Professional Documents

Culture Documents

Reverse Engg

Uploaded by

Martha Bianca ZunigaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reverse Engg

Uploaded by

Martha Bianca ZunigaCopyright:

Available Formats

1. Spindle for Film - It is to be used for electric motor and film rewind handle 2.

Film Turner - This part leads from the outer casing to the inside gears that turn the spindle for the film. The part is of a specific design for this camera because it is an extension of the original disposable camera through the waterproof casing to the outside. This part consists of material that has a grip to it as well as notches to allow for easy turning capabilities. There are two gears connected to this inside the camera that turn the spindle to move the film out of the cannister. One of these gears is specifically designed to have numbers on it to allow the user to know how many pictures are left on the camera. 3. Center Sprocket Gear - By spinning the sprockets, the camera can pull the film, advancing it for the next exposure. These sprockets are made of plastic or metal, and are attached to either the motor drive or the film advance lever. 4. Exposure Number Gear - Controls the exposure of the camera 5. O-ring Gasket - They are used primarily for sealing. - The only thing sitting between the camera and the ocean - To keep water out - A means for closing off a passageway preventing an unwanted escape or loss of fluid. - O-rings are the most important components of your underwater camera system. If the O-ring is lubricated, it will be elastic enough to shape itself uniformly around the channel. If it is dry, there will be too much friction to allow it to reshape itself uniformly. 6. Film Turner Gear - Associated with film turner for turning capabilities of the film 7. Film Casing - To seal the simple disposable camera to prevent water from entering inside and ruining the camera. The grip on this section of the camera is ergonomically designed to fit the grip of a person taking a picture.

Rubber The resistance of rubber to water and to the action of most fluid chemicals has led to its use in rainwear, diving gear, and chemical and medicinal tubing, and as a lining for storage tanks, processing equipment, and railroad tank cars. Rubber is also strong, long lasting and durable. An important part of the camera, the o-ring gasket, is commonly made of rubber. This is the material used for this component because of the resistance of rubber to water. This property of the material is suitable for the function of the o-ring which is for sealing and preventing water to get in the camera. Rubber is also used for the waterproof casing. Applying a breathable, water-resistant coating to a porous surface usually involves silicon-based materials. The most common varieties include siloxane, silane, and silicone rubber, which are appealing due to their effectiveness in penetrating substrates without compromising porousness. In addition to being silicon-based, these materials share a number of other characteristics, including a high level of breathability and the capacity for being applied to most products without noticeably altering their appearance. Silicone rubber is a thermally resistant waterproofing material with a silicon-oxygen base. As a type of rubber, it exhibits standard elastomeric properties, such as high flexibility and tensile strength. When used in waterproofing, it is usually room temperature vulcanized and can undergo a chemical reaction to form resin in a substrate without the presence of alkaline or silica. This allows silicone rubber to effectively waterproof very porous surfaces, such as those made of natural stone and wood. Some of the other defining characteristics of silicone rubber include: Increased Resistance: Due to the production and refinement processes required to make silicone rubber, it is essentially an inorganic material. This makes it more resistant than silane and siloxane are to acid rain, ultraviolet light, sodium, and corrosive airborne particles. Elasticity: Even after vulcanization, silicone rubber retains much of its original flexibility, enabling it to repair minor cracks or fractures in a substrate when applied as a waterproofing material. Longevity: Its broader range of resistances allows silicone rubber to maintain a waterproof seal for longer periods than its silane and siloxane counterparts. Although it is less prone to deterioration than silane and siloxane, silicone rubber also penetrates surfaces to a shallower depth, meaning its waterproof seal only adheres to the surface of a product or structure. Rubber Hardness

A property of the rubber you have to consider when choosing an O-ring -- the hardness of the rubber. Rubber material can be made very soft, a low durometer reading, to very hard, a high durometer reading. The hardness is usually called out in increments of 5 durometer points, for example 60, 65, 70 and so on. The hardness of rubber also has a tolerance of 5 points. This is due to the fact the hardness is hard to control because of all the variables involved in the compounding and the manufacturing process. Sources: http://www.steves-digicams.com/knowledge-center/how-tos/digital-cameraoperation/camera-parts-winding-sprockets.html http://blogs.saic.edu/fvnmatech/files/2012/09/BolexStarterGuide.pdf http://www.thomasnet.com/articles/plastics-rubber/silicon-based-waterproof-material

You might also like

- RJDFGDocument1 pageRJDFGMartha Bianca ZunigaNo ratings yet

- Ref Paper CwtsDocument1 pageRef Paper CwtsMartha Bianca ZunigaNo ratings yet

- A. Light Spectra of Different Colored Leds A.1 RedDocument5 pagesA. Light Spectra of Different Colored Leds A.1 RedMartha Bianca ZunigaNo ratings yet

- Ferdinand Marcos Regime and the Rise of OFWsDocument1 pageFerdinand Marcos Regime and the Rise of OFWsMartha Bianca ZunigaNo ratings yet

- Bio RPRPDocument1 pageBio RPRPMartha Bianca ZunigaNo ratings yet

- Autho LetterDocument2 pagesAutho LetterMartha Bianca ZunigaNo ratings yet

- BiowDocument2 pagesBiowMartha Bianca ZunigaNo ratings yet

- Plant Tour Reaction PaperDocument1 pagePlant Tour Reaction PaperMartha Bianca ZunigaNo ratings yet

