Professional Documents

Culture Documents

Catálogo Completo Contatores

Uploaded by

diegoparodeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catálogo Completo Contatores

Uploaded by

diegoparodeCopyright:

Available Formats

Main Catalogue Contactors

Motor Protection

Accessories

1SBC 0004 99 R1001

Low Voltage Products

Main Catalogue

Contactors

o

Motor Protection

o

Accessories

Low Voltage Products

1SBC 0004 99 R1001

1

2

3

4

5

6

7

8

9

10

Low Voltage Products

As part of its on-going product improvement, ABB reserves the right to modify the characteristics of the products described in this catalogue.

The information given is not contractual. For further details please contact the ABB company marketing these products in your country.

Product Range

A, AE, BC, EH, EK Contactors

N and KC Contactor Relays

Accessories

for A, AE, BC, EH, EK Contactors

and N, KC Contactor Relays

TA and T Thermal O/L Relays

E Electronic O/L Relays

General Technical Data

Standards, Approvals

Terminal Marking and Positioning

Star-Delta Starter Diagrams

Dimensions

Reference Index

List of Addresses

IEC

VDE

UTE

# #

#

#

#

# #

#

# #

#

# #

# #

B(C) 6 and B(C) 7 Mini Contactors - Reversing Contactors

K(C) 6 Mini Contactor Relays

T 7 DU Thermal O/L Relay

1SBC 0004 99 R1001

Low Voltage Products

Conformity with Standards

The standards and specifications cited for different types of devices, e.g. IEC, BS, VDE, NFC, EN

Publications, should be considered as statements of conformity in the sense of article 10 of the

E.E.C. Low Voltage Directive of 19 February 1973.

There is no label on ABB L.V. control apparatus identifying a national certification organization.

The ABB logo figuring on devices, labels and documents certifies the conformity of devices with

respect to the applicable standards.

CE marking is proof of conformity with the European Directives concerning the product. It must

not be confused with a mark of quality.

CE marking is part of an exclusively administrative procedure designed to guarantee the free

movement of the product inside the European Community.

However, for some countries and some ship certification and classification organizations,

certification is compulsory. In this case, the mark (or logo) of the given organization figures on the

devices if so required (see pages 7/4 and 7/5).

Files pertaining to certifications and approvals obtained are available on request.

Liability

The devices in this catalogue do not endanger safety when they are installed, mounted and used

according to their application and in compliance with the installation rules and standards which

apply to them.

Quality

ABB has set up a quality assurance organisation in compliance with the requirements of

ISO 9001 standard.

ABB factories are ISO 9001 approved.

ABB Low Voltage Products meet with a high quality standard. It is developed, manufactured and

tested under the sole responsibility of ABB.

In compliance with the regulations set out by the ISO 9000 series standard, ABB sets up and

manages the procedures and files relating to product quality and actions having an effect on

quality.

Guarantee

The information contained in this catalogue reflects the current state of our knowledge and aims

to present our products and their possible applications. Thus, the information does not guarantee

certain specific characteristics of products or their aptitude for a specific utilization. All filed legal

patents or industrial property rights must be respected.

Conformity with Standards,

Liability, Quality and

Guarantee

1SBC 0004 99 R1001

Low Voltage Products

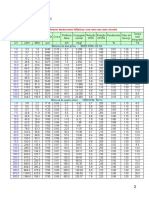

The currents given below concern standard, 1 500 r.p.m. 50 Hz, three-phase cage motors.

These values are for your information and may vary according to the motor manufacturer and depending on the number of poles.

Motor power motor nominal current at:

220-230 V 240 V 380 V 415 V 440 V 500 V 600 V 660-690 V

380-400 V

kW PS = hp A A A A A A A A

0.06 1/12 0.38 0.35 0.22 0.20 0.19 0.16 0.12

0.09 1/8 0.55 0.50 0.33 0.30 0.28 0.24 0.21

0.12 1/6 0.76 0.68 0.42 0.40 0.37 0.33 0.27

0.18 1/4 1.1 1 0.64 0.60 0.55 0.46 0.40

0.25 1/3 1.4 1.38 0.88 0.85 0.76 0.59 0.56

0.37 1/2 2.1 1.93 1.22 1.15 1.06 0.85 0.77 0.7

0.55 3/4 2.7 2.3 1.5 1.40 1.25 1.20 1.02 0.9

0.75 1 3.3 3.1 2 2 1.67 1.48 1.22 1.1

1.1 1.5 4.9 4.1 2.6 2.5 2.26 2.1 1.66 1.5

1.5 2 6.2 5.6 3.5 3.5 3.03 2.6 2.22 2

2.2 3 8.7 7.9 5 5 4.31 3.8 3.16 2.9

2.5 3.4 9.8 8.9 5.7 5.5 4.9 4.3 3.59 3.3

3 4 11.6 10.6 6.6 6.5 5.8 5.1 4.25 3.5

3.7 5 14.2 13 8.2 7.5 7.1 6.2 5.2 4.4

4 5.5 15.3 14 8.5 8.4 7.6 6.5 5.6 4.9

5 6.8 18.9 17.2 10.5 10 9.4 8.1 6.9 6

5.5 7.5 20.6 18.9 11.5 11 10.3 8.9 7.5 6.7

6.5 8.8 23.7 21.8 13.8 12.5 12 10.4 8.7 8.1

7.5 10 27.4 24.8 15.5 14 13.5 11.9 9.9 9

8 11 28.8 26.4 16.7 15.4 14.4 12.7 10.6 9.7

9 12.5 32 29.3 18.3 17 15.8 13.9 11.6 10.6

11 15 39.2 35.3 22 21 19.3 16.7 14.1 13

12.5 17 43.8 40.2 25 23 21.9 19 16.1 15

15 20 52.6 48.2 30 28 26.3 22.5 19.3 17.5

18.5 25 64.9 58.7 37 35 32 28.5 23.5 21

20 27 69.3 63.4 40 37 34.6 30.6 25.4 23

22 30 75.2 68 44 40 37.1 33 27.2 25

25 34 84.4 77.2 50 47 42.1 38 30.9 28

30 40 101 92.7 60 55 50.1 44 37.1 33

37 50 124 114 72 66 61.9 54 45.4 42

40 54 134 123 79 72 67 60 49.1 44

45 60 150 136 85 80 73.9 64.5 54.2 49

51 70 168 154 97 90 83.8 73.7 61.4 56

55 75 181 166 105 96 90.3 79 66.2 60

59 80 194 178 112 105 96.9 85.3 71.1 66

75 100 245 226 140 135 123 106 90.3 82

80 110 260 241 147 138 131 112 96.3 86

90 125 292 268 170 165 146 128 107 98

100 136 325 297 188 182 162 143 119 107

110 150 358 327 205 200 178 156 131 118

129 175 420 384 242 230 209 184 153 135

132 180 425 393 245 242 214 186 157 140

140 190 449 416 260 250 227 200 167 145

147 200 472 432 273 260 236 207 173 152

160 220 502 471 295 280 256 220 188 170

180 245 578 530 333 320 289 254 212 190

184 250 590 541 340 325 295 259 217 200

200 270 626 589 370 340 321 278 235 215

220 300 700 647 408 385 353 310 260 235

250 340 803 736 460 425 401 353 295 268

257 350 826 756 475 450 412 363 302 280

295 400 948 868 546 500 473 416 348 320

315 430 990 927 580 535 505 445 370 337

355 480 1080 1010 636 580 549 483 405 366

400 545 1250 1130 710 650 611 538 450 410

450 610 1410 1270 800 740 688 608 508 460

475 645 1490 1340 850 780 730 645 540 485

500 680 1570 1420 890 830 770 680 565 510

560 760 1750 1580 1000 920 860 760 630 570

600 810 1080 990 920 810 680 610

670 910 1200 1100 1030 910 760 680

Motor Nominal Powers and

Currents

0/0

1SBC 0004 99 R1001

Low Voltage Products

Coil Voltage Code for

Completing Order Codes

A.C. Coils

Types of contactors: Code

N, A 9 to A 110, GA 75

UA 26 to UA 110 and UA16-R to UA75-R

V (50 HZ) V (60 HZ) R I I . .

24 24 8 1

26 28 1 6

28 32 1 7

42 42 8 2

42 48 2 0

48 48 8 3

60 60 7 3

100 100 - 110 7 4

105 110 - 127 2 6

110 110 - 120 8 4

110 - 115 115 - 127 8 9

120 140 2 9

125 - 127 150 3 0

175 208 3 4

190 220 3 6

200 200 - 220 7 5

210 240 4 0

220 - 230 230 - 240 8 0

230 - 240 240 - 260 8 8

230 - 240 277 4 2

380 - 400 400 - 415 8 5

400 - 415 415 - 440 8 6

400 440 5 0

400 - 415 480 5 1

415 - 440 440 - 460 8 7 (1)

440 500 5 3

500 600 5 5

550 5 6

660 - 690 5 8

(1) Unsuitable for 3 or 4-pole A 45 - A 75 contactors.

Standard voltages Code

Types of contactors V (50 Hz) V (60 Hz) I I

EH 145 - EH 300

24 A A

EK 110 - EK 210

24 A B

48 A C

48 A D

110 A E

110 120 A F

127 A G

208 A Z

190 220 A H

240 A K

EH 145 - EH 800 220 - 230 * A L

EK 110 - EK 550 230 - 240 A M

380 A N

380 - 400 440 A P

400 - 415 A R

480 A S

440 A T

500 A U

600 A V

* Read 240V 60Hz for EH 370 ... EH 800 and EK 370 ... EK 550.

Dual frequency coils

2 auxiliary contact blocks maximum per contactor, ambient

temperature 55C and mounting positions

2 and 6 excluded.

