Professional Documents

Culture Documents

Len Zing

Uploaded by

khali54Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Len Zing

Uploaded by

khali54Copyright:

Available Formats

Journal of Loss Prevention in the Process Industries 11 (1998) 391395

Critical mass ow rate in accordance with the omega-method of DIERS and the Homogeneous Equilibrium Model

T. Lenzing a, L. Friedel

a

a,*

, M. Alhusein

b,1

Department of Fluid Mechanics, Technische Universita t Hamburg, Eisendorfer Strasse 38, 21073 Hamburg, Germany b Mutah University, Al Karak, Jordan

Abstract A correlation frequently used in practice for the design of the relief cross-section next to the Homogeneous Equilibrium Model is the so-called -method. For the determination of the -parameter a denition was originally reported by J.C. Leung in 1986. A new expression was proposed by the same author in 1995. Predictions of the critical mass ow rate using both the new and the old -parameter formulations as well as the Homogeneous Equilibrium Model are compared for some typical substances. Results demonstrate that the deviations as a rule are acceptable for practical use, if the proposed range of application and recommended property data calculation are respected. 1998 Elsevier Science Ltd. All rights reserved.

Keywords: -method; Homogeneous Equilibrium Model; Critical mass ow; Two-phase ow

Nomenclature cp G* h n p s T x* x0 Subscripts V/G L G hom crit 0 Specic heat at constant pressure Mass ow rate Specic enthalpy Exponent of the state change Pressure Specic entropy Temperature Specic volume Flow mass vapour/gas quality Stagnation mass vapour/gas rate Isentropic exponent Vapour Liquid Gas Homogeneous Fluid dynamic critical condition Stagnation condition

1. Introduction Proper calculation of the critical mass ow rate plays a signicant role in the uid dynamic design for twophase ow duty, e.g. of safety relief systems. Overestimation may result in a serious accident by undersizing the safety valve that would not be able to reduce the pressure in the protected installation. On the other hand, underestimation of the critical mass ow rate may lead to overload in the outlet installation. The classical Homogeneous Equilibrium Model (HEM) was recently chosen by the DIERS for emergency relief sizing design (Fisher, 1991; Huff, 1985; Leung, 1992). Although this is considered by experts to be a conservative method with respect to the calculation of the required relief area, evaluation of the HEM involves a lengthy (iterative) procedure and requires detailed thermodynamic property tabulation (Leung & Nazario, 1990). A generalised correlation for onecomponent homogeneous equilibrium ashing choked ow was published by J.C. Leung in 1986 (Leung, 1986) for simplifying this procedure. It has come to be known as the omega method since an -parameter rst proposed by Epstein et al. (1983), comprising dimensionless physical property groups, was introduced to characterise a wide range of uid conditions. As only stagnation

* Corresponding author. Tel.: + 49-40-77183052; Fax: + 49-4077182573. 1 Alexander von Humboldt Fellow.

09504230/98/$see front matter 1998 Elsevier Science Ltd. All rights reserved. PII: S 0 9 5 0 - 4 2 3 0 ( 9 8 ) 0 0 0 2 2 - 9

392

T. Lenzing et al. / Journal of Loss Prevention in the Process Industries 11 (1998) 391395

properties are required, this method can be used in most engineering calculations, especially those where extensive property data are not readily available. In 1995, a slightly modied form of the -parameter was proposed by Leung (1995), which has the attribute of bringing out key parameters in connection with the compressible nature of a two-phase ow system. The denition of the -parameter was originally based on the assumption of an isothermal state change of the two-phase mixture (Leung, 1986). With this, deviations appear with respect to the critical mass ow rate as opposed to the normally isentropic gas or vapour state change, as a limiting case of the two-phase ow, of up to 20%. In the modied correlation this limit value is more adequately included. So, the question arises of how far this correction affects the critical mass ow rate predictions in the complete range of the two-phase ow. To answer this question, the predictions in accordance with both the old and the new -parameter formulations, as well as the HEM, were compared for some typical substances and different operational conditions. The most essential calculation equations are presented. 2. Critical mass ow rate models The critical mass ow rate formulations according to both the HEM and the -method are presented only briey. However, these equations and the way they are arrived at can be found elsewhere (Leung, 1986, 1995; VDI-Wa rmeatlas, 1994). In the HEM the ideal case of a frictionless, adiabatic ow, and the immediate delay free establishment of saturation values for density and temperature during the (fast) relief are assumed. Furthermore, the two phases ow with the same average velocity. The mass ow rate is dened as G* = 2(h(p0) h(p))/hom(p) with h(p) = x*hV/G(p) + (1 x*)hL(p) and

