Professional Documents

Culture Documents

Fifty Years of Bridge History

Uploaded by

monolith80Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fifty Years of Bridge History

Uploaded by

monolith80Copyright:

Available Formats

Fifty years of Bridge History

Jacques COMBAULT Technical Director Finley Engineering Group Tallahassee, FL, USA

Jacques.combault@finleyengineering group.com Jacques Combault, born 1943, received his engineering degree from the Ecole Centrale de Lyon in 1967. He devoted most of his carrier to the design and construction of bridges with Campenon Bernard and GTM (now parts of Vinci). President of IABSE from 2007 to 2010, Jacques is presently Technical Director of Finley Engineering Group.

Summary

Looking at the past, several key innovations in the field of bridge engineering and technology are worth mentioning: the prefabrication of concrete box girders in short sections, match cast and assembled using a well adapted equipment, which has become the best way to build short and medium span bridges; the combination of external prestressing and optimized steel-concrete composite decks made of concrete slabs connected to steel trusses or corrugated webs, a promising technique for spans up to 250 meters; the development of the necessary calculation tools for the design and safe erection of cable-stayed bridges, which offer a large variety of appearances and presently lead to exceptional achievements all over the world. Indeed, bridges to be built in the future will be gigantic, impressive, light and heavy, deep and high, wide and long. They will be challenging major straits, mitigating natural disasters, fighting the power of the wind, of the sea, of the earth, but linking people, countries, continents. They will have to be erected within a short time to improve our daily life as quickly as possible; they will have to be durable and easily maintained. The fantastic boom of the past fifty years in the field of structural engineering will have to be improved in such a way that our infrastructures become definitely sustainable. Keywords: Cable-stayed bridges; composite decks; durability; external prestressing; innovations, maintenance; prefabrication.

1.

Introduction

If we look at the past, in terms of centuries, the most significant evolution which has been made in the field of structural engineering and more especially in the field of bridges is related to the materials and combination of materials. For a long time, wood and stone have been the only available construction materials. In the second part of the nineteenth century and beginning of the twentieth century, stone has been progressively replaced by iron first, then by steel or concrete, mainly when concrete has been reinforced with steel or prestressed with tendons made of high strength steel wires; indeed, the idea of pre-stressing developed at the beginning of the previous century can be considered as one of the most homogeneous and fruitful construction technique ever imagined. Of course, structures and forms have been simultaneously adapted to the evolution of resistant materials and corresponding technologies leading to the fantastic development of many structural concepts, including cable stayed bridges, while old construction methods were improved, or new ones developed, thanks to the imagination of construction engineers.

2.

The Past

2.1 The sixties From this point of view, it must be recognized that, since they have been imagined fifty years ago, Prefabrication of concrete box girders in short segments and Balanced Cantilever Assembly using

PT tendons of these prefabricated elements across bridge supports have definitely marked the construction of bridges. As a matter of fact, the only way to prefabricate a bridge deck made of a concrete box girder was to cut it up into short sections, cast them in series against each other in the same order as they will be assembled, such as the joints perfectly match and structural continuity could be restored in the most perfect manner after assembly. The prefabrication installations used can be organized very differently, depending on the available area on the construction site or the type of segments to be produced. When possible, the prefabrication installations consist of a long casting bed, having the appropriate geometry. The other option is to use fixed casting units.