- MtinDocument1 pageMtinMartha Bianca ZunigaNo ratings yet

- Sperm Gene Points To Infertility CureDocument1 pageSperm Gene Points To Infertility CureMartha Bianca ZunigaNo ratings yet

- Assigns PowsDocument2 pagesAssigns PowsMartha Bianca ZunigaNo ratings yet

- Girl with Pearl Earring Painting AnalysisDocument1 pageGirl with Pearl Earring Painting AnalysisMartha Bianca ZunigaNo ratings yet

- Bio R AdaDocument6 pagesBio R AdaMartha Bianca ZunigaNo ratings yet

- Bio DataDocument1 pageBio DataMartha Bianca ZunigaNo ratings yet

- Alcohol HealthDocument1 pageAlcohol HealthMartha Bianca ZunigaNo ratings yet

- First McDonald's in the PhilippinesDocument2 pagesFirst McDonald's in the PhilippinesMartha Bianca ZunigaNo ratings yet

- 4th YearDocument1 page4th YearMartha Bianca ZunigaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Comp7 - Answer Key - Dec. Exam - 1st SetDocument2 pagesComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaNo ratings yet

- Pic24fj256ga705 Family Data Sheet Ds30010118eDocument424 pagesPic24fj256ga705 Family Data Sheet Ds30010118eD GzHzNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Oral Hygiene: Presented By: Anis Anis Andreas KyriakidisDocument60 pagesOral Hygiene: Presented By: Anis Anis Andreas Kyriakidislenami_91No ratings yet

- The Evolution of Order DiprotodontiaDocument35 pagesThe Evolution of Order DiprotodontiaMarianne Michelle Quiambao de la RosaNo ratings yet

- IOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Document82 pagesIOM Paquetes DX Precedent RT-SVX22U-EN - 03072018Mario Lozano100% (1)

- Culinary History and Nouvelle CuisineDocument4 pagesCulinary History and Nouvelle CuisineARPITA BHUNIANo ratings yet

- SWZ Upgrade Points 062022Document19 pagesSWZ Upgrade Points 062022IcyAviatorNo ratings yet

- Comparing characteristics and properties of various crude oilsDocument2 pagesComparing characteristics and properties of various crude oilsnishant bhushanNo ratings yet

- 1625-De Dwks Parts ListDocument69 pages1625-De Dwks Parts ListSasan AbbasiNo ratings yet

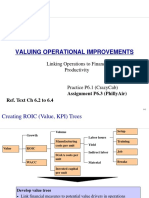

- 2 Linking Operations To Finance and ProductivityDocument14 pages2 Linking Operations To Finance and ProductivityAidan HonnoldNo ratings yet

- Audit Reveals Optimization Opportunities for Cement Ball Mill SystemDocument19 pagesAudit Reveals Optimization Opportunities for Cement Ball Mill SystemVijay Bhan100% (2)

- Elcometer Wet-Film Gage 115 Spec SheetDocument2 pagesElcometer Wet-Film Gage 115 Spec SheetMary CasillasNo ratings yet

- X Wing - Quick.referenceDocument6 pagesX Wing - Quick.referenceatilaT0RNo ratings yet

- World Ranking For Industrial Trucks DHF 2015Document2 pagesWorld Ranking For Industrial Trucks DHF 2015MA TotalforkliftNo ratings yet

- Science Technologyand International RelationsDocument20 pagesScience Technologyand International RelationsMuhammad HussainNo ratings yet

- Tests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Document1 pageTests On Cement: IS: 4031 Part 4 1988 (Indian Standards)Lorna BacligNo ratings yet

- AmadeusDocument3 pagesAmadeusCleofe Mae Piñero AseñasNo ratings yet

- Ahmed 2022Document20 pagesAhmed 2022Mariela Estefanía Marín LópezNo ratings yet

- Hoa ReviewerDocument3 pagesHoa ReviewerRachel Mae BahoyNo ratings yet

- Water Demand Fire Flow Calculation Hydraulic ModelingDocument110 pagesWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNo ratings yet

- Aqua Mon 4000 PH Red Ox AnalyserDocument4 pagesAqua Mon 4000 PH Red Ox Analyserarvindgupta_2005No ratings yet

- Simple LED Flasher CircuitsDocument5 pagesSimple LED Flasher CircuitsVivek BNo ratings yet

- HTP 12 SkodaDocument3 pagesHTP 12 SkodamihnutzuNo ratings yet

- Chapter 4: Input/Output Programming of 8051 CPUDocument7 pagesChapter 4: Input/Output Programming of 8051 CPUIsmailNo ratings yet

- Price List Grand I10 Nios DT 01.05.2022Document1 pagePrice List Grand I10 Nios DT 01.05.2022VijayNo ratings yet

- Premchand Deliverance Download in PDFDocument4 pagesPremchand Deliverance Download in PDFRiya W100% (3)

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- Max 223C Pipeline Welding InverterDocument2 pagesMax 223C Pipeline Welding InvertermtonellyNo ratings yet