the stagnation mass quality x0 is determined as: x0 = MV/G MV/G + ML

The critical mass ow rate is obtained by numerically searching for the maximum value as a function of the (static) nozzle exit pressure: starting at the stagnation pressure the exit pressure is lowered in discrete steps until the critical ow rate is obtained. As an explicit approximate solution for the HEM the -method contains a polytropic instead of an isentropic state change of the two-phase mixture. The critical mass ow rate results from the quotient of sound velocity a2ph and specic volume of the homogeneous mixture hom at the so-called uid dynamic critical pressure G*crit = 2ph/hom = 2p0/hom(p0)( ln(pcrit/p0) + (1 )(pcrit/p0 1))/ ((p0/pcrit 1) + 1) where the critical pressure can be calculated from (pcrit/p0)2 + (2 2)(1 pcrit/p0)2 + 22 ln(pcrit/p0) + 22(1 pcrit/p0) = 0 To solve iteratively for the determination of the uid dynamic critical pressure, the equation can be replaced through for the range from 1 to 100 pcrit = p0(0.55 + 0.217 ln() 0.046(ln())2 + 0.004(ln())3) The -parameter characterises the initial compressibility of the mixture and the increase due to the phase transition. It contains the mean void fraction in the stagnation state as well as the Jakob number (Epstein et al., 1983) and has the following denition for the old expression:

1986 = x0V(p0)/hom(p0) + cpLT(p0)p0/hom(p0)

hom(p) = (x*V/G(p) + (1 x*)L(p)

Here h is the specic enthalpy, s is the specic entropy, L, V/G and hom are the specic volumes of liquid, vapour or gas and the homogeneous mixture, respectively, p0 is the stagnation pressure and x* is the mass ow vapour/gas quality. For an isentropic state change the quality is x* = x0(sV/G(p0) sL(p0)) + sL(p0)) sL(pcrit) sV/G(pcrit) sL(pcrit)

V(p0) L(p0) hV(p0) hL(p0)

and for the modied correlation is

1995 = x0V(p0)/hom(p0) 1

+ cpLT(p0)p0/hom(p0)

2p0(V(p0) L(p0)) hV(p0) hL(p0)

V(p0) L(p0) hV(p0) hL(p0)

T. Lenzing et al. / Journal of Loss Prevention in the Process Industries 11 (1998) 391395

393

Here T denotes the temperature and cpL is the liquid specic heat. The expressions can be reduced for two-phase mixtures with a negligibly small evaporation to

1986 = x0G(p0)/hom(p0) 1995 = x0/G(p0)/hom(p0)

For the calculation of the critical mass ow rates at a thermodynamic critical pressure or temperature ratio of more than 0.5 and 0.9, respectively, the liquid specic heat, which is not usually known in this range sufciently exactly, is replaced by the term hL/Tp0 (Leung, 1986), in which J.C. Leung (personal communication, 1996) recommends a temperature difference of 2 K. An advantage of the -method, besides the possibility of the explicit calculation of the critical mass ow rate, is the low number of required uid properties. Only at the set pressure of the safety device are the temperature and pressure as well as the specic volumes and enthalpies needed. However, this simplication has an adverse effect on the calculation of the specic volume (Simpson, 1995). For example, for an air/water mixture at a pressure of 50 bar (absolute) and temperature of 25C, the specic volume differs by around 27% and in the case of a butane gas/liquid mixture at a pressure of 30 bar (absolute) the difference is about 14% of the correct uid property. These inaccuracies lead to considerable deviations in the calculated values of the critical mass ow rate compared with the values calculated by the HEM. The determination of the liquid enthalpy temperature gradient also causes difculties in practice, because the uid properties of the sub-cooled liquid are needed, which are only known for a few substances, as a rule. In the following, the predictions of the critical mass ow rates according to the HEM and both correlations of the -method are compared for selected two-phase mixtures and operating states.