Figure 1: Construction of Avignon Viaducts (French TGV) Segments and Launching Gantry Correct positioning of the segments, with respect to each other, is obtained by keys provided on the matching faces while the physical continuity of the deck is obtained by coating the joints with epoxy glue. Associated with the balanced cantilever erection technique (Figure 1), so well adapted to the modular implementation of PT tendons in each segment, or with any other assembly method, the prefabrication process of box girders, according to the long or short line methods, became rapidly extensively used in France and is today intensively used worldwide. Indeed, this was an opportunity for structural engineers to imagine and develop progressively some powerful assembly techniques, using movable cranes or simple beam and winch systems, the most effective method, however, being to install the prefabricated segments using steel girders launched over the deck part to be built; this process, which was used for the first time in the construction of the Oleron viaduct, makes it possible to take advantage of the high production rate of the segments, since the rate of installation of the prefabricated segments can be as high as their production rate. 2.2 The seventies and the eighties

2.2.1 New construction methods It was towards the latter part of the seventies that the first spectacular applications of external prestressing, combined with innovative construction methods, were to be seen. The progressive construction method with temporary stay cables (Figure 2) is based on a very simple idea. It consists of placing the prefabricated segments of a deck continuously, from the first abutment to the other one. Though limited to span length of the order of 55 meters, the method allows the construction of bridge decks (whatever their alignment and profile) spanning any kind of urban area and many types of obstacles with light equipment.

All the construction materials, components and personnel are provided with a high degree of safety at the end of the progressing deck. The stability of the deck during construction, provision and progressive placing of the segments is essentially provided by the temporary stay cable arrangement. As a result, the pre-stressing of a completed span can be done after its completion and the permanent bending moments in the deck are exactly the same as those of the entire bridge cast-in place since match cast segments are used over the total length of the deck; there is therefore no redistribution of bending moments and stresses in the box girder due to creep effects. This means that the tendons just have to run from pier segment to pier segment and, as a consequence, can be easily anchored in the diaphragms ensuring the force transfer to the bearings at deck supports. Prestressing tendons encased in a grouted polyethylene duct, can be located outside the concrete, within the void of the box girder, and simply deflected in deviation saddles and the pre-stressing tendon layout of spans built that way is more economical than those used in cantilever construction.

Figure 2: Progressive construction with temporary stay cables When implemented for the first time, segment by segment progressive construction of the deck did not allow a high speed of erection. From this point of view, assembling the segments of a span on a truss seems to be more efficient. But it has to be feasible and this is probably the reason why this way of construction could be successfully developed for the very large bridges to be reconstructed in the Florida Keys. Long Key Bridge was the first erected using the span-by-span construction method, the segments being placed on an assembly truss moved from span to span after tensioning the whole set of external PT tendons of each span typically 36 meters long. Although the speed of erection was routinely two spans a week, it was necessary to increase this pace for the construction of Seven Mile Bridge; this is the reason why the typical segments of each span (typically 41.15 meters long) were preassembled atop a steel lifting frame aboard a shuttle barge which was moved beneath the bridge; a self launching truss lifted the pier segment, which also accompanied the preassembled span, to the top of the next pier and finally raised the lifting frame supporting the segmental span assembly from the barge below. This was a first step towards many successful and powerful techniques; this was the step from light to heavy prefabrication. 2.2.2 Cable stayed bridges But the structural concept which marked the last part of the twentieth century in the field of bridges was clearly the combination of bridge decks and stay cables. The first modern cable-stayed bridges consisted of steel decks built using free cantilever construction, supported by a small number of stay cables. The idea was to make long spans feasible by replacing expensive intermediate supports by active supporting cables. As a result, stay cables were big units generating large forces at anchorages and the deck structure had to resist large bending moments during erection.

