Professional Documents

Culture Documents

Oleic Acid - Production, Uses and Potential Health Effects 2014

Uploaded by

Americo MolinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oleic Acid - Production, Uses and Potential Health Effects 2014

Uploaded by

Americo MolinaCopyright:

Available Formats

BIOCHEMISTRY RESEARCH TRENDS

OLEIC ACID

PRODUCTION, USES AND POTENTIAL

HEALTH EFFECTS

No part of this digital document may be reproduced, stored in a retrieval system or transmitted in any form or

by any means. The publisher has taken reasonable care in the preparation of this digital document, but makes no

expressed or implied warranty of any kind and assumes no responsibility for any errors or omissions. No

liability is assumed for incidental or consequential damages in connection with or arising out of information

contained herein. This digital document is sold with the clear understanding that the publisher is not engaged in

rendering legal, medical or any other professional services.

BIOCHEMISTRY RESEARCH TRENDS

Additional books in this series can be found on Novas website

under the Series tab.

Additional e-books in this series can be found on Novas website

under the e-book tab.

BIOCHEMISTRY RESEARCH TRENDS

OLEIC ACID

PRODUCTION, USES AND POTENTIAL

HEALTH EFFECTS

LYNETTE WHELAN

EDITOR

New York

Copyright 2014 by Nova Science Publishers, Inc.

All rights reserved. No part of this book may be reproduced, stored in a retrieval system or

transmitted in any form or by any means: electronic, electrostatic, magnetic, tape,

mechanical photocopying, recording or otherwise without the written permission of the

Publisher.

For permission to use material from this book please contact us:

Telephone 631-231-7269; Fax 631-231-8175

Web Site: http://www.novapublishers.com

NOTICE TO THE READER

The Publisher has taken reasonable care in the preparation of this book, but makes no

expressed or implied warranty of any kind and assumes no responsibility for any errors or

omissions. No liability is assumed for incidental or consequential damages in connection

with or arising out of information contained in this book. The Publisher shall not be liable

for any special, consequential, or exemplary damages resulting, in whole or in part, from

the readers use of, or reliance upon, this material. Any parts of this book based on

government reports are so indicated and copyright is claimed for those parts to the extent

applicable to compilations of such works.

Independent verification should be sought for any data, advice or recommendations

contained in this book. In addition, no responsibility is assumed by the publisher for any

injury and/or damage to persons or property arising from any methods, products,

instructions, ideas or otherwise contained in this publication.

This publication is designed to provide accurate and authoritative information with regard

to the subject matter covered herein. It is sold with the clear understanding that the

Publisher is not engaged in rendering legal or any other professional services. If legal or any

other expert assistance is required, the services of a competent person should be sought.

FROM A DECLARATION OF PARTICIPANTS JOINTLY ADOPTED BY A

COMMITTEE OF THE AMERICAN BAR ASSOCIATION AND A COMMITTEE OF

PUBLISHERS.

Additional color graphics may be available in the e-book version of this book.

Library of Congress Cataloging-in-Publication Data

Library of Congress Control Number: 2014934750

Published by Nova Science Publishers, Inc. New York

ISBN: 978-1-63117-577-0 (eBook)

CONTENTS

Preface vii

Chapter 1 Optimization of the Media Volume, Aeration Rate

and Inoculum Size for Sophorolipid Production

from Candida bombicola ATCC 22214 1

Stephanie Grieb, Fred J. Rispoli and Vishal Shah

Chapter 2 Influence of Oleic Acid on Self-Assembled Liquid

Crystalline Nanostructures 9

Intan Diana Mat Azmi and Anan Yaghmur

Chapter 3 Oleic Acid and Its Potential Health Effects 35

Igor Pravst

Chapter 4 Oleic Acid and Microbial Lipases:

An Efficient Combination 55

Fabiano Jares Contesini, Danielle Branta Lopes,

Elaine Berger Ceresino, Jose Valdo Madeira Junior,

Paula Speranza, Francisco Fbio Cavalcante Barros

and Ricardo Rodrigues de Melo

Chapter 5 Synthesis of Oleic Acid Alkil Esters

via Homogeneous Catalysis 83

Mrcio Jos da Silva and Abiney Lemos Cardoso

Chapter 6 Effects of Temperature on Oleic Acid Percentage

During Grain-Filling in Sunflowers and Other Oil

Crops 99

Rouxlne van der Merwe and Maryke Labuschagne

Index 129

PREFACE

Oleic acid is a monounsaturated fatty acid and natural constituent of a

number of foods, particularly vegetable oils. On the basis of proven beneficial

health effects it is also a possible ingredient in processed functional foods.

However, due to its high energy content it is not recommended to increase the

consumption of any particular fat, but to substitute other lipids with oleic acid.

While there is a well-established consensus that replacing saturated fats in the

diet with oleic acid or other unsaturated fats contributes to the maintenance of

normal blood cholesterol levels, a series of other effects has also been studied,

including the modulation of inflammatory markers, blood pressure, insulin

sensitivity, gastrointestinal functions and even various cancers. This book

discusses oleic acid's health effects, as well as its production, and how it is

used.

Chapter 1 In the current study the influence of aeration rate, inoculum

size and fermentation medium volume on the sophorolipids production from

the yeast Candida bombicola have been studied. Using the data obtained from

a two-level Placket-Burman experimental design, linear and cubic models

were obtained to understand the interaction amongst the ingredients. The cubic

model was used to find the optimal aeration rate, inoculum size and the

fermentation medium volume. The maximum production of SLs is predicted to

be obtained when the medium volume is 10 mL (in 125 mL Erlenmeyer flask),

is inoculated with 5% of the inoculum and incubated at 350 rpm.

Chapter 2 Various studies in the literature suggested a link between the

consumption of olive oil and different food products enriched with oleic acid

(OA) and various positive health effects. The central focus of this research

field is on learning and predicting how OA intake induces these health

benefits. In recent years, there is a growing interest in understanding the

biological role of this monounsaturated cis fatty acid in regulating cell

Lynette Whelan viii

membranes and its effect on biological processes. In this context, it is

interesting to explore the effect of its incorporation on the model membrane

characteristics and properties. These studies are considered as first steps

towards a deeper understanding of the molecular mechanisms underlying OA

beneficial health effects and their association with the biological membrane

properties.

This chapter summarizes recent studies conducted on the influence of OA

and its counterparts (saturated and trans fatty acids) on model lipid

membranes. In particular, the main focus is to present recent investigations on

the structural characterization and also the potential applications of lipidic

non-lamellar self-assembled nanostructures loaded with OA. These lyotropic

liquid crystalline (LLC) phases and microemulsions are attractive as drug

delivery systems. The most investigated LLC phases are the inverted-type

hexagonal (H

2

) and the inverted-type bicontinuous cubic (V

2

) nanostructures.

These unique inverted type self-assembled systems are compatible, digestible,

and bioadhesive matrices that are able to co-exist under equilibrium conditions

with excess water. They display nanostructures closely related to those

observed in biological membranes and posess interesting characteristics such

as the high interfacial area (specific interfacial area up to 400 m

2

/g), the high

solubilization capacities of drugs with different physicochemical properties

(hydrophilic, amphiphilic, and hydrophobic molecules), and the potential of

controlling drug release. In particular, there is an enormous interest in testing

the possibility of utilizing these LLC phases for enhancing the solubilization

of poorly water-soluble drugs, obtaining sustained drug release, and improving

the in vivo performance of various drug substances.

The scope of this chapter also covers recent studies that have attempted to

shed light on the possible fragmentation of these inverted type self-assembled

nanostructures for forming nanoparticlulate formulations attractive for food

and pharmaceutical applications. These nanostructured aqueous dispersions

(mainly cubosomes, hexosomes, and micellar cubosomes) in which the

submicron-sized dispersed particles envelope distinctive well-defined self-

assembled nanostructures can be utilized in different applications owing to

their low viscosity as compared to the corresponding non-dispersed bulk liquid

crystalline phases and their biological relevance.

