Professional Documents

Culture Documents

Fatigue-Crack Growth in Inconel 718

Uploaded by

Khin Aung ShweCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fatigue-Crack Growth in Inconel 718

Uploaded by

Khin Aung ShweCopyright:

Available Formats

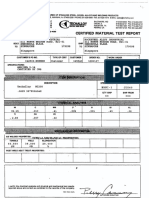

Fatigue-Crack G r o w t h in Inconel 718 Weldments at Elevated Temperatures

A "modified" vs. "conventional" postweld heat treatment results in lower crack growth rates and higher toughness that are thought to be associated with a more complete dissolution of the "brittle" Laves phase which forms during welding

BY L A. JAMES

ABSTRACT. The techniques of linearelastic fracture mechanics were used to characterize the fatigue-crack growth behavior of Inconel 718 gas tungsten arc (GTA) weldments over the temperature range 24-649 C (75-1200 F). Two different postweld heat treatments were employed: the " c o n v e n t i o n a l " (ASTM A637) treatment, and a " m o d i f i e d " heat treatment designed to eliminate the brittle Laves phase that forms during the welding process. Weldment specimens given the modified postweld heat treatment consistently exhibited superior fatigue-crack growth behavior relative to conventionally-treated weldments. In addition, weldment specimens treated by either process exhibited higher crack growth rates than plate specimens similarly heat treated. Introduction Inconel* 718 is a precipitation-hardenable nickel-base alloy that is utilized extensively where high strength and corrosion resistance are required at elevated temperatures. For these reasons, the alloy is employed in some nuclear reactor structural components, particularly where strength, swelling behavior, and creep resistance are important. Such structural components are often subjected to cyclic loadings in service, and hence the potential exists for subcritical extension of cracks or crack-like flaws during service. *lnconel is a registered trademark of the International Nickel Company.

The techniques of linear-elastic fracture mechanics are particularly useful for estimating in-service crack extension, 1 and considerable progress has been made in characterizing the effect of various parameters upon the crack growth behavior of structural alloys. The present paper addresses the fatigue-crack growth behavior of Inconel 718 base metal and weldments at several temperatures, and w i t h t w o different postweld heat treatments. Experimental Procedure Several heats of material were utilized in this study and are desigL. A. IAMES is a Fellow Engineer, Westinghouse Hanford Company, Richland, Washington.

nated as heats A-F in Table 1. The chemical compositions of these heats are given in Table 2. Two different heat treatments were employed: the " c o n ventional" heat treatment, 2 and the " m o d i f i e d " heat treatment developed at the Idaho National Engineering Laboratory (INEL). 3 The heat treatments were as follows: 1. " C o n v e n t i o n a l " - a n n e a l e d at 954 C (1750 F), and air-cooled to room temperature. Aged 8 h at 718 C (1325 F), furnace-cooled to 621 C (1150 F) and held at 621 C (1150 F) for a total aging time of 18 h, and air-cooled to room temperature. 2. " M o d i f i e d " - s o l u t i o n - a n n e a l e d 1 h at 1093 C (2000 F), cooled to 718 C (1325 F) at 56 C/h (100 F/h), aged 4 h at 718 C (1325 F), cooled to 621 C (1150 F)

Table 1Identification of Material Heats Heat identification A B C D E F

Producer heat no. Haynes 2810-9-9104 Haynes 2180-1-9345 Haynes 2180-4-9478 Huntington 52C9EK Huntington 60C7E Huntington 52B0E

Product form 0.5 in. plate 0.5 in. plate 0.5 in. plate 0.5 in. plate 0.062 filler 0.045 filler in. diam. metal in. diam. metal

Melt practice"' VIM-VAR VIM-ESR VIM-ESR VIM-EFR

Purchase specification AMS 5597 AMS 5596C AMS 5596C AMS 5596C AMS 5832A AMS 5832A

""VIM-VARvacuum induction melled, followed by vacuum arc remelting; VIM-ESRvacuum induction melted, followed by electroslag remelting; VIM-EFRvacuum induction melted, followed by electro-flux remelting; VIM-ESR and VIM-EFR are essentially the same process.

W E L D I N G RESEARCH S U P P L E M E N T I 17-s

Table 2-Chemical Composition, Wt-% Heat identification A B C D E F

"Not determined.

C .05 .06 .05 .07 .04 .04

Mn .19 .08 .21 .08 .09 .04

Fe Bal. Bal. Bal. 18.19 17.97 17.60

S .003 <.005 .005 .007 .007 .007

Si

Cu

Ni 53.00 52.88 52.63 53.44 53.84 54.58

Cr 17.95 18.06 18.21 18.11 18.04 17.91

Al .46 .51 .54 .49 .55 .49

Ti .95 1.11 .97 1.08 1.01 .99

Co .07 .22 .30 .03 .03 .04

P .003 <.005 .005

(a)

Mo 3.16 2.89 3.05 3.00 3.00 2.96

B .003 .004 .002

(a)

Cb&Ta 5.17 5.04 5.08 5.10 5.12 5.08

Cb

!

