Professional Documents

Culture Documents

1 Speed Control PDF

Uploaded by

Jisha KuruvillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Speed Control PDF

Uploaded by

Jisha KuruvillaCopyright:

Available Formats

International Journal of Reconfigurable and Embedded Systems (IJRES) Vol. 1, No. 2, July 2012, pp.

43~48 ISSN: 2089-4864

43

FPGA Based a PWM Technique for Permanent Magnet AC Motor Drives

Tole Sutikno1, Nik Rumzi Nik Idris2, Nuryono Satya Widodo1, Auzani Jidin3

Departement of Electrical Engineering, Universitas Ahmad Dahlan (UAD), Indonesia Department of Energy Conversion, Universiti Teknologi Malaysia (UTM), Malaysia 3 Departement of Power Electronics and Drives, Universiti Teknikal Malaysia Melaka (UTeM), Malaysia

2 1

Article Info Article history: Received Apr 5, 2012 Revised June 15, 2012 Accepted June 21, 2012 Keyword: BLDC Commutation state machine FPGA Permanent magnet AC motor PWM

ABSTRACT

The permanent magnet AC motor trapezoidal (BLDC motor) is not strictly DC motor, which uses a pulsed DC fed to the stator field windings to create a rotating magnetic field. Therefore, the motor needs an electronic commutation to provide the rotating field. A pair of switches must be turned on sequentially in the correct order to energize a pair of windings. If the incorrect order is applied, then the BLDC motor will not operate properly. This paper presents a smart guideline to ensure that the order to energize a pair of windings is correct. To prove the guideline, FPGA based a simple commutation state machine scheme to control BLDC motor is presented. The experiment results have shown that the guideline was correct. The commutation scheme was successfully realized using Altera's APEX20KE FPGA to control BLDC motor in both of forward/reverse rotations or forward/reverse regenerative braking properly.

Copyright 2012 Institute of Advanced Engineering and Science. All rights reserved.

Corresponding Author: Tole Sutikno, Department of Electrical Engineering, Universitas Ahmad Dahlan, Jln. Prof. Soepomo, Janturan, Yogyakarta, Indonesia 55164 Email: tole@ee.uad.ac.id

INTRODUCTION Brushless DC (BLDC) motor is defined as a permanent magnet synchronous motor with a trapezoidal back electromagnetic fields (EMF) waveform shape. The BLDC motor combines the positive attributes of AC and DC systems. The term BLDC is used to identify the combination of AC motor, inverter and rotor position sensor to offer a linear torque characteristic as in a conventional DC motor in a drive system. BLDC drive does not require a precision rotor position sensor and only requires discrete position sensors, such as Hall Effect sensor. As a result, BLDC motors are now replacing traditional brushed DC motors due to higher reliability, efficiency, and lower noise, and their usage in new applications continues to grow [1-3]. In BLDC motors, the conventional multi-segment commutators as a mechanical rectifier are replaced with an electronic circuit to do the commutation. The electronic commutation in brushless drives eliminates need for brushes in the motor, and therefore all associated maintenance. Accordingly, a BLDC motor requires less maintenance, relatively low cost and is quite robust [1, 4-5]. However, a BLDC requires relatively complex electronics for control. In this control scheme, torque production follows the principle that current should flow in only two of the three phase at a time and that there should be no torque production in the region of back EMF zero crossings. Knowledge of rotor position is critical to correctly energize the windings to sustain motion. Therefore, a pair of switches must be turned on sequentially in the correct order to energize a pair of windings. The BLDC motor will not operate properly Journal homepage: http://iaesjournal.com/online/index.php/IJRES

1.

44

ISSN: 2089-4864

if the incorrect switch order is applied [1, 4-5]. This paper presents a smart guideline to ensure that the order to energize a pair of windings is correct. The rationalization of the commutation sequence in both of forward or reverse rotations, and also in both of forward or reverse regenerative braking mode will be introduced clearly. To prove the guideline, a simple commutation state machine scheme to control BLDC motor in both of forward/reverse rotations or forward/reverse regenerative braking mode based on FPGA is conducted.