Chapter 3 Oleic acid is a monounsaturated fatty acid and natural

constituent of a number of foods, particularly vegetable oils. On the basis of

proven beneficial health effects it is also a possible ingredient in processed

functional foods. However, due to its high energy content it is not

recommended to increase the consumption of any particular fat, but to

Preface ix

substitute other lipids with oleic acid. While there is a well-established

consensus that replacing saturated fats in the diet with oleic acid or other

unsaturated fats contributes to the maintenance of normal blood cholesterol

levels, a series of other effects has also been studied, including the modulation

of inflammatory markers, blood pressure, insulin sensitivity, gastrointestinal

functions and even various cancers. Commercial communication of such

effects is only ethical where such effects are relevant to human health and

proven using the highest possible standards, preferably with well-performed,

double-blind, randomised, placebo-controlled human intervention trials. Most

intervention studies investigating the health effects of oleic acid are performed

using vegetable oils which also contain other fatty acids and minor

constituents. This represents a possible confounding factor and makes

interpretations difficult. In this chapter, the health effects of oleic acid are

discussed together with the possibilities of using oleic-acid-related health

claims on foods in commercial communications in the European Union.

Chapter 4 Oleic acid is a monounsaturated fatty acid found in high

concentrations in vegetable oils, presenting a broad number of applications in

many industrial areas, such as food, pharmaceutical, cosmetic, oleochemical

and biodiesel industries. Due to the lipophilicity, unsaturation and acidic

characteristics that this compound presents, oleic acid can be effectively used

in esterification and acidolysis, among other reactions. Recent studies have

used oleic acid as an efficient substrate for synthesis of trimethylolpropane

esters by esterification using lipase from Candida Antarctica, since this polyol

ester is widely applied in hydraulic fluids with several applications. Other

studies used C. antarctica lipase for improving the lipophilicity of bioactive

molecules, such as ferulic acid and L-ascorbic acid by esterification with oleic

acid, which is very interesting, taking into account that it increases the

solubility of these molecules in hydrophobic environments, resulting in higher

biological activities. On the other hand, some studies showed that lipases can

be used to convert oleic acid into epoxies, which are useful intermediates in

organic synthesis due to the high reactivity they present. They are used to

produce plasticizers that increase flexibility, workability or distensibility of

plastics, hence rendering them suitable for several applications. One study

reported biodiesel production by esterification of oleic acid with aliphatic

alcohols using immobilized Candida antarctica lipase, showing high yields of

biodiesel (above 90%) in less than 24 h with ethanol, n-propanol and n-

butanol; whereas with methanol, the enzyme was inactive after ten cycles of

reaction. In addition to the various reactions involving oleic acid as a

promising substrate for various reactions, oleic acid can also be used to induce

Lynette Whelan x

microbial lipase production, as seen in a study using the fungal strain Rhizopus

arrhizus. Therefore, different high-added-value compounds can be obtained

using oleic acid as a cheap and efficient substrate for microbial lipases, which

can be considered as environmentally friendly alternatives for chemical

catalysts. Within this context, this chapter reviews some studies and trends on

the use of oleic acid as an efficient substrate for microbial lipases.

Chapter 5 Recently, due to inevitable exhaustion of the fossil petroleum

reserves, and the environmental impact generated by the green-house effect

gas emission, to develop efficient processes for the production of fuels and

chemicals from the renewable feedstock has been pursued researchers in

worldwide. In this sense, since the oleic acid is a common component of

vegetal oils and animal fatty, it raise as a highly attractive raw material, due to

its high availability and affordability. In general, the oleic acid is present in

different feedstock as a free fatty acid or as glyceryl ester. Several chemicals

of interest for plentiful industries can be obtained via different catalytic

reactions starting from the oleic acid as source, such as alkyl esters or ethers

and epoxide-derivatives. Particularly, alkyl oleate esters are useful as

lubricant, surfactant, emulsifying agent, emollient, fuels additive and

biodiesel. Actually, the main component of biodiesel is in general the methyl

or ethyl oleate, which is manufactured by the alkaline transesterification of

edible or non-edible vegetable oils via a well-established industrial process.

However, the conventional alkaline homogeneous process results in large

generation of effluents and residues of neutralization, in addition the laborious

steps to remove the non-reusable catalyst, being because of these reasons a

non-friendly environment process. In this work, the authors wish the recent

advances achieved in the development of catalytic processes for the production

of alkyl esters of oleic acid via acid catalysis, however, using recyclable

catalysts. They will pay special attention to development of homogeneous

catalysts that can be recovery and reusable without loss of activity in the oleic

acid esterification reactions. These catalysts are solid when pure and soluble in

the reaction being thus recovered after solvent distillation and extraction of

products. Numerous industries in all parts of world have crescent demand by

developing of environmentally friendly technologies for the production of

biodiesel and chemicals, which are especially attractive when are based on

reusable catalysts. Herein, the authors focus the use of two different sorts of

catalysts: the former, Lewis acid such as tin compounds, and the second one,

Brnsted acid catalysts, which are based on Keggin-type heteropolyacids. The

catalysts performance it was assessed in the esterification reactions with short

chain alkyl alcohols (i.e., methyl, ethyl, propyl, isopropyl and butyl alcohols).

Preface xi

A comparison with the traditional catalysts used in these reactions also was

performed. The development of new, efficient, and environmentally benign

catalytic processes that may lead to high value added products, starting of

renewable raw material such as oleic acid, is still an challenge to be overcome.

The authors hope that this work can significantly contribute to improvement of

this important research field.

Chapter 6 Most vegetable oils are obtained from beans or seeds, which

furnish valuable and high quality oil commodities in the world oil market.

Seed oil quality is related to oil percentage and fatty acid composition and

defines the oils value for industry. With emerging new markets and increased

concerns about the health risks of foods, changes in the oil quality of various

crops have been demanded. Plant breeders have been successful in developing

novel oil types in sunflower, soybean, peanut and others with increased

percentages of oleic acid. Genotype is the most important factor that defines

the oil fatty acid composition, but environmental factors, particularly during

the grain-filling period, can widely affect both oil content and oleic acid

percentage. Various environmental factors including temperature (heat and

cold, day/night differences), solar radiation, humidity, day length and moisture

availability (rainfall distribution and intensity, drought or flooding) affect seed

oil percentage and composition. When environmental factors deviate from the

optimal quantity or intensity for the crop plant, stress is caused. Changes in

both oil percentage and fatty acid composition caused by environmental stress

could have a dynamic effect on the quantity and quality of oil that is

extractable by seed processors. Temperature is a major environmental factor

that determines the rate of oil accumulation. Generally warm temperatures

during the entire growing season or a period of heat stress during grain-filling

favors the production of oleic acid, while cooler temperatures favor the

production of linoleic acid in traditional oil crops. However, not all genotypes

are similarly affected by temperature and show strong genotype by

environment interaction. Generally the novel sunflower genotypes with

increased oleic acid contents display more stable oleic to linoleic acid ratios

across different environments than standard types with high linoleic acid

percentages. In novel soybean varieties, the high oleic acid content fluctuates

with temperature differences. In order to improve oil quality in traditional oil

crops, it is necessary to understand the temperature effects on oleic acid

content. In addition, since agricultural and management practices can alter

temperature and other important environmental factors that plants are exposed

to during grain-filling, altered production practices could contribute to

modified oleic acid contents in vegetable oil crops.

In: Oleic Acid ISBN: 978-1-63117-576-3

Editor: Lynette Whelan 2014 Nova Science Publishers, Inc.

Chapter 1

OPTIMIZATION OF THE MEDIA VOLUME,

AERATION RATE AND INOCULUM SIZE

FOR SOPHOROLIPID PRODUCTION FROM

CANDI DA BOMBI COLA ATCC 22214

Stephanie Grieb

1

, Fred J . Rispoli

2

and Vishal Shah

*

1

1

Department of Biology, Dowling College, Oakdale, NY, US

2

Department of Mathematics, Dowling College, Oakdale, NY, US

ABSTRACT

In the current study the influence of aeration rate, inoculum size and

fermentation medium volume on the sophorolipids production from the

yeast Candida bombicola have been studied. Using the data obtained

from a two-level Placket-Burman experimental design, linear and cubic

models were obtained to understand the interaction amongst the

ingredients. The cubic model was used to find the optimal aeration rate,

inoculum size and the fermentation medium volume. The maximum

production of SLs is predicted to be obtained when the medium volume is

10 mL (in 125 mL Erlenmeyer flask), is inoculated with 5% of the

inoculum and incubated at 350 rpm.

*

Corresponding author: Phone: 631-244-3339; Fax: 631-244-1033; Email: ShahV@dowling.

edu.