Ta

(a)

.09 <.01 .07 .04 .10 .02 .17 .11 .18 .10 .19 .05

(a)

(a) (a) (a)

Ca)

fal (a)

.010 .011

.0042 .0031

5.11 5.07

.01 .01

at 56 C/h (100 F/h), aged 16 h at 621 C (1150 F), and air-cooled to room temperature. Weldments were made w i t h the material in the annealed condition and then given either the conventional or modified heat treatments following gas-tungsten arc welding. All w e l d ments were of double V groove design. The ASTM "Compact Type" specimen was employed in the fatigue tests. The w i d t h (W) and thickness (B) were approximately 50.8 mm (2.0 in.) and 11.4 mm (0.45 in.), respectively, for all specimens, except for those n u m bered 835 and above, w h i c h had W and B dimensions of approximately 29.3 mm (1.154 in.) and 7.8 mm (0.31 in.), respectively. The specimens were tested on an MTS servo-controlled testing machine employing load as the control parameter. The cyclic frequency was 40 cpm (0.667 Hz) except at room temperature where frequency is not expected to be an important variable. Sinusoidal loading waveforms with a stress ratio (R = K m i n /K m a x ) of 0.05 were employed on all tests. Cracks in weldment specimens were centered in the weld deposit, and were oriented

parallel to the direction of welding. Specimen identification is given in Table 3. Elevated temperature tests were conducted in an air-circulating furnace, and temperatures were controlled to within about 1 C ( 2 F). Crack lengths were determined periodically throughout each test using a travelling microscope. Crack growth rate (da/dN) was calculated by dividing each increment of crack extension (Aa) by the number of cycles producing that increment (AN). The stress intensity factor (K) was calculated from a determined relationship^ using the average crack length for each growth increment. The results were then plotted as log (da/ dN) as a function of log (AK), where AK is the stress intensity factor range. Results and Discussion Tests were conducted at temperatures of 24 C (75 F), 427 C (800 F), 538 C (1000 F), and 649 C (1200 F), w i t h the emphasis being placed on the 427 C and 538 C temperatures where both the conventional and modified heat treatments were studied. The results

are plotted in Figs. 1-6 where the behavior of a weldment at a given temperature is compared to the behavior of base metal given the same heat treatment. Although not shown in the present paper, additional results for plate material at other temperatures and with other heat treatments, were reported in the literature. 5 Tensile tests were conducted on some of the material/heat treatment combinations employed in this study, and the results are given in Table 4. More extensive results are contained in the literature." The crack in each weldment spec; imen was approximately centered in the weld deposit and oriented parallel to the direction of welding. As crack extension occurred during each test, the cracks remained roughly normal to the direction of applied loading (i.e., parallel to the direction of welding). This is in contrast to the behavior observed" for bimetallic weldment specimens (Inconel 718 welded to either Inconel 600 or Type 316 stainless steel, using Inconel 82 filler metal in both cases) where crack extension directions deviated considerably from the normal to the loading time. Figures 1-6 reveal that somewhat greater data scatter is generally observed for the weldment specimens relative to that in the plate specimens. This is in agreement with similar observations for weldments in ferritic 7 and austenitic" steels. Considerable scatter in the crack growth behavior of Inconel 718 weldments has also been noted at 538 C (1000 F),!' but in this case approximately the same degree of scatter was also noted in the results for base metal. In general, Inconel 718 has very good weldability. However, in some cases difficulties have been encountered achieving adequate ductility and impact strength, especially when the weldments are given the " c o n v e n t i o n a l " heat treatment following w e l d ing. 3 1 " These difficulties are apparently associated with the formation of a " b r i t t l e " Laves phase in the weld fusion zone, and the inability of the 954 C (1750 F) annealing temperature in the conventional postweld heat treatment to eliminate the Laves

Table 3Specimen Identification Heat identification"" A D C/E D D D/F C/E D/F C/E A A D D D B/E B/E D/F D/F D D/F

Specimen no. 128 158 862 162 255 835 852 840 864 130 131 165 250 251 368 369 487 841 252 486

Material Plate Plate Weldment Plate Plate Weldment Weldment Weldment Weldment Plate Plate Plate Plate Plate Weldment Weldment Weldment Weldment Plate Weldment

Heat treatment Conventional Conventional Conventional Conventional Modified Conventional Conventional Modified Modified Conventional Conventional Conventional Modified Modified Conventional Conventional Modified Modified Modified Modified

Test temperature 24 24 24 427 427 427 427 427 427 538 538 538 538 538 538 538 538 538 649 649 C C C C C C C C C C C C C C C C C C C C (75 F) (75 F) (75 F) (800 F) (800 F) (800 F) (800 F) (800 F) (800 F) (1000 F) (1000 F) (1000 F) (1000 F) (1000 F) (1000 F) (1000 F) (1000 F) (1000 F) (1200 F) (1200 F)

"Designations incorporating a slash mark mean: base metal heat/filler metal heat.