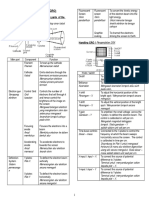

COMMUTATION STATE MACHINE To ensure that the BLDC motor will operate properly, a smart guideline to realize the commutation sequence in both of forward or reverse rotations /regenerative braking mode is very important. In order to get constant output torque, current is driven through a motor winding during the flat portion of the back-EMF waveform. Thus, only two switches are turned on at a time, one in a high side and the other in a low side. Figure 1 show the both correct and incorrect commutation state machine. Sensor and drive bits by phase order in both of forward/reverse rotations or forward/reverse regenerative braking are shown in Table 1 and Table 2, respectively

2.

a. correct commutation state

b. incorrect commutation state

Fig.1. Hall effect sensor, gating signal of inverter, phase current and back EMF

IJRES Vol. 1, No. 2, July 2012 : 43 48

IJECE

ISSN: 2088-8708 Table 1. Sensor And Drive Bits By Phase Order In Both Of Forward And Reverse Rotations

45

Hall Hall Hall effect effect effect sensor sensor sensor phase A B C 0 0 1 1 0 1 1 2 0 1 0 3 1 1 0 4 1 0 0 5 1 0 1 6

A high drive 1 1 0 0 0 0

Forward rotation A B B low high low drive drive drive 0 0 0 0 0 1 0 0 1 1 0 0 1 1 0 0 1 0

C high drive 0 0 1 1 0 0

Reverse rotation C A A B B C C low phase high low high low high low drive drive drive drive drive drive drive 1 0 1 0 0 1 0 6 0 0 1 1 0 0 0 5 0 0 0 1 0 0 1 4 0 1 0 0 0 0 1 3 0 1 0 0 1 0 0 2 1 0 0 0 1 1 0 1

Table 2. Sensor and drive bits by phase order in both of forward and reverse regenerative braking

Hall Hall Hall effect effect effect sensor sensor sensor phase A B C 0 0 1 1 0 1 1 2 0 1 0 3 1 1 0 4 1 0 0 5 1 0 1 6 Forward regenerative braking A A B B C high low high low high drive drive drive drive drive 0 0 0 0 0 0 0 0 1 0 0 0 0 1 0 0 1 0 0 0 0 1 0 0 0 0 0 0 0 0 Reverse regenerative braking C A A B B C C low phase high low high low high low drive drive drive drive drive drive drive 1 0 1 0 0 0 0 6 0 0 1 0 0 0 0 5 0 0 0 0 0 0 1 4 0 0 0 0 0 0 1 3 0 0 0 0 1 0 0 2 1 0 0 0 1 0 0 1

EXPERIMENT SETUP In this paper, a simple digital three-phase Pulse Width Modulation (PWM) controller for a BLDC motor has been proposed, as shown Figure 2. In this system, the BLDC motor is treated as a digital system. Speed regulation is achieved by varying PWM duty cycle. However, the state machine commutation is heart of the system, and the PWM generator only to make varying of duty cycle. The three-phase PWM technique is conducted to reduce the commutation current ripple. The motor drive system use hall-effect sensors which track the motor's position, for changing the PWM method to threephase one. The experiment setup is shown as Figure 3.

3.

Fig. 2. Simple PWM BLDC Motor Control Based On Commutation State Machine

FPGA Based a PWM Technique for Permanent Magnet AC Motor Drives (First Author)

46

ISSN: 2089-4864

APEX20K Altera FPGA Gate Drivers Three-phase Inverter

BLDC motor with gearbox

Fig. 3. Experiment setup

RESULTS AND DISCUSSIONS In the research, the simple control of BLDC motor based on commutation state machine utilizing FPGA was successfully developed. The current and back-EMF results of six-step BLDC motor drive based on FPGA are shown in Figure 4. The Figure 4 (a) is six-step BLDC motor drive in forward rotation, and it is shown in Figure 4 (b) for reverse rotation. To improve the performance and to adjustable speed drive, the PWM is implemented in this system. The current and back-EMF of the proposed method is shown in Figure 5. From Figure 5, it can be seen that the PWM has successfully be implemented. Figure 5 (a), it has shown for forward rotation and Figure 5 (b) for reverse rotation. The switching frequency of inverter is at 20 kHz.