Using smaller cables regularly distributed along the deck was therefore a major improvement as it was then possible to optimize the span-to-depth ratio of the deck structure. In addition, the idea rapidly appeared as being an extension of the classical post-tensioned tendon layout of concrete bridges, in which PT tendons are placed outside the concrete deck with increased eccentricities, and made it possible to design long span concrete bridges: Completed in 1978, the cable stayed portion of the Pasco-Kennewick Bridge (USA) had unique features that made it remarkable at that time as it was made of precast segments, fully suspended between the two back piers and relatively slender with a 140 span to depth ratio; the Brotonne Bridge (France), completed and opened to traffic in July 1977, also had a number of unique distinctions which produced a world record in the field of prestressed concrete bridges: A main span 320 meters long; a single box girder deck, 19.20 meters wide, consisting of 20 centimeter thick thin prefabricated and prestressed webs, a bottom slab, a top slab and two internal struts cast in place; two axial pylons and axial cable planes, the cables consisting of seven wire PT strands encased in a steel pipe and grouted after tensioning operations. 2.3 The nineties Steel and concrete can be associated in various ways. This includes classic bridge types as well as cable-stayed bridges. To what degree steel and concrete can be used cooperatively depends on the width of the deck, the span arrangement and main span length, the number of cable planes and the available construction methods. Built in a severe environment, the Second Severn Crossing (UK) carries three lanes of traffic plus an emergency lane in each direction. The main component of the crossing is a symmetrical cablestayed bridge with a central span of 456 meters formed from composite construction with steel longitudinal and transverse girders and a reinforced concrete slab. One of the most significant aspects of the bridge is the way it was built. The 7.30 meter long deck elements were prefabricated full width on a pre-assembly bed before being transported and bolted to the already-built cantilevers. A 2.00-meter-wide strip of the concrete slab was finally cast in place before tensioning of the cables.

Figure 3: The Normandie Bridge during construction and after completion The Normandie Bridge (France) over the Seine River (Figure 3), completed in 1994, earned the distinction of worlds longest cable-stayed bridge, with a main span of 856 meters up to 1999, when the Tatara Bridge took that record away with a main span 890 meters long. It consists of a bridge deck, 21.20 meters wide and 3.00 meters deep, rigidly connected to the 202 meter high inverted Y concrete pylons. It is made of a three-cell concrete box in the approach spans and the start of the center span, while the major part of it consists of a single orthotropic steel box, the span-to-depth ratio being 285. The unusual concept of the steel-concrete composite pylon head made it possible to anchor the two cable planes on a rather short length.

3.

From Past to Present

Several major fixed links and long span bridges have been built during the last twenty years thanks to the development and the integration of powerful construction methods into the design of these

structures. Two of them will be mentioned for their exceptional characteristics and the way they have been made feasible. 3.1 The Confederation Bridge The 12.9 kilometer long Confederation Bridge (Figure 4), probably the longest bridge in the world across ice-covered water, joins the provinces of New Brunswick and Prince Edward Island in Eastern Canada. At the crossing location, the Northumberland Strait is approximately 13 kilometers wide, with water depth ranging from zero to 30 meters.

Figure 4: The Confederation Bridge between New Brunswick and Prince Edward Island (Canada) The Bridge consists of three sections: The West approach, the Main bridge and the East approach, with transition spans between the approaches and the main bridge. The depth of the main bridge deck varies from 14.00 meters at pier to 4.50 meters at mid span. The main bridge comprises 22 repetitive portal frames, 440 meters long, made of a 250 meter centre span and two 95 meter overhangs on each side of the centre span, the tips of these cantilevers being simple supports for the drop-in girders connecting adjacent portal frames. The resulting 43 repetitive 250 meter spans have been made of four typical prefabricated units referred to as: pier bases, pier shafts, main girders, and drop-in girders. Each typical pier base consists of 22.00 meter diameter and 4.00 meter wide ring footing topped by a conical shell, a cylindrical barrel and a male cone supporting the pier shaft. Each pier shaft consists of the ice shield and the shaft itself. The ice shield is conical with base diameter of 20.00 meters and a 52 degree angle to break ice flows. The pier shaft is equipped with a template which was match cast to the soffit of the main girder. Each main girder consists of a 192.50 meter long double cantilever. The drop-in girders were either 52 or 60 meters long. Through a sound structural concept, durability could be achieved by a selection of appropriate materials and construction methods and correction of initial defects. The individual bridge components weighing up to 8,000 metric tons were pre-cast on land. The precasting yard was arranged in four production lines. Six pier bases and four pier shafts were fabricated simultaneously at different locations. The main girders were made of 19 segments fabricated in ten fixed locations and the drop-in spans were prefabricated in one piece at one location. All precast units were being moved on stainless steel tracks along the production lines and from the storage area to the load out jetty where they were picked and transported to their final location by the Heavy Lift Vessel Svanen (Figure 5). Once the sea bed was dredged to competent bedrock and a trench into the rock corresponding to the geometry of the ring footing was made at pier locations, pier bases were placed and the trench was filled with tremie concrete ensuring complete contact of the pier on the rock. The pier shaft/ice shield element was placed on top of the pier base. The two units were made monolithic with a closure joint and continuity PT tendons.