Code

Types of contactors V (50 Hz) V (60 Hz) I I

110 110 - 120 E F

EH 145 110 - 115 115 - 127 E G

EH 370 - EH 800 220 220 - 240 E L

EK 370 - EK 550 220 - 230 230 - 255 E M

380 380 - 415 E P

380 - 400 400 - 440 E R

0/1

Multi-frequency coils Code

Types of contactors V (40 - 400 Hz) I I

110 - 120 E F

115 - 127 E G

EH 175 - EH 300 220 - 230 E L

EK 110 - EK 210 230 - 240 E M

380 - 400 E P

400 - 415 E R

Dual voltage coils for Code

N, A 9, A 12 and A 16 contactors

V (50 HZ) V (60 HZ) R I I . .

230/400 6 2

230/400 6 3

D.C. Coils

Types of contactors:

KC, BC - and AE -, GAE 75

KC, BC - AE -, GAE 75

V.d.c Code Code

R I . . I R I I . .

12 0 . . 7 8 0

24 0 . . 1 8 1

42 0 . . 2 8 2

48 1 . . 6 8 3

50 1 . . 7 2 1

60 0 . . 3 8 4

75 2 . . 2 8 5

110 0 . . 4 8 6

125 2 . . 7 8 7

220 0 . . 5 8 8

240 3 . . 3 8 9

250 3 . . 4 3 8

Code

Types of contactors V d.c. I I

12 (2) D A

24 D B

36 D C

EH 145 - EH 800

48 D D

60 D T

EK 110 - EK 550

75 D G

110 D E

125 D U

220 D F

(2) Unsuitable for EH 370 - EH 800, EK 370 and EK 550 contactors.

1SBC 0004 99 R1001

Low Voltage Products

General Data

Ordering Details

When placing an order give either the Order Code or Type.

In most cases these are completed with other references, e.g. a contactor's coil voltage. This is why the order codes and types figuring in the "Ordering

Details" tables have boxes I to be completed.

Packaging

G Individual standard packaging

Contactors, contactor relays, thermal overload relays and other basic products are supplied in individual packaging. Some small contactors (e.g.

B6 and B7 - Section 6) or accessories are in individual batches of "n" pieces as indicated in the "Packaging" column of the "Ordering Details"

table.

The weight and order code always correspond to a single part.

Other products are supplied as a "set" and are thus marked in the "Packaging" column of the "Ordering Details" table. In this case, the weight and

order code correspond to a set.

G Collective packaging

To limit the amount of wasted packaging, simplify handling and checking of deliveries, we offer the collective packaging solution.

The weight and order code correspond to a single part.

Products chosen for this type of packaging are detailed below.

0/2

Type Order code Product Pack

ing

Weight

features

Clearly marked to be completed with

coil voltage: I coil voltage: I I

see below See below See page : pieces kg

4-pole - a.c. operated, 1 stack contactor relays

N 22 E I 1SBH 14 1001 T I I 22 3/6 10 0.34

N 31 E I 1SBH 14 1001 T I I 31 3/6 10 0.34

N 40 E I 1SBH 14 1001 T I I 40 3/6 10 0.34

8-pole - a.c. operated, 2 stack contactor relays

N 44 E I 1SBH 14 1001 T I I 44 3/6 10 0.40

N 53 E I 1SBH 14 1001 T I I 53 3/6 10 0.40

N 62 E I 1SBH 14 1001 T I I 62 3/6 10 0.40

N 71 E I 1SBH 14 1001 T I I 71 3/6 10 0.40

N 80 E I 1SBH 14 1001 T I I 80 3/6 10 0.40

3-pole - a.c. operated contactors

A 9-30-10 I 1SBL 14 1001 T I I 10 2/12 10 0.34

A 9-30-01 I 1SBL 14 1001 T I I 01 2/12 10 0.34

A 9-30-22 I 1SBL 14 1001 T I I 22 2/12 10 0.40

A 9-30-32 I 1SBL 14 1001 T I I 32 2/12 10 0.40

A 12-30-10 I 1SBL 16 1001 T I I 10 2/12 10 0.34

A 12-30-01 I 1SBL 16 1001 T I I 01 2/12 10 0.34

A 12-30-22 I 1SBL 16 1001 T I I 22 2/12 10 0.40

A 12-30-32 I 1SBL 16 1001 T I I 32 2/12 10 0.40

A 16-30-10 I 1SBL 18 1001 T I I 10 2/12 10 0.34

A 16-30-01 I 1SBL 18 1001 T I I 01 2/12 10 0.34

A 16-30-22 I 1SBL 18 1001 T I I 22 2/12 10 0.40

A 16-30-32 I 1SBL 18 1001 T I I 32 2/12 10 0.40

A 26-30-10 I 1SBL 24 1001 T I I 10 2/12 10 0.60

A 26-30-01 I 1SBL 24 1001 T I I 01 2/12 10 0.60

4-pole - a.c. operated contactors

A 9-40-00 I 1SBL 14 1201 T I I 00 2/16 10 0.34

A 16-40-00 I 1SBL 18 1201 T I I 00 2/16 10 0.34

A 26-40-00 I 1SBL 24 1201 T I I 00 2/16 10 0.61

Replacement coils for N, A 9, A 12 and A 16 contactors

ZA 16 1SBN 15 1410 T I I 06 4/29 10 0.08

Type Order code Product Pack

ing

Weight

features

See page : pieces kg

Auxiliary contact blocks

CA 5-10 1SBN 01 0010 W1010 4/4 60 0.014

CA 5-01 1SBN 01 0010 W1001 4/4 60 0.014

CAL 5-11 1SBN 01 0020 W1011 4/4 100 0.050

Interface block

RA 5 1SBN 06 0000 T1000 4/16 10 0.050

TE5S-24 1SBN 02 0010 T1001 4/6 10 0.080

TE5S-120 1SBN 02 0010 T1002 4/6 10 0.080

TE5S-240 1SBN 02 0010 T1003 4/6 10 0.080

TE5S-440 1SBN 02 0010 T1004 4/6 10 0.080

Additional code for coil voltages

A.C. Voltages

V (50 Hz) V (60 Hz) code I I . .

24 24 8 1

42 42 8 2

48 48 8 3

110 110 - 120 8 4

110 - 115 115 - 127 8 9

220 - 230 230 - 240 8 0

230 - 240 240 - 260 8 8

380 - 400 400 - 415 8 5

400 - 415 415 - 440 8 6

415 - 440 440 - 460 8 7

1

1/1

1SBC 0004 99 R1001

Low Voltage Products

Product Range

Contents

Product Range Presentation

Block Contactors and O/L Relays ................................................................................... 1/2, 1/3

Mini Contactors, Compact Reversing Contactors and O/L Relays ................................. 1/4, 1/5

Contactor Relays and Mini Contactor Relays ........................................................................ 1/6

