Professional Documents

Culture Documents

Lathe Drilling Notes

Uploaded by

Soham Bhattacharya0 ratings0% found this document useful (0 votes)

99 views16 pageslathe drilling notes

Original Title

Lathe Drilling notes

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlathe drilling notes

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

99 views16 pagesLathe Drilling Notes

Uploaded by

Soham Bhattacharyalathe drilling notes

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 16

Elements of Mechanical Engineering.

Unit 5: Lathe and Drilling Machines.

Cutting tools:- Tools which are used to separate/remove material stock from the work piece are

known as cutting tools. Ex hack saw, chisel etc.

Machine tools: - Machine tools are power driven cutting tools or machines which enable the

removal of excess stock of material from the work piece.

Relative Motion: - change in position of a obect ! fixed/moving" with respect to the other obect

!fixed/moving"is called as relative motion.

#athe:-

#athe is one of the most widel$ used machine tools in metal cutting work.

#athe is usuall$ used for machining !metal removal" the ob which is rotated and a cutting

tool is fed to cause the cutting action.

#athe is generall$ used for machining c$lindrical obs.

Working principle of Lathe

The work piece is hold firml$ in the work holding device called the chuck and is supported b$ the

dead center as shown in the fig.above

The chuck is rotated at a particular speed b$ some mechanisms% the cutting tool is moved against the

rotating work piece to facilitate the removal of material.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

freevtunotes.blogspot.com

Elements of Mechanical Engineering.

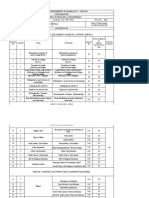

chematic diagram of Lathe Machine.

!. "ed: The lathe bed provides a heav$ rigid frame on which all the main components like

headstock, tail stock and carriage are mounted. (t comprises inner and outer guide rails that are

precision machined. bed is made out of cast iron allo$.

#. $eadstock: (t is mounted in a fixed position at the left end on the bed. (t carries a hollow spindle

which can rotate at different speeds.

The spindle carries a work-holding device which in turn rotates the ob to be machined. The spindle

speed is controlled b$ a stepped cone pulle$ and back

gear arrangement both of which are housed inside the headstock.

%. &ailstock: (t is mounted at the left end on the bed and can slide towards the headstock. (t can be

fixed at an$ position on the bed to suit the length of the work to hold a lathe center, drill bit or other

such tool. The tailstock is used for drilling,

reaming, tapping, threading and centering parts.

'. Carriage: (t moves on the guide wa$s of the lathe bed. ) cutting tool is fixed in the tool post, the

movement of which is guided b$ the carriage. The carriage is e*uipped with levers, clutches and

gears that control its movement either b$ hand or b$ power feed. (t carries the following

units.

( addle: (t is the main part or the base of the carriage which slides along the bed wa$s. (t supports

cross-slide, compound rest and tool post. +enerall$, it uses a hand wheel to move along the bed but it

can also be power operated through the apron mechanism.

( Cross slide: (t is mounted on the saddle and slides in a direction perpendicular to the axis of the

spindle

( Compound rest: (t is mounted on the top of the cross-slide. (t can swivel to an$ desired

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

angle in a hori,ontal plane. (t is operated b$ a handwheel through the compound rest.

.Tool post: It is fixed on top of the compound rest and mounts the tool holder, in which the cutting

tools are clamped.

. Apron is attached to the front of the carriage and bears the mechanism which controls the

movement of the carriage and the cross slide.

. Legs: The whole machine is supported on two legs made out of cast iron. The leg on left side

houses the electric motor and the headstock, the right side leg houses tailstock and other parts.

Lathe Operations

The lathe is the most versatile general-purpose machine tool. (t is capable to perform a large variet$

of operations .

-ollowing are a few operations that can be performed on a lathe:

.. Turning: Turning is a lathe operation in which the cutting tool removes metal from the outside

diameter of a workpiece. (n other words, reduction in the diameter of the workpiece is called turning.

&epending upon the ob re*uirement, the turning operation ma$ be of various t$pes

such as

a. 'traight turning

b.'tepped turning

c.Taper turning

d./ontour turning.

0. -acing: -acing is the process of removing metal from the end of a workpiece to produce a flat

surface.

(n other words a reduction in length of the workpiece is called facing. The cutting tool is fed into the

workpiece in a direction perpendicular to its axis

a. traight &urning b. tep &urning

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

&aper &urning )nurling

*rooving Chamfering &hread cutting

Drilling "oring

+arting ,ff: (t uses a cutting tool to cut-off the workpiece at a specific length.. (t is normall$ used

to remove the finished end of a workpiece from the bar stock!raw material" that is clamped in the

chuck.