Figure 5: Confederation Bridge - Transportation of a Main Girder and Placing of a Drop-in-Span The top of the shaft was then prepared to receive the main span. This was achieved by the use of a precast alignment template which had match-cast shear keys fitting exactly into the underside of the main girder. Once the main girder unit was placed, final continuity post-tensioning tendons were installed and stressed, to create a moment-resisting connection between main girder and pier shafts, and mid-span girders were placed, the central span of each frame being made continuous by external PT tendons. Works on site, performed by Strait Crossing joint Venture; started at the end of 1993 while prefabrication of the main bridge components started at the end of 1994 and placing of these components started during the summer of year 1995. The assembly of the whole bridge was finished in November 1996 and its worth mentioning that, in August 1996 and therefore in one month, two kilometers of the bridge were prefabricated and erected in the Northumberland Strait including foundation preparation and completion.

Figure 6: The Rion-Antirion Bridge - The bridge (left) and the concept (right) 3.2 The Rion-Antirion Bridge The Rion-Antirion Bridge (Figure 6), about three kilometers long, crosses the Gulf of Corinth near Patras, in western Greece. The concept of this Bridge is a good example of what has to be done to make a bridge feasible in a severe environment. It is also a good example of new trends in bridge construction using experience from both prefabrication and concrete offshore oil drilling platform techniques. This new link consists of a main bridge, 2252 meters long, connected to land by two approaches on each side of the gulf.

An exceptional combination of physical conditions made this project quite unusual as it is located in an area where the water depth is high, the bedrock is probably more than 500 meters below the sea bed level, there is a risk of strong seismic activity with possibly slow but important tectonic movements and a heavy ship impact has to be taken into account. Clearly, this conjunction of so many adverse site conditions should have favored the design of a suspension bridge; unfortunately, major slope stability concerns on the Antirion side eliminated such a solution from the very beginning of the conceptual design stage. Indeed, the bridge type and the span length had to be selected simply to make the bridge feasible and the global cost of the project acceptable by reducing the number of the supports located in the Strait. This lead to an exceptional multi-cable stayed span bridge, made of three central spans, 560 meters long, and two side spans, two hundred and eighty six meters long. With no bedrock within reach, friction piles were to be discarded and the only way to make this impressive project feasible was to design shallow pad foundations. The four pylons of the main bridge (Figure 7) therefore rest simply on the sea bed through a large concrete substructure foundation, 90 meters in diameter, 65 meters high at the deepest location, which distributes all the forces to the soil. Consequently, the strength of the heterogeneous and weak soil layers below these gigantic substructures was improved by means of inclusions which consist of steel pipes, 25 to 30 meters long and 2.00 meters in diameter, driven at a regular spacing of 7.00 or 8.00 meters and covered by several calibrated gravel layers which provide a transition between the structure and the reinforced soil.