Index Main Summary

Main Summary

1SBC 0004 99 R1001

1/2 Low Voltage Products

Block Contactors Pages

G 3-pole

A, EH Contactors, a.c. operated 2/12, 2/13

BC, AE, EH Contactors, d.c. operated 2/14, 2/15

TBC, TAE Contactors d.c. operated, large coil voltage range 2/24

AF Contactors, a.c./d.c. operated with controlled supply 2/27

EHL Magnetically Latched Contactors, a.c. or d.c. operated 2/29

G 4-pole

A, EK Contactors, a.c. operated 2/16

BC, AE, EK Contactors, d.c. operated 2/17

TBC, TAE Contactors, d.c. operated, large coil voltage range 2/24

AF Contactors, a.c./d.c. operated, with controlled supply 2/27

EKL Magnetically Latched Contactors, a.c. or d.c. operated 2/29

G 3-pole

UA Contactors, a.c. operated 2/21

UA..-R Contactors, a.c. operated 2/22

A, EH Contactors, a.c. operated 2/12, 2/13

G 1-pole

GA Contactor, a.c. operated 2/28

GAE Contactor, d.c. operated 2/28

G 3-pole

A, EH Contactors, a.c. operated 2/46, 2/47

BC, AE, EH Contactors, d.c. operated 2/462/48

G 4-pole

A, EK Contactors, a.c. operated 2/46, 2/47

BC, AE, EK Contactors, d.c. operated 2/462/48

Product Range Presentation

Block Contactors

Section 2

a

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

a

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

c

a

p

a

c

i

t

o

r

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

c

a

p

a

c

i

t

o

r

s

w

i

t

c

h

i

n

g

d

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

d

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

A

p

p

l

i

c

a

t

i

o

n

s

A

p

p

l

i

c

a

t

i

o

n

s

Section

Section

Index

1

1/3

1SBC 0004 99 R1001

Low Voltage Products

Product Range Presentation

Block Contactors

Overload Relays

Block Contactors Pages

G 3-pole

A Contactors, a.c. operated 2/44, 2/45

AE Contactors, d.c. operated 2/44, 2/45

G 4-pole

A Contactors, a.c. operated 2/44, 2/45

AE Contactors, d.c. operated 2/44, 2/45

G 3-pole

A, EH Contactors, a.c. operated 2/49

AE, EH Contactors, d.c. operated 2/49

G 3-pole

A, EH Contactors, a.c. operated 2/50, 2/51

Overload Relays Pages

G 3-pole

E 16 DU Electronic O/L Relay 5/19

T, TA Thermal O/L Relays 5/45/6

Section 2

Section 5

A

p

p

l

i

c

a

t

i

o

n

s

A

p

p

l

i

c

a

t

i

o

n

s

l

i

g

h

t

i

n

g

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

l

i

g

h

t

i

n

g

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

t

r

a

n

s

f

o

r

m

e

r

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

t

r

a

n

s

f

o

r

m

e

r

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

s

l

i

p

-r

i

n

g

m

o

t

o

r

s

w

i

t

c

h

i

n

g

3

-p

h

a

s

e

s

l

i

p

-r

i

n

g

m

o

t

o

r

s

w

i

t

c

h

i

n

g

M

o

t

o

r

p

r

o

t

e

c

t

i

o

n

M

o

t

o

r

p

r

o

t

e

c

t

i

o

n

Section

Section

Index

1SBC 0004 99 R1001

1/4 Low Voltage Products

Section 6

Product Range Presentation

Mini Contactors, Compact Reversing Contactors

Mini Contactors,

Compact Reversing Contactors Pages

G 3-pole

B 6, B 7 Mini Contactors, a.c. operated 6/2

BC 6, BC 7 Mini Contactors, d.c. operated 6/2

TBC 7 Mini Contactors, d.c. operated, large coil voltage range 6/8

G 4-pole

B 6, B 7 Mini Contactors, a.c. operated 6/2

G 3-pole

VB 6, VB 7 Compact Reversing Contactors, a.c. operated 6/3

VB 6A, VB 7A Compact Reversing Contactors, a.c. operated 6/4

VBC 6, VBC 7 Compact Reversing Contactors, d.c. operated 6/3

VBC 6A, VBC 7A Compact Reversing Contactors, d.c. operated 6/4

Mini Contactors,

Compact Reversing Contactors Pages

G 3-pole

B 6, B 7 Mini Contactors, a.c. operated 6/11

BC 6, BC 7 Mini Contactors, d.c. operated 6/11

G 4-pole

B 6, B 7 Mini Contactors, a.c. operated 6/11

G 3-pole

VB 6, VB 7 Compact Reversing Contactors, a.c. operated 6/11

VBC 6, VBC 7 Compact Reversing Contactors, d.c. operated 6/11

Section 6

d

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

d

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

a

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

a

.

c

.

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

A

p

p

l

i

c

a

t

i

o

n

s

A

p

p

l

i

c

a

t

i

o

n

s

Section

Section

Index

1

1/5

1SBC 0004 99 R1001

Low Voltage Products

Product Range Presentation

Mini Contactors, Compact Reversing Contactors

Overload Relay

Section 6

Section 6

l

i

g

h

t

i

n

g

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

l

i

g

h

t

i

n

g

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

M

o

t

o

r

p

r

o

t

e

c

t

i

o

n

M

o

t

o

r

p

r

o

t

e

c

t

i

o

n

A

p

p

l

i

c

a

t

i

o

n

s

A

p

p

l

i

c

a

t

i

o

n

s

P

L

C

's

O

u

t

p

u

t

P

L

C

's

O

u

t

p

u

t

I

n

t

e

r

f

a

c

e

I

n

t

e

r

f

a

c

e

Mini Contactors,

Compact Reversing Contactors Pages

G 3-pole

B 6, B 7 Mini Contactors, a.c. operated 6/12

BC 6, BC 7 Mini Contactors, d.c. operated 6/12

G 4-pole

B 6, B 7 Mini Contactors, a.c. operated 6/12

G 3-pole

VB 6, VB 7 Compact Reversing Contactors, a.c. operated 6/12

VBC 6, VBC 7 Compact Reversing Contactors, d.c. operated 6/12

G 3-pole

BC 6, BC 7 Interface Mini Contactors, d.c. operated 6/5

G 3-pole

B 6S, B 7S Mini Contactors for PLC's Output, d.c. operated 6/5

Overload Relay Pages

G 3-pole

T 7 DU Thermal Overload Relay 6/17

Section

Section

Index

1SBC 0004 99 R1001

1/6 Low Voltage Products

Section 6

Product Range Presentation

Contactors Relays

Mini Contactor Relays

A

p

p

l

i

c

a

t

i

o

n

s

A

p

p

l

i

c

a

t

i

o

n

s

Section 3 Contactor Relays Pages

G 4-pole

N Contactor Relays, a.c. operated 3/6

KC Contactor Relays, d.c. operated 3/6

TKC Contactor Relays, d.c. operated, large coil voltage range 3/7

G 8-pole

N Contactor Relays, a.c. operated 3/6

KC Contactor Relays, d.c. operated 3/6

TKC Contactor Relays, d.c. operated, large coil voltage range 3/7

Mini Contactor Relays Pages

G 4-pole

K 6 Mini Contactor Relays, a.c. operated 6/6

KC 6 Mini Contactor Relays, d.c. operated 6/6

KC 6 Interface Mini Contactor Relays, d.c. operated 6/6

K 6S Mini Contactor Relay for PLC's Output, d.c. operated 6/6

C

o

n

t

r

o

l

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

C

o

n

t

r

o

l

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

C

o

n

t

r

o

l

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

C

o

n

t

r

o

l

c

i

r

c

u

i

t

s

w

i

t

c

h

i

n

g

Section

Section

Index

2/1

1SBC 0004 99 R1001

Low Voltage Products

2

A, AE, BC, EH and EK

Contactors

Ratings 9 to 800 A

Contents

Selection Tables

A and EH 3-pole Contactors ................................................................................................. 2/2

A and EK 4-pole Contactors ............................................................................................... 2/4

Star-delta Starting ............................................................................................................. 2/31

Description and Mounting of Accessories

A and AE Contactors .......................................................................................................... 2/6

EH and EK Contactors ........................................................................................................ 2/8

BC Contactors ................................................................................................................... 2/10

Ordering Details

A 3-pole Contactors - A.C. Operated ................................................................................ 2/12

EH 3-pole Contactors - A.C. Operated ............................................................................. 2/13

BC 3-pole Contactors - D.C. Operated ............................................................................. 2/14

AE and EH 3-pole Contactors - D.C. Operated ................................................................ 2/15

A and EK 4-pole Contactors - A.C. Operated ................................................................... 2/16

BC, AE and EK 4-pole Contactors - D.C. Operated.......................................................... 2/17

A 4-pole Contactors with N.O. and N.C. Main Poles - A.C. Operated .............................. 2/18

BC and AE 4-pole Contactors with N.O. and N.C. Main Poles - D.C. Operated............... 2/19

3-pole Contactors for 3-phase Capacitor Switching - A.C. Operated ................................ 2/ 20

UA 3-pole contactors .................................................................................................... 2/ 21

UA..-R 3-pole contactors ............................................................................................... 2/ 22

TBC and TAE Contactors - D.C. Operated with Large Coil Voltage Range ..................... 2/24

AF Contactors with Controlled Supply A.C./D.C. Operated .............................................. 2/26

GA 75 and GAE 75 Contactors for D.C. Circuit Switching ................................................ 2/28

EHL and EKL Magnetically Latched Contactors - A.C./D.C. Operated ............................. 2/29

EH Mechanically Interlocked or Mechanically Latched Contactors .................................. 2/30

Technical Data

A, EH and EK Contactors - A.C. Operated ....................................................................... 2/32

BC, AE and EH, EK Contactors - D.C. Operated.............................................................. 2/38

Lighting Circuit Switching .................................................................................................. 2/44

D.C. Circuit Switching ......................................................................................................... 2/46

LV/LV 3-phase Transformer Switching ............................................................................. 2/49

Control of 3-phase Slip-ring Motors .................................................................................... 2/50

Influence of the Length of Conductors Used in Contactor Control Circuit ........................ 2/52

Parallel Connection of Main Poles - Temporary or Intermittent Duty ................................ 2/54

Contactor Utilization Categories and Electrical Durability ................................................. 2/55

Additional Information

Accessories and Coils ............................................................................................... Section 4

General Technical Data, Approvals and Classifications ........................................... Section 7

Terminal Marking and Positioning............................................................................. Section 8

Dimensions ............................................................................................................... Section 9

Index Main Summary

Main Summary

Low Voltage Products

1SBC 0004 99 R1001

2/2

3-pole contactors Type A 9 A 12 A 16 A 26 A 30 A 40 A 50 A 63 A 75

Rated operational power AC-3 (1) 55 C (2)

220-230-240 V kW 2.2 3 4 6.5 9 11 15 18.5 22

380-400 V kW 4 5.5 7.5 11 15 18.5 22 30 37

415 V kW 4 5.5 9 11 15 18.5 25 37 40

440 V kW 4 5.5 9 15 18.5 22 25 37 40

500 V kW 5.5 7.5 9 15 18.5 22 30 37 45

690 V kW 5.5 7.5 9 15 18.5 22 30 37 40

1000 V kW - - - - - - 30 33 37

Rated operational current I

e

/AC- 3 (1) 55 C (2)

220-230-240 V A 9 12 17 26 33 40 53 65 75

380-400 V A 9 12 17 26 32 37 50 65 75

415 V A 9 12 17 26 32 37 50 65 72

440 V A 9 12 16 26 32 37 45 65 70

500 V A 9 12 14 22 28 33 45 55 65

690 V A 7 9 10 17 21 25 35 43 46

1000 V A - - - - - - 23 25 28

Rated operational current I

e

/AC-1 - U

e

max. 690V

40 C (2) A 25 27 30 45 55 60 100 115 125

55 C (2) A 22 25 27 40 55 60 85 95 105

70 C (2) A 18 20 23 32 39 42 70 80 85

with conductor cross-sectional area mm

2

2.5 4 4 6 10 16 35 50 50

Short-circuit protection for contactors without

add-on thermal O/L relays - Motor protection excluded (3)

U

e

500 V a.c. - gG (gI) max. fuses A 25 32 32 50 63 63 100 125 160

Coil consumption

Average pull-in value - 50 Hz VA 70 120 180

- 60 Hz VA 80 140 210

- 50/60 Hz (4) VA/VA 74/70 125/120 190/180

Average holding value - 50 Hz VA/W 8/2 12/3 18/5.5

- 60 Hz VA/W 8/2 12/3 18/5.5

- 50/60 Hz (4) VA/W 8/2 12/3 18/5.5

Mechanical durability

in millions of operating cycles 10

Electrical durability for I

e

/ AC-3 max.

in millions of operating cycles 1.5

Thermal O/L relays Type TA 25 DU TA 75 DU

Setting range A 0.1 - 32 18 - 80

Type TA 42 DU

Setting range A 18 - 42

TA 25 DU TA 42 DU TA 75 DU

(1) For the corresponding kW/hp/A value of 1500 r.p.m., 50 Hz, 3-phase motors, refer to page 0/0. (2) Temperature close to contactor.