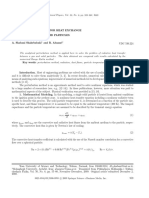

Fig. 1. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for water at a thermodynamic critical pressure ratio of 0.09.

with the old -parameter the lower boundary is given. However, deviations between the predictions of the calculation methods should, for technical reasons, be negligible, especially as the preference for the models selection is based on a convention. At a pressure of 100 bar (absolute), which equals a thermodynamic critical pressure ratio of 0.45, the term hL/Tp0 is used instead of the specic heat. This is because the relative temperature ratio of 0.9 as a limit is about to be exceeded. This is also contrary to the recommendation that the critical mass ow rate is applied by using the specic heat (Leung, 1986). Here, this still does not lead to deviations and the trends of the predictions are almost identical as shown in Fig. 2. The differences between the two mass ow rates predicted by the -method are based on the denition of the parameter in both old and new correlations. As opposed to the critical mass ow rates calculated with the HEM the deviations are approximately 6% and 3%, respectively. Once

3. Predictions of the critical mass ow rates The calculations were made at rst for a steam/water mixture at three thermodynamic critical conditions of pressure and temperature. In Fig. 1 the critical mass ow rate is plotted against the stagnation mass quality at a relative pressure ratio of 0.09. All curves show a similar course, starting from the largest mass ow rate at liquid ow, decreasing strongly with increasing stagnation mass quality and approaching asymptotically the lower value at steam ow, which is, however, only reached by the HEM. The latter represents the upper limitation about the complete range of the two-phase ow, whereas

Fig. 2. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for water at a thermodynamic critical pressure ratio of 0.45.

394

T. Lenzing et al. / Journal of Loss Prevention in the Process Industries 11 (1998) 391395

more, with the HEM one can get the highest results whereas the lowest are obtained by the old -method. Also, as demonstrated in Fig. 3, this order continues near the thermodynamic critical condition at a pressure ratio of 0.9 (a pressure of water of 200 bar absolute). Again, the HEM represents the upper limit. With the old and new -parameter, using three values of temperature difference (1, 2 and 5 K) clearly lower results are obtained. The deviations are directly proportional to the size of the temperature difference. The lower this is, the smaller the discrepancies between the calculated critical mass ow rates in accordance with the -method and the HEM. The lowest results for the critical mass ow rate are calculated using the liquid specic heat (contrary to the recommendation given in Leung, 1986). They are up to 50% lower than those in accordance with the HEM. The deviations which result from the new expression of the polytropic exponent are once more against this by only about 6%. On the basis of the uid properties of the refrigerant R12 the fundamental course of the curves is the same as before (Figs. 4 and 5). However, at a thermodynamic critical pressure ratio of 0.9 the differences increase between the calculations with increasing stagnation mass quality, in which for the case of a vapour ow the predictions in accordance with the -method are up to 22% too small (Fig. 6). The HEM represents an upper limit once more. The deviations between the predictions of the critical mass ow rates, using the specic heat, are lower here as in the case of steam/water mixture. Nevertheless, in principle, Leungs instruction to use the enthalpy gradient with respect to temperature, as an alternative the term hL/Tp0 is sound. Calculations for a chlorine vapour/liquid mixture at a thermodynamic critical pressure ratio of 0.9 conrm the observations for water and the refrigerant R12 in terms of the trend of the curves; however, the relative differ-

Fig. 4. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for refrigerant R12 at a thermodynamic critical pressure ratio of 0.09.

Fig. 5. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for refrigerant R12 at a thermodynamic critical pressure ratio of 0.45.

Fig. 3. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for water at a thermodynamic critical pressure ratio of 0.9.

Fig. 6. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for refrigerant R12 at a thermodynamic critical pressure ratio of 0.9.

T. Lenzing et al. / Journal of Loss Prevention in the Process Industries 11 (1998) 391395

395

poses. However, it is surprising, that the predictions in accordance with the -method lie insignicantly over those obtained with the HEM.