Figure 7: Rion-Antirion Bridges Pylon and Pylon Base concepts The Pylon bases consist of a large footing made of 32 peripheral cells enclosed in a 9.00 meters high perimeter wall and covered by a conical shaft rising more than sixty three meters over the gravel bed. These huge bases support, through vertical octagonal pylon shafts, 24 meters wide and nearly 29 meters high, a 15.80 meters high pyramidal capital which spreads to form the 3.50 meters thick and 40.50 meters wide square base of four concrete legs. The four legs converge above the next 78 meters, giving the pylon head the appropriate rigidity, and merge for the final 35 meters into one vertical steel - concrete composite section at the top of the pylons. Especially designed to anchor and stress the stay cables, this last section is made of a steel core embedded in two concrete walls giving the pylon head the desired elegance. The deck is a composite steel-concrete structure, 27.20 meters wide, made of a concrete slab connected to twin longitudinal steel I girders, 2.20 meters deep, braced every 4.00 meters by transverse cross beams. It is continuous and therefore entirely supported by eight sets of twenty three pairs of cables and built in one piece, with expansion joints only at the ends. Hydraulic dampers connecting the deck to the pylons will steady it in the event of an earthquake while a strut, acting as a fuse, prevents the deck from moving transversally under wind effects. The innovative concept of the foundations of the Rion-Antirion Bridge is typically the result of an appropriate seismic design approach. As no connection exists between the inclusions and the foundation raft, each foundation is therefore free to uplift, or to slide. Clearly, the foundations look like piled foundations but they do not behave as such. The pylons will slide during the most

unfavorable seismic event, but displacements are kept under control, the fully suspended deck will align automatically and the whole structure will still be standing without being seriously damaged. Pylon bases were built in two stages near Antirion; the footings were cast first in a dry dock. The conical shafts were completed later in a wet dock (Figure 8) where water deep enough was available. Cells in the base were progressively flooded to sink the structure and maintain a constant height above water. When a pylon base was tall enough to stand a few meters above water, three tugs were taking it to its prepared bed where it was precisely ballasted down. The four bases were placed within a five centimeter tolerance with regards to their theoretical location.

Figure 8: Rion-Antirion Bridge - Towing of a pylon base (left) and erection of the deck (right) Foundation work began in October 1999 by dredging bed locations, laying 90 centimeters of sand, driving the inclusions and leaving them projecting 1.50 meters above the sand to be finally covered by a 1.90 meter thick layer of rounded river gravel and a 50 centimeter thick layer of crushed gravel. All these marine works were performed, step by step, from a tensioned leg platform anchored in movable concrete blocks by adjustable chains. When pylon bases were placed, the octagonal shafts of the pylons were cast in place with self climbing formworks and topped by the huge inverted pyramidal capitals, which are key elements of the Pylon structures and heavily reinforced and prestressed. The pylon legs were progressing step by step, in 5.00 meter long sections, up to the point where they have merged to support the cable anchoring zone. The steel core of the pylon head is made of two pieces which were placed at their final location by a huge floating crane. The method of construction of the composite steel concrete deck (Figure 8) was similar to the one successfully used on the second Severn crossing. Twelve meters long steel-concrete deck elements were prefabricated on a pre-assembly bed; they were placed at their final location by the floating crane and bolted to the previously assembled segments according to the classical balanced cantilever erection method. For practical reasons, first elements had to be skidded in between the pylon legs up to their final location. The following elements were quickly placed thanks to an adapted connecting device which temporarily secured them up to the end of the bolting operation. Clearly, the Rion-Antirion Bridge is a major and impressive link when compared to other achievements. The design and construction of this bridge could overcome an exceptional combination of adverse environmental conditions thanks to the choice of an appropriate concept and seismic design philosophy. Completed in August 2004, the Rion-Antirion Bridge is the longest fully suspended cable-stayed bridge deck in the world.

4.

Present

The concept of cable-stayed bridges has considerably extended the field of Structural Engineering to the design of many crossings which were not possible in the past. Cable-stayed bridges offer a large variety of appearances and presently lead to exceptional achievements all over the world.

