizesfastenersworld100% (1)

- Fasteners StandardsDocument98 pagesFasteners StandardsRahul Betgeri100% (4)

- 1 4 1 Application FormDocument1 page1 4 1 Application FormfastenersworldNo ratings yet

- Astm A182Document2 pagesAstm A182fastenersworldNo ratings yet

- 1 3 1 Fees-challan-FormDocument1 page1 3 1 Fees-challan-FormfastenersworldNo ratings yet

- Chemical Comp PDFDocument1 pageChemical Comp PDFfastenersworldNo ratings yet

- Bolt HangarDocument1 pageBolt HangarfastenersworldNo ratings yet

- PronounciationDocument4 pagesPronounciationfastenersworldNo ratings yet

- Cr6 Geomat DetailsDocument27 pagesCr6 Geomat DetailsfastenersworldNo ratings yet

- Tpi Whitworth BSW BSFDocument2 pagesTpi Whitworth BSW BSFfastenersworldNo ratings yet

- DecarbDocument2 pagesDecarbfastenersworldNo ratings yet

- Bolt Grade Cross RefDocument3 pagesBolt Grade Cross Refsamnm1971No ratings yet

- Cathodic Disbondment TestingDocument2 pagesCathodic Disbondment Testingravi00098No ratings yet

- Summary of Specifications: 1.1 Schedule of Exterior FinishesDocument2 pagesSummary of Specifications: 1.1 Schedule of Exterior FinishesanaNo ratings yet

- Saic M 1035Document4 pagesSaic M 1035noor mohamedazeezNo ratings yet

- Dialnet UsoDeTablaPsicrometricaEnLaIndustriaDeLaMadera 5123335Document1 pageDialnet UsoDeTablaPsicrometricaEnLaIndustriaDeLaMadera 5123335neymarronNo ratings yet

- Aqua Shield 4Document2 pagesAqua Shield 4aneeshp_4No ratings yet

- Mitsu Turning Tools Insert GuideDocument110 pagesMitsu Turning Tools Insert GuideJeka MazurovskyNo ratings yet

- Plinth Area Rate 2011 12Document14 pagesPlinth Area Rate 2011 12sankum0100% (2)

- TYPICAL ROAD SECTION-ModelDocument1 pageTYPICAL ROAD SECTION-ModelEmmanuel Simangon AgudaNo ratings yet

- Selection and Application of Piping System Materials: Standard Practice ForDocument23 pagesSelection and Application of Piping System Materials: Standard Practice ForRoberto Omar Morante VillarrealNo ratings yet

- WIweld01 Co2 Welding Rev 01Document1 pageWIweld01 Co2 Welding Rev 01Gautam KumarNo ratings yet

- 23.1 Insulation of PipingDocument21 pages23.1 Insulation of PipingSaid SalemNo ratings yet

- 12 - Sheet Metalworking (Chapter 16)Document51 pages12 - Sheet Metalworking (Chapter 16)Taher al suhamiNo ratings yet

- KnaufDocument2 pagesKnaufknudsenDenmarkNo ratings yet

- Aashto M 55 03 PDFDocument5 pagesAashto M 55 03 PDFCristian RubioNo ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- List of Items and Corresponding Test For QCPDocument4 pagesList of Items and Corresponding Test For QCPSheila Marie Menes OmegaNo ratings yet

- Atlac 430 - 010389Document2 pagesAtlac 430 - 010389Mounir ZerroukNo ratings yet

- DR - Fixit Pidicrete - CF BRLDocument1 pageDR - Fixit Pidicrete - CF BRLnickdash09No ratings yet

- Concrete Cost Calculator: DepreciationDocument11 pagesConcrete Cost Calculator: Depreciationmarlynrich3652No ratings yet

- Collins Weldability Corrosion 316L ReportDocument11 pagesCollins Weldability Corrosion 316L ReportamanNo ratings yet

- Understanding the Difference Between Alkali-Activated Materials and GeopolymersDocument10 pagesUnderstanding the Difference Between Alkali-Activated Materials and GeopolymersManuel AlejandroNo ratings yet

- Dupont™ Tyvek® Building Envelope Emea Standard Offering 2017Document32 pagesDupont™ Tyvek® Building Envelope Emea Standard Offering 2017Geraldine GacitúaNo ratings yet

- Life Safety Systems in Buildings PDFDocument25 pagesLife Safety Systems in Buildings PDFAlthea PeralesNo ratings yet

- Cement Fineness Test (ASTM C 184 - 94)Document4 pagesCement Fineness Test (ASTM C 184 - 94)Hazem Diab33% (3)

- Why Matters in Concrete: ChemistryDocument6 pagesWhy Matters in Concrete: Chemistryjulianc08No ratings yet

- BUTTING Pipeline Systems For The Pneumatic ConveyingDocument16 pagesBUTTING Pipeline Systems For The Pneumatic ConveyingAleksandar KosticNo ratings yet

- Selection of Welding Electrodes PDFDocument1 pageSelection of Welding Electrodes PDFAnonymous VohpMtUSNNo ratings yet

- Installation Procedure for TowersDocument4 pagesInstallation Procedure for TowersRachel FloresNo ratings yet

- Typical General Arrangement of A BuildingDocument1 pageTypical General Arrangement of A BuildingSamitha SoysaNo ratings yet

- Cmaa CM01 2019Document32 pagesCmaa CM01 2019Moren AlfonsoNo ratings yet