4.

a. forward rotation

b. reverse rotation

Fig. 4. Current and Back-EMF of Six-step BLDC Motor Control Based On Commutation State Machine

IJRES Vol. 1, No. 2, July 2012 : 43 48

IJECE

ISSN: 2088-8708

47

a. forward rotation

b. reverse rotation

Fig. 5. Current and Back-EMF of the Proposed PWM BLDC Motor Control Based On Commutation State Machine

However, the PWM method proposed still has a problem to significantly reduce the commutation current ripple because the research not yet considers the commutation period to generate PWM signal. From Figure 5, it still can be see that the current ripple is very dominant in commutation period. To overcome the problem, the basic idea is to retain the same magnitude of current slew rate with opposite sign for the incoming and outgoing phases. The idea can be achieved by controlling the duty during commutation. Obviously, the detection circuits are needed to indicate the commutation period [6-7].

CONCLUSION This paper has presented a smart guideline to ensure that the order to energize a pair of windings is correct. To prove the guideline, FPGA based a simple commutation state machine scheme to control BLDC motor has been successfully type-tested. The experiment results have shown that the guideline was correct. The commutation schemes have successfully realized to control BLDC motor using Altera's APEX20KE FPGA in both of forward/reverse rotations or forward/reverse regenerative braking properly.

5.

ACKNOWLEDGEMENTS The authors would like to thank the Ministry of Higher Education (MOHE) of the Malaysian government and Universiti Teknologi Malaysia (UTM) under Grant VOT 78584 for providing the funding for this research.

REFERENCES

[1] T. Hemanand and T. Rajesh, "Speed control of brushless DC motor drive employing hard chopping PWM technique using DSP," in Power Electronics, 2006. IICPE 2006. India International Conference on, 2006, pp. 393-396. [2] L. Yong, et al., "Direct torque control of brushless DC drives with reduced torque ripple," Industry Applications, IEEE Transactions on, vol. 41, pp. 599-608, 2005. [3] I. Kim, et al., "Compensation of torque ripple in high performance BLDC motor drives," Control Engineering Practice, vol. 18, pp. 1166-1172, 2010. [4] J. Cody, et al., "Regenerative Braking in An Electric Vehicle," Zeszyty Problemowe Maszyny Elektryczne, vol. 81, pp. 113-118, 2009. [5] A. Sathyan, et al., "An FPGA-Based Novel Digital PWM Control Scheme for BLDC Motor Drives," Industrial Electronics, IEEE Transactions on, vol. 56, pp. 3040-3049, 2009. [6] K. Dae-Kyong, et al., "Commutation Torque Ripple Reduction in a Position Sensorless Brushless DC Motor Drive," Power Electronics, IEEE Transactions on, vol. 21, pp. 1762-1768, 2006. [7] Y. Lin and Y. Lai, "Pulse-width Modulation Technique for BLDCM Drives to Reduce Commutation Torque Ripple without Calculation of Commutation Time," Industry Applications, IEEE Transactions on, vol. PP, pp. 1-1, 2011.

FPGA Based a PWM Technique for Permanent Magnet AC Motor Drives (First Author)

48 BIOGRAPHY OF AUTHORS

ISSN: 2089-4864

Tole Sutikno received his B.Eng. and M.Eng. degree in Electrical Engineering from Diponegoro University, Indonesia and Gadjah Mada University, Indonesia, in 1999 and 2004, respectively. Since 2001 he has been a lecturer in Electrical Engineering Department, Universitas Ahmad Dahlan (UAD), Indonesia. Currently, he is pursuing PhD degree at the Universiti Teknologi Malaysia (UTM), Malaysia. His research interests include the field of power electronics, motor drive systems and FPGA applications.

Nik Rumzi Nik Idris received the B.Eng. degree in Electrical Engineering from the University of Wollongong, Australia, the M.Sc. degree in power electronics from Bradford University, West Yorkshire, U.K., and the Ph.D. degree from Universiti Teknologi Malaysia (UTM) in 1989, 1993, and 2000, respectively. He is an Associate Professor at the Universiti Teknologi Malaysia, and an Administrative Committee Member of the Industry Applications Societies/Power Electronics/Industrial Electronics Joint Chapter of IEEE Malaysia Section. His research interests include ac drive systems and DSP applications in power electronic systems.