(3) For short-circuit protection of motor starters, see page 7/17 (4) 50/60 Hz coils: voltage codes I I to I I, see page 0/1.

Other technical information: page 2/32.

1500 r.p.m. - 50 Hz

or 1800 r.p.m. - 60 Hz

3-phase Motors

3-phase Motors

8 0 8 8

A and EH 3-pole Contactors - A.C. Operated

TA and T Thermal O/L Relays

Selection Table

Index Section

Section

2/3

1SBC 0004 99 R1001

Low Voltage Products

2

A and EH 3-pole Contactors - A.C. Operated

TA and T Thermal O/L Relays

Selection Table

3-pole contactors Type A 95 A 110 EH 145 EH 175 EH 210 EH 260 EH 300 EH 370 EH 550 EH 700 EH 800

Rated operational power AC-3 (1)

55 C (2) 220-230-240 V kW 25 30 45 55 59 80 90 110 160 220 220

380-400 V kW 45 55 75 90 110 140 160 200 280 370 400

415 V kW 55 59 75 90 110 140 160 220 315 400 425

440 V kW 55 59 75 90 110 140 160 220 315 400 450

500 V kW 55 59 90 110 132 180 200 250 400 480 520

690 V kW 55 75 110 132 160 200 250 355 500 600 650

1000 V kW 40 40 110 132 160 180 200 220 250 315 315

Rated operational current I

e

/ AC- 3 (1)

55 C (2) 220-230-240 V A 96 110 150 185 210 260 305 400 550 700 750

380-400 V A 96 110 145 185 210 260 305 400 550 700 750

415 V A 96 110 145 185 210 260 300 400 550 700 720

440 V A 93 100 145 185 210 240 280 370 550 700 720

500 V A 80 100 145 170 210 240 280 370 550 700 720

690 V A 65 82 120 170 210 220 280 370 550 700 720

1000 V A 30 30 80 94 113 125 140 155 175 220 220

Rated operational current I

e

/AC-1

U

e

max. 690 V

40 C (2) A 145 160 230 260 300 400 445 550 800 1000 1000

55 C (2) A 135 145 200 230 270 340 375 470 650 800 800

70 C (2) A 115 130 160 170 215 290 325 400 575 720 720

with conductor cross-sectional area mm

2

50 70 120 150 185 300 300 2 x 185 2 x 240 2 x 300 2 x 300

gG (gI) max. fuses A 160 200 250 355 355 500 500 630 800 1000 1000

Coil consumption

Average pull-in value - 50 Hz VA 350 430 800 1100 2600 3500

- 60 Hz VA 450 490 900 1200 2900 4000

- 50/60 Hz (4) VA/VA 410/365 460/400 500 630 2800/2450 3800/3400

Average holding value - 50 Hz VA/W 22/6.5 30/11 44/15 52/18 90/ 36 125/ 50

- 60 Hz VA/W 26/8 35/12 52/18 65/22 105/44 140/ 60

- 50/60 Hz (4) VA/W 27/7.5 38/12 2.5/2.5 2.5/2.5 100/47 140/60

Mechanical durability

in millions of operating cycles 10 10 5

Electrical durability I

e

/AC- 3 max.

in millions of operating cycles > 1 > 1 > 0.6 > 0.5

Thermal O/L relays Type TA 80 DU T 200 DU T 900 DU/SU

Setting range A 29 - 80 100 - 200 265 - 850

Type TA 110 DU T 450 DU/SU

Setting range A 65 - 110 130 - 400

TA 80 DU TA 110 DU T 200 DU T 450 DU T 900 DU

(1) For the corresponding kW/hp/A value of 1500 r.p.m., 50 Hz, 3-phase motors, refer to page 0/0. (2) Temperature close to contactor.

(3) For short-circuit protection of motor starters, see page 7/17 (4) 50/60 Hz coils: voltage codes I I to I I and E I, see page 0/1.

please consult co-ordination tables (ref. ITSCB 649171/002 9-1996).

Other technical information: page 2/33.

8 0 8 8

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/4

4-pole contactors Type A 9 A 16 A 26 A 45 A 50 A 75

Rated operational voltage U

e

max. V 690 690 690

Rated operational current I

e

/ AC-1

40 C (1) A 25 30 45 70 100 125

55 C (1) A 22 27 40 60 85 105

70 C (1) A 18 23 32 50 70 85

with conductor cross-sectional area mm

2

2.5 4 6 25 35 50

Short-circuit protection for contactors without

thermal O/L relays - Motor protection excluded

U

e

500V a.c. - gG (gI) max. fuses A 25 32 50 80 100 160

Coil consumption

Average pull-in value - 50 Hz VA 70 120 180

- 60 Hz VA 80 140 210

- 50/60 Hz (2) VA/VA 74/70 125/120 190/180

Average holding value - 50 Hz VA/W 8/2 12/3 18/5.5

- 60 Hz VA/ W 8/2 12/3 18/5.5

- 50/60 Hz (2) VA/W 8/2 12/3 18/5.5

Mechanical durability

in millions of operating cycles 10

Electrical durability for I

e

/ AC-1 max.

in millions of operating cycles See curves page 2/56

(1) Temperature close to contactor.

(2) 50/60 Hz coils: voltage codes I I to I I, see page 0/1.

Other technical information: page 2/32.

A and EK 4-pole Contactors - A.C. Operated

Selection Table

8 0 8 8

Index Section

Section

2/5

1SBC 0004 99 R1001

Low Voltage Products

2

A and EK 4-pole Contactors - A.C. Operated

Selection Table

Type EK 110 EK 150 EK 175 EK 210 EK 370 EK 550

U

e

max. V 690

Rated operational current I

e

/AC-1

40 C (1) A 200 250 300 350 550 800

55 C (1) A 180 230 270 310 470 650

70 C (1) A 155 200 215 250 400 575

with conductor cross-sectional area mm

2

95 150 185 240 2 x 185 2 x 240

gG (gI) max. fuses A 250 355 630 800

Coil consumption

Average pull-in value - 50 Hz VA 800 1100 3500 3500

- 60 Hz VA 900 1200 4000 4000

- 50/60 Hz (2) VA/VA 500 630 3800/3400 3800/3400

Average holding value - 50 Hz VA/W 44/15 52/18 125/50 125/50

- 60 Hz VA/W 52/18 65/22 140/60 140/60

- 50/60 Hz (2) VA/W 2.5/2.5 2.5/2.5 140/60 140/60

Mechanical durability

in millions of operating cycles 5

Electrical durability for I

e

/ AC-1 max.

in millions of operating cycles See curves page 2/56

(1) Temperature close to contactor.

(2) 50/60 Hz coils: voltage codes E I , see page 0/1.

Other technical information: page 2/33.

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/6

Application

A contactors are mainly used for controlling 3-phase motors and generally speaking for controlling power circuits corresponding to their operating

characteristics up to 690 and even 1000 V a.c. and 440 V d.c.

Description of 3-pole and 4-pole contactors: A 9 - A 110

All A and AE contactors can be assembled side by side.

The add-on or built-in auxiliary contacts are suitable for low level currents.

When fitted with a 4-pole CA5 auxiliary contact block, A9 - A16 2-stack or 1-stack contactors ensure positive safety between their auxiliary contacts.

G Control circuit variants:

A contactors: a.c. operated with laminated magnetic circuit.

AE contactors: with laminated magnetic circuit and double-winding coil fed from d.c. supply via a CDL5 insertion contact mounted on the device.

The CDL5 has an N.C. lagging contact for insertion of the second winding.

G Contact variants:

3-pole contactors - with N.O. or N.C. built-in auxiliary contact for A 9 - A 40 contactors.

- with or without side-mounted, factory-assembled auxiliary contacts for A 50 - A 110 contactors.

4-pole contactors: 4-pole make or 2-pole make and 2-pole break without mounted auxiliary contacts.

3-pole/2-stack contactors: the first stack is made of a standard 3-pole contactor and the second stack of an irremovable 4-pole auxiliary contact

block. The width does not exceed that of the 1-stack contactor, only the depth is increased.

G Contactors for specific applications:

UA and UA..-R types for 3-phase capacitor switching.

GA and GAE types for d.c. circuit switching.

TAE d.c. operated type with large coil voltage range.

AF a.c. and d.c. operated type with controlled supply.

A and AE Contactors

Description

A 9 - A 110

G Ordering Details ......................................................... pages 2/12, 2/16 G General - Approvals .............................................................. Section 7

G Technical Data ....................................................................... page 2/32 G Terminal Marking and Positioning ....................................... Section 8

G Accessories ............................................................................ Section 4 G Dimensions ............................................................................. Section 9

Location of surge suppressors

Terminals delivered in open position with captive

screws (screws of unused terminals must be tightened).

Screwdriver guidance for all terminals makes it

possible to use motorized screwdrivers.

All terminals provide protection against accidental

di rect contact wi th l i ve parts accordi ng to

VDE 0106 - Part. 100.

