Professional Documents

Culture Documents

Hydraulic Specs Rev0

Uploaded by

vhpatel67Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Specs Rev0

Uploaded by

vhpatel67Copyright:

Available Formats

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 1 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

TECHNICAL SPECIFICATIONS FOR

HYDRAULIC SYSTEM

P13010102S0001

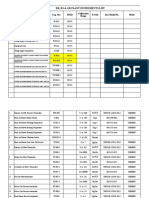

0 28-12-13 VP KS AA Issued for comments

Rev Date Prepared by Checked by Approved by Comments

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 2 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

1 Introduction:

The Reduction Reactor caters the purpose of reduction of Iron ore by Syn gas. The users of Hydraulic

system are part of Reduction Reactor assembly, and are used to control/ assist/ isolation of solid material

flow.

The Reduction Reactor has two slide gates for isolation - Upper slide gate and Lower slide gate. Both of

these gates are hydraulically operated.

The Reduction Reactor has oscillating internals called Burden feeders at three levels, Upper Burden feeder,

Middle Burden feeder and Lower Burden feeder. These Burden feeders oscillate by action of Hydraulic

cylinders and assist in material movement.

The Reactor discharges material into intermediate equipment, namely Product Discharge Hopper. This

Hopper again has oscillating internals to faciliate material movement. These internals are Wiper bar,

Screen sizers and Flow Stimulator.

The Product Discharge Hopper can discharge Product material through either or combination of three

discharge legs. These legs again have Slide gates for isolation, each of which is hydraulically operated.

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 3 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

2 Reference Documents/ Drawings:

Latest revisions of following documents/ drawings shall be referred to with respect to this Technical

specification.

No. Doc/ Dwg no. Title Type of Doc/ Dwg

1

P13010101X0161 Reactor Hydraulic System P & I drawing

2

P13010101X0162

Product Discharge

Hydraulic System - 1

P & I drawing

3

P13010101X0163

Product Discharge

Hydraulic System - 2

P & I drawing

4

P13010102X0024 Upper Slide gate cylinder Mechanical drawing

5 P13010102X0216

Reduction Furnace Upper

Burden Feeder Hydraulic

Cylinder Clevis

Mechanical drawing

6 P13010102X0241

Reduction Furnace MBF

Hydraulic Cylinder

Mechanical drawing

7 P13010102X0258

Reduction Furnace LBF

Hydraulic Cylinder

Mechanical drawing

8 P13010102X0344

wiper bar hydraulic

cylinder

Mechanical drawing

9 P13010102X0351

Flow stimulator hydraulic

Cyliner

Mechanical drawing

10 P13010102X0352

Screen sizer hydraulic

cylinder

Mechanical drawing

11 P13010102X0387 FLSG Hydraulic Cylinder Mechanical drawing

12 P13010102X0311

Lower Slide Gate

Hydraulic Cylinder

Mechanical drawing

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 4 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

3 System description:

Refer following P&I diagrams:

P13010101X0161 Reactor Hydraulic System

P13010101X0162 Product Discharge Hydraulic System - 1

P13010101X0163 Product Discharge Hydraulic System - 2

There are two types of Hydraulic Units. Each is defined depending on the operational pressure level, viz.

High Pressure (HP) Hydraulic Unit and Low Pressure (LP) Hydraulic Unit.

The HP Hydraulic Unit caters the following users:

Upper Slide gate

Upper Burden feeders

Lower Slide gate

Feed leg Slide gates

The LP Hydraulic Unit caters the following users:

Middle Burden feeders

Lower Burden feeder

Wiper bar

Screen sizers

Flow Stimulator

4 Scope of supply:

The broad scope of supply shall be divided into three sections

4.1 Hydraulic Unit

These shall be complete pumping units with accessories and instruments for both types of

Hydraulic systems, viz. HP and LP.

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 5 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

4.2 Hydraulic valve stands

These shall be the valve stands complete with Control valves and Accumulators as applicable for

each user/ group of users.

4.3 Hydraulic cylinders

Each user shall have suitable Hydraulic cylinder/s.

5 Technical specifications:

The technical requirements and specifications for each section of supply are as under:

5.1 Hydraulic Unit

The Hydraulic system shall have two dedicated systems, namely Low pressure (LP) and High Pressure (HP)

systems.