4. Conclusions In general, it is valid to say that the use of either the old or the new -parameter correlation could result in deviations between each other in the calculation of critical mass ow rates. These should be negligible in practice, as a rule, if faults of up to 10% are tolerable. For the uids considered, the contrary use of the specic heat near the thermodynamic critical state shows, in contrast to the predictions in accordance with the homogeneous equilibrium model, deviations of up to 50% with increasing pressure. With correct use of the temperature gradient on the liquid enthalpy curve at constant pressure the size of the differences calculated for the critical mass ow rates depends on the temperature difference. The value recommended by J.C. Leung of 2 K leads in individual cases to deviations of up to 25% as opposed to the predictions of the homogeneous equilibrium model. Leung (1996) Personal communication not cited in text.

Fig. 7. Critical mass ow rate according to J.C. Leungs original and modied model and the homogeneous equilibrium model as a function of stagnation quality for chlorine at a thermodynamic critical pressure ratio of 0.9.

References

Epstein, M., Henry, R. E., Midvidy, W., & Pauls, R. (1983). Onedimensional modeling of two-phase jet expansion and impingement. Second International Topical Meeting on ThermalHydraulics Nuclear Reactors, St. Barbara. Fisher, H. G. (1991). An overview of emergency relief system design practice. Plant/Operations Progress, 10(1), 1. Huff, J. E. (1985). Multiphase ashing ow in pressure relief systems. Plant/Operations Progress, 4, 191. Leung, J. C. (1986). A generalized correlation for one-component homogeneous equilibrium ashing choked ow. AIChE J., 32(10), 17431746. Leung, J. C. (1992). Size safety relief valves for ashing liquids. Chem. Eng. Progress, 88(2), 70. Leung, J. C. (1995). The Omega method for discharge rate evaluation. Runaway Reactions and Pressure Relief Design. Int. Symp., Boston. Leung, J. C. (1996). Personal communication, September 11th. Leung, J. C., & Nazario, F. N. (1990). Two-phase ashing ow methods and comparisons. J. Loss Prevention Process Industries, 3(2), 253. Simpson, L. L. (1995). Navigating the two-phase maze. Runaway Reactions and Pressure Relief Design. Int. Symp., Boston. VDI-Wa rmeatlas (1994). Berechnungsbla tter fu rmeu r den Wa bergang, Abschn. Lgcl/2: Kritische Massenstromdichte, Du sseldorf.

Fig. 8. Critical mass ow rate according to J.C. Leungs original and modied model as a function of stagnation quality and pressures for an air/water mixture.

ences are lower (Fig. 7). In general, for single-component two-phase ows, a better adjustment of the predictions is carried out with the modied -parameter than one in accordance with the HEM. Comparing the predictions for the case of an air/water mixture it can be recognized that unlike the previous results in the range of small to nearly medium mean stagnation mass qualities, the results obtained lie closer to those of the HEM when the old -parameter method is used compared with the new denition (Fig. 8). The differences between the curves corresponding to the old and the new expressions become larger with increasing pressure; however, they are negligible for technical pur-

You might also like

- Multiparameter Equations of State An Accurate Source of Thermodynamic Property Data Span 2000Document46 pagesMultiparameter Equations of State An Accurate Source of Thermodynamic Property Data Span 2000Fátima ReyesNo ratings yet

- Two Phase Flow Safety ValveDocument7 pagesTwo Phase Flow Safety Valversingle81No ratings yet

- Phase Change SimulationDocument106 pagesPhase Change SimulationAshish AgarwalNo ratings yet

- Implementation of Optimal Operation For Heat Integrated Distillation ColumnsDocument5 pagesImplementation of Optimal Operation For Heat Integrated Distillation ColumnsbiniyamNo ratings yet

- Fast Evaluation of Thermodynamic Properties of Superheated Steam A Cubic Equation of StateDocument9 pagesFast Evaluation of Thermodynamic Properties of Superheated Steam A Cubic Equation of StateShalehAhmadNo ratings yet

- Thermodynamics 2Document77 pagesThermodynamics 213670319No ratings yet

- Byoyancy Flow in Free Fluids PDFDocument12 pagesByoyancy Flow in Free Fluids PDFAl Farabi100% (1)

- Phase Equilibria Gernert Et Al Fpe 2014Document10 pagesPhase Equilibria Gernert Et Al Fpe 2014RoseJauneNo ratings yet