18-sl J A N U A R Y 1978

STRESS INTENSITY FACTOR RANGE, AK, kg/(mm)

STRESS INTENSITY FACTOR RANGE AK, kg/(mm)" IO 2

to 2

PLATE

INCONEL 718 CONVENTIONAL HEAT-TREATMENT TESTED IN AIR AT75F(24C) ( 500 cpm. R - 0.05 O SPECIMEN 128, PLATE O SPECIMEN 158, PLATE A SPECIMEN 862, WELDMENT

INCONEL 718 CONVENTIONAL HEAT-TREATMENT TESTED IN AIR AT S00F (427C) f 40 cpm, R = 0.05 O SPECIMEN 162, PLATE D SPECIMEN 835, WELDMENT A SPECIMEN 852, WELDMENT

STRESS INTENSITY FACTOR RANGE, AK, Ih/lin) ^ J

.,3/2 STRESS INTENSITY FACTOR RANGE, AK, Ib/linl* , , , I i, i . I

10 STRESS INTENSITY FACTOR RANGE, AK, MN/tm 3/2

10 1

STRESS INTENSITY FACTOR RANGE, AK, MN/(m)

102

3/2

Fig. 1Fatigue-crack growth behavior of Inconel 718 plate and weldments tested in an air environment at room temperature (conventional heat treatment)

Fig. 2Fatigue-crack growth behavior weldments tested in an air environment treatment)

of Inconel 718 plate and at 427 C (conventional heat

STRESS INTENSITY FACTOR RANGE, AK, kg/(mm) ,2

3/2

STRESS INTENSITY FACTOR RANGE, AK

kg/t mm I'

3/2

10

1

: _

y ^

,'

1

SPECIMEN 368 FRACTURED

'

'

V

A/ A/ / /

- ^-^

j ? 10'

PLATE

WELDMENTS^

~*7^fv ^^

y^j? PLATE

%!^r

At

10

INCONEL 718 MODIFIED HEAT-TREATMENT TESTED IN AIR AT 800F (427CI

f 40 cpm, R0L05

INCONEL 718 CONVENT 1ONAL HEAT-TREATMENT TESTED IN AIR AT 1000F (538C) f - 40 cpm, R = 0.05 D O d V A SPECIMEN SPECIMEN SPECIMEN SPECIMEN SPECIMEN 130, 131, 165, 368, 369, PLATE PLATE PLATE WELDMENT WELDMENT

"IO"4

I

3D

O SPECIMEN 255, PLATE D SPECIMEN 840, WELDMENT A SPECIMEN 864, WELDMENT

;

~, , i

^ 1 1 , 1

STRESS INTENSITY FACTOR RANGE, AK, I b / l i n P '

_

10 10 STRESS INTENSITY FACTOR RANGE, AK, M N / ( m ) 3 / 2

STRESS INTENSITY FACTOR RANGE, AK, IbNin. I , , I , , , , I

3/2

10' Fig. 4Fatigue-crack growth behavior weldments tested in an air environment treatment)

10" 3'2 STRESS INTENSITY FACTOR RANGE, AK, MN/lml" of Inconel 718 plate and at 538 C (conventional heat

Fig. 3Fatigue-crack growth behavior of Inconel 718 plate and weldments tested in an air environment at 427 C (modified heat treatment)

WELDING RESEARCH SUPPLEMENT I 19-s

phase. For this reason, the " m o d i f i e d " heat treatment was developed at the INEL.3 The 1093 C (2000 F) postweld annealing temperature and subsequent modified heat treatment restores adequate ductility and impact strength to the weldments by dissolution of the Laves phase. Similar conclusions were reached in Canada.10 Since the nuclear applications of Inconel 718 are mainly in the temperature range 427-538 C (800-1000 F), the present study emphasized this region. Both conventional and modified heat treatments on plate material and w e l d ments were studied in this temperature range. The results, shown in Figs. 2-5, reveal several trends in the data. Least-squares regression analyses were conducted for each group of data (e.g., weldments in a given heat treated condition at a given test temperature), and are shown as linear or bi-linear lines in the Figs. 2-5. It will be seen that, at each test temperature/heat treatment combination, the crack growth rates are somewhat higher in the weldments than in the plate material. In some cases (e.g., Fig. 2) the differences are minimal and may not be statistically significant,* while in other cases (e.g., Figs. 1 and 3) the differences are appreciable. This observation of higher crack growth rates in weldments than in base metal is in contrast to most observations on the behavior of weldments in ferritic 7 and austenitic 8 steels. Comparing the results for both heat treatments at a given temperature (e.g., comparing Figs. 2 and 3, or Figs. 4 and 5) reveals that in all cases the modified heat treatment produces lower crack growth rates in a given material than does the conventional treatment. In other words, crack growth rates in weldments given the modified treatment f o l l o w i n g welding are lower than those in weldments given the conventional postweld heat treatment; also, growth rates in plates given the modified treatment are lower than those in plates given the conventional treatment. In fact, the differences between differing heat treatments on the same product form (e.g., weldments) are often greater than the difference between different product forms given the same heat treatment. It is apparent, then, that postweld heat-treatment is a parameter that must be given careful consideration. It is likewise apparent that the modified treatment appears to give