All A 9 - A 40 contactor terminals as well as

A 45 - A 110 contactor auxiliary contact and coil

terminals ensure IP 20 degree of protection according

to IEC 947-1.

Location of side-mounted accessories: on right or left

hand side. Factory-mounted on:

left hand side for CAL5 on A 50 - A 110-30-11,

right hand side for CDL5/CCL5 on AE 45 - AE 110.

Quick fixing on mounting rail according to IEC 715,

EN 50022 and EN 50023 standards:

35 x 7.5 mm for A 9 - A 40,

35 x 15 mm for A 9 - A 75,

75 mm for A 45 - A 110.

Holes for screw fixing (screws not supplied).

Distance between holes according to

EN 50003 (contactors for 11 kW motors).

Terminal screws:

Pozidriv (+,-) N 2 for all A9 - A 40 terminals and

for A 45 - A 110 coil terminals.

M8 screws with 6.5 mm slot for A 45 - A 75 main

terminals.

HC, M8 for A 95/110 main terminals.

Terminal marking according to IEC 947-4-1,

EN 50005, EN 50012 and NEMA standards.

Connecting point for control leads in top part of

main terminals of A 45 - A 75 contactors.

Clear marking of coil voltages and frequencies.

Location of function marker.

Stops for attaching front-mounted accessories.

Sommaire Chapitre

Index Section

Section

2/7

1SBC 0004 99 R1001

Low Voltage Products

2

A and AE Contactors

Accessories and Thermal O/L Relays

* Use electronic timer TE 5S (page 4/6) with A(E) 95 and A(E) 110 contactors.

The same accessories can be added on to A 9, A 16, A 26, A 45, A50 and A 75 4-pole contactors as 3-pole contactors.

Sommaire Chapitre

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/8

Application

EH 3-pole contactors are mainly used for controlling 3-phase motors and generally speaking for controlling power circuits corresponding to their

operating characteristics up to voltages of 1000 V a.c. and 440 V d.c.

EK 4-pole contactors are mainly used for controlling back-up circuits and all distribution circuits where the neutral needs to be broken.

Description of EH 145 - EH 800 and EK 110 - EK 550 contactors

G One N.O. + N.C. auxiliary contact block is fitted to the left hand side of 3-pole and 4-pole contactors. (Three other auxiliary contact blocks can be added). Complete

closing is ensured, even at the lowest control voltage, by a patented spring system. The coil is compound-filled in heat-resistant, glass-fibre

reinforced resin. Exact ordering and marking details are automatically obtained when the coil is changed.

G EH 3-pole contactors and EK 4-pole contactors can be supplied:

with a laminated magnetic circuit and a coil fed directly from an a.c. current supply for a.c. control

with a laminated magnetic circuit and a coil fed from a d.c. current supply across an economy resistor connected via an auxiliary contact block

comprising an N.C. lagging contact for d.c. control.

G Ordering Details ........................................................... pages 2/13, 2/15, 2/16 G General - Approvals ......................................................... Section 7

G Technical Data ....................................................................... pages 2/33, 2/39 G Terminal Marking and Positioning ................................. Section 8

G Accessories ....................................................................................... Section 4 G Dimensions ....................................................................... Section 9

Separate arcing contacts for EH 370 - EH 800.

Main contacts with high-conductivity

and low-oxidation coating.

Terminal marking according to IEC 947-4-1,

EN 50005, EN 50012 and NEMA. Clearly marked

main terminals and phase conductors.

Plain holes for M4 screws

(auxiliary circuit wires).

M10 earth screw for EH 370 - 800. Can also be

fitted at the bottom.

Screw, nut and washer supplied for every main terminal.

Connectors for either copper or aluminium can be

supplied separately.

EH 145 - EH 800

Separate arcing contacts for EH 370 - EK 550.

Main contacts with high-conductivity

and low-oxidation coating.

Terminal marking according to IEC 947-4-1,

EN 50005, EN 50012 and NEMA. Clearly marked

main terminals and phase conductors.

Clearly marked coil voltage and frequency. Terminals

provide protection against accidental contact with live

parts (IP 20).

M 10 earth screw for EK 370 and EK 550.

Can also be fitted at the bottom.

Screw, nut and washer supplied for every main

terminal.

Connectors for either copper or aluminium can be

supplied separately.

EK 110 - EK 550

Clearly marked coil voltage and frequency. Terminals

provide protection against accidental contact with live

parts (IP 20).

Plain holes for M4 screws

(auxiliary circuit wires).

Removable coil for EH 175 - EH 300.

The coil can be changed on the contactor installed.

Removable coil for EK 110 - EK 210.

The coil can be changed on the contactor installed.

EH and EK Contactors

Description

Glass-fibre reinforced polyester arc chute.

Quick-release clip for access to arc chute.

Terminals protected against accidental contact

with live parts (IP 20).

Auxiliary contact block supplied.

High quality plastic case for EH 145 - 300 and

moulded light alloy case for EH 370 - 800.

Dampers for EH 370 - 800 are supplied with

screws and washers.

Quick-release clip for arc chutes.

Glass-fibre reinforced polyester arc chute.

Dampers for EK 370 and 550 are supplied with

screws and washers.

Terminals protected against accidental direct

contact with live parts (IP 20).

Auxiliary contact block supplied.

Index Section

Section

2/9

1SBC 0004 99 R1001

Low Voltage Products

2

The same accessories can be added on to EK 4-pole contactors as EH 3-pole contactors.

EH and EK Contactors

Accessories and Thermal O/L Relays

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/10

Application

BC contactors are mainly used for controlling 3-phase motors and generally speaking for controlling power circuits corresponding to their operating

characteristics up to 690 V a.c. and 440 V d.c.

Description of 3-pole or 4-pole contactors: BC 9 - BC 30

For BC and TBC type contactors make sure that the mounting distance specified in the "Ordering Details" pages 2/14, 2/17, 2/19 and 2/24 is

respected for "side by side" (position 1) and "stacked" (positions 3 and 4) mounting.

The add-on or built-in auxiliary contacts are suitable for low level currents.

BC 9, BC 16, TBC 9 and TBC 16 2-stack or 1-stack contactors fitted with a 4-pole CA5 auxiliary contact block ensure positive safety between their

auxiliary contacts.

G Type of magnetic circuit:

Solid magnetic circuit with d.c. fed coil.

G Contact variants:

3-pole contactors with built-in N.O. or N.C. auxiliary contact for BC 9 - BC 25 contactors.

4-pole contactors: 4-pole make or 2-pole make and 2-pole break without built-in auxiliary contacts.

2-stack 3-pole contactors: the first stack is made of a standard contactor and the second stack of an irremovable 4-pole auxiliary contact block.

The width does not exceed that of the 1-stack contactor, only the depth is increased.

G Contactors for specific applications:

D.C. operated TBC - types with large voltage range. Variants specific to traction are not given in this catalogue. Please consult us.

BC Contactors

Description

Stops for attaching front-mounted accessories.

Clear marking of coil d.c. voltage.

Terminal marking according to IEC 947-4-1,

EN 50005, EN 50012 and NEMA standards.

Quick fixing on mounting rail according to IEC 715

and EN 50022 standards:

35 x 7.5 mm,

35 x 15 mm.

Location of function marker.

Dove tail anchoring for surge suppressor

assembly.

BC 9 - BC 30

Terminals delivered in open position with captive

screws (screws of unused terminals must be tightened).

Screwdriver guidance for all terminals makes it

possible to use motorized screwdrivers.

All terminals provide protection against accidental

direct contact with live parts according to

VDE 0106 - Part. 100.

Holes for screw fixing (screws not supplied).

Distance between holes according to

EN 50003 (contactors for 11 kW motors).

Terminal screw types:

Pozidriv (+,-) N 2; M 3.5 for all BC 9 and BC 16

terminals and BC 18 - BC 30 coil terminals.

Pozidriv (+,-) N 2; M 4 for BC 18 and BC 25 main

terminals.

Pozidriv (+,-) N 2; M 5 for BC 30 main terminals.

G Ordering Details .................................................... pages 2/14, 2/17, 2/19, 2/24 and 2/25 G General - Approvals .................................................................. Section 7

G Technical Data .................................................................................................. page 2/38 G Terminal Marking and Positioning .......................................... Section 8

G Accessories ....................................................................................................... Section 4 G Dimensions ............................................................................... Section 9

Index Section

Section

2/11

1SBC 0004 99 R1001

Low Voltage Products

2

The same accessories can be added on to BC 9, BC 16 and BC 25 4-pole contactors as 3-pole contactors.

* For selection and use of surge suppressors, see notes page 4/14.