Nuryono Satya Widodo received his B.Eng. and M.Eng. degree in Electrical Engineering from Gadjah Mada University, Indonesia, in 2001 and 2010, respectively. Since 2001 he has been a lecturer in Electrical Engineering Department, Universitas Ahmad Dahlan (UAD), Indonesia. His research interests include Robotics, Microcontroller application and the field of power electronics.

Auzani Jidin received his B.Eng. degree, M.Eng. and PhD degree in Power Electronics & Drives from Universiti Teknologi Malaysia (UTM), Malaysia in 2002, 2004 and 2011, respectively. He is a lecturer in Department of Power Electronics and Drives, Faculty of Electrical Engineering at Universiti Teknikal Melaka Malaysia (UTeM), Malaysia. His research interests include the field of power electronics, motor drive systems, FPGA and DSP applications.

IJRES Vol. 1, No. 2, July 2012 : 43 48

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- RC2 Series Screw Compressor Maintenance ManualDocument161 pagesRC2 Series Screw Compressor Maintenance ManualMichele CassiniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Basic Metatrader 5 GuideDocument22 pagesBasic Metatrader 5 GuideDavid Al100% (1)

- Presented by Ajish V C (Ce) Sudheer Padikkal (Ce) Rajesh Menon B (Me)Document21 pagesPresented by Ajish V C (Ce) Sudheer Padikkal (Ce) Rajesh Menon B (Me)Jisha KuruvillaNo ratings yet

- Ms-Mech-10, Ms Fabrication of PipingDocument13 pagesMs-Mech-10, Ms Fabrication of PipingBabar Manzoor GhauriNo ratings yet

- Ussocom 006Document52 pagesUssocom 006RTSLLCNo ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- C W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasDocument8 pagesC W Rystalline Aterproofing: (An 9001: 2015, 14001: 2015 & 18001: 2007 Certified Company) ISO ISO OhsasgangadevimgmNo ratings yet

- Boiler FormulasDocument5 pagesBoiler FormulasAnonymous 6Mb7PZjNo ratings yet

- Costiuc Silvia - Culas in Oltenia - CNHC 2011Document25 pagesCostiuc Silvia - Culas in Oltenia - CNHC 2011trancalina100% (1)

- Tusker On Weighbridge Press MatterDocument1 pageTusker On Weighbridge Press MatterJisha KuruvillaNo ratings yet

- Practice Exam 1Document5 pagesPractice Exam 1Jisha KuruvillaNo ratings yet

- II ModuleDocument51 pagesII ModuleJisha KuruvillaNo ratings yet

- Practice Exam 1Document5 pagesPractice Exam 1Jisha KuruvillaNo ratings yet

- Ray Diagrams and Mirror EquationsDocument6 pagesRay Diagrams and Mirror EquationsJisha KuruvillaNo ratings yet

- Linear System Analysis Course Performance AnalysisDocument1 pageLinear System Analysis Course Performance AnalysisJisha KuruvillaNo ratings yet

- Physics Chapter on Image Formation in Spherical MirrorsDocument25 pagesPhysics Chapter on Image Formation in Spherical MirrorsJisha KuruvillaNo ratings yet

- Electric Drives: Drive BasicsDocument5 pagesElectric Drives: Drive BasicsJisha KuruvillaNo ratings yet

- DATA ANALYSIS AND PROCESSING TECHNIQUESDocument44 pagesDATA ANALYSIS AND PROCESSING TECHNIQUESJisha KuruvillaNo ratings yet

- Hypothesis Generation and Formulation of The ProblemDocument55 pagesHypothesis Generation and Formulation of The ProblemJisha KuruvillaNo ratings yet

- Linear System Analysis Course Performance AnalysisDocument1 pageLinear System Analysis Course Performance AnalysisJisha KuruvillaNo ratings yet

- Dorfch1 PDFDocument36 pagesDorfch1 PDFA6427531100% (1)

- 14 ResearchDocument43 pages14 ResearchJisha KuruvillaNo ratings yet

- Experimental Research Design GuideDocument52 pagesExperimental Research Design GuideJisha KuruvillaNo ratings yet

- Introduction To MATLAB: ES 156 Signals and Systems 2007 Harvard SEASDocument26 pagesIntroduction To MATLAB: ES 156 Signals and Systems 2007 Harvard SEASKareena GuptaNo ratings yet

- Effects of Poles and Zeros On Performance of Control SystemsDocument18 pagesEffects of Poles and Zeros On Performance of Control SystemsMuriz AdemovićNo ratings yet