superior results in both weldments and plate material. The limited results at 24 C (75 F) and 649 C (1200 F) also show the same trend of somewhat higher crack growth rates in the weldments relative to those in plate. These results, however, are of less practical interest since the lower temperature is below that of most reactor applications, while the higher temperature is slightly above the final precipitation temperature, and hence overaging could result. As mentioned earlier, previous studies 310 had suggested that the higher annealing temperature in the modified postweld heat treatment produced a greater dissolution of the Laves phase, and that this in turn produced the improvement in ductility and impact strength. The dissolution of the Laves phase is dramatically illustrated by comparing the photomicrographs of Figs. 7 and 8 for the conventional and modified heat treatments, respectively. The Laves phase (the small w h i t e etching areas surrounded by the darketching areas) present in the conventionally-treated weldment (Fig. 7) is almost completely absent in the w e l d ment given the modified treatment (Fig. 8). Very similar photomicrographs may also be seen in the literature. 1 " It is therefore reasonable to speculate that the improvement in fatigue-crack growth resistance noted in the w e l d ments given the modified treatment may at least in part be due to the dissolution of the " b r i t t l e " Laves phase. Three of the "conventionally" treated weldment specimens (specimens 368, 835 and 852) failed during fatigue testing. The fracture surfaces of these specimens were flat and devoid of shear lips, indicating a low-energy fracture. Taking specimen 368 as an example and assuming that the failure occurred at the maximum fatigue load, and using the final crack length (taken from the fracture faces), an approximate final value of K may be calculated to be 62.5 M P a y T r i (56,900 psi

was faster than allowed by E399. Nevertheless, it is interesting to make the calculation (per E399) to see if specimen 368 was sufficiently thick to produce a "plane-strain" fracture: B >2.5

(ir

where B = the specimen thickness, and o"ys = the material yield strength at that temperature. Substituting K = 62.5 MPay-Tn (56,900 p s i - / m . ) and o-ys = 928.7 MPa (134,700 psi) the above relationship predicts that a thickness of 11.33 mm (0.446 in.) would have been sufficient to produce a " v a l i d " plane-strain fracture, provided of course, that all of the other requirements of E399-74 were met. Specimen 368 had a thickness of 11.53 mm (0.454 in.), slightly greater than that required by E399. This is a surprisingly low toughness for a test temperature as high as 538 C (1000 F). Specimens 835 and 852, which were tested at 427 C (800 F), also fractured during fatigue testing. Both failed at final K levels of approximately 57.7 M P a v / r n (52,500 psi^/Tn.). The yield strength of the deposited weld metal at 427 C (800 F) was 933.6 MPa (135,400 psi), and hence a thickness of 9.55 mm (0.376 in.) w o u l d have been necessary to produce "plane-strain" fracture. The thicknesses were slightly less, approximately 8.13 mm (0.32 in.), but the fracture surfaces were nevertheless flat and devoid of shear tips. It is apparent from the above discussion that conventionally-treated w e l d ments can possess relatively low values of toughness, even at temperatures in the range 427-538 C (800-1000 F). In addition, other results 1 " show that such weldments have low impact toughness at room temperature. In contrast, none of the weldment specimens given the modified heat treatment fractured during fatigue testing, even through the tests were carried to higher K-levels. The toughness of modified weldments is not presently known quantitatively, but J-integral toughness tests of weldments w i t h both heat treatments are presently in progress at Westinghouse Hanford Company. Some tests have been conducted at Westinghouse Hanford Company comparing the fracture toughness of Inconel 718 plate given both heat treatments. 12 At room temperature, conventionally-treated plate had a Jk. toughness of 72.5 m m - N / ( m m ) 2 (414 in.-lb/(in.) 2 ), while plate given the modified treatment had a toughness of 146.9 m m - N / ( m m ) 2 (839 in.-lb/(in.) 2 ). These correspond to approximate K,c values of 120.5 MPav/Tn (109.6 ks\^/Tr\.) and 171.4 MPa^/"rn (156.0 ksiy/ln.), respectively. At 427 C (800 F), conventionally-

y/m.).