- Buoyancy Flow in Free Fluids: Created in COMSOL Multiphysics 5.4Document12 pagesBuoyancy Flow in Free Fluids: Created in COMSOL Multiphysics 5.4Sadegh AhmadiNo ratings yet

- Solutions To Gas Dyamics FunctionsDocument17 pagesSolutions To Gas Dyamics Functionsir-onesNo ratings yet

- Comp Gas Flow FormulaDocument10 pagesComp Gas Flow FormulajamestppNo ratings yet

- Measuring saturation properties of waterDocument6 pagesMeasuring saturation properties of waterKalson UmpuNo ratings yet

- Applications: of ThermDocument7 pagesApplications: of ThermThaligari Sandeep KumarNo ratings yet

- Technip Separations PDFDocument35 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Steady Periodic Gas Flow Around A Well of A CAES Plant: Roy Kushnir Amos Ullmann Abraham DayanDocument20 pagesSteady Periodic Gas Flow Around A Well of A CAES Plant: Roy Kushnir Amos Ullmann Abraham DayansasikalasivakumarNo ratings yet

- Calculation of Vapor-Liquid-Liquid Equilibria For The Fischer-Tropsch Reactor Effluents Using Modified Peng-Robinson Equation of StateDocument31 pagesCalculation of Vapor-Liquid-Liquid Equilibria For The Fischer-Tropsch Reactor Effluents Using Modified Peng-Robinson Equation of StatekenymorenoNo ratings yet

- Major equations of state overviewDocument12 pagesMajor equations of state overviewDHe Vic'zNo ratings yet

- Processes: Simulation of High Pressure Separator Used in Crude Oil ProcessingDocument14 pagesProcesses: Simulation of High Pressure Separator Used in Crude Oil ProcessingManuel ChNo ratings yet

- Calculation JT CoefficientDocument5 pagesCalculation JT CoefficientGabriel Pereira CrivellariNo ratings yet

- Michelsen The Isothermal Flash Problem 2 PhasDocument20 pagesMichelsen The Isothermal Flash Problem 2 Phasgggggg82No ratings yet

- IsentropicDocument42 pagesIsentropicDeepak JayNo ratings yet

- 1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenDocument15 pages1987 - Multiphase Isenthalpic and Isentropic Flash Algorithms - MichelsenhakeemniyasNo ratings yet

- Rheology of Oil Base MudDocument12 pagesRheology of Oil Base MudSi UcOpNo ratings yet

- Ie9706424 PDFDocument6 pagesIe9706424 PDFIsrael HernándezNo ratings yet

- Muhammad H. GhaniDocument18 pagesMuhammad H. GhaniKhalid Al-RawiNo ratings yet

- Finite Element Analysis of Coupled Thermoelasticity PDFDocument8 pagesFinite Element Analysis of Coupled Thermoelasticity PDFCarlosNo ratings yet

- Chap 4Document15 pagesChap 4DrRat P RatanamalayaNo ratings yet

- Asst. Prof. Dr. Hayder Mohammad Jaffal: Homogeneous Two-Phase FlowDocument28 pagesAsst. Prof. Dr. Hayder Mohammad Jaffal: Homogeneous Two-Phase FlowprasanthiNo ratings yet

- Density Variation in Finite Volume SchemesDocument5 pagesDensity Variation in Finite Volume Schemeshhqq2010No ratings yet

- HETP Por Metodos CortrosDocument4 pagesHETP Por Metodos CortrosmisaelNo ratings yet

- Application of The Van Der Waals Equation of State To Polymers I. CorrelationDocument28 pagesApplication of The Van Der Waals Equation of State To Polymers I. CorrelationFernando HenriqueNo ratings yet

- Thermodynamics Selection in Chemcad1Document39 pagesThermodynamics Selection in Chemcad1Yashpal MalikNo ratings yet

- What Is The Joule-Thomson Effect?Document10 pagesWhat Is The Joule-Thomson Effect?Vivi OktaviantiNo ratings yet

- SenkinDocument26 pagesSenkinSudip AdhikariNo ratings yet

- Simple Functions For Fast Calculations of Selected Thermodynamic Properties of The Ammonia-Water SystemDocument7 pagesSimple Functions For Fast Calculations of Selected Thermodynamic Properties of The Ammonia-Water SystemEngineer1987No ratings yet