Hydraulic fluid shall be Minerol Oil.

Hydraulic fluid reservoir tank:

The LP & HP system shall have a common oil reservoir tank

Tank capacity: min 2500 liters

Dimensions: By vendor (cuboid shape)

Temp, min / normal / max: 25 / 55 / 65 deg C

Material of Construction: Carbon Steel

Finish: Sand/ Shot blasted, protected internally and externally, surface finish compatible with the

Hydraulic fluid

Insulation: Insulation for Winterization

The Hydraulic tank shall have return oil filters, refilling filters, oil cooler/s, air breathers, visual level

indicators, level alarms/ switches, temperature gauges, temperature alarms/ switches, man hole, drain

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 6 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

with valve, suitable baffles and lifting lugs. The oil shall be returned to tank from top and dropped to

bottom most surface of tank.

The oil coolers shall be water cooled and are envisaged separate for both circuits, HP and LP. However, the

vendor may consider common oil cooler for both circuits.

The Hydraulic tank shall have an internal electric heating coil to heat up the oil during start-up after

extended shutdown or during extreme cold weather.

There shall be dedicated pumping units for LP & HP system. The pumps shall be supplied with suitable

motor, coupled by means of flexible coupling.

LP pumps:

Type: Variable displacement Radial piston

No. of pumps: 3 no. (2 operating + 1 standby)

Capacity: 80 lpm each

Operating pressure: 100 bar g

Noise level: < 85 dBA

HP pumps:

Type: Variable displacement Radial piston

No. of pumps: 2 no. (1 operating + 1 standby)

Capacity: 77 lpm

Operating pressure: 200 bar g

Noise level: < 85 dBA

The pump pressures shall be allowed to vary according to system resistance against the hydraulic cylinder

while flow is maintained constant in accordance from the control signal.

Adjustable pressure controls shall be used to limit the operating pressure. Over pressure protection for

each pump shall be provided by relief valves.

A drip tray shall be provided to collect all external leakage and the drip tray shall cover the entire area of

unit

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 7 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

5.2 Hydraulic valve stands

5.2.1 For HP system:

Slide gates:

Dedicated valve stands shall be supplied for following users (total 3 nos):

Upper Slide gate

Lower Slide gate

Feed leg Slide gates (combined valve stand)

o Briquetter Feed leg Slide gate #1

o Briquetter Feed leg Slide gate #2

o Bypass Feed leg Slide gate

Each valve stand should be designed so as to open the respective Slide gate when energized.

Also, each valve stand should have Accumulator so as to close the respective Slide gate with loss of power.

Each valve stand should be complete with following items for each user:

1 no. Flow regulating valve

1 no. Direction controlling valve

1 no. Pressure regulating valve

1 no. Bladder type vertical Accumulator under Nitrogen pressure. Accumulator should be able to

close the Slide gate with loss of power/ de-energization of DCV. The capacity and holding pressure

of Accumulator should be enough to close the Slide gate in 5 seconds. It should be supplied with

Pressure Relief valve, Provision for charging/ testing, Provision for draining as required etc.

Interconnecting piping Carbon Steel

Pressure gauge/ transmitter

Check-valves, Pressure relief valves, isolation valves as necessary

A drip tray shall be provided to collect all external leakage and the drip tray shall cover the entire

area of valve stand.

The flows for each Slide gate are summarized below:

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 8 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

No. User Flow, lpm

1 Upper Slide Gate 26.4

2 Lower Slide Gate 50.8

3 Briquetter Feed leg Slide gate #1 36.9

4 Briquetter Feed leg Slide gate #2 36.9

5 Bypass Feed leg Slide gate 36.9

Upper Burden feeder:

The valve stand for Upper Burden feeder should be complete with:

1 no. Flow regulating valve

1 no. Direction controlling valve

1 no. Pressure regulating valve

Interconnecting piping Carbon Steel

Pressure gauge/ transmitter

Check-valves, Pressure relief valves, isolation valves as necessary

A drip tray shall be provided to collect all external leakage and the drip tray shall cover the entire

area of valve stand.