There are a number of reasons why the K value should not be construed as Klc since many of the criteria of ASTM E399-74 were not met: 1. Since this was a fatigue test, no crack opening deflection transducers were installed as w o u l d be necessary in a facture toughness test. 2. The final fatigue crack length was longer than that specified in E399 and "precracking" occurred at approximately the same load as the failure load, rather than at the lower precracking loads required in E399. 3. The load rise time (one-half the fatigue cyclic period for a sine wave)

M n ASTM round-robin test program" has established that a factor of two scatter on da/dN can be expected for intralaboratory tests on a single heat of material, and a factor of three for interlaboratory tests. 20-s I J A N U A R Y 1978

STRESS

STRESS INTENSITY FACTOR RANGE, AK, kg/lmmr

3/2

STRESS INTENSITY FACTOR RANGE, AK, MN/(m)'

STRESS INTENSITY FACTOR RANGE, AK, MN/lmr''

Fig. 5Fatigue-crack growth behavior of Inconel 718 plate and weldments tested in an air environment at 538 C (modified heat treatment)

Fig. 6Fatigue-crack growth behavior of Inconel 718 plate and weldments tested in an air environment at 649 C (modified heat treatment)

Table 4Mechanical Properties'" Total elongation, Uniform elongation,

o/ /o

(b)

Heat identification A D D D D D D D E E E F F

Heat treatment Conv. Conv. Conv. Conv. Mod. Mod. Mod. Mod. Conv. Conv. Conv. Mod. Mod.

Test temperature 24 C 75 F 24 C 75 F 427 C 800 F 538 C 1000 F 24 C 75 F 427 C 800 F 538 C 1000 F 649 C 1200 F 24 C 75 F 427 C 800 F 538 C 1000 F 24 C 75 F 427 C 800 F

0.2% yield strength 1110.7 161.1 1037.7 150.5 925.3 134.2 893.6 129.6 1011.5 146.7 889.4 129.0 866.0 125.6 828.7 120.2 1017.0 147.5 933.6 135.4 928.7 134.7 970.1 140.7 872.2 126.5 MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi

Ultimate strength 1366.5 198.2 1319.0 191.3 1139.7 165.3 1112.1 161.3 1325.2 192.2 1209.3 175.4 1182.4 171.5 907.4 131.6 1269.3 184.1 1119.7 162.4 1129.4 163.8 1323.8 192.0 1182.5 171.5 MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi MPa ksi

%

20.5 18.7 17.7 15.8 11.2 13.0 14.8 10.3 14.9 17.6 14.6 20.3 13.2

Reduction in area, %

<b)

Notations

17.6 14.0 13.9 10.8 11.9 12.9 6.2 14.5 12.7 13.3

(b)

32.1 30.9 27.7 18.0 17.7 24.4 17.7 17.1 23.6 22.8 24.3 18.6

(ct

(c)

(c)

(d)

(d)

(d)

(c.d.e)

(bl

(c.d.e)

'Strain rate = 3 X 1 0 * s"' 'Not determined. 'Average of multiple tests. 'Specimens oriented parallel to direction of welding and were comprised entirely of deposited filler metal. 'From the literature."

WELDING RESEARCH SUPPLEMENT | 21-s

treated plate had a J,,. toughness of 76.2 m m - N / ( m m ) 2 (435 in.-lb/(in.) 2 ), and the modified treatment plate had a toughness of 126.1 m m - N / ( m m ) 2 (720 in.-lb/(in.)-), again corresponding to approximate Kk, values of 116.4 M P a v ^ m (105.9 ksiy^Tn.) and 149.8 MPay^fn (136.3 ksi v/Tn.). The above value of equivalent K of 120.5 M P a - i / l r i (109.6 ksi-^/Tn.) for conventionally-treated plate at room temperature compares favorably w i t h the value of 109.9 M P a ^ / m (100 ksi v ^ n . ) that has been given for plate material. 11 It has also been found that Klc of Inconel 718 weld metal at room temperature was 54.9 M P a i / T n (50

- ^ - ^ .

" * * , ,

'V***>

*>*>:

'

,.vk

"Ti

<{

ksi-v/tn.). 18

. s^

It will be noted that at each of the temperatures where conventionallytreated weldments were studied (Figs. 1, 2, and 4), fatigue-crack growth rates tend to accelerate at the higher levels of AK. Fatigue-crack growth curves over wide ranges of AK are often observed to be sigmoidal in nature, tending downward toward a vertical asymptote at low values of AK as the crack growth threshold is approached, and tending upward toward a vertical asymptote at high values of AK as the onset of instability is approached. Therefore, the upward slope transitions observed in Figs. 1, 2 and 4 at the higher values of AK probably reflect the rapid acceleration in crack growth rates as Kmax in the fatigue test approaches the material fracture toughness. One possible explanation for the increased crack growth rates in conventionally-treated weldments relative to those in modified weldments, could be that the " b r i t t l e " Laves particles could be fracturing in the highlydeformed area ahead of the crack tip. The fractured Laves particles could, in turn, initiate microcracks in the matrix material which could then interact with the main fatigue crack. Such a mechanism has indeed been observed microscopically by Barnby1"' studying the role of carbide particles in the fatigue behavior of thermally-aged austenitic steels, and the same mechanism has also been suggested as responsible for the degraded fatiguecrack growth behavior of thermallyaged austenitic steels at room temperature. 1 " The tensile properties of the as-heat treated weld filler metals are shown in Table 4. Comparing the t w o heat treatments, it will be seen that slightly lower strengths are obtained with the modified treatment. However, perhaps the most significant observation is that although the ductility parameters (elongation and reduction of area) of the conventionally-treated weldments appear to be quite satisfactory in the tensile specimens, these results mask

'*-J!.*^> - - . "

fi

. *r .