- On The Validity of The Boussinesq Approximation in A Tall Differentially Heated Cavity With WaterDocument7 pagesOn The Validity of The Boussinesq Approximation in A Tall Differentially Heated Cavity With WatercrazzyrajNo ratings yet

- Simulation of Oil Tank FiresDocument12 pagesSimulation of Oil Tank Firesengtrader100% (1)

- Averaging Nonuniform Flow For A PurposeDocument10 pagesAveraging Nonuniform Flow For A PurposeAli Al-hamalyNo ratings yet

- Thermo FluidDocument15 pagesThermo FluidLau YeowhongNo ratings yet

- Prediction of Two-Phase Pressure Gradients of Refrigerants in Horizontal TubesDocument13 pagesPrediction of Two-Phase Pressure Gradients of Refrigerants in Horizontal TubesNguyen Chien100% (1)

- Calculation of Phase Envelopes and Critical Points For Multicomponent MixturesDocument10 pagesCalculation of Phase Envelopes and Critical Points For Multicomponent Mixturesflavio_cordero_1No ratings yet

- How to Estimate Compressor Efficiency in 3 StepsDocument11 pagesHow to Estimate Compressor Efficiency in 3 Stepsruben pachonNo ratings yet

- SOP CalculationDocument8 pagesSOP Calculationmatteo2009No ratings yet

- Liquid Holdup in Geothermal Wells: Sabodh K. Garg, John W. Pritchett, and James H. AlexanderDocument7 pagesLiquid Holdup in Geothermal Wells: Sabodh K. Garg, John W. Pritchett, and James H. AlexanderIrwan JanuarNo ratings yet

- AIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A ReappraisalDocument10 pagesAIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A Reappraisalneozero2006No ratings yet

- Joule ThomsonDocument3 pagesJoule ThomsonLeandro BuosiNo ratings yet

- CO2 Depressurisation OLGADocument8 pagesCO2 Depressurisation OLGAMaheshNo ratings yet

- (Doi 10.1002/3527601996.ch13) Wittig, Sigmar Vöhringer, Otmar Kim, Soksik - High Intensity Combustors - Steady Isobaric Combustion (DFG SF High-Int. Combust. O-BK) - Numerical Modelling of CombuDocument17 pages(Doi 10.1002/3527601996.ch13) Wittig, Sigmar Vöhringer, Otmar Kim, Soksik - High Intensity Combustors - Steady Isobaric Combustion (DFG SF High-Int. Combust. O-BK) - Numerical Modelling of CombuawarialocksNo ratings yet

- Martinez Hw1Document6 pagesMartinez Hw1Fernando Arellano GuerreroNo ratings yet

- M24 - Thermodynamic PropertiesDocument38 pagesM24 - Thermodynamic Propertieshoghost123No ratings yet

- Combustion and Flame Volume 48 Issue None 1982 (Doi 10.1016/0010-2180 (82) 90112-2) W.P. Jones J.H. Whitelaw - Calculation Methods For Reacting Turbulent Flows - A ReviewDocument26 pagesCombustion and Flame Volume 48 Issue None 1982 (Doi 10.1016/0010-2180 (82) 90112-2) W.P. Jones J.H. Whitelaw - Calculation Methods For Reacting Turbulent Flows - A Reviewcoolatuber1No ratings yet

- Vent Sizing Applications For Reactive SystemsDocument10 pagesVent Sizing Applications For Reactive SystemsAritraDalalNo ratings yet

- Compositional Hydrocarbon Reservoirs. Continuous ThermodynamicsDocument16 pagesCompositional Hydrocarbon Reservoirs. Continuous Thermodynamicsleo_rugeNo ratings yet

- PHASE CHANGESDocument12 pagesPHASE CHANGESmegakiranNo ratings yet

- A Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir FluidsDocument17 pagesA Improving Predictions of Equation of State by Modifying Its Parameters For Super Critical Components of Hydrocarbon Reservoir Fluids13670319No ratings yet