The flows for Upper Burden feeder are summarized below:

No. User

Flow, lpm

Min Normal Max

1 Upper Burden feeder 14.7 17.4 19.3

5.2.2 For LP system:

Dedicated valve stands shall be supplied for following LP users (total 3 nos):

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 9 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

Middle Burden feeders

Lower Burden feeder

PDH users

o Wiper bar

o Screen sizer #1

o Screen sizer #2

o Flow Stimulator

Each valve stand should be complete with following items for each user:

1 no. Flow regulating valve

1 no. Direction controlling valve

1 no. Pressure regulating valve

Interconnecting piping Carbon Steel

Pressure gauge/ transmitter

Check-valves, Pressure relief valves, isolation valves as necessary

A drip tray shall be provided to collect all external leakage and the drip tray shall cover the entire

area of valve stand.

The flows for all LP users are summarized below:

No. User

Flow, lpm

Min Normal Max

1 Middle Burden feeder 9.3 11.0 12.2

2 Lower Burden feeder 13.2 15.6 17.3

3 Wiper bar 31.5 37.3 41.5

4 Screen sizer #1 25.1 25.1 25.1

5 Screen sizer #2 25.1 25.1 25.1

6 Flow Stimulator 25.1 25.1 25.1

SHANXI TIAHANG MINING

CSTM

0.3 MMTPY HBI PROJECT

MME

Project No: P1301 MME No: P13010102S0001 Date: 28-12-13 Rev: 0 Page 10 of 10

Confidential: This document and the information disclosed are the property of MME. The document discloses proprietary

information and may not be reproduced nor disclosed to any person, nor used for any purpose except with the written permission of

MME.

5.3 Hydraulic cylinders

The Hydraulic fluid flow through the cylinders shall be as per the details given under section/s above.

All the HP and LP cylinders shall be designed and supplied as per mechanical drawings in reference. They

shall be supplied complete with accessories like clevis, mounting arrangement, connections, hose

assembly, protection covers etc.

The Cylinder rods shall be case hardened and Chrome-plated or equal.

The seals shall be compatible with the Hydraulic fluid and should be suitable for the operation range of

temperatures.

Metallic rod scrappers shall be provided with Cylinders.

Refer following Mechanical drawings for the details of all Hydraulic cylinders

P13010102X0024 Upper Slide gate cylinder

P13010102X0216 Reduction Furnace Upper Burden Feeder Hydraulic Cylinder /Clevis

P13010102X0241 Reduction Furnace MBF Hydraulic Cylinder

P13010102X0258 Reduction Furnace LBF Hydraulic Cylinder

P13010102X0344 Wiper bar hydraulic cylinder

P13010102X0351 Flow stimulator hydraulic Cylinder

P13010102X0352 Screen sizer hydraulic cylinder

P13010102X0387 Feed leg Slide gate Hydraulic Cylinder

P13010102X0311 Lower Slide Gate Hydraulic Cylinder

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Set Point of Steam Control Valve SP X901 AY X142 Desired Value of Feed Gas H2O (Operator Set)Document1 pageSet Point of Steam Control Valve SP X901 AY X142 Desired Value of Feed Gas H2O (Operator Set)vhpatel67No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- MedicalDocument101 pagesMedicalvhpatel67No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- P08010001X1148 2Document1 pageP08010001X1148 2vhpatel67No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Client: Asco Steel Plant: SR NO Tag No Detail Unit Locat ION Range HH H L LLDocument1 pageClient: Asco Steel Plant: SR NO Tag No Detail Unit Locat ION Range HH H L LLvhpatel67No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- DR Instrument List RevisedDocument42 pagesDR Instrument List Revisedvhpatel67No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CompareDocument21 pagesComparevhpatel67No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Client: Asco Steel Plant: Description: Line List Page 1 of 1 Date: 18/8/2001 Rev. No: 0Document1 pageClient: Asco Steel Plant: Description: Line List Page 1 of 1 Date: 18/8/2001 Rev. No: 0vhpatel67100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- courier Tracking NumberDocument1 pagecourier Tracking Numbervhpatel67No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Railway Time Table Ahmedabad-MehsanaDocument6 pagesRailway Time Table Ahmedabad-Mehsanavhpatel67No ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Critical Machinery - ManagementDocument89 pagesCritical Machinery - Managementvhpatel67No ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 210 Performance Measurement of Steam Jet Ejectors EN PDFDocument9 pages210 Performance Measurement of Steam Jet Ejectors EN PDFAditya SinghNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CA-2000 Volumetric Infusion Pump: Product SpecificationsDocument2 pagesCA-2000 Volumetric Infusion Pump: Product SpecificationsGrace XieNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- KITS Bomba Combustível FUEL CAT C0375A 01.21 Int enDocument216 pagesKITS Bomba Combustível FUEL CAT C0375A 01.21 Int enAndre FilipeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- SWIMMING POOL DESIGN & CONSTRUCTION GUIDEDocument14 pagesSWIMMING POOL DESIGN & CONSTRUCTION GUIDEAiom AlNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Case Skid Steer Loader Service Manual Pgs 29-987Document959 pagesCase Skid Steer Loader Service Manual Pgs 29-987gregfortkamp83% (35)