Fig. 7Photomicrograph of weld deposit in specimen 368 showing Laves phase (small white-etching areas surrounded by the dark areas). A (top)-XlOO; B (bottom)-enlargement of an area in A, x 750. 10% oxalic acid etch (reduced 50% on reproduction)

heats involved is much too small to make general observations concerning heat-to-heat variations, Figures 2 and 3 show little or no difference in the behavior of the weldments employing the different filler metals. Similarly, there is no apparent difference in the behavior of plate specimens at 24 C (75.2 F) in Fig. 1 and 538 C (1000 F) in Fig. 5 fabricated from different plates. The potential for heat-to-heat and/or melt practice variations is currently being examined in the author's laboratory. Finally, the observation may be made in comparing the results in Figs. 1-6, that fatigue-crack growth rates generally increase w i t h increasing temperature. This general observation has been noted in numerous previous studies on a wide variety of different alloy systems tested in an air environment.

Conclusion The fatigue-crack growth behavior of Inconel 718 plate and weldments given either a " c o n v e n t i o n a l " (ASTM A637) heat treatment or a " m o d i f i e d " (INEL designed to minimize the presence of Laves phase) heat treatment was studied. The results of this study may be summarized as follows: 1. In general, fatigue-crack growth rates in Inconel 718 plate and w e l d ments tested in an air environment increase w i t h increasing test temperature. 2. For the t w o heat treatments studied, crack growth rates are generally somewhat higher in weldments than in plate material. 3. For a given product form (e.g., weldments or plate), crack growth rates are generally higher in material given the conventional heat treatment than in material given the modified treatment. 4. Conventionally treated weldments apparently exhibit relatively low toughness in the range 427-538 C (800-1000 F), while weldments given the modified treatment apparently have a higher (but unknown) toughness. 5. The improvement in the crack growth and fracture toughness behavior of weldments given the modified heat treatment is thought to be associated w i t h the more complete dissolution of the " b r i t t l e " Laves phase obtained w i t h that treatment. Acknowledgments This paper is based on work performed under U.S. Energy Research and Development Administration contract EY-76-C-14-2170 w i t h the Westinghouse Hanford Company, a subsidiary of the Westinghouse Electric

the relatively low toughness possessed by these weldments in the presence of a sharp crack. Hence, it is wise to also consider properties other than tensile tests when attempting to evaluate inservice behavior of these weldments. Two different heats of filler metal were employed w i t h both postweld heat treatments studied at 427 C (800 F). Although the number of tests and

Fig. 8Photomicrograph of weld deposit in specimen 487 showing almost complete dissolution of the Laves phase. A (top)-x100; B (bottom)enlargement of an area in A, X750. 10% oxalic acid etch

22-sl I A N U A R Y 1978

Corporation. T h e c a r e f u l e f f o r t s o f D. J. C r i s w e l l i n helping to conduct t h e tests is acknowledged, and the continued e n c o u r a g e m e n t a n d s u p p o r t o f J. R. H u n t e r , A. V a n E c h o a n d E. E. H o f f m a n o f LJSERDA is also a p p r e c i a t e d . T h e a u t h o r also w i s h e s t o t h a n k Drs. G . E. K o r t h a n d D. D. Keiser o f INEL f o r g e n e r o u s l y f u r n i s h i n g m a n y of t h e w e l d m e n t s u s e d in t h i s s t u d y . References 1. James, L. A., "Estimation of Crack Extension in a Piping Elbow Using Fracture Mechanics Techniques," lournal oi Pressure Vessel Technology, Trans. ASME, Vol. 96, No. 4, 1974, pp. 273-278. 2. "Precipitation Hardening Nickel Alloy Bars, Forgings, and Forging Stock for HighTemperature Service: A 637-70," 7977 Annual Book of ASTM Standards, Part 4, American Society for Testing and Materials, 1971, pp. 813-821. 3. Smolik, G. R., and Reuter, W . C , "Heat Treatment Investigations for W e l d e d Inconel 718 Pressure Vessels for the Power Burst Facility," Report ANCR-1227, Aerojet Nuclear Company, Idaho Falls, Idaho, 1975.