- Numerical Analysis of Suction MufflersDocument11 pagesNumerical Analysis of Suction MufflersJose PradoNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- La Propagation de FlammeDocument3 pagesLa Propagation de Flammekhali54No ratings yet

- OSHA To Inspect Plants Like Ga. Refinery: News NationDocument2 pagesOSHA To Inspect Plants Like Ga. Refinery: News Nationkhali54No ratings yet

- Chemical Kinetics of Biomass PyrolysisDocument10 pagesChemical Kinetics of Biomass Pyrolysiskhali54No ratings yet

- Solving ODEs With Matlab Instructors Manual - L.F. ShampineDocument36 pagesSolving ODEs With Matlab Instructors Manual - L.F. ShampineHermes®No ratings yet

- Burner Management System Safety Integrity Level SelectionDocument12 pagesBurner Management System Safety Integrity Level SelectionpeterholidayNo ratings yet

- Ws 2016 13-Pdf-EnDocument2 pagesWs 2016 13-Pdf-EnMuhammadUsmanSaeedNo ratings yet

- Yao R. MATLAB Programming in 8 Hours. For Beginners... 2021Document121 pagesYao R. MATLAB Programming in 8 Hours. For Beginners... 2021khali54No ratings yet

- Pipe Labeling To Ansi Asme A13.1Document3 pagesPipe Labeling To Ansi Asme A13.1khali54No ratings yet

- Pipe Flow Expert Quick Start GuideDocument35 pagesPipe Flow Expert Quick Start GuideHadrianus Handoko SaputroNo ratings yet

- DEC09ts PDFDocument19 pagesDEC09ts PDFBoomdayNo ratings yet

- Calculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsDocument5 pagesCalculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsfoamtrailerNo ratings yet

- Pumping Fluids and Getting Fluid To The PumpDocument3 pagesPumping Fluids and Getting Fluid To The PumpTeng Chuan OngNo ratings yet

- The Call of The Wild Illustrated - Cs PDFDocument108 pagesThe Call of The Wild Illustrated - Cs PDFkhali54No ratings yet

- Introduction To MATLAB - Sikander M. MirzaDocument45 pagesIntroduction To MATLAB - Sikander M. MirzaNasir JumaniNo ratings yet

- Net Positive Suction Head or NPSHDocument4 pagesNet Positive Suction Head or NPSHsateesh chandNo ratings yet

- Valeur KV Calcul de Vanne PDFDocument2 pagesValeur KV Calcul de Vanne PDFkhali54No ratings yet

- Loss Prevention in Heavy Industry Risk Assessment of LargeDocument8 pagesLoss Prevention in Heavy Industry Risk Assessment of Largekhali54No ratings yet

- Chapter 14D1 15Document15 pagesChapter 14D1 15khali54No ratings yet

- Valeur KV Calcul de Vanne PDFDocument2 pagesValeur KV Calcul de Vanne PDFkhali54No ratings yet

- Chemcad 6 User GuideDocument202 pagesChemcad 6 User Guideerhan ünal100% (1)

- Inherent SafetyDocument16 pagesInherent Safetykirandevi1981No ratings yet

- Calculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsDocument5 pagesCalculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsfoamtrailerNo ratings yet

- Valeur KV Calcul de Vanne PDFDocument2 pagesValeur KV Calcul de Vanne PDFkhali54No ratings yet

- Control System Design PDFDocument6 pagesControl System Design PDFkhali54No ratings yet

- Perturbation method for heat exchange between gas and particlesDocument6 pagesPerturbation method for heat exchange between gas and particleskhali54No ratings yet

- DocuVS7 1 4Document8 pagesDocuVS7 1 4khali54No ratings yet

- ExlopaDocument8 pagesExlopakhali54No ratings yet

- Simplified Risk Analysis (LOPA)Document8 pagesSimplified Risk Analysis (LOPA)hmatora72_905124701No ratings yet

- Explosions in The Process IndustriesDocument19 pagesExplosions in The Process Industrieskhali54No ratings yet

- Chemical Exposure IndexDocument23 pagesChemical Exposure IndexwankartikaNo ratings yet

- Salvador, S - EXP4 - Adiabatic Flame TemperatureDocument19 pagesSalvador, S - EXP4 - Adiabatic Flame Temperatureshy salvadorNo ratings yet