*rooving: (t is an operation of reducing diameter of the workpiece in the form of a neck or a narrow

groove of desired shape, ma$ be a round, a s*uare or a 1 shape.

Chamfering: (t is a process of cutting the sharp edge at the end of a ob to produce a beveled edge at

a desired angle.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

Drilling: (t is a lathe operation b$ which an axial hole is created in a solid workpiece. (t is done with

the help of a special multi-point tool called a drill.

Reaming: (t is an operation b$ which the surface of a drilled hole is finished. (t is done with the help

of a special multi-point tool called a reamer.feed !2.3-0 mm ".

"oring: (t is an operation b$ which a drilled hole is enlarged in diameter. (t is done with the help of a

single-point cutting tool called a boring bar.

)nurling: (t is a special operation b$ which a smooth-turned surface is made rough b$ impressing a

diamond shaped or straight line pattern. (t is done for the purpose of creating a better

gripping.surface.

4nurling is performed with special metal wheels called a knurling tool.

&hread Cutting: (t is a process of cutting helical grooves of a standard thread form. (t ma$ be of

two t$pes, namel$, external thread cutting and internal thread cutting.

!tapping,taperboring,undercutting,milling,counterboring,grooving,filling,polishing,spinning,spring

winding5 forming"

&aper &urning

Taper turning is the process of generating a conical surface.

Taper turning on a lathe is done b$ feeding the cutting tool at an angle to the axis of rotation the

workpiece.

) taper is a uniform increase or decrease in the diameter of the workpiece along its length.

There are four basic methods of turning tapers on a lathe:

6 b$ form tool%

6 b$ compound rest swivel%

6 b$ tailstock set-over%

6 b$ taper turning attachment.

Determination of angle of taper:

/onsider a c$lindrical workpiece of length # and diameter &.as shown in fig below (t is re*uired to

reduce the diameter & to d uniforml$ over the length #. The amount of taper in the workpiece is

usuall$ specified as conicity. (t is denoted b$ letter 4.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

7here &- dia at the larger end, d-dia at the smaller end, #8 length of workpiece

&aper &urning b- .iveling the Compound Rest

9The work piece is rotated on lathe axis .The cutting tool mounted on the compound rest is attached

to a circular base which can be swiveled and locked at an$ desired taper angle as shown in -ig.

9/ompound rest ma$ be swiveled at either side of the lathe. 7hen the compound rest set at the

desired taper angle is moved against the workpiece the cutting tool generates

the re*uired tapered surface on the workpiece.

9)s the compound tool rest has onl$ limited movement, this method can generate onl$ short

tapers.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

&aper &urning b- &aper &urning /ttachment

9:ere a taper attachment which is set at an angle to the axis of rotation of the workpiece. guide the

tool in a straight path to cut both internal and external tapers as shown in -ig. >The workpiece held

between the centers and is aligned to the lathe axis.

9The attachment consists of bracket or frame connected to the rear end of the lathe bed.

) guide bar having graduations in degrees ma$ be swiveled either side of the ,ero.

+raduation on a pivot mounted over the bracket as shown in fig.

The cross slide is made free from lead screw and its rear end is attached to the guide block b$ means

of a bolt.

7hen the longitudinal feed is given b$ moving the carriage, the guide block slides over guide bar set

at half the taper angle. The tool mounted on the cross slide follows the angular path and generates the

re*uired taper.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

&aper &urning b- &ailstock et0over

:ere the workpiece is held between the live center and the dead center of the tailstock. ;ut the

tailstock is offset at an angle e*ual to half the taper angle as shown in -ig.

The cutting tool is fed parallel to the lathe axis. )nd the desired taper is produced.

&aper &urning b- a 1orm &ool

9:ere a taper tool of broad nose having straight cutting edge is used to produce the desired taper

as shown in -ig.

9since this method produces taper onl$ for short length it is not widel$ used.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

pecification of Lathe:

) lathe is mainl$ specified b$ the maximum si,e of the work that it can handle.

<ther important specifications include the following

..The largest diameter of the workpiece, commonl$ called the swing.

0. The maximum distance between headstock and tailsstock centers.

=. power of the main drive, that is, motor%

>. range of spindle speeds%

3. range of feeds%

?. space occupied b$ the machine

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

Drilling is an operation of producing holes in a solid metal2non metals b- means of a revolving

tool called drill or t.ist drill.

The machines emplo$ed for drilling holes are called drilling machines. The drilling machine

.&rilling machine is the one of the essential machine tool used in fabrication, production shop and

tool rooms, for machining/producing holes.

The machine consists of a spindle which provides rotar$ motion to the drilling tool!twist". The

spindle ma$ also produce motion to table on which the work rests.

TYPES OF DRILLING MACHINES

&rilling machines are manufactured in various si,es and varieties to suit different t$pes

work. The$ are classified as follows.

l" @ortable drilling machine

0" 'ensitive or bench drilling machine

=" Ap-right drilling machine

>" Badial drilling machine

3" +ang drilling machine

?" Multiple-spindle drilling machine

C" &eep-hole drilling machine

+ortable Drilling Machine:

(t is small drilling machine designed to drill small holes up to .D mm diameter. The machine can be

carried to the obs which normall$ cannot be brought to the workshop, such as concrete selling

slabs,walls,heav$ machiner$, and fabrication sites.

(t is ver$ light in weight and can be convenientl$ handled. -ig above shows a portable hand held

drilling machine.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

ensitive or "ench0&-pe Drilling Machine

The drilling head along with the column is mounted and clamped on a bench. The workpiece can be

clamed to the work table or on the base with the help of T-slots. The worktable can be moved up and

down along the vertical column and clamped at an$ desired height.

The drill is mounted in a drill chuck which is rotated b$ the drive s$stem of the machine.

The chuck is moved up and down b$ handle with the help of a rack-and-pinion mechanism.

'ensitive drilling machine is designed for drilling small holes, usuall$ less than .0 mm,

diameter. The name EsensitiveE is used because the machinist can EfeelE the action of the drill as it

goes into the work.

-ollowing are its main parts:

6 1ertical column: (t is the basic structure to hold the other parts.

6 &rilling head: This has a box-t$pe structure. (t houses the power drive and gear boxesF

change of speed and feed.

6 'pindle: (t holds and provides rotar$ motion and feed motion to the drill.

6 Table: (t has T-slots on the top surface. The ob is clamped on the table using a drilling

Gig or machine vice.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

Upright2+illar Drilling Machine

This machine is *uite similar to the bench drilling machine but of little larger si,e and higher

capacit$ and is fixed on the floor foundation.

This drilling machine is able to take larger drills.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

Radial Drilling Machine:

The machine consists of a vertical column mounted on a large base.

(t supports a radial arm which can swing about the column axis and move verticall$ up and down.

The radial arm carries a drill head which can slide in its guidewa$s and clamped at the desired

position. ) motor is mounted on the drill head to rotate the drill spindle. ) feed lever on the drill

head guides the feed motion.

) combination of these movements helps to locate the drill at an$ desired position. This t$pe of

drilling machine is used in tool rooms and in large scale manufacturing units.

,ther drillings machines

.. &eephole drilling machines

0. Aniversal drilling machines

=. +ang drilling machines

>. Multispindle drilling machine

3. /H/ drilling machines.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

Drilling

(t is a process of creating or originating a hole in a solid workpiece using a tool called Twist drill.

Reaming:

Beaming is the operation of finishing an alread$ drilled hole using a reamer. ) reamer which

matches the diameter of the alread$ existing hole is fitted in to the machine spindle and reaming

operation is carried over which is similar to drilling operation except higher spindle speed in reaming

.The material removed is ver$ less and the drilled hole surfaces are finished with high accurac$. The

accurac$ of a reamed hole is around 2.223 mm.

"oring

;oring is the operation of enlarging an alread$ drilled hole using a boring tool. The boring tool is

fixed to the boring bar which in turn fits into the machine spindle. The speed of rotation of a boring

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

tool is lesser than the speed of rotation of a corresponding reamer. :oles with accurac$ of 2.22 .03

mm can be obtained b$ this operation.

Counter0"oring

(t is a special operation performed on drilling machine for enlarging a limited portion of the hole.

The bottom surface of the enlarged hole is flat. (t is generall$ used when a bolt or cap head screw or

a nut is re*uired to sit below the level of a workpieceFs surface.

/ounter-boring is done with the help of a special tool called a counter-bore. The counter-bore is

guided in drilled hole with the help of a pilot fixed at its lower end.

Counter0inking:

I

(t is a process of making a conical hole to a limited depth at the entrance to c$lindrical hole. )

counter-sunk hole allows sitting the conical head of a bolt or a screw below surface of the workpiece.

(t is cut with the help of a tool called a counter-sinking tool.

/ounter sink cutters are manufactured with six common included angles which are ?2J, D0J, K2J,

.22,..2J or .02J.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

Elements of Mechanical Engineering.

&apping:

(t is process of thread cutting inside a drilled or a bored hole using a tool called taL

) special attachment containing a reversing mechanism is re*uired for tapping.

pecification of drilling machine

(" The si,e of the working table and capacit$ of the machine.

0" Maximum si,e of the work piece on the particular machine.

=" Maximum diameter of drill on the particular machine.

>" Humber of spindles on the particular machine.

5) #ength of arm and column diameter must be specified for radial drilling machine.

&ept. of Mechanical Engineering, 'rinivas 'chool of Engineering, Mangalore.

freevtunotes.blogspot.com

You might also like

- LatheDocument6 pagesLatheRavichandran GNo ratings yet

- Operations in TurningDocument8 pagesOperations in Turningcanavarsanayok100% (1)

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocument13 pagesVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNo ratings yet

- Lathe MachineDocument7 pagesLathe MachineJacTomlinNo ratings yet

- Lathe Part IDocument151 pagesLathe Part Ishiva100% (1)

- Lathe MachineDocument16 pagesLathe MachineVanamali Thirumalai100% (4)

- Lathe - LVDocument23 pagesLathe - LVakshaygiitmNo ratings yet

- Production & Special Purpose LathesDocument38 pagesProduction & Special Purpose LathesShubham Shekhar100% (1)

- Lathe Machine - All Parts and Functions With Diagrams and UsesDocument11 pagesLathe Machine - All Parts and Functions With Diagrams and UsesSATYANARAYANANo ratings yet

- LatheDocument130 pagesLatheAjay Sharma86% (7)

- Lathe Machine: Description and Function of Lathe PartsDocument16 pagesLathe Machine: Description and Function of Lathe PartsRenjith Rajendraprasad100% (1)

- The Indexing or Dividing Head For Milling MachineDocument4 pagesThe Indexing or Dividing Head For Milling MachineDion Adi PutraNo ratings yet

- Central Lathe Machine GuideDocument130 pagesCentral Lathe Machine GuideNitin B maskeNo ratings yet

- Lathe AccessoriesDocument6 pagesLathe AccessoriesAnand Balaji100% (1)

- Fitting LabDocument8 pagesFitting LabArun kumar rouniyarNo ratings yet

- Lathe Machine PrinciplesDocument15 pagesLathe Machine Principlesscratch89No ratings yet

- Lathe ppt2Document130 pagesLathe ppt2manikanth100% (1)

- KFUPM Lathe Machines GuideDocument5 pagesKFUPM Lathe Machines Guidegunawan refiadiNo ratings yet

- GEOMETRY OF SINGLE POINT TOOLSDocument13 pagesGEOMETRY OF SINGLE POINT TOOLSAkshay KakaniNo ratings yet

- Milling Machine (Group 7)Document52 pagesMilling Machine (Group 7)Faisal Maqsood100% (1)

- Lathe Miscellaneous FunctionDocument7 pagesLathe Miscellaneous FunctionsuryavenkatramanNo ratings yet

- Lathe OperationsDocument35 pagesLathe OperationsMuraliNo ratings yet

- Mesin LarikDocument12 pagesMesin LariknorzaiwanNo ratings yet

- Lathe Machine ToolDocument59 pagesLathe Machine ToolSiva BhaskarNo ratings yet

- Chapter 2 - Metal Cutting LatheDocument165 pagesChapter 2 - Metal Cutting LathebmdbmdbmdNo ratings yet

- LatheDocument4 pagesLatheAnees Calicut100% (1)

- Generalized Kinematics of Five-Axis Serial Machines WithDocument47 pagesGeneralized Kinematics of Five-Axis Serial Machines WithJoss Joss100% (1)

- JJ 104 Workshop Technology 1 MillingDocument44 pagesJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Milling MachineDocument43 pagesMilling MachineJUAN DAVID MOSQUERA GARCIANo ratings yet

- What Is Milling MachineDocument6 pagesWhat Is Milling MachineGlenn VergaraNo ratings yet

- Name of The Experiment:: Study and Operation Bench Drilling MachineDocument5 pagesName of The Experiment:: Study and Operation Bench Drilling MachinemadNo ratings yet

- LatheDocument63 pagesLatheRandom100% (1)

- Grinding MachineDocument9 pagesGrinding Machinejineesha p jNo ratings yet

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocument7 pagesLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNo ratings yet

- Presentation Brake & ClutchDocument39 pagesPresentation Brake & ClutchArief Izz100% (1)

- IndexingDocument10 pagesIndexingsaddam hosenNo ratings yet

- CNC Lathe Machines PDFDocument7 pagesCNC Lathe Machines PDFMetwally Naser100% (1)

- Tool & Cutter GrinderDocument64 pagesTool & Cutter GrinderAFIFAHZABIDI ZABIDINo ratings yet

- Manufacturing of Spur Gear: Aim of The ExperimentDocument5 pagesManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNo ratings yet

- Capstan vs Turret Lathe: Key DifferencesDocument101 pagesCapstan vs Turret Lathe: Key DifferencesRavichandran GNo ratings yet

- Drilling Machine Types GuideDocument42 pagesDrilling Machine Types GuideSomenath RahaNo ratings yet

- SHEETMETAL DESIGNDocument9 pagesSHEETMETAL DESIGNHimanshu SagarNo ratings yet

- Tail Stock of LatheDocument7 pagesTail Stock of LatheKIÊN HOÀNG TRUNG100% (1)

- Unit - V: Manufacturing TechnologyDocument54 pagesUnit - V: Manufacturing TechnologyIjanSahrudinNo ratings yet

- Lab Session Introduction To Lathe MachineDocument5 pagesLab Session Introduction To Lathe MachineAqib ZamanNo ratings yet

- Unit II - MCMTDocument50 pagesUnit II - MCMTSai RamNo ratings yet

- Production Technology (IV Sem)Document24 pagesProduction Technology (IV Sem)Shubham AgrawalNo ratings yet

- Lathe Workholding and Operations GuideDocument4 pagesLathe Workholding and Operations GuideBOT-X GAMING100% (1)

- 2016 Machine Shop Manual PDFDocument95 pages2016 Machine Shop Manual PDFShravan Shetty100% (1)

- 90-1 Rotary Table GuideDocument5 pages90-1 Rotary Table GuidehdquanNo ratings yet

- MechanismDocument17 pagesMechanismm_er100No ratings yet

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocument8 pagesConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09No ratings yet

- Use of Dividing HeadDocument20 pagesUse of Dividing Headajs_pto3117No ratings yet

- Unit 5 Lathe DrillingDocument16 pagesUnit 5 Lathe Drilling1994prdpNo ratings yet

- Unit 5: Lathe and Drilling MachinesDocument16 pagesUnit 5: Lathe and Drilling MachinesSHANKAREGOWDA K CNo ratings yet

- Machine Tools, CNC and Robotics ElementsDocument31 pagesMachine Tools, CNC and Robotics ElementsZeeshanNo ratings yet

- IME (BESCK204D) Module-2Document16 pagesIME (BESCK204D) Module-2SusheelabaiNo ratings yet

- Machine Lab - ReportDocument11 pagesMachine Lab - Reportsaiq kamranNo ratings yet

- Metal Cutting ProcessesDocument67 pagesMetal Cutting ProcessesAbhay SontakkeNo ratings yet

- Presentation On Lathe and Shaper MachineDocument13 pagesPresentation On Lathe and Shaper Machinemukul anand jhaNo ratings yet

- Unit 6 BoilerDocument11 pagesUnit 6 BoilerJagdeep ArryNo ratings yet

- Mechanical EngineeringDocument1 pageMechanical EngineeringManjunatha EikilaNo ratings yet

- 3 Work, Power and Energy: Table of ContentsDocument14 pages3 Work, Power and Energy: Table of ContentsManjunatha EikilaNo ratings yet

- Open Loop and Closed Loop SystemsDocument1 pageOpen Loop and Closed Loop SystemsManjunatha EikilaNo ratings yet

- USN 18ME15/25Document2 pagesUSN 18ME15/25Manjunatha EikilaNo ratings yet

- Energy and EnvironmentDocument18 pagesEnergy and EnvironmentManjunatha EikilaNo ratings yet

- P 84Document1 pageP 84Manjunatha EikilaNo ratings yet

- Energy ResourcesDocument1 pageEnergy ResourcesManjunatha EikilaNo ratings yet

- CH 11Document2 pagesCH 11Manjunatha EikilaNo ratings yet

- GKDocument16 pagesGKManjunatha EikilaNo ratings yet

- Boiler & Steam PropertiesDocument5 pagesBoiler & Steam PropertiesManjunatha EikilaNo ratings yet

- Elecments of Mechanical EngineeringDocument2 pagesElecments of Mechanical EngineeringManjunatha EikilaNo ratings yet

- Main Reason of Bellow FailureDocument10 pagesMain Reason of Bellow FailureManjunatha EikilaNo ratings yet

- The Effect of Road Surfacing Condition On Tyre Life: WjvdmsteynandmhawDocument11 pagesThe Effect of Road Surfacing Condition On Tyre Life: WjvdmsteynandmhawManjunatha EikilaNo ratings yet