4. Srawley, ). E., " W i d e Range Stress Intensity Factor Expressions for ASTM E399 Standard Fracture Toughness Specimens," International lournal of Fracture, Vol. 12, No. 3, 1976, pp. 475-476. 5. James, L. A., "Fatigue-Crack Propagation Behavior of Inconel 718," Report HEDL-TME 75-80, Westinghouse Hanford Company, 1975. 6. |ames, L. A., "Fatigue-Crack G r o w t h Behavior in Dissimilar Metal W e l d m e n t s , " Report HEDL-TME 76-93, Westinghouse Hanford Company, 1977. 7. James, L. A., "Fatigue-Crack Propagation Behavior of Several Pressure Vessel Steels and W e l d m e n t s , " Welding lournal 56(12), Dec. 1977, Research SuppE, pp. 386-s to 391-s. Behavior in Type 304 Stainless Steel W e l d ments at Elevated Temperature," Welding lournal, 52(4), April 1973, Research Suppl. pp. 173-s to 179-s. 9. Popp, H. G., and Coles, A., "Subcritical Crack G r o w t h Criteria for Inconel 718 at Elevated Temperatures," Proceedings Air Force Conference on Fatigue and Fracture of Aircraft Structures and Materials, H. A. W o o d et al (Eds.), Report AFFDL TR 70-144, Air Force Flight Dynamics Laboratory, September 1970, pp. 71-86. 10. Cordine, J., "Some Problems in W e l d ing Inconel 718," Welding lournal, 50(11),

Nov. 1971, Research Suppl. pp. 480-s to 484-s. 11. Clark, Jr., W. G., and Hudak, Jr., S. J., "Variability in Fatigue-Crack G r o w t h Rate Testing," lournal oi Testing and Evaluation, Vol. 3, No. 6, 1975, pp. 454-476. 12. Mills, W . J., and Knecht, R. L, "The Effect of Heat Treatment on the Fracture Toughness Response of Inconel 718 at 75F and 800F," Report ORNL-5237, Oak Ridge National Laboratory, 1976, pp. 258-263. 13. Pettit, D. E., Feddersen, C E., and M i n d l i n , H., "Flaw Growth Behavior of Inconel 718 at Room and Cryogenic Temperatures," Report NASA CR-101942, Battelle-Columbus, 1969. 14. Reuter, W. G., "Design Data for the '/4-Inch Thick Alloy 718, In-Pile Tube," Report TREE-NUREG-1087, EG&G Idaho Inc., 1977. 15. Barnby, I. T., and Peace, F. M " I n fluence of Carbides on the Low-Cycle Fatigue Strength of an Austenitic Steel," Effect of Second-Phase Particles on the Mechanical Properties of Steel, The Iron and Steel Institute, London, 1971, pp. 124127. 16. James, L. A., "Effect of Thermal Aging Upon the Fatigue-Crack Propagation of Austenitic Stainless Steels," Metallurgical Transactions, Vol. 5, No. 4, 1974, pp. 831838.

AWS A2.4-76Symbols for Welding and Nondestructive Testing

Provides the means for placing complete welding information on drawings. Symbols in this publication are intended to be used to facilitate communications among designers and shop and fabrication personnel. Many changes were made f r o m the previous edition in recognition of the increasingly international use of welding symbols. Illustrations showing brazing and its symbols have been added to more clearly define usage. Part B, Nondestructive Testing Symbols, establishes the symbols for use on drawings to specify nondestructive examination for determining the soundness of materials. The price of A2.4-76 Symbols for Welding and Nondestructive Testing is $5.00. Discounts: 25% to A and B members; 2 0 % to bookstores, public libraries and schools; 15% to C and D members. Send your orders to the American Welding Society, 2501 N.W. 7th St., Miami, FL 33125. Florida residents add 4 % sales tax.

AWS A5.17-76Specification for Bare Carbon Steel Electrodes and Fluxes for Submerged Arc Welding

Prescribes and fluxes low alloy requirements for submerged steels for carbon steel electrodes and arc welding of carbon

A5.17-76 covers Classification and Acceptance of Electrodes and Fluxes, Chemical Analysis of Electrodes, and Required Tests for Classifying Fluxes. Appendix A: Guide to AWS Classification of Bare Carbon Steel Electrodes and Fluxes for Submerged Arc Welding and Appendix B: Metric Equivalents have been added for your convenience. The price of AWS A5.17-76, Specification for Bare Carbon Steel Electrodes and Fluxes for Submerged Arc Welding is $3.50. Discounts: 25% to A and B members; 20% to bookstores, public libraries and schools; 15% to C and D members. Send your orders to the American Welding Society, 2501 N.W. 7th St., Miami, FL 33125. Florida residents add 4 % sales tax.

WELDING

RESEARCH S U P P L E M E N T I 23-s

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Experimental Investigation On Weld Ability of Cast IronDocument5 pagesExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweNo ratings yet

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDocument4 pagesFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweNo ratings yet

- ERNI-1 Cast Iron ElectrodeDocument1 pageERNI-1 Cast Iron ElectrodeKhin Aung ShweNo ratings yet

- Microscopy With Light and ElectronsDocument36 pagesMicroscopy With Light and ElectronsCORE Materials100% (1)

- Austenitic Ductile Iron For Low Temperature ApplicationDocument6 pagesAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweNo ratings yet

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Document68 pagesTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweNo ratings yet

- Manual de Servicio Olympus SZ-IIIDocument18 pagesManual de Servicio Olympus SZ-IIIcarlosibaNo ratings yet

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaNo ratings yet

- Fracture and Crack Propagation in WeldmentsDocument66 pagesFracture and Crack Propagation in WeldmentsKhin Aung ShweNo ratings yet