BC Contactors

Accessories and Thermal O/L Relays

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/12

Type Order code Mounted aux. contacts Rated operational Motor power AC-3 Weight

State coil to be completed with coil 1

st

stack 2

nd

stack voltage 220 V 380 V in kg

voltage: I voltage code: I I AC-1 AC-3 230 V 400 V 415 V 690 V

40C 400 V 240 V Pack

ing

See page 0/1 See page 0/1 A A kW kW kW kW 1 piece

A 9-30-10 I 1SBL 14 1001 R I I 10 1 25 9 2.2 4 4 5.5 0.34

A 9-30-01 I (1) 1SBL 14 1001 R I I 01 1 25 9 2.2 4 4 5.5 0.34

A 9-30-22 I 1SBL 14 1001 R I I 22 2 2 25 9 2.2 4 4 5.5 0.40

A 9-30-32 I 1SBL 14 1001 R I I 32 1 2 2 25 9 2.2 4 4 5.5 0.40

A 12-30-10 I 1SBL 16 1001 R I I 10 1 27 12 3 5.5 5.5 7.5 0.34

A 12-30-01 I (1) 1SBL 16 1001 R I I 01 1 27 12 3 5.5 5.5 7.5 0.34

A 12-30-22 I 1SBL 16 1001 R I I 22 2 2 27 12 3 5.5 5.5 7.5 0.40

A 12-30-32 I 1SBL 16 1001 R I I 32 1 2 2 27 12 3 5.5 5.5 7.5 0.40

A 16-30-10 I 1SBL 18 1001 R I I 10 1 30 17 4 7.5 9 9 0.34

A 16-30-01 I (1) 1SBL 18 1001 R I I 01 1 30 17 4 7.5 9 9 0.34

A 16-30-22 I 1SBL 18 1001 R I I 22 2 2 30 17 4 7.5 9 9 0.40

A 16-30-32 I 1SBL 18 1001 R I I 32 1 2 2 30 17 4 7.5 9 9 0.40

A 26-30-10 I 1SBL 24 1001 R I I 10 1 45 26 6.5 11 11 15 0.60

A 26-30-01 I 1SBL 24 1001 R I I 01 1 45 26 6.5 11 11 15 0.60

A 26-30-32 I 1SBL 24 1001 R I I 32 1 2 2 45 26 6.5 11 11 15 0.66

A 30-30-10 I 1SBL 28 1001 R I I 10 1 55 32 9 15 15 18.5 0.71

A 30-30-01 I 1SBL 28 1001 R I I 01 1 55 32 9 15 15 18.5 0.71

A 30-30-32 I 1SBL 28 1001 R I I 32 1 2 2 55 32 9 15 15 18.5 0.77

A 40-30-10 I 1SBL 32 1001 R I I 10 1 60 37 11 18.5 18.5 22 0.71

A 40-30-01 I 1SBL 32 1001 R I I 01 1 60 37 11 18.5 18.5 22 0.71

A 40-30-32 I 1SBL 32 1001 R I I 32 1 2 2 60 37 11 18.5 18.5 22 0.77

A 50-30-00 I 1SBL 35 1001 R I I 00 100 50 15 22 25 30 1.16

A 50-30-11 I 1SBL 35 1001 R I I 11 1 1 100 50 15 22 25 30 1.20

A 50-30-22 I 1SBL 35 1001 R I I 22 2 2 100 50 15 22 25 30 1.23

A 63-30-00 I 1SBL 37 1001 R I I 00 115 65 18.5 30 37 37 1.16

A 63-30-11 I 1SBL 37 1001 R I I 11 1 1 115 65 18.5 30 37 37 1.20

A 63-30-22 I 1SBL 37 1001 R I I 22 2 2 115 65 18.5 30 37 37 1.23

A 75-30-00 I 1SBL 41 1001 R I I 00 125 75 22 37 40 40 1.16

A 75-30-11 I 1SBL 41 1001 R I I 11 1 1 125 75 22 37 40 40 1.20

A 75-30-22 I 1SBL 41 1001 R I I 22 2 2 125 75 22 37 40 40 1.23

A 95-30-00 I 1SFL 43 1001 R I I 00 145 96 25 45 55 55 2.00

A 95-30-11 I 1SFL 43 1001 R I I 11 1 1 145 96 25 45 55 55 2.04

A 95-30-22 I 1SFL 43 1001 R I I 22 2 2 145 96 25 45 55 55 2.07

A 110-30-00 I 1SFL 45 1001 R I I 00 160 110 30 55 59 75 2.00

A 110-30-11 I 1SFL 45 1001 R I I 11 1 1 160 110 30 55 59 75 2.04

A 110-30-22 I 1SFL 45 1001 R I I 22 2 2 160 110 30 55 59 75 2.07

(1) In mounting position 5, do not use more than 2 front-mounted N.C. auxiliary contacts.

The CAL 5-11 side-mounted blocks provide additional N.C. contacts.

G Technical Data ...................................................... page 2/32 G General - Approvals .............................................. Section 7

G Accessories ........................................................... Section 4 G Terminal Marking and Positioning ...................... Section 8

G Thermal O/L Relays .............................................. Section 5 G Dimensions ............................................................ Section 9

S

B

7

3

1

2

S

2

S

B

7

3

1

0

S

2

S

B

7

3

2

0

S

2

S

B

7

3

1

5

S

2

S

B

7

3

2

4

S

2

A 3-pole Contactors - A.C. Operated

A.C. Circuit Switching

Ordering Details

A 9-30-10

A 16-30-10

A 30-30-10

A 50-30-00

A 95-30-00

Index Section

Section

2/13

1SBC 0004 99 R1001

Low Voltage Products

2

Type Order code Mounted Rated operational Motor power AC-3 Weight

State coil to be completed with coil aux. cont. current 220 V 380 V in kg

voltage: I voltage: I I AC-1 AC-3 230 V 400 V 415 V 690 V

40C 400 V 240 V Pack

ing

See page 0/1 See page 0/1 A A kW kW kW kW 1 piece

EH 145-30-11 I SK 824 021- I I 1 1 230 145 45 75 75 110 2.30

EH 145-30-22 I SK 824 031- I I 2 2 230 145 45 75 75 110 2.35

EH 175-30-11 I SK 825 401- I I 1 1 260 185 55 90 90 132 4.65

EH 175-30-21 I SK 825 401- E I 2 1 260 185 55 90 90 132 4.65

EH 175-30-22 I SK 825 411- I I 2 2 260 185 55 90 90 132 4.70

EH 210-30-11 I SK 825 402- I I 1 1 300 210 59 110 110 160 4.65

EH 210-30-21 I SK 825 402- E I 2 1 300 210 59 110 110 160 4.65

EH 210-30-22 I SK 825 412- I I 2 2 300 210 59 110 110 160 4.70

EH 260-30-11 I SK 826 402- I I 1 1 400 260 80 140 140 200 6.20

EH 260-30-21 I SK 826 402- E I 2 1 400 260 80 140 140 200 6.20

EH 260-30-22 I SK 826 412- I I 2 2 400 260 80 140 140 200 6.25

EH 300-30-11 I SK 826 401- I I 1 1 445 305 90 160 160 250 6.20

EH 300-30-21 I SK 826 401- E I 2 1 445 305 90 160 160 250 6.20

EH 300-30-22 I SK 826 411- I I 2 2 445 305 90 160 160 250 6.25

EH 370-30-11 I SK 827 004- I I 1 1 550 400 110 200 220 355 12.40

EH 370-30-22 I SK 827 030- I I 2 2 550 400 110 200 220 355 12.45

EH 550-30-11 I SK 827 005- I I 1 1 800 550 160 280 315 500 12.40

EH 550-30-22 I SK 827 031- I I 2 2 800 550 160 280 315 500 12.45

EH 700-30-11 I SK 828 004- I I 1 1 1000 700 220 370 400 600 17.10

EH 700-30-22 I SK 828 030- I I 2 2 1000 700 220 370 400 600 17.15

EH 800-30-11 I SK 828 005- I I 1 1 1000 750 220 400 425 650 17.30

EH 800-30-22 I SK 828 031- I I 2 2 1000 750 220 400 425 650 17.35

- E I = 40 - 400 Hz coil with built-in rectifier.

G Technical Data ............................................ pages 2/33, 2/39 G General - Approvals .............................................. Section 7

G Accessories ............................................................. Section 4 G Terminal Marking and Positioning ...................... Section 8

G Thermal O/L Relays ................................................ Section 5 G Dimensions ............................................................ Section 9

EH 700-30-11

EH 3-pole Contactors - A.C. Operated

A.C. Circuit Switching

Ordering Details

EH 145-30-11

EH 370-30-11

EH 260-30-11

EH 175-30-11

S

B

7

3

3

8

S

2

S

B

7

3

4

5

S

2

S

B

7

3

4

8

S

2

S

B

7

3

4

7

S

3

S

B

7

3

5

1

S

3

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/14

}

G Technical Data ...................................................... page 2/38 G General - Approvals .............................................. Section 7

G Accessories ........................................................... Section 4 G Terminal Marking and Positioning ...................... Section 8

G Thermal O/L Relays .............................................. Section 5 G Dimensions ............................................................ Section 9

BC 3-pole Contactors - D.C. Operated

A.C. Circuit Switching

Ordering Details

Type Order code Mounted aux. contacts Rated operational Motor power AC-3 Weight

State coil to be completed with coil 1

st

stack 2

nd

stack current 220 V 380 V in kg

voltage: I voltage: I . . I AC-1 AC-3 230 V 400 V 415 V 690 V

40C 400 V 240 V Pack

ing

See page 0/1 See page 0/1 A A kW kW kW kW 1 piece

BC 9-30-10 I FPL 141 3001 R I 10 I 1 22 9 2.2 4 4 4 0.54

BC 9-30-01 I FPL 141 3001 R I 01 I 1 22 9 2.2 4 4 4 0.54

BC 16-30-10 I FPL 181 3001 R I 10 I 1 28 16 4 7.5 7.5 5.5 0.54

BC 16-30-01 I FPL 181 3001 R I 01 I 1 28 16 4 7.5 7.5 5.5 0.54

BC 18-30-22 I GJL 222 3001 R I 22 I 2 2 36 16 4 7.5 7.5 7.5 0.57

BC 25-30-10 I GJL 241 3001 R I 10 I 1 45 25 6.5 * 11 11 11 0.62

BC 25-30-01 I GJL 241 3001 R I 01 I 1 45 25 6.5 * 11 11 11 0.62

BC 30-30-00 I GJL 281 3001 R I 00 I 55 30 9 15 15 15 0.70

BC 30-30-22 I GJL 282 3001 R I 22 I 2 2 55 30 9 15 15 15 0.76

* 7.5 kW at 240 V.