Stephanie Grieb, Fred J. Rispoli and Vishal Shah 2

Biosurfactants have become increasingly popular in the recent times

owing to their environmental friendly properties. One of the biosurfactants that

is gaining attraction for its biological properties are Sophorolipids (SLs). SLs

are low-molecular weight biosurfactants produced by yeasts such as Candida

bombicola, Yarrowia lipolytica, Candida apicola, and Candida bogoriensis

when grown on carbohydrates and lipophilic substrates. [1] The biological

properties of the compounds include anticancer [2], antibacterial [3],

antifungal [4], antiviral [5] and spermicidal activity. [6] In addition, SLs have

also shown to be an effective septic shock antagonist [7,8] and have been

proposed to have applications in food thickening, herbicide and pesticide

formulations, consumer product manufacturing (e.g. detergents and

cosmetics), and lubricant formulations. [9]

Not many studies have been published to optimize the fermentation

conditions for obtaining maximum SL yields. In our recent study, we

optimized the fermentation medium for the maximum production of SLs using

the yeast Candida bombicola ATCC 22214. [8] Sixteen different media

ingredients were screened and the fermentation medium composed of sucrose,

malt extract, oleic acid, K

2

HPO

4

and CaCl

2

was shown to provide the highest

yield of the glycolipids. However, no physical parameters were optimized in

the earlier study. Using a two-level Placket-Burman design, three physical

process parameters are optimized in the current study to obtain high yields of

SLs under batch fermentation. The process parameters are aeration rate,

medium volume and the age of the inoculum. Aeration rate and medium

volume are critical in determining the amount of oxygen transferred into the

fermentation medium. Oxygen supply is important in the SL fermentation

because the yeast is very sensitive to the oxygen limitation during their

exponential growth phase Guilmanov et al. have carried out a detailed

investigation on the influence of oxygenation on the SL production under fed-

batch conditions using shake-flask method [9]. They reported that higher

levels of oxygenation resulted in increased SL formation and that the oxygen

transfer rate has to be between 50 and 80 mM O

2

/L h

-1

for obtaining high

yields. The study however was carried out using an un-optimized media of

glucose, yeast extract and urea, and also included a step of centrifuging the

cells from the inoculum media before introducing them into the fermentation

media. In our preliminary study, we found that centrifugation of cells before

introducing them to the fermentation media decreases the yield of SL (data not

shown). Thus, the process parameters of media volume and agitation rate were

selected in the current study. As the culture flasks will be of identical size,

cultures of higher medium volumes represent lower oxygenation rate and those

Optimization of the Media Volume, Aeration Rate 3

with smaller volumes represent higher oxygenation. Higher aeration rate

results in higher oxygenation rate, and smaller aeration rates results in lower

oxygenation rate. Inoculum volume was selected as the third parameter

because it is known that the production of SL begins only when the nitrogen in

the fermentation media is depleted. [10] The inoculum size would determine

how many yeast cells are introduced in the fermentation medium and hence

the rate at which the nutrients are utilized.

Candida bombicola ATCC 22214 was used for SL production. The

protocol described in Rispoli et al. [8] was used for Sophorolipid production.

The fermentation was carried out in 125 mL Erlenmeyer flasks and the

fermentation media was composed of sucrose, 125 g/L; oleic acid, 166.67 g/L;

CaCl2, 2.5 g/L; K2HPO4, 1.5 g/L and malt extract 25 g/L. The amount of

fermentation medium in the flask and the volume of inoculum added to the

media were varied as per the experimental design described in Table 1. The

flasks were incubated for 8 days at 30 1.5 C in a rotary shaker. The

extraction and estimation of SLs was carried out following the protocol

described earlier [8] A Plackett-Burman two-level experimental design was

obtained with one block for three independent variables. Fusion Pro version

7.3.20 (S-Matrix Corp., USA) software was used to obtain the design. The

obtained design is shown in Table 1. The statistical analysis of data was

carried out using Statistica release 8 (StatSoft Inc., USA).

Table 1. Experimental design matrix and the obtained yields of

Sophorolipids under each condition

Experiment

Number

Aeration

(rpm)

Media

volume

a

(mL)

Inoculum

(%)

SL Yield

(g/L)

1 50 10 5 26.14

2 50 10 15 23.33

3 50 40 5 9.67

4 50 40 15 7.85

5 200 25 10 15.49

6 350 10 5 87.84

7 350 10 15 74.2

8 350 40 5 15.29

9 350 40 15 15.2

a

The media volume is the final volume in the flask after addition of the inoculum.

As can be seen in Table 1, the media volume in the flask was varied from

1/10 (10 mL) of the total flask volume to 1/3 (40 mL). Similarly, the aeration

Stephanie Grieb, Fred J. Rispoli and Vishal Shah 4

was varied from 50 rpm to 350 rpm. Thus, experiment number 6 and 7 which

have a volume of 10 mL and were incubated at 350 rpm receive highest

oxygenation. Whereas experiment number 3 and 4 have the lowest

oxygenation. SL yield indicates that the highest yield was obtained when the

yeast received high amount of oxygen. When one compares the SL yield

obtained in experiment 1 and 3, 6 and 8 it can be concluded that increasing the

media volume decreases the production of SLs. These comparisons were

carried out because between the experiments, the other two variables have

same value. Comparison between experiments 1 and 6, 2 and 7, indicates that

increasing aeration has a positive influence on the yield.

Table 2. Linear and cubic model obtained by analyzing the data described

in Table 1

Variable Linear model Cubic model

R

2

= 0.71 R

2

= 0.94

x

1

50.72 86.30

x

2

-21.53 8.13

x

3

14.74 21.79

x

1

.x

2

- -80.68

x

1

.x

3

- -35.43

x

2

.x

3

- -23.61

x

1

.x

2

.x

3

- 37.16

Both a linear and a cubic model were obtained using regression analysis

(Table 2). The primary effect of each of the variables can be evaluated based

on a liner regression model. Based on the coefficients, aeration has the highest

positive influence on the yield, whereas media volume has a strong negative

influence. The amount of inoculum added also has a positive influence on the

production of SLs. The low fit of the linear model with the experimental data

is an indication that apart from the primary effect for each independent

variable, there is a high degree of interaction that is undetected by the linear

model. The quadratic model result has R

2

value of 0.94. The improvement of

the R

2

value from 0.70 to 0.94 is due to the two-way and three-way interaction

terms incorporated into the cubic model. Interestingly, the cubic model shows

that the primary effects of all the variables (including media volume) are

positive and the observed overall effect for each variable is due to the

interactions with other variables. The model shows that all the two-way

interactions are negative. Confirmation of the interaction can be obtained from

Optimization of the Media Volume, Aeration Rate 5

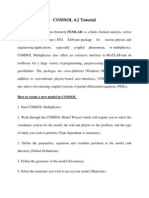

the ternary plot illustrated in Figure 1. Maximum yield is predicted near the

vertex of the aeration and along the inoculum aeration axis. Very low yield

is predicted when the aeration has a lower value (along the inoculum media

volume axis).

Figure 1. Ternary plot of the quadratic model predicting the production of

Sophorolipids under various conditions.

The optimization of the process variables was carried out using Frontline

Solver, optimization software built into Microsoft Excel. The cubic model

described in Table 2 was selected as the objective function. The optimal

solution obtained was aeration of 350 rpm, inoculum volume of 5% and media

volume of 10 mL and the maximum yield predicted is 86.29 g/L under optimal

conditions. The optimal conditions predicted by Solver are similar to those in

experiment 6, and the yield obtained experimentally was 87.84 g/L.

In conclusion, the influence of the aeration, inoculum volume and media

volume have been studied in the current study and the optimal values of the

three obtained to achieve highest SL yield. During the course of study we have

also identified several confounding variables including the amount of cells in

the inoculum and the physiology of the organisms (data not shown). Studies

Stephanie Grieb, Fred J. Rispoli and Vishal Shah 6

are now being carried out in our laboratory to investigate how these variables

influence the SL production by Candida bombicola. In addition, it has been

recently shown that the structural composition of SL is highly dependent on

the aeration rate. [12] A regression model that is able to predict the

composition of the SL based on the fermentation conditions is also being

developed.

ACKNOWLEDGMENT

The study was funded by National Science Foundation (Grant # CBET

0828292).

REFERENCES

[1] Gobbert, U., Lang, S. and Wagner, F. (1984) Biotechnol Lett. 6, 225-

230.

[2] Chen, J., Song, X., Zhang, H. and Qu, Y. (2006) Enzyme Microbial

Technol. 39, 501-506.

[3] Shah, V., Badia, D. and Ratsep, P. (2007) Antimicrobial Agents and

Chemotheraphy. 51, 397-400.

[4] Gross, R. and Shah, V. (2004) Antifungal properties of various forms of

sophorolipids. US Patent application No. 20050164955.