- Lab Exericise 3 For MicroscopeDocument9 pagesLab Exericise 3 For MicroscopeKhin Aung ShweNo ratings yet

- JK Stereo1Document26 pagesJK Stereo1Yongliang LiuNo ratings yet

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDocument10 pagesInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweNo ratings yet

- DryerDocument80 pagesDryerAaron Paulo Bernardo100% (2)

- Safety of Machinery - Principles of Risk AssessmentDocument27 pagesSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweNo ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- Mo SteelDocument0 pagesMo SteelSamsi B HanifNo ratings yet

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDocument1,080 pagesအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Lampiran PQR 003Document3 pagesLampiran PQR 003Khin Aung ShweNo ratings yet

- Welding of Nonferrous Metal and Their AlloysDocument62 pagesWelding of Nonferrous Metal and Their AlloysKhin Aung ShweNo ratings yet

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDocument33 pagesBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Braze Cast Iron - Videos, Tips and ProceduresDocument5 pagesBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweNo ratings yet

- Fundamentals of Metal CastingDocument14 pagesFundamentals of Metal CastingKhin Aung ShweNo ratings yet

- The Crucible Arthur Miller Play AllegoryDocument11 pagesThe Crucible Arthur Miller Play AllegoryKhin Aung Shwe100% (1)

- Effect of Pouring Temperature and Stirring Speed OnDocument6 pagesEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Boiler Furnace TheoryDocument8 pagesBoiler Furnace TheoryArun YogaNo ratings yet

- Waste Materials Storage and Disposition Written Test 1Document4 pagesWaste Materials Storage and Disposition Written Test 1GENEBEI FAITH SAJOLANNo ratings yet

- Ductable Fan Coil Unit: Product Selection DataDocument26 pagesDuctable Fan Coil Unit: Product Selection DataNelson MartinsNo ratings yet

- 301 Basic Mechanics Course DescriptionDocument2 pages301 Basic Mechanics Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- Closer #1Document32 pagesCloser #1Mike SmallNo ratings yet

- Glowing TreesDocument2 pagesGlowing TreesJonathan SwiftNo ratings yet

- Chemistry 3202 Reaction Rates and Equilibrium NotesDocument4 pagesChemistry 3202 Reaction Rates and Equilibrium NotesMorgan SearsNo ratings yet

- TD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelDocument2 pagesTD-esc-02-De-En-16-010 Rev000 Morgan Rekofa Slip Ring Unit LabelFelipe SilvaNo ratings yet

- Pump Inlet Piping DesignDocument2 pagesPump Inlet Piping DesignWayaya WaziwupyaNo ratings yet

- Daewoo 4603Document42 pagesDaewoo 4603David LovatoNo ratings yet

- Label Odner BantexDocument4 pagesLabel Odner Bantexdana setiawanNo ratings yet

- Techniques de Commande Des Machines Electriques - Cours Et Problèmes..Document2 pagesTechniques de Commande Des Machines Electriques - Cours Et Problèmes..Tko ToolNo ratings yet

- WP Bdi GB 1000 2012Document10 pagesWP Bdi GB 1000 2012prijepolje72No ratings yet

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarNo ratings yet

- 1st PU Chemistry May 2015 PDFDocument2 pages1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- Oil & Gas Financial JourneyDocument85 pagesOil & Gas Financial Journeyabsolutvacio82No ratings yet

- Tk09 Report Assignment 4Document112 pagesTk09 Report Assignment 4Bella Novia BerlianaNo ratings yet

- Sil IndexDocument162 pagesSil IndexBenjamin Strickland100% (1)

- Dennis Miru Graphic Design PortfolioDocument9 pagesDennis Miru Graphic Design PortfoliodenosciNo ratings yet

- I2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionDocument7 pagesI2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionMariusNo ratings yet

- Boiler Operation Manual ESB - WOPDocument115 pagesBoiler Operation Manual ESB - WOPMoaaz Khan100% (1)

- 3 Goshu 3Document18 pages3 Goshu 3nega cheruNo ratings yet

- 3TNV70 ASA BroDocument1 page3TNV70 ASA BroSaMos AdRiianNo ratings yet

- 1000 Most Common Words in English - Numbers Vocabulary For 1Document12 pages1000 Most Common Words in English - Numbers Vocabulary For 1izmitlimonNo ratings yet

- Solar GeometryDocument34 pagesSolar GeometryPatricia Franchette AmoraNo ratings yet

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet

- Innovation SiemensDocument11 pagesInnovation SiemensOviri Charles Umude-IgbruNo ratings yet

- Electrician Training - Troubleshooting and Fault FindingDocument11 pagesElectrician Training - Troubleshooting and Fault FindingOgunjimi Taofiki AdebisiNo ratings yet

- Chapter 1Document27 pagesChapter 1Omotayo PaulNo ratings yet

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- An Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationDocument18 pagesAn Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationRadu GodinaNo ratings yet