- VF Dura 15 Eu 182-Vf-16 TechnosheetDocument3 pagesVF Dura 15 Eu 182-Vf-16 TechnosheetHenrique Vieira GonçalvesNo ratings yet

- Eurol Vacuumolie ISO-VG 100: Mineral Vacuum Pump OilDocument1 pageEurol Vacuumolie ISO-VG 100: Mineral Vacuum Pump Oilاحمد سعيدNo ratings yet

- So-1271-C Neptune CHS VLCC-DH User ManualDocument176 pagesSo-1271-C Neptune CHS VLCC-DH User Manualsorinn1987No ratings yet

- Spare Parts For Peougeot 306 Comm. Part No. Part NameDocument189 pagesSpare Parts For Peougeot 306 Comm. Part No. Part NameMarco D'AndreaNo ratings yet

- MSPharma Hygenic Design Presentation by GEA 20200901 PDFDocument59 pagesMSPharma Hygenic Design Presentation by GEA 20200901 PDFBashar JaafrehNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fluid mechanics exam guideDocument3 pagesFluid mechanics exam guideV V DEVADASNo ratings yet

- Black Out ProcedureDocument3 pagesBlack Out Proceduremarkjames castroNo ratings yet

- Low Delta T Syndrome in Constant Primary and Variable Secondary Chilled Water SystemDocument4 pagesLow Delta T Syndrome in Constant Primary and Variable Secondary Chilled Water SystemPradeep SukumaranNo ratings yet

- KLINGER Gland Packing Selection GuideDocument1 pageKLINGER Gland Packing Selection Guidesf wNo ratings yet

- Hydraulic SystemDocument23 pagesHydraulic SystemMarie Montecillo100% (1)

- TF4JJ PDFDocument992 pagesTF4JJ PDFDelia Maribel Velez Cueva100% (4)

- Manual Bomba de ClorinadorDocument159 pagesManual Bomba de ClorinadorJennifer SimpsonNo ratings yet

- Transtec Servicio Pesado 2018Document5 pagesTranstec Servicio Pesado 2018Ana Karina González Moreno100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- ReminderDocument172 pagesReminderMohamedHanyNo ratings yet

- Jain College of Engineering, Belagavi: Fluid Power Engineering (18ME55)Document17 pagesJain College of Engineering, Belagavi: Fluid Power Engineering (18ME55)Getresponsespatil 1No ratings yet

- Welcome To Presentation: Sea Water Intake SystemDocument22 pagesWelcome To Presentation: Sea Water Intake SystemSumanta Bhaya100% (1)

- Manual QSK19Document634 pagesManual QSK19Drillco98% (48)

- FMDS1002 Emergency ResponseDocument14 pagesFMDS1002 Emergency Responsedg ds50% (2)

- TO Automation Systems: Water Is Life..Document14 pagesTO Automation Systems: Water Is Life..Kapil BajajNo ratings yet

- Francis turbine document analysisDocument19 pagesFrancis turbine document analysisKen EsparragoNo ratings yet

- CombiJET 9NET EnglishDocument6 pagesCombiJET 9NET EnglishGerardo BaltazarNo ratings yet

- Jcs2 Mech SealDocument6 pagesJcs2 Mech SealManojkumar ThilagamNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CEMS GuidlinesDocument94 pagesCEMS GuidlinesBiohm ConsultareNo ratings yet

- PFT Overview BrochureDocument25 pagesPFT Overview BrochureMohamed GuezguezNo ratings yet

- IEEE 957 (1995) - Guía para Limpieza de AisladoresDocument61 pagesIEEE 957 (1995) - Guía para Limpieza de AisladoresRodrigo VillaNo ratings yet