[5] Shah, V., Doncel, G. F., Seyoum, T., Eaton, K. M., Zalenskaya, I,

Hagver, R., Azim, A. and Gross, R. (2005) Antimicrobial Agents and

Chemotherapy. 49, 4093-4100.

[6] Bluth, M.H., Kandil, E., Mueller, C. M., Shah, V., Lin, Y. Y., Zhang, H.,

Dresner, L., Lempert, L., Nowakowski, M., Gross, R., Schulze, R. and

Zenilman, M. E. (2006) Crit. Care Med. 34, 188-195.

[7] Solaiman, D. K. Y. (2005) Inform. 16, 408-410.

[8] Rispoli, F. J., Badia, D. and Shah, V. (2010) Biotechnol. Progress, 26,

938-944

[9] Guilmanov, V., Ballistreri, A., Impallomeni, G.. and Gross, R. A. (2002)

Biotechnol. Bioeng, 77, 489-494.

[10] Lien, C-C. (2007) Ph. D. Thesis. Polytechnic University of New York.

2007.

Optimization of the Media Volume, Aeration Rate 7

[11] Shah, V., Jurjevic, M. and Badia, D. (2007) Biotechnol. Prog. 23, 512-

515.

[12] Ratsep, P. and Shah, V. (2009) J. Microbiol. Methods. 78, 354-356.

In: Oleic Acid ISBN: 978-1-63117-576-3

Editor: Lynette Whelan 2014 Nova Science Publishers, Inc.

Chapter 2

INFLUENCE OF OLEIC ACID

ON SELF-ASSEMBLED LIQUID

CRYSTALLINE NANOSTRUCTURES

I ntan Diana Mat Azmi and Anan Yaghmur

*

Department of Pharmacy, Faculty of Health and Medical Sciences,

University of Copenhagen, Denmark

ABSTRACT

Various studies in the literature suggested a link between the

consumption of olive oil and different food products enriched with oleic

acid (OA) and various positive health effects. The central focus of this

research field is on learning and predicting how OA intake induces these

health benefits. In recent years, there is a growing interest in

understanding the biological role of this monounsaturated cis fatty acid in

regulating cell membranes and its effect on biological processes. In this

context, it is interesting to explore the effect of its incorporation on the

model membrane characteristics and properties. These studies are

considered as first steps towards a deeper understanding of the molecular

mechanisms underlying OA beneficial health effects and their association

with the biological membrane properties.

This chapter summarizes recent studies conducted on the influence of

OA and its counterparts (saturated and trans fatty acids) on model lipid

*

Corresponding author: Tel.: +45 35 33 65 41, Fax: +45 35336030, e-mail: anan.yaghmur

@sund.ku.dk.

Intan Diana Mat Azmi and Anan Yaghmur 10

membranes. In particular, the main focus is to present recent

investigations on the structural characterization and also the potential

applications of lipidic non-lamellar self-assembled nanostructures loaded

with OA. These lyotropic liquid crystalline (LLC) phases and

microemulsions are attractive as drug delivery systems. The most

investigated LLC phases are the inverted-type hexagonal (H

2

) and the

inverted-type bicontinuous cubic (V

2

) nanostructures. These unique

inverted type self-assembled systems are compatible, digestible, and

bioadhesive matrices that are able to co-exist under equilibrium

conditions with excess water. They display nanostructures closely related

to those observed in biological membranes and posess interesting

characteristics such as the high interfacial area (specific interfacial area

up to 400 m

2

/g), the high solubilization capacities of drugs with

different physicochemical properties (hydrophilic, amphiphilic, and

hydrophobic molecules), and the potential of controlling drug release. In

particular, there is an enormous interest in testing the possibility of

utilizing these LLC phases for enhancing the solubilization of poorly

water-soluble drugs, obtaining sustained drug release, and improving the

in vivo performance of various drug substances.

The scope of this chapter also covers recent studies that have

attempted to shed light on the possible fragmentation of these inverted

type self-assembled nanostructures for forming nanoparticlulate

formulations attractive for food and pharmaceutical applications. These

nanostructured aqueous dispersions (mainly cubosomes, hexosomes, and

micellar cubosomes) in which the submicron-sized dispersed particles

envelope distinctive well-defined self-assembled nanostructures can be

utilized in different applications owing to their low viscosity as compared

to the corresponding non-dispersed bulk liquid crystalline phases and

their biological relevance.

INTRODUCTION

The negative health effects associated with the consumption of food

products containing trans-fatty acids (TFAs) remain a major concern for the

consumers [1]. The overall awareness about the significant role of these fatty

acids in human nutrition has been raised since 1980s [2-4]. These unsaturated

fatty acids contain at least one double bond of trans configuration and are

mainly generated by the process of partial hydrogenation of vegetable oils,

which is used in food manufacturing industry to commercially produce edible

solid fats with an increased shelf life that can substitute animal fats in diet [2,

5-7]. The major concern is that the trans configuration affects not only the

Self-Assembled Liquid Crystalline Nanostructures 11

physicochemical properties of the fatty acids [2, 7] but also it attributes to

multiple negative effects [6-14]. Various epidemiologic and clinical studies

reported on the influence of the TFA intake on increasing the risk of coronary

heart disease [5-8, 15] and cancer [6, 7, 16], increasing the blood low density

to high density lipoprotein (LDL/HDL) ratio [6, 17, 18]. More than one third

of cancer incidence and other chronic diseases such as cardiovascular risk

factors were claimed to be associated with the nutrition-related attitudes [19-

22]. In addition, different studies suggested an important link between the

TFA intake and insulin sensitivity [6], systemic inflammation [6, 23], and

impairing the endothelial function [14]. Diabetes was also reported to be

associated with the TFA dietary that stimulated a greater adipogenic effect [11,

24]. A growing body of evidence on the adverse negative health effects

associated with TFA consumption suggests introducing TFA-free food

products to the market [25-27].

In contrast to trans-fat dietary, the consumption of olive oil, which is rich

in oleic acid (a monounsaturated fatty acid with the natural cis configuration),

is associated with positive health effects [28-30]. In European countries such

as Greece and Italy and in the Middle East the intake of olive oil is high and is

linked in different regions to a relatively reduced blood pressure and a reduced

risk of developing coronary heart disease, a reduced breast cancer, and a low

level of plasma cholesterol [30-32]. The past decade has witnessed a

tremendous interest in understanding why the consumption of oleic acid-rich

diet is important to our health and wellness. It was reported that oleic acid

(OA) reduces a cluster of prevalence metabolic syndrome (MetS) including

obesity, hypertension, impaired fasting glucose (insulin resistance at pre-

diabetic state), blood pressure, high-density lipoprotein cholesterol [HDL-C]

levels, and the risk of coronary heart disease [20, 33-39]. It was also found that

this monounsaturated fatty acid (MUFA) is an active component that

influences the proliferation of immune cells in comparison with other fatty

acids [36, 40] as well as it reduces the risk of ulcerative colitis (UC) disease

[41]. Not only that, OA is used as a penetration enhancer to increase the

permeability of active molecules to the skin [42-44]. Most interestingly, the

role of OA in inhibiting cell proliferation and inducing apoptosis in carcinoma

cells has received great attention [16, 45, 46]. It was suggested therefore to use

OA as an antitumoral agent [29, 40, 47-50]. In an interesting report, it was

found that the combination of OA with the drug trastuzumab leads to the

occurrence of a synergistic cytotoxic effect towards breast cancer [51].

There is a growing research interest on exploring the effect of OA on

biological membrane structures due to the implications of its daily

Intan Diana Mat Azmi and Anan Yaghmur 12

consumption in vital biological processes related to health and disease, and its

possible use as one of the main components in the formation of soft lipidic

nanoparticlulate formulations attractive for delivering drugs or functional

foods [25, 52-55]. Understanding the effect of this free cis-fatty acid on

regulating cell membranes is considered as first step towards a deeper

understanding of the biological membrane properties and the molecular

mechanisms underlying OA beneficial health effects. In this contribution, the

main attention is to focus on the influence of OA and its counterparts

(saturated and trans fatty acids) on the structural characterization and the

potential pharmaceutical applications of lipidic non-lamellar lyotropic liquid

crystalline (LLC) phases and their corresponding aqueous dispersions

(cubosomes and hexosomes).