- Tutorial SheetsDocument2 pagesTutorial SheetsshinussssNo ratings yet

- Paper 3Document6 pagesPaper 3Srinivasan VairamanickamNo ratings yet

- Indiabix ThermoDocument44 pagesIndiabix ThermoZir AeNo ratings yet

- Depressuring A Practical GuideDocument30 pagesDepressuring A Practical GuidePhuoc VoNo ratings yet

- Quick Study Academic Physics 600dpiDocument6 pagesQuick Study Academic Physics 600dpiSunshineK95100% (8)

- Modeling Chemical ReactionsDocument4 pagesModeling Chemical ReactionsAllie LordNo ratings yet

- Preboards 3-PipeDocument4 pagesPreboards 3-PipeChyno KangNo ratings yet

- Eff FormulaDocument59 pagesEff FormulaVenkateswara Rao DoodalaNo ratings yet

- Energy Balance: Hydrogen ProductionDocument7 pagesEnergy Balance: Hydrogen ProductionMohit MangalNo ratings yet

- Possible Origin of Differences Between Vant Hoff and Calorimetric Enthalpy EstimatesDocument9 pagesPossible Origin of Differences Between Vant Hoff and Calorimetric Enthalpy EstimatesFadi Simon de Souza MagalhãesNo ratings yet

- 1) Vaporation Power For Helium Bath After JT-Valve: Principles For Measurement of Heat LoadDocument6 pages1) Vaporation Power For Helium Bath After JT-Valve: Principles For Measurement of Heat Loadteman_jawaNo ratings yet

- Materials & Streams Report for Insulferm1 ProcessDocument8 pagesMaterials & Streams Report for Insulferm1 ProcessWilliamLoobyNo ratings yet

- Numerical Analysis of Engineering SystemsDocument16 pagesNumerical Analysis of Engineering SystemsCKNo ratings yet

- Thermal Performance Analysis of Counterflow Cooling Tower by Merkel's MethodDocument32 pagesThermal Performance Analysis of Counterflow Cooling Tower by Merkel's MethodADITYA BANERJEENo ratings yet

- Kaya - 2007 - Mathematical Modeling of Multiple Effect Evaporators and Energy EconomyhDocument7 pagesKaya - 2007 - Mathematical Modeling of Multiple Effect Evaporators and Energy EconomyhGabriel NguyenNo ratings yet

- Tutorial 4Document3 pagesTutorial 4Majid Aishah100% (1)

- Chemical Engineering Thermodynamics BasicsDocument46 pagesChemical Engineering Thermodynamics Basicsdppriya1984No ratings yet

- Power Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)Document12 pagesPower Plant and Calculations - Boiler Calculations For Boiler Operation Engineer Exam (BOE)RajeshNo ratings yet

- Chem 3615 Chapter 10 Entropy and The Second Law of Thermodyanmics PDFDocument26 pagesChem 3615 Chapter 10 Entropy and The Second Law of Thermodyanmics PDFNitya DewiNo ratings yet

- Lecture 5 Latest JuDocument117 pagesLecture 5 Latest JuSolomon GebremariamNo ratings yet

- Chapter 2 (Numerical+solution)Document60 pagesChapter 2 (Numerical+solution)Sudeep magarNo ratings yet

- Thermophysical Properties of Fluids. II. Methane, Ethane, Propane, Lsobutane and N-ButaneDocument222 pagesThermophysical Properties of Fluids. II. Methane, Ethane, Propane, Lsobutane and N-ButaneCan YıldırımNo ratings yet

- Fluid Package EOSDocument12 pagesFluid Package EOSdani2611No ratings yet

- Unit 1Document24 pagesUnit 1yashrajNo ratings yet

- Lecture#3Document8 pagesLecture#3Anmar A. Al-joboryNo ratings yet

- CombustionDocument46 pagesCombustionIrene Kaye AceroNo ratings yet

- Cooling Tower PowerpointDocument17 pagesCooling Tower Powerpointdebu1985No ratings yet

- Performance Analysis and Optimization of Double-Flash Geothermal Power Plants PDFDocument9 pagesPerformance Analysis and Optimization of Double-Flash Geothermal Power Plants PDFManahan SinagaNo ratings yet