- Measurement and Scaling: Group No: 16Document35 pagesMeasurement and Scaling: Group No: 16Jisha KuruvillaNo ratings yet

- Earlier in Lesson 3: Mirror Equation Magnification EquationDocument6 pagesEarlier in Lesson 3: Mirror Equation Magnification EquationJisha KuruvillaNo ratings yet

- Group 18Document63 pagesGroup 18Jisha KuruvillaNo ratings yet

- Data Collection Procedures Errors and ValidationDocument19 pagesData Collection Procedures Errors and ValidationJisha KuruvillaNo ratings yet

- Synchronous MachinesDocument24 pagesSynchronous MachinesJones Bk EssumanNo ratings yet

- Master Sathyan Sabin 2013 PDFDocument56 pagesMaster Sathyan Sabin 2013 PDFJisha KuruvillaNo ratings yet

- F9 PDFDocument112 pagesF9 PDFqwertyNo ratings yet

- Synchronous MachinesDocument24 pagesSynchronous MachinesJones Bk EssumanNo ratings yet

- Synchronous Reluctance MotorDocument10 pagesSynchronous Reluctance MotorJisha KuruvillaNo ratings yet

- PHY 142! Lenses and Mirrors ExplainedDocument7 pagesPHY 142! Lenses and Mirrors ExplainedRyan Busante Dela CruzNo ratings yet

- Synchronous MachinesDocument24 pagesSynchronous MachinesJones Bk EssumanNo ratings yet

- Synchronous MachinesDocument9 pagesSynchronous MachinesJisha KuruvillaNo ratings yet

- Master Sathyan Sabin 2013 PDFDocument56 pagesMaster Sathyan Sabin 2013 PDFJisha KuruvillaNo ratings yet

- Drum Unloading SystemDocument2 pagesDrum Unloading SystemJas SumNo ratings yet

- SPECIFICATION WRITING MODULEDocument3 pagesSPECIFICATION WRITING MODULEHana YeppeodaNo ratings yet

- Aceros PoscoDocument35 pagesAceros PoscoregistrosegNo ratings yet

- Net Positive Suction HeadDocument4 pagesNet Positive Suction Headjorge alarconNo ratings yet

- JCL LC SLIDES01 FP2005 Ver1.0Document51 pagesJCL LC SLIDES01 FP2005 Ver1.0api-27095622100% (2)

- As3000 Service Manual PDFDocument180 pagesAs3000 Service Manual PDFsambadeeNo ratings yet

- Tobaco VaccDocument19 pagesTobaco VaccSisay KebebeNo ratings yet

- INA FAG Water Pump BearingsDocument31 pagesINA FAG Water Pump Bearings2bjornNo ratings yet

- MPTO Charts566662Document25 pagesMPTO Charts566662andres ortizNo ratings yet

- QSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualDocument86 pagesQSEE6800+H Signal Monitor Video and Thumbnail Streamer: Installation and Operation ManualTechne PhobosNo ratings yet

- How Objects Are Discovered and Monitored in Operations ManagerDocument2 pagesHow Objects Are Discovered and Monitored in Operations ManagerAkhilesh NandanwarNo ratings yet

- ITU Rec. BT.709-5 Defines Parameters for HDTV StandardsDocument31 pagesITU Rec. BT.709-5 Defines Parameters for HDTV StandardsHarold Coila VillenaNo ratings yet

- My ResumeDocument4 pagesMy ResumeYasok AyobNo ratings yet

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNo ratings yet

- Killexams HPE0 S46 Real Exam Questions Answers PDFDocument6 pagesKillexams HPE0 S46 Real Exam Questions Answers PDFopen_666No ratings yet

- Cathode Ray Oscilloscope (Cro)Document2 pagesCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comNo ratings yet

- Silent Sound TechnologyDocument22 pagesSilent Sound TechnologyPurnima K100% (2)

- Indigo GdpiDocument1 pageIndigo Gdpimanoj agrawallaNo ratings yet

- OpenDSS Level 1 TrainingDocument85 pagesOpenDSS Level 1 Trainingraul_bsu100% (1)

- PNG382 FT en 11Document2 pagesPNG382 FT en 11Misu1983No ratings yet