I. OLEIC ACID: BIOLOGICAL ACTIVITY

AND PHARMACEUTICAL USES

OA-rich diets are associated with increasing the level of this fatty acid in

human plasma membrane [56, 57]. The health benefits of OA intake has been

subjected to a large number of reports [16, 46, 58], but its specific mechanism

of action remains poorly understood. It was suggested that OA intake

modulates the structure of cell membranes [59-61]. For instance, a recent

interesting study suggested an important role of this monounsaturated cis-fatty

acid in modulating the adrenoreceptor signaling pathway that induces a

reduction in the blood pressure (BP) [62]. This G protein-associated signaling

activity was found in both in vivo (in human) and in cell culture studies, but

apparently not detected in the membrane-free system [62, 63]. In contrast, the

counterparts elaidic (EA, trans C18:1t9) or stearic (SA, C18:0) acids, which

are structurally different than OA at the molecular level, do not induce

significant activity on the adrenoreceptor signaling pathway. This structural

difference between trans- (a rod-like structure) and cis-FA (a boomerang-

shaped structure with prominent kink in the molecular backbone) leads to

important biophysical and biological consequences [64]. It was reported that

the conformational flexibility of OA molecule induces a major structural

alteration of the hydrophobic core of the lipid bilayer and perturb the

membrane structure as compared to the rod-like molecular structure of trans-

FA that leads only to a little disorganization [62].

Self-Assembled Liquid Crystalline Nanostructures 13

It was reported that the molecular mechanisms by which OA affects the

biological membrane involve a very specific link between the membrane lipid

structure and the BP regulation [39]. In this context, it was demonstrated that

the penetration of OA molecules into the lipid membrane structure leads to a

marked reduction in the lamellar (L

)-to-hexagonal (H

2

) phase transition as

compared to the trans or saturated FA counterparts [59, 60]. The presence of

this non-lamellar prone lipid in the cell membrane significantly alters the

membrane curvature strain to be more negative [60]. It was assumed that the

transition to hexagonal (H

2

) phase favors the docking of certain peripheral

signaling G protein, which in turn affects the BP [39, 65]. It is also interesting

that the structural analogue of synthetic OA, 2-hyroxyoleic acid (2OHOA) acts

as a potent antitumor drug for glioma by inducing important signaling changes

that end up with cell death [66, 67]. Martnez et al. reported on the propensity

of 2OHOA to organize the lipid membrane into a non-lamellar phase, which

promotes the recruitment of protein kinase C (PKC) to the cell [68]. It was

suggested that the transition to the H

2

phase leads to impair of cell progression

and simultaneously inhibits the growth of the tumor cells [68]. In another

report, the apoptotic activity of OA/protein complexes, known as HAMLET

(Human Alpha-lactalbumin Made LEthal to Tumor cells) was attributed also

to the role of OA in membrane perturbation. As an initial step of killing the

tumor cells, OA alters the membrane and compromises its integrity [64, 69,

70].

Besides the widespread research interests in understanding the role of OA

in regulating biological functions, the use of OA as a main essential

constituent in various drug nanoparticulate formulations including liposomes,

microemulsions, and nanoemulsions has attracted a great attention in the last

two decades [1, 55, 71]. For instance, the utilization of OA-loaded liposomes

(LipoOA) as promising candidates in transdermal applications was suggested

in the literature due to the therapeutic efficacy of these soft drug nanocarriers

in eradicating drug resistance and enhancing its skin penetration [72, 73]. It

was also reported that the association of OA in lipidic nanoparticles (LNPs)

enhances the cellular uptake and hepatic delivery of siRNA and microRNA

[74]. In addition, self-assembled gelatin-OA nanoparticles and OA-loaded

microemulsion were found attractive candidates for improving the

solubilization of poorly water-soluble drugs and controlling their release [71,

75-77].

Intan Diana Mat Azmi and Anan Yaghmur 14

II. FORMATION OF SELF-ASSEMBLED NANOSTRUCTURES

Surfactant-like lipids adopt either normal (type 1) or inverted (type 2) self-

assembled phases, resulting in either oil-in-water (o/w) phases with convex

curvature lipid/water interface or water-in-oil (w/o) phases with a concave

interface, respectively. The formation of a normal or an inverted self-

assembled nanostructure in water mainly depends on the lipids molecular

shape, as discussed in the seventies by Israelachvili and co-workers [78]. In

this regard, the geometric shape of the lipid can be a useful tool for predicting

the water-lipid interface curvature and also can be helpful in understanding the

phase behavior of binary, ternary, and even multi-component systems [79].

For this purpose, the shape factor or more commonly known in the literature as

the critical packing parameter (CPP) was defined [78] as:

(1)

where v

s

is the effective hydrophobic chain volume, a

0

is the headgroup area,

and l is the hydrophobic chain length. The inverted type phases are favored

when CPP > 1 and therefore are generally formed when adding to water

wedge-shaped lipids with hydrophobic tails having a relatively large volume

(v

s

) as compared to the hydrophobic chain length (l) and the headgroup area

(a

0

). Balanced surfactants with CPP 1 tend to form planar bilayers (the

lamellar phase); whereas normal type liquid crystalline phases and micellar

solutions are displayed in the presence of surfactants having CPP < 1. It is

worth noting that the CPP is affected by different variables including lipid

composition, hydration level, electrostatic interactions, presence of

hydrophilic, hydrophobic and amphiphilic additives, and applied experimental

conditions [79-82].

From applicational point of view, there is a noteworthy difference in the

hydration behavior between the normal and inverted type self-assembled

phases. The normal type phases can be easily destabilized in the presence of

excess water, as the surfactant monomers are dissolved in the aqueous

environment when approaching a concentration lower than its critical micellar

concentration (cmc). In contrast, the inverted type phases are independent of

water content under full hydration conditions and therefore are stable against

water dilution [83]. Thus, these systems have recently gained considerable

CPP

v

s

a

0

l

Self-Assembled Liquid Crystalline Nanostructures 15

interest in designing drug and functional food delivery systems due to their

unique properties [84].

Owing to this attractiveness to potential pharmaceutical applications, the

focus in the next sections will exclusively be on describing the formation and

the characterization of inverted type dispersed and non-dispersed phases.

III. INVERTED TYPE LYOTROPIC LIQUID

CRYSTALLINE PHASES

Certain biologically relevant amphiphilic (surfactant-like) lipids including

monoglycerides, glycolipids, and phospholipids have the ability to self-

assemble upon hydration into inverted type lyotropic liquid crystalline (LLC)

phases or micellar systems [79, 85].

This process of self-assembly depends on various parameters including

the chemical structure of the lipid and its composition [86]. It results under

certain experimental conditions on the formation of highly ordered liquid

crystalline phases or micellar solutions consisting of discrete aqueous and

lipidic regions upon direct contact of the surfactant-like lipid with water [87].

These self-assembled systems include lamellar (L

) and non-lamellar (two

and three dimensional bicontinuous and discontinuous nanostructures) phases,

and inverted type micellar solution (L

2

).

Among the inverted type non-lamellar phases, various studies have been

reported on the formation of bicontinuous cubic (V

2

) phases, the hexagonal

(H

2

) phase, and the discontinuous cubic (I

2

) phase of the symmetry Fd3m [81,

88, 89].

The three dimensional (3D) cubic V

2

phases are arranged as single

continuous lipid curved bilayers forming a complex network containing two

non-intersecting water channels [90]. Three different bicontinuous cubic

nanostructures (a family of closely related phases) have been identified in the

literature. They have a primitive (P), a gyroid (G), or a diamond (D) infinite

periodic minimal surface (IPMS) [88, 89].

The minimal surfaces have zero mean curvature and are therefore as

convex as concave at all points. The space groups corresponding to these three

IPMSs are Im3m (the primitive type, C

p

), Ia3d (the gyroid type, C

G

), and

Pn3m (the diamond type, C

D

) respectively [79, 88, 91, 92].

The two-dimensional (2D) reverse hexagonal (H

2

) phase consists of

water-filled cylindrical rods (hydrophilic nanochannels) embedded in a

Intan Diana Mat Azmi and Anan Yaghmur 16

continuous hydrophobic medium. The discontinuous cubic (I

2

) phase with the

space group Fd3m that was identified in different lipid-based systems consists

of two different quasi-spherical micelles packed in a 3D cubic lattice; whereas

the L

2

phase is a reversed micellar solution with no long-range order

[31, 79, 93].

The non-lamellar liquid crystalline matrices (mainly the inverted-type

hexagonal phase (H

2

) and inverted-type bicontinuous cubic (V

2

)) display

nanostructures closely related to those observed in different biological

membranes and have unique properties such as high interfacial area

(estimation of about 400 m

2

/g of surfactant) [94], capability to solubilize

amphiphilic, hydrophobic, and hydrophilic drugs in their highly ordered self-

assembled interiors, biocompatibility and capability to exist under equilibrium

condition with excess water [95-97].