Completed at the end of 2004, the Millau viaduct is one of them. This multi-span cable-stayed bridge was incrementally launched, from both sides of the valley by using temporary supports at mid span. Axial masts and stay cables were installed later before temporary pier removal. Consisting of six main spans, 342 meters long, and two side spans, 204 meters long, the Millau viaduct is crossing a deep valley. As a result, the highest pier, 245 meters high, makes the corresponding pylon culminating at 343 meters above the ground. The continuous trapezoidal orthotropic steel deck, designed to resist wind forces, is 32.00 meters wide and 4.20 meters deep. Incremental launching is another heritage from the past which is worth mentioning. Today, cable-stayed bridges are at the origin of a long list of major achievements, with spans ranging from 600 to more than 1,100 meters, most of them being located in China.

Figure 9: The Russky Island Bridge World record in the field of cable stayed bridges It has to be pointed out that, in less than twenty years, the length of the longest span has almost been doubled. The previous record, which was hold since two 2008 by the Sutong bridge across the Yangtze River (China) with a 1,088 meter long main span, has been broken in 2012 by the Russky Island Bridge (Figure 9) crossing the Eastern Bosphorus Strait near Vladivostok (Russia) with a main span 1,104 meters long, a 320 meter high pylon and a longest cable 580 meters in length.

Figure 10: The first extradosed bridge imagined by Jacques Mathivat Today, Extradosed bridges, a concept imagined by Jacques Mathivat in 1988 (Figure 10) as a result of a compromise between classical bridges and cable-stayed bridges are experiencing a fantastic development all over the world. Composite bridges with corrugated steel webs, a structural concept

which was born in France thirty years ago, have a huge success in Japan and start to develop in some other Asian countries. Many kinds of precast segments are produced and assembled every day in the world.

5.

Future

The present is still marked by the past and the future will be undoubtedly impregnated by the present, for some time at least. Present challenges will lead unavoidably to the construction of long links and long span bridges which will reduce the distances between people, the cost of transportation and the necessary time to travel around the world. New materials like High Strength Concrete, Self Compacting concrete, Fiber Reinforced Polymers, Ultra High Performance and Fiber Reinforced Concrete, are already being used. Structures will develop accordingly by using the right material at the right place. Construction techniques have been efficiently improved by using the power of available engines; they might still be surprisingly more impressive in the future thanks to the imagination of engineers. As in the past, structures and construction methods will take advantage of the progress made in other fields of activity. Main span of cable-stayed bridges will undoubtedly reach 12 hundred meters in length, perhaps more, providing that the aerodynamic stability of these sensitive structures is definitely mastered; for this purpose, long span bridges might have to be beneficially equipped with electromechanical computer controlled intelligent systems. There is a lot of inspiration to be picked up from looking "over the fence" to neighboring industries, or simply to other structural fields, by bridge engineers when facing new challenges. As seen previously, huge pier bases have been built by using the construction techniques of gravity based offshore platform and placed in deep water on a well prepared bed from the surface by using techniques used for laying accurately the gravel bed of the Oresund prefabricated immersed tunnel elements. In the same way, the planned Femern fixed link, which will create a direct road between Denmark and Germany, will be made of huge immersed concrete tunnel elements produced in a casting yard, according to the best refinements of the incremental launching construction methods developed for bridges, before being floated and towed to their final location. Global Thinking will be a key for the future of Structural Engineering The use of proven technologies developed in other fields of structural engineering or other industries has brought important advances in the art of bridge engineering in the past fifty years. No doubt this will happen even more in the future as mechanical, electrical and electro hydraulic systems with robot technologies and artificial intelligence become more and more used. Structures to be built in the future will be gigantic, impressive, light and heavy, deep and high, wide and long. They will be challenging major straits, mitigating natural disasters, fighting the power of the wind, of the sea, of the earth, but linking people, countries, continents. They will have to be erected within a short time to improve our daily life as quickly as possible; they will have to be durable and nevertheless maintained. The way this is going to be achieved can be seen from the progress made in design and construction methods. Gigantism is not a fact; it is a need to erect major links, quickly, economically, and safely.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Shear Behaviour of Reinforced Concrete Members Without Stirrups and SubjectedDocument2 pagesShear Behaviour of Reinforced Concrete Members Without Stirrups and Subjectedmonolith80No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Evaluation of Damage Equivalent Factor For Roadway BridgesDocument8 pagesEvaluation of Damage Equivalent Factor For Roadway Bridgesmonolith80No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shrinkage Effect On Beams Strengthened With Additional Concrete LayersDocument2 pagesShrinkage Effect On Beams Strengthened With Additional Concrete Layersmonolith80No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Metropol Parasol, Plaza de La Encarnación - Adventures in EngineeringDocument2 pagesMetropol Parasol, Plaza de La Encarnación - Adventures in Engineeringmonolith80No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