Mounting Distance required between BC contactors.

d

(1)

D

(2)

Ambient temperature Max. switching frequency

mm mm C Operating cycles/h

2 20 20 1200

5 20 55 1200

Mounting Positions of BC contactors.

The following table gives the permissible mounting positions depending on the ambient temperature, contactor

coil operating limits and whether or not there are add-on accessories: auxiliary contact blocks, pneumatic timer.

Ambient Contactor Permissible Coil Add-on accessories

temp. without accessory mounting operating 1-pole aux. contacts or 4-pole aux. contacts or Timer

Poles Built-in positions limits CA5-10 CA5-01 CA5-40 (4 x N.O.) TP 40 DA/IA

aux. cont.

(N.O.) (N.C.) or CA5-31 (3 x N.O. + 1 x N.C.) orTP 180 DA/IA

or CA5-22 (2 x N.O. + 2 x N.C.)

or CA5-04 (4 x N.C.)

C Pos. x U

c

Qty: Qty: Qty: Qty:

1, 3, 4 0.85 -1.1 1 to 4 1 1

55 130, 2, 6 0.95 -1.1 1 to 4 1 1

5* 0.85 -1.1 1 to 4 inc. 2xN.C. max. 1** TP..DA

> 55

1,

130,

and 2, 3, 4 U

c

1 to 4 1 1

70 5* U

c

1 to 4 inc. 2xN.C. max. 1** TP..DA

* In position 5, do not use the RD7 diode unit: consult us. Maximum operating voltage: U

e

< 440 V a.c.

** In position 5, do not use the CA5-04 auxiliary contact block.

Note: For selection and use of surge suppressors (e.g. diode, varistor, etc.), see notes page 4/14.

BC 9-30-10

S

B

6

9

9

4

S

4

BC 25-30-10

BC 30-30-00

S

B

6

4

9

0

S

4

S

B

6

9

9

7

S

4

BC 9 - BC 25 - 30 - 10

BC 30 - 30 - 00

BC 9 - 30 - 01

BC 16 - 30 - 01

BC 25 - 30 - 01

BC 9 - BC 25 - 30 - 10

BC 30 - 30 - 00

BC 9 - 30 - 01

BC 16 - 30 - 01

BC 25 - 30 - 01

}

Index Section

Section

2/15

1SBC 0004 99 R1001

Low Voltage Products

2

Type Order code Mounted Rated operational Motor power AC-3 Weight

State coil to be completed with coil aux. cont. current 220 V 380 V in kg

voltage: I voltage: I I AC-1 AC-3 230 V 400 V 415 V 690 V

40C 400 V 240 V Pack

ing

See page 0/1 See page 0/1 A A kW kW kW kW 1 piece

AE 50-30-00 I 1SBL 35 9001 R I I 00 100 50 15 22 25 30 1.20

AE 50-30-11 I 1SBL 35 9001 R I I 11 1 1 100 50 15 22 25 30 1.24

AE 63-30-00 I 1SBL 37 9001 R I I 00 115 65 18.5 30 37 37 1.20

AE 63-30-11 I 1SBL 37 9001 R I I 11 1 1 115 65 18.5 30 37 37 1.24

AE 75-30-00 I 1SBL 41 9001 R I I 00 125 75 22 37 40 40 1.20

AE 75-30-11 I 1SBL 41 9001 R I I 11 1 1 125 75 22 37 40 40 1.24

AE 95-30-00 I 1SFL 43 9001 R I I 00 145 96 25 45 55 55 2.04

AE 95-30-11 I 1SFL 43 9001 R I I 11 1 1 145 96 25 45 55 55 2.07

AE 110-30-00 I 1SFL 45 9001 R I I 00 160 110 30 55 59 75 2.04

AE 110-30-11 I 1SFL 45 9001 R I I 11 1 1 160 110 30 55 59 75 2.07

EH 145-30-21 I SK 824 021- I I 2 1 230 145 45 75 75 110 2.30

EH 175-30-21 I SK 825 401- I I 2 1 260 185 55 90 90 132 4.70

EH 210-30-21 I SK 825 402- I I 2 1 300 210 59 110 110 160 4.70

EH 260-30-21 I SK 826 402- I I 2 1 400 260 80 140 140 200 6.20

EH 300-30-21 I SK 826 401- I I 2 1 445 305 90 160 160 250 6.25

EH 370-30-21 I SK 827 004- I I 2 1 550 400 110 200 220 355 12.40

EH 550-30-21 I SK 827 005- I I 2 1 800 550 160 280 315 500 12.40

EH 700-30-21 I SK 828 004- I I 2 1 1000 700 220 370 400 600 17.10

EH 800-30-21I SK 828 005- I I 2 1 1000 750 220 400 425 650 17.30

Block diagram for AE Contactor Coil Supply.

G Technical Data ...................................................... page 2/38 G General - Approvals .............................................. Section 7

G Accessories .......................................................... Section 4 G Terminal Marking and Positioning ...................... Section 8

G Thermal O/L Relays .............................................. Section 5 G Dimensions ............................................................ Section 9

AE and EH 3-pole Contactors - D.C. Operated

A.C. Circuit Switching

Ordering Details

N.C. lagging auxiliary contact block with built-in varistor:

CDL 5-01 type on AE 50-AE 75 contactors.

CCL 5-01 type on AE 95 and AE110 contactors.

AE 50-30-00

S

B

7

5

8

2

S

4

EH 210-30-11

S

B

7

5

9

2

S

4

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/16

G Technical Data ....................................................... page 2/32 G Terminal Marking and Positioning ...................... Section 8

G Accessories ............................................................. Section 4 G Dimensions ............................................................ Section 9

G General - Approvals ................................................ Section 7

A and EK 4-pole Contactors - A.C. Operated

A.C. Circuit Switching

S

B

7

3

1

9

S

3

S

B

7

3

4

3

S

3

Ordering Details

Type Order code Mounted aux. Rated operational Weight

State coil to be completed with coil contacts current in kg

voltage: I voltage code: I I AC-1 AC-1

40C 55C Pack

ing

See page 0/1 See page 0/1 A A 1 piece

A 9-40-00 I 1SBL 14 1201 R I I 00 25 22 0.34

A 16-40-00 I 1SBL 18 1201 R I I 00 30 27 0.34

A 26-40-00 I 1SBL 24 1201 R I I 00 45 40 0.61

A 45-40-00 I (1) 1SBL 33 1201 R I I 00 70 60 1.39

A 50-40-00 I (1) 1SBL 35 1201 R I I 00 100 85 1.39

A 75-40-00 I (1) 1SBL 41 1201 R I I 00 125 105 1.39

EK 110-40-11 I SK 824 440- I I 1 1 200 180 4.30

EK 110-40-21 I SK 824 440- E I 2 1 200 180 4.30

EK 110-40-22 I SK 824 450- I I 2 2 200 180 4.35

EK 150-40-11 I SK 824 441- I I 1 1 250 230 4.35

EK 150-40-21 I SK 824 441- E I 2 1 250 230 4.35

EK 150-40-22 I SK 824 451- I I 2 2 250 230 4.40

EK 175-40-11 I SK 825 440- I I 1 1 300 270 6.60

EK 175-40-21 I SK 825 440- E I 2 1 300 270 6.60

EK 175-40-22 I SK 825 448- I I 2 2 300 270 6.65

EK 210-40-11 I SK 825 441- I I 1 1 350 310 6.60

EK 210-40-21 I SK 825 441- E I 2 1 350 310 6.60

EK 210-40-22 I SK 825 451- I I 2 2 350 310 6.65

EK 370-40-11 I SK 827 040- I I 1 1 550 470 17.2

EK 370-40-22 I SK 827 042- I I 2 2 550 470 17.2

EK 550-40-11 I SK 827 041- I I 1 1 800 650 17.2

EK 550-40-22 I SK 827 043- I I 2 2 800 650 17.2

- E I = 40 - 400 Hz coil with built-in rectifier.

(1) 60 Hz coil voltage

Mounting positions 1 to 5 (see page 2/37) and ambient temperature 55C: tolerance reduced to 0.9 - 1.1 U

c

(instead of 0.85 - 1.1 U

c

) for coil

voltage codes 7 I and 8 I. This only concerns devices fitted with CA 5 - and CAL5-11 auxiliary contacts or TP timer.

For mounting position 6 or ambient temperature of +55 to +70 C the information given on page 2/34 remains applicable.

A 45-40-00

EK 370-40-11

S

B

7

3

1

4

S

2

A 9-40-00

EK 175-40-11

S

B

7

3

4

1

S

3

Index Section

Section

2/17

1SBC 0004 99 R1001

Low Voltage Products

2

Ordering Details

Type Order code Mounted aux. Rated operational Weight

State coil to be completed with coil contacts current in kg

voltage: I voltage: I I AC-1 AC-1

40C 55C Pack

ing

See page 0/1 See page 0/1 A A 1 piece

BC 9-40-00 I (1) FPL 141 3201 R I 00 I 22 20 0.54

BC 16-40-00 I (1) FPL 181 3201 R I 00 I 28 25 0.54

BC 25-40-00 I (1) GJL 241 3201 R I 00 I 45 40 0.62

AE 45-40-00 I 1SBL 33 9201 R I I 00 70 60 1.43

AE 50-40-00 I 1SBL 35 9201 R I I 00 100 85 1.43

AE 75-40-00 I 1SBL 41 9201 R I I 00 125 105 1.43

EK 110-40-21 I SK 824 440- I I 2 1 200 180 4.35

EK 150-40-21 I SK 824 441- I I 2 1 250 230 4.40

EK 175-40-21 I SK 825 440- I I 2 1 300 270 6.65

EK 210-40-21 I SK 825 441- I I 2 1 350 310 6.65

EK 370-40-21 I SK 827 040- I I 2 1 550 470 17.2

EK 550-40-21 I SK 827 041- I I 2 1 800 650 17.2

(1) G Distances and mounting positions: see page 2/14.