Monolinolien (MLO) is among the surfactant-like lipids with propensity

to form inverted type non-lamellar phases. The binary MLO-water phase

diagram is shown in Figure 1 [83].

A variety of mesophases is formed depending on the water content and the

investigated temperature. Right of the phase separation line, the mesophases

co-exist with excess water, thus their fully hydrated structures are independent

of water content in the biphasic regions.

It is evident that the bicontinuous cubic phases can solubilize significantly

more water at ambient temperatures in their hydrophilic nanochannels as

compared to those of the H

2

and L

2

phases that are formed at higher

temperatures [83].

The phase behavior of the binary MLO-water system is similar to that of

the well-studied monoglyceride monoolein (MO) [98]. Both amphiphilic lipids

have cis-configuration that introduces a kink in their acyl chain [79]. These

lipids are widely used in food industry as they are specified as GRAS

(generally recognized as safe). They are subject to enzymatic lipolysis in a

wide range of tissues and therefore are considered biocompatible and

biodegradable materials [94].

Figure 1 (right) illustrates the phase behavior in a binary or ternary lipid

system. The self-assembled nanostructure follows the phase sequence of L

V

2

H

2

I

2

L

2

with increasing solubilized oil content and/or

temperature, ranking the inverse phases by increasing values of their mean-

interfacial curvature or CPP value [83, 99]_ENREF_96. The CPP increases

with temperature due to the increased fluctuation of the hydrophobic chains of

the investigated surfactant-like lipid [83].

Figure 1. Left: Phase diagram of the binary MLO-water system. Right: Phase sequence in a binary or ternary lipid system that is

displayed upon increasing temperature and/or solubilizing oil. The phases are the following: (A) a fluid lamellar (L

) phase, (B) three

bicontinuous cubic (V

2

) phases, (C) a H

2

phase, (D) a discontinuous cubic Fd3m phase, (E) and an inverted-type water-in-oil (W/O)

microemulsion system (the L

2

phase) (the figures have been taken with permission from reference [83]).

Figure 2. Left: SAXS patterns taken from MLO-based aqueous dispersions (red lines) and its corresponding fully hydrated non-

dispersed system (black lines) at three different temperatures (the figure was adapted with permission from reference [83]). Right: cryo-

TEM images of four tetradecane-free and tetradecane-loaded MLO-based aqueous dispersions; (a) tetradecane-free cubosomes, (b)

hexosomes, (c) micellar cubosomes, and (d) EMEs (the figures have been taken with permission from references [100, 108]).

Self-Assembled Liquid Crystalline Nanostructures 19

This results in a larger effective hydrophobic chain volume (v

s

) with a

simultaneous decrease in the solubilized water content (a decrease of a

0

value

due the dehydration of the hydrophilic headgroups of the lipid). A similar

effect on v

s

and a

0

can be obtained upon the solubilization of hydrophobic

additives at a constant temperature [83, 100-102].

IV. AQUEOUS DISPERSIONS OF LYOTROPIC LIQUID

CRYSTALLINE PHASES AND MICROEMULSIONS

The non-dispersed bulk non-lamellar LLC phases (the V

2

and H

2

nanostructures) are highly viscous. This limits their pharmaceutical

applications as they are difficult to inject and can cause irritation when having

direct contact with epithelial cells [103]. Therefore, an interesting approach in

literature is based on dispersing these LLC phases into low viscous

nanoparticles with retained internal structures [83, 104, 105]. Examples of

these aqueous dispersions are cubosomes with an internal V

2

phase and

hexosomes with an internal H

2

phase [106, 107]. In addition, other aqueous

nanostructured dispersions were reported including micellar cubosomes with

an internal I

2

phase of the symmetry Fd3m, emulsified L

2

system (oil-free L

2

phase), and emulsified microemulsions (EMEs) with an internal W/O

microemulsion system (L

2

). These aqueous dispersions consist of kinetically

stabilized submicron sized particles enveloping internally self-assembled

nanostructures. They have identical unique properties as their corresponding

non-dispersed LLC phases and microemulsions, including high interfacial area

and biological relevance [100].

The most used techniques for characterizing the internal nanostructures of

aqueous dispersions of LLC phases are the small angle X-ray (SAXS) and

neutron (SANS) scattering techniques. Figure 2 (left) shows the typical SAXS

patterns for the fully hydrated non-dispersed V

2

, H

2

, and L

2

bulk phases (black

lines) and their corresponding nanostructured aqueous dispersions (red lines)

[83]. It is evident from the SAXS patterns in Figure 2 (left) that the internal

nanostructures are preserved upon dispersing the bulk phases in excess water,

as the same characteristic X-ray diffraction peaks are observed for the

dispersed and the non-dispersed phases.

As a complementary technique to SAXS, the cryogenic Transmission

Electron Microscopy (cryo-TEM) enables the visualization of the shape of the

dispersed particles and their internal nanostructures. The right side of Figure 2

Intan Diana Mat Azmi and Anan Yaghmur 20

presents cryo-TEM observations of four MLO-based aqueous dispersions

loaded with tetradecane.

V. EFFECT OF OA AND ITS COUNTERPARTS ON LIPIDIC

SELF-ASSEMBLED NANOSTRUCTURES

Fatty acids (FAs) are abundant components in plasma and other biological

membranes that are present as free or bound to phospholipids or cholesterol

esters [60]. It is crucial to understand how low levels of free fatty acids (FFAs)

affect the membrane structure in order to gain insight into the underlying

mechanisms behind the interaction of OA with biological membranes and its

influence on the associated positive health effects. In spite of the fact that

elaidic acid (EA, C18:1t9: the most abundant fatty acid in TFAs) and its

counterpart oleic acid (OA, C18:1c9) have the same molecular weight, but the

difference in the structure at the molecular level and the associated health

effects with their intake is significant. Funari et al. studied the effect of loading

OA, EA and stearic acid (SA, C18:0) on the structural properties of fully

hydrated phosphatidylethanolamines (PEs) [60]. They found that OA

significantly alters the membrane structure and reduces up to 2023 C of the

lamellar-to-hexagonal transition temperature. Interestingly, the replacement of

OA with its congeners EA and SA does not induce a significant effect on the

structure. Both EA and SA display a very modest effect of about 1-4 C

reduction of the transition temperature. It was suggested that the effect of OA

on the structure is not attributed only to the presence of a double bond at the

position 9 in its backbone or the total carbon atoms, but it is most likely

attributed to the molecular shape as OA has a wedge-shaped molecule with a

kink in the middle of its acyl chain [59-61].

In a recent report, the effect of solubilizing EA and OA on the

nanostructure of fully hydrated monoelaidin (ME, a neutral rod-like

monoacylglycerol with a hydrophobic tail consists of a straight acyl chain

(EA, C18:1t9)) was investigated [31]. It was proposed in the literature to use

ME as a model lipid for investigating the lamellar-to-nonlamellar transitions,

which are of biological relevance and take place in different biological

membranes under certain circumstances [109-112].

Figure 3 shows a rich polymorphism upon the solubilization of OA and

EA in the fully hydrated ME-based system: different inverted-type self-

assembled liquid crystalline phases and microemulsions are displayed [31].

Self-Assembled Liquid Crystalline Nanostructures 21

OA shows a greater tendency to perturb the ME bilayers and makes the

membrane curvature more negative and therefore it is more efficient than EA

in inducing the formation of the discontinuous Fd3m and L

2

(inverted-type

microemulsion) phases [31].

The addition of vegetable oils or fatty acids to fully hydrated

monoglycerides such as ME, monoolein (MO) or MLO makes the spontaneous

curvature more negative and therefore induces the formation of highly curved

structures (discontinuous Fd3m and L

2

phases) [31,86,95,100,114].

As a consequence, these hydrophobic guest molecules can be added to

tune the interface curvature for obtaining the desired nanostructure. The

solubilization of the saturated hydrocarbon tetradecane tunes the internal

nanostructure of aqueous dispersions based on MLO (Figure 2) in the classical

sequence described above for the non-dispersed fully hydrated monoglyceride-

based systems (see section IV): a transition from (a) cubosomes, via (b)

hexosomes and (c) micellar cubosomes, to (d) EMEs was reported [100,108].

Similar behavior was also observed when loading OA to MO in the non-

dispersed and dispersed states [113,114].

MO has a different molecular shape than ME due to the cis configuration

present in its hydrophobic tail and therefore it tends at ambient temperatures to

form the bicontinuous cubic Pn3m phase under full hydration conditions;

whereas the fully hydrated rod-like lipid ME adopts a lamellar phase [31,109,

113-115].