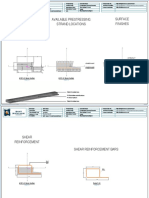

- Prestressed Concrete Girder Bridges Using Large 0.7 Inch StrandsDocument8 pagesPrestressed Concrete Girder Bridges Using Large 0.7 Inch Strandsmonolith80No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Poverty Alleviation Through Bridge BuildingDocument2 pagesPoverty Alleviation Through Bridge Buildingmonolith80No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Innovation in Long Span Concrete BridgesDocument2 pagesInnovation in Long Span Concrete Bridgesmonolith80No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- High-Rise Buildings With Transfer Floors: Drift CalculationsDocument2 pagesHigh-Rise Buildings With Transfer Floors: Drift Calculationsmonolith80100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Rehabilitation and Upgrading of Major Dhyan Chand National StadiumDocument2 pagesRehabilitation and Upgrading of Major Dhyan Chand National Stadiummonolith80No ratings yet

- New football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingDocument2 pagesNew football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingmonolith80No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Challenges in Implementing Urban Transport Projects in MumbaiDocument2 pagesChallenges in Implementing Urban Transport Projects in Mumbaimonolith80No ratings yet

- Suppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000Document19 pagesSuppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000monolith80No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PE Registration Document in Oregon U.SDocument18 pagesPE Registration Document in Oregon U.Smonolith80No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Long-Term Monitoring of White Rhino, Building With Tensegrity SkeletonsDocument9 pagesLong-Term Monitoring of White Rhino, Building With Tensegrity Skeletonsmonolith80No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- A Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary ShapeDocument8 pagesA Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary Shapemonolith80No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SS1 - 1 Chakraborty - LONG PDFDocument7 pagesSS1 - 1 Chakraborty - LONG PDFmonolith80No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Aerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005Document8 pagesAerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005monolith80No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Construction of The La Plata Twinstar DomeDocument7 pagesConstruction of The La Plata Twinstar Domemonolith80No ratings yet

- Hurricane Wind Power Spectra, Cospectra, and Integral Length ScalesDocument20 pagesHurricane Wind Power Spectra, Cospectra, and Integral Length Scalesmonolith80No ratings yet

- Nonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005Document28 pagesNonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005monolith80No ratings yet

- An Analysis of Binary Flutter of Bridge Deck SectionDocument12 pagesAn Analysis of Binary Flutter of Bridge Deck Sectionmonolith80No ratings yet

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Document11 pagesComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80No ratings yet

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Document11 pagesComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bridge Design Manual M 23-50.06 July 2011Document1,316 pagesBridge Design Manual M 23-50.06 July 2011monolith80No ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- Amendment of IRC-SP-114-2019 - Aug 2019 PDFDocument30 pagesAmendment of IRC-SP-114-2019 - Aug 2019 PDFNilay Gandhi100% (2)

- Vertical Equation Foundation-Spread Sheet PDFDocument6 pagesVertical Equation Foundation-Spread Sheet PDFmassive85No ratings yet

- Guidelines For Repair, Retrofitting, and Restoration of Mansory BuildingsDocument28 pagesGuidelines For Repair, Retrofitting, and Restoration of Mansory BuildingsSam Chong100% (1)

- Analysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporDocument4 pagesAnalysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporBilal Ahmed BarbhuiyaNo ratings yet

- Design of Walls and Shear WallsDocument19 pagesDesign of Walls and Shear WallsMay100% (1)

- 4 - Strength Design Method Part 1Document25 pages4 - Strength Design Method Part 1Mohamad Duhoki100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- AWC Beam FormulasDocument26 pagesAWC Beam FormulasR ASTUSNo ratings yet

- 13 - Chapter13Document27 pages13 - Chapter13HundeejireenyaNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- 9011S124 SampleDocument5 pages9011S124 SampleAlbert DimayugaNo ratings yet

- 2770 - 1 (Method of Testing Bond in Reinforced Concrete Part-1 PDFDocument12 pages2770 - 1 (Method of Testing Bond in Reinforced Concrete Part-1 PDFRaj BharaliNo ratings yet

- RCD3601Document20 pagesRCD3601mahmoudNo ratings yet

- Shear Walls: An Introduction to Their Purpose and DesignDocument18 pagesShear Walls: An Introduction to Their Purpose and DesignRubina HannureNo ratings yet

- Macro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtDocument28 pagesMacro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtHemant SonawadekarNo ratings yet

- Japan's 98% recycling rate for asphalt concreteDocument8 pagesJapan's 98% recycling rate for asphalt concreteJin XiaoqingNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design of Shear WallDocument34 pagesDesign of Shear WallSandesh Kumar100% (1)

- APPROVED SOLUTIONS FOR BUILDING CONTROLDocument70 pagesAPPROVED SOLUTIONS FOR BUILDING CONTROLchristian06jbsNo ratings yet

- Theory 1 Plate No. 1Document2 pagesTheory 1 Plate No. 1Reynan FernandezNo ratings yet

- ZZ - 70 - 20 - 10 - 10 - 0072 - (MYE1 Beam Typical Details)Document2 pagesZZ - 70 - 20 - 10 - 10 - 0072 - (MYE1 Beam Typical Details)Eloy Jimenez OntiverosNo ratings yet

- Prevent Plastic Shrinkage Cracks in ConcreteDocument2 pagesPrevent Plastic Shrinkage Cracks in ConcreteSwëêt Rãsçäl SëlvåNo ratings yet

- BOQ Sample For BOQ Magic ToolDocument38 pagesBOQ Sample For BOQ Magic Toolstimayo010809No ratings yet

- Materials and Workmanship Specifications (Revision A9, May 2009) - NewDocument562 pagesMaterials and Workmanship Specifications (Revision A9, May 2009) - NewTint Lwin Oo100% (1)

- Methods of Analysis For Earthquake Resistant Structures Wendor CherekeDocument40 pagesMethods of Analysis For Earthquake Resistant Structures Wendor CherekeTem Pouno100% (1)

- Jon Williams Dam Sftey Article Townsville - PDF GHD Design Lenthalls Dam GatesDocument7 pagesJon Williams Dam Sftey Article Townsville - PDF GHD Design Lenthalls Dam GatesLenthallsdamgatefailNo ratings yet

- Standard Designs & Details - Drawings: Network Rail StandardsDocument18 pagesStandard Designs & Details - Drawings: Network Rail StandardsjonNo ratings yet

- Government of Nepal road construction bill of quantitiesDocument24 pagesGovernment of Nepal road construction bill of quantitiesnitish JhaNo ratings yet

- FEA of Axial Members, Beams and Frames (Lecture 1-4)Document51 pagesFEA of Axial Members, Beams and Frames (Lecture 1-4)Hammad PervezNo ratings yet

- STEEL STRUCTURES (Lect#01)Document36 pagesSTEEL STRUCTURES (Lect#01)Rizwan DogerNo ratings yet

- Raft Xls - ProjectDocument10 pagesRaft Xls - ProjectDilon TkhomaNo ratings yet

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)