G For selection and use of surge suppressors (e.g. diode, varistor, etc.) see notes page 4/14.

Block Diagram for AE Contactor Coil Supply.

G Technical Data ..................................................... page 2/38 G General - Approvals .............................................. Section 7

G Accessories ........................................................... Section 4 G Terminal Marking and Positioning ...................... Section 8

G Thermal O/L Relay ................................................ Section 5 G Dimensions ............................................................ Section 9

BC, AE and EK 4-pole Contactors - D.C. Operated

A.C. Circuit Switching

S

B

6

9

9

2

S

2

BC 16-40-00

EK 110-40-21

AE 50-40-00

S

B

7

5

9

4

S

4

S

B

7

5

9

0

S

4

Mounting Distance required between BC contactors.

d

(1)

D

(2)

Ambient temperature Max. switching frequency

mm mm C Operating cycles/h

2 20 20 1200

5 20 55 1200

Mounting Positions of BC contactors.

The following table shows permissible mounting positions depending on the ambient temperature, contactor

coil operating limits and whether or not there are add-on accessories: auxiliary contact blocks, pneumatic timer.

Ambient Contactor Permissible Coil Add-on accessories

temp. without accessory mounting operating 1-pole aux. contacts or 4-pole aux. contacts or Timer

Poles Built-in . positions limits CA5-10 CA5-01 CA5-40 (4 x N.O.) TP 40 DA/IA

aux. cont.

(N.O.) (N.C.) or CA5-31 (3 x N.O. + 1 x N.C.) orTP 180 DA/IA

or CA5-22 (2 x N.O. + 2 x N.C.)

or CA5-04 (4 x N.C.)

C Pos. x U

c

Qty: Qty: Qty: Qty:

1, 3, 4 0.85 -1.1 1 to 4 1 1

55 BC 9 - BC 25 - 40 - 00 130, 2, 6 0.95 -1.1 1 to 4 1 1

5* 0.85 -1.1 1 to 4 inc. 2xN.C. max. 1** TP..DA

> 55

BC 9 - BC 25 - 40 - 00

1,130,2,3,4 U

c

1 to 4 1 1

and

< 70 5* U

c

1 to 4 inc. 2xN.C. max. 1** TP..DA

* In position 5, do not use the RD7 diode unit, please consult us. Maximum operating voltage: U

e

< 440 V a.c.

** In position 5, do not use the CA5-04 auxiliary contact block.

Note: For selection and use of surge suppressors (e.g. diode, varistor, etc.), see notes page 4/14.

}

}

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/18

A 4-pole Contactors with N.O. and N.C. Main Poles

A.C. Circuit Switching

A.C. Operated

Description

G 4-pole contactors fitted with 2 N.C. main poles and 2 N.O. main poles.

G These contactors are suitable for controlling 2 separate circuits, i.e. 2 loads with 2 separate supplies, or

1 circuit comprising 2 separate loads with a single supply (see diagram below). When the contactor operates

there is no mechanical overlapping between the N.O. poles and the N.C. poles: BREAK before MAKE.

These contactors are not suitable for a reversing starter or star-delta starter or for controlling a single

load from 2 separate supplies.

Block Diagrams

G Single supply and 2 separate loads G 2 separate supplies and 2 separate loads

Ordering Details

Type Order code Mounted Rated operational Weight

State coil to be completed with coil aux. contacts current at U

e

690 V in kg

voltage: I voltage: I I AC-1 AC-1

40C 55C Pack

ing

See page 0/1 See page 0/1 A A 1 piece

A 9-22-00 I (1) 1SBL 14 1501 R I I 00 25 22 0.34

A 16-22-00 I (1) 1SBL 18 1501 R I I 00 30 27 0.34

A 26-22-00 I 1SBL 24 1501 R I I 00 45 40 0.61

A 45-22-00 I (1) (2) 1SBL 33 1501 R I I 00 70 60 1.40

A 75-22-00 I (1) (2) 1SBL 41 1501 R I I 00 125 105 1.40

(1) For A 9 and A 16-22 in position 5 or A 45 and A 75-22 in positions 1, 2, 3, 4, or 6 (position 5 unauthorised), do not use more than 2 add-on front-

mounted N.C. auxiliary contact blocks. CAL 5-11 side-mounted blocks provide extra N.C. auxiliary contacts

(2) A 45 and A 75-22 contactors:

Shock withstand: in position 1, contactors being screwed on their support and without extra N.C. auxiliary contact.

1

/2 sinusoidal shock, 11 ms: no change in contact position.

Shock directions : A, C1, C2 : 20g

B1 : 3g

B2 : 10g.

60 Hz Coil Voltage: for mounting positions 1 to 4 and ambient temperature < 55 C: tolerance reduced to 0.9 - 1.1 Uc

(instead of 0.85 - 1.1 Uc) for 7 I and 8 I coil voltage codes.

This only concerns devices fitted with CA 5 - and CAL 5-11 auxiliary contacts or TP timer.

Position 5 unauthorised.

For mounting position 6 or ambient temperature of +55 to +70 C, the information given on page 2/34 remains applicable.

G Technical Data ....................................................... page 2/32 G Terminal Marking and Positioning ...................... Section 8

G Accessories ............................................................. Section 4 G Dimensions ............................................................ Section 9

G General - Approvals ................................................ Section 7

A 26-22

S

B

7

5

8

8

S

4

A 45-22

S

B

7

8

1

9

S

4

Mounting positions:

Index Section

Section

2/19

1SBC 0004 99 R1001

Low Voltage Products

2

Description (as for page 2/18)

Ordering Details

Type Order code Mounted Rated operational Weight

State coil to be completed with coil aux. contacts current at Ue 690 V in kg

voltage: I voltage: I I AC-1 AC-1

40C 55C Pack

ing

See page 0/1 See page 0/1 A A 1 piece

BC 9-22-00 I FPL 141 3501 R I00 I 22 20 0.540

BC 16-22-00 I FPL 181 3501 R I00 I 28 25 0.540

BC 25-22-00 I GJL 241 3501 R I00 I 45 40 0.620

AE 45-22-00 I 1SBL 33 9501 R I I 00 70 60 1.44

AE 75-22-00 I 1SBL 41 9501 R I I 00 125 105 1.44

}

}

}

}

}

BC and AE 4-pole Contactors

with N.O. and N.C. Main Poles

A.C. Circuit Switching - D.C. Operated

G Technical Data ....................................................... page 2/38 G Terminal Marking and Positioning ...................... Section 8

G Accessories ............................................................. Section 4 G Dimensions ............................................................ Section 9

G General - Approvals ................................................ Section 7

Mounting Distance required between BC contactors.

d

(1)

D

(2)

Ambient temperature Max. switching frequency

mm mm C Operating cycles/h

2 20 20 600

5 20 55 600

Mounting Positions of BC 9 - BC 25-22, AE 45 and AE 75-22 4-pole contactors.

The following table shows permissible mounting positions in relation to the ambient temperature, contactor coil

operating limits and whether or not there are add-on accessories: auxiliary contact blocks, pneumatic timer.

Ambient Contactor Permissible Coil Add-on accessories

temp. without accessory mounting operating 1-pole aux. contacts or 4-pole aux. contacts or Timer

Poles Built-in positions limits CA5-10 CA5-01 CA5-40 (4 x N.O.) TP 40 DA/IA

aux. cont.

(N.O.) (N.C.) or CA5-31 (3 x N.O. + 1 x N.C.) orTP 180 DA/IA

or CA5-22 (2 x N.O. + 2 x N.C.)

C Pos. x U

c

Qty: Qty: Qty: Qty:

BC 9 - 22 - 00

1, 2, 3, 4 0.85 -1.1 1 to 4 inc. 2xN.C max. 1 -

55

BC 16 - 22 - 00

1 30 0.85 -1.1 1 to 4 - 1 CA5-40 -

6 0.95 -1.1 1 to 4 inc. 2xN.C. max. 1 -

> 55 BC 9 - 22 - 00

1, 2, 3, 4 U

c

1 to 4 inc. 2xN.C. max. 1 -

and

< 70 BC 16 - 22 - 00

1 30 Uc 1 to 4 - 1 CA5-40 -

< 55 BC 25 - 22 - 00

1, 2 0.85 -1.1

1 to 4 - 1 CA5-40 -

130,3,4,6 0.95 -1.1

> 55 1, 1 30

and

< 70

BC 25 - 22 - 00

2, 3, 4

Uc 1 to 4 - 1 CA5-40 -

AE 45 - 22 - 00

1, 1 30

0.85 - 1.1

1 1

< 55 2, 3, 4 1 to 6 inc. 2xN.C.max. +1 to 2 CA5 1-pole +1 to 2 CA5

AE 75 - 22 - 00

6 0.95 - 1.1 Do not exceed 2xN.C. 1-pole

> 55 AE 45 - 22 - 00 1, 1 30

and

< 70

AE 75 - 22 - 00 2, 3, 4

Uc 1 to 6 inc. 2xN.C.max.

Note: For selection and use of surge suppressors (e.g. diode, varistor, etc.) with BC - contactors

see notes page 4/14.

S

B

6

9

9

3

S

3

BC 9-22-00

AE 45-22-00

S

B

7

5

9

1

S

4

1 1

+1 to 2 CA5 1-pole +1 to 2 CA5

Do not exceed 2xN.C. 1-pole

}

Index Section

Section

Low Voltage Products

1SBC 0004 99 R1001

2/20

3-pole Contactors

for 3-phase Capacitor Switching

A.C. Operated

General