Figure 3. Temperature-dependence behavior of the fully hydrated OA-loaded (A) and

EA-loaded (B) ME systems. The experiments for both self-assembled systems were

performed with RWT ratio in the range of 00.6 and were used to construct the partial

phase diagrams. The dashed/dotted curves indicate the approximate phase boundaries

between the different phases. These phase boundaries are tentative (they are not well

characterized) (the figure has been taken with permission from reference [31]).

Intan Diana Mat Azmi and Anan Yaghmur 22

Figure 4. Representative animal SPECT/CT images showing biodistribution of

subcutaneously administered 99mTc-SpmTrien-hexosomes at different time points.

(A) 99mTc-SpmTrienhexosomes 5 min post-injection; (B) 3 h post-injection of

99mTc-SpmTrien-hexosomes; (C) 6 h post-injection of 99mTc-SpmTrien-hexosomes,

and (D) 99mTc-SpmTrien-hexosomes at 24 h post-injection (the figure has been

adapted with permission from reference [119]).

VI. RADIOLABELING OF OA-LOADED HEXOSOMES

FOR THERANOSTIC APPLICATIONS

The research area of molecular imaging has been rapidly developed due to

the potential of biomedical and pharmaceutical applications and the

advantages of non-invasive visualization of delivering, targeting, detection of

cancer, adjustment of treatment protocols, and so forth [116]. Among different

imaging techniques, the radiotracer imaging based on single-photon emission

computed tomography (SPECT) or positron-emission tomography (PET) is a

Self-Assembled Liquid Crystalline Nanostructures 23

useful tool in the detection and treatment of severe disease such as cancer by

the conjugation of radionuclides to nanoparticles and monitoring their uptake

in the whole-body basis [117, 118]. In a recent report, a highly efficient

radiolabelling method based on OA-loaded hexosomes using SpmTrien

(polyamine 1, 12-diamino-3, 6, 9-triazododecane) as a chelating agent was

successfully developed [119]. The

99m

Tc-labeled SpmTrien-hexosomes were

synthesized with good radiolabeling (84%) and high radiochemical purity (>

90%). The interested reader is referred to ref. 119 for further details on the

applied surface chelation method. The

99m

Tc-SpmTrien-hexosomes were

subcutaneously injected to the flank of healthy mice and the in vivo imaging

for the distribution of these radiolabeled nanoparticles was followed by

SPECT in combination with computed tomography (CT). Figure 4 shows

representative SPECT/CT images of the biodistribution and accumulation of

99m

Tc-SpmTrien-hexosomes at different time intervals after administration

[119]. It is interesting that the investigated

99m

Tc-SpmTrien-hexosomes form a

depot in the subcutaneous adipose tissue without any significant accumulation

in other tissues or organs after 24 hrs of injecting the nanostructured aqueous

dispersion [119]. These radiolabeled hexosomes can serve as a promising non-

invasive visualization tool applicable for investigating the in vivo performance

of hexosomal nanocarriers intended for theranostic applications by using

SPECT/CT [119].

CONCLUSION

The last two decades have witnessed an enormous interest in

understanding the role of oleic acid (OA) in modulating the function of various

proteins and the related health-promoting effects as well as the protective

effects against tumoral and hypertensive pathologies. It was the main attention

in the present contribution to summarize recent studies on the role of OA in

regulating biological functions and its use as an essential component in

formulating soft self-assembled drug nanocarriers. In spite of various

published studies to date, the relationship between the molecular interactions

of OA with the plasma membrane and the activation of different intracellular

pathways associated with the health implications is still lacking. It is still of

utmost importance to examine the reasons behind the potential beneficial

effects associated with OA intake.

Intan Diana Mat Azmi and Anan Yaghmur 24

REFERENCES

[1] Lee, J. & Kellaway, I. W. (2000). Combined effect of oleic acid and

polyethylene glycol 200 on buccal permeation of D-Ala(2), D-Leu(5)

enkephalin from a cubic phase of glyceryl monooleate. International

Journal of Pharmaceutics, 204(1-2), 137-44.

[2] Board, F. a. N. Letter report on dietary reference intake of trans fatty

acids. Accessed December 13, 2013. Available from: URL:

http://www.iom.edu/Object.File/Master/13/083/0.pdf.

[3] Kritchevsky, D. (1982). Trans fatty acid effects in experimental

atherosclerosis. Journal of Federation Proceeding, 41(11), 2813-7.

[4] Ruttenberg, H., Davidson, L. M., Little, N. A., Klurfeld, D. M. &

Kritchevsky, D. (1983). Influence of trans unsaturated fats on

experimental atherosclerosis in rabbits. Journal of Nutrition, 113(4),

835-44.

[5] Mozaffarian, D., Katan, M. B., Ascherio, A., Stampfer, M. J. & Willett,

W. C. (2006). Trans fatty acids and cardiovascular disease. New England

Journal of Medicine, 354(15), 1601-13.

[6] Gebauer, S., Psota, T. & Kris-Etherton, P. (2007). The diversity of

health effects of individual trans fatty acid isomers. Lipids, 42(9),

787-99.

[7] Gebauer, S. K., Chardigny, J. M, Jakobsen, M. U., Lamarche, B., Lock,

A. L, Proctor, S. D & Baer, D. J. (2011). Effects of ruminant trans fatty

acids on cardiovascular disease and cancer: a comprehensive review of

epidemiological, clinical, and mechanistic studies. Advance in Nutrition,

2(4), 332-54.

[8] Combe, N., Clouet, P., Chardigny, J-M., Lagarde, M. & Lger, C. L.

(2007). Trans fatty acids, conjugated linoleic acids, and cardiovascular

diseases. European Journal of Lipid Science and Technology, 109(9),

945-53.

[9] Bendsen, N. T., Christensen, R., Bartels, E. M. & Astrup, A. (2011).

Consumption of industrial and ruminant trans fatty acids and risk of

coronary heart disease: a systematic review and meta-analysis of cohort

studies. European Journal of Clinical Nutrition, 65(7), 773-83.

[10] Thompson, A. K, Shaw, D. I, Minihane, A. M. & Williams, C. M.

(2008). Trans-fatty acids and cancer: the evidence reviewed. Nutrition

Research Reviews, 21(2), 174-88.

Self-Assembled Liquid Crystalline Nanostructures 25

[11] Thompson, A. K., Minihane, A. M. & Williams, C. M. (2011). Trans

fatty acids and weight gain. International Journal of Obesity (London),

35(3), 315-24.

[12] Bruckert, E. & Rosenbaum, D. (2011). Lowering LDL-cholesterol

through diet: potential role in the statin era. Current Opinion in

Lipidology, 22(1), 43-8.

[13] Anderson, A. K, Bignell, W. E. & Chakraborty, P. (2011). Negative

effect of industrial produced trans fatty acid (elaidic acid) on pregnancy

outcome and early postpartum life. Agro Food Industry Hi-Tech,

22(5),10-2.

[14] Mozaffarian, D., Aro, A. & Willett, W. C. (2009). Health effects of

trans-fatty acids: experimental and observational evidence. European

Journal of Clinical Nutrition, 63, S5-S21.

[15] Willett, W. C. (2006). Trans fatty acids and cardiovascular disease-

epidemiological data. Atherosclerosis Supplements, 7(2), 5-8.

[16] Astorg, P. (2005). Dietary fatty acids and colorectal and prostate

cancers: epidemiological studies. Bulletin of Cancer, 92(7), 670-84.

[17] Mensink, R. P. & Katan, M. B. (1990). Effect of dietary trans fatty acids

on high-density and low-density lipoprotein cholesterol levels in healthy

subjects. New England Journal of Medicine, 323(7), 439-45.

[18] Ascherio, A. (2006). Trans fatty acids and blood lipids. Atherosclerosis

Supplements, 7(2), 25-7.

[19] Byers, T. (1999). What can randomized controlled trials tell us about

nutrition and cancer prevention? CA: A Cancer Journal for Clinicians,

49(6), 353-61.

[20] Grosso, G., Mistretta, A., Frigiola, A., Gruttadauria, S., Biondi, A.,

Basile, F. & Biondi, A. (2013). Mediterranean Diet and Cardiovascular

Risk Factors: A Systematic Review. Critical Reviews in Food Science

and Nutrition, 54(5), 593-610.

[21] Alarcon de la Lastra, C., Barranco, M. D., Motilva, V. & Herrerias, J. M.

(2001). Mediterranean diet and health: Biological importance of olive

oil. Current Pharmaceutical Design, 7(10), 933-50.

[22] Dontas, A. S., Zerefos, N. S., Panagiotakos, D. B. and Valis, D. A.

(2007). Mediterranean diet and prevention of coronary heart disease in

the elderly. Clinical Interventions in Aging, 2(1), 109-15.

[23] Mozaffarian, D., Pischon, T., Hankinson, S. E., Rifai, N., Joshipura, K.,

Willett, W. C. and Rimm, E. B. (2004). Dietary intake of trans fatty

acids and systemic inflammation in women. The American Journal of

Clinical Nutrition, 79(4), 606-12.

Intan Diana Mat Azmi and Anan Yaghmur 26

[24] Hu, F. B., Manson, J. E., Stampfer, M. J., Colditz, G., Liu S, Solomon,

C. G. & Willett, W. C. (2001). Diet, lifestyle, and the risk of type 2

diabetes mellitus in women. New England Journal of Medicine, 345(11),

790-7.

[25] Tarrago-Trani, M. T., Phillips, K. M., Lemar, L. E. & Holden, J. M.

(2006). New and Existing Oils and Fats Used in Products with Reduced

Trans-Fatty Acid Content. Journal of the American Dietetic Association,

106(6), 867-80.

[26] Tan, A. S. L. (2011). An approach to building the case for nutrition

policies to limit trans-fat intake A Singapore case study. Health Policy,

100(23), 264-72.

[27] Remig, V., Franklin, B., Margolis, S., Kostas, G., Nece, T. & Street, J.

C. (2010). Trans fats in America: a review of their use, consumption,

health implications, and regulation. Journal of the American Dietetic

Association, 110(4), 585-92.

[28] Alarcon de la Lastra, C., Barranco, M. D., Motilva, V. & Herrerias, J. M.

(2001). Mediterranean diet and health: biological importance of olive

oil. Current Pharmaceutical Design, 7(10), 933-50.

[29] Escrich, E., Solanas, M. & Moral, R. (2014). Olive oil and other dietary

lipids in breast cancer. Cancer Treatment and Research, 159, 289-309.

[30] Contaldo, F., Pasanisi, F. & Mancini, M. (2003). Beyond the traditional

interpretation of Mediterranean diet. Nutrition, Metabolism and

Cardiovascular Diseases, 13(3), 117-9.

[31] Yaghmur, A., Sartori, B. & Rappolt, M. (2012). Self-assembled

nanostructures of fully hydrated monoelaidin-elaidic acid and

monoelaidin-oleic acid systems. Langmuir, 28(26), 10105-19.

[32] Panico, S., Mattiello, A., Panico, C. & Chiodini, P. (2014).

Mediterranean dietary pattern and chronic diseases. Cancer Treatment

and Research, 159, 69-81.

[33] Kiortsis, D. N. & Simos, Y. V. (2014). Mediterranean diet for the

prevention and treatment of metabolic syndrome: is it worth it?

Angiology, 65(1), 5-8.

[34] Kastorini, C. M., Milionis, H. J., Esposito, K., Giugliano, D.,

Goudevenos, J. A. & Panagiotakos, D. B. (2011). The effect of

Mediterranean diet on metabolic syndrome and its components: a meta-

analysis of 50 studies and 534,906 individuals. Journal of the American

College of Cardiology, 57(11), 1299-313.

[35] Vassiliou, E. K., Gonzalez, A., Garcia, C., Tadros, J. H., Chakraborty,

G. & Toney, J. H. (2009). Oleic acid and peanut oil high in oleic acid

Self-Assembled Liquid Crystalline Nanostructures 27

reverse the inhibitory effect of insulin production of the inflammatory

cytokine TNF-alpha both in vitro and in vivo systems. Lipids in Health

and Disease, 8, 25.

[36] Jeffery, N. M, Yaqoob, P., Newsholme, E. A. & Calder, P. C. (1996).

The effects of olive oil upon rat serum lipid levels and lymphocyte

functions appear to be due to oleic acid. Annals of Nutrition &

Metabolism, 40(2), 71-80.

[37] Ruiz-Gutierrez, V., Muriana, F. J., Guerrero, A., Cert, A. M. & Villar, J.

(1996). Plasma lipids, erythrocyte membrane lipids and blood pressure

of hypertensive women after ingestion of dietary oleic acid from two

different sources. Journal of Hypertension, 14(12), 1483-90.

[38] Sales-Campos, H., de Souza, P. R., Peghini, B. C., da Silva, J. S. &

Cardoso, C. R. (2013). An overview of the modulatory effects of oleic

acid in health and disease. Mini-Reviews in Medicinal Chemistry, 13(2),

201-10.

[39] Teres, S., Barcelo-Coblijn, G., Benet, M., Alvarez, R., Bressani, R.,

Halver, J. E. & Escriba, P. V. (2008). Oleic acid content is responsible

for the reduction in blood pressure induced by olive oil. Proceedings of

the National Academy of Sciences of the United States of America,

105(37), 13811-6.

[40] Carrillo, C., Cavia Mdel, M. & Alonso-Torre, S. (2012). Role of oleic

acid in immune system; mechanism of action; a review. Nutricion

Hospitalaria, 27(4), 978-90.

[41] de Silva, P. S. A., Luben, R., Shrestha, S. S., Khaw, K. T. & Hart, A. R.

(2014). Dietary arachidonic and oleic acid intake in ulcerative colitis

etiology: a prospective cohort study using 7-day food diaries. European

Journal of Gastroenterology & Hepatology, 26(1), 11-8.

[42] Touitou, E., Godin, B., Karl, Y., Bujanover, S. & Becker, Y. (2002).

Oleic acid, a skin penetration enhancer, affects Langerhans cells and

corneocytes. Journal of Controlled Release: Official Journal of the

Controlled Release Society, 80(1-3), 1-7.

[43] Francoeur, M. L., Golden, G. M. & Potts, R. O. (1990). Oleic-acid - its

effects on stratum-corneum in relation to (trans)dermal drug delivery.

Pharmaceutical Research, 7(6), 621-7.

[44] Anderson, W. B. & Jaworski, C. J. (1977). Modulation of adenylate-

cyclase activity of fibroblasts by free fatty-acids and phospholipids.

Archives of Biochemistry and Biophysics, 180(2), 374-83.

Intan Diana Mat Azmi and Anan Yaghmur 28

[45] Carrillo, C., Cavia Mdel, M. & Alonso-Torre, S. R. (2012). Antitumor

effect of oleic acid; mechanisms of action: a review. Nutricion

Hospitalaria, 27(6), 1860-5.

[46] Colomer, R. & Menendez, J. A. 82006). Mediterranean diet, olive oil

and cancer. Clinical and Translational Oncology, 8(1), 15-21.

[47] Escrich, E., Moral, R. & Solanas, M. (2011). Olive oil, an essential

component of the Mediterranean diet, and breast cancer. Public Health

Nutrition, 14(Special Issue 12A), 2323-32.

[48] Cardeno, A., Sanchez-Hidalgo, M., Cortes-Delgado, A. & de la Lastra,

C. A. (2013). Mechanisms involved in the antiproliferative and

proapoptotic effects of unsaponifiable fraction of extra virgin olive oil

on HT-29 cancer cells. Nutrition and Cancer, 65(6), 908-18.

[49] Grosso, G., Buscemi, S., Galvano, F., Mistretta, A., Marventano, S., La

Vela, V., Drago, F., Gangi, S., Basile, F. & Biondi, A. (2013).

Mediterranean diet and cancer: epidemiological evidence and

mechanism of selected aspects. BMC Surgery, 13, S2-S14.

[50] Menendez, J. A. & Lupu, R. (2006). Mediterranean dietary traditions for

the molecular treatment of human cancer: anti-oncogenic actions of the

main olive oil's monounsaturated fatty acid oleic acid (18:1n-9). Current

Pharmaceutical Biotechnology, 7(6), 495-502.

[51] Schwartz, B. & Madar, Z. (2010). Chapter 103 - Olive oil prevents

experimentally induced breast and colon carcinogenesis. In: V. R.

Preedy, & R. R. Watson, (Eds.), Olives and olive oil in health and

disease prevention (pp. 961-8). San Diego: Academic Press.

[52] Phuong Ha-Lien, T., Thao Truong-Dinh, T. & Lee, B-J. (2014).

Biodistribution and pharmacokinetics in rats and antitumor effect in

various types of tumor-bearing mice of novel self-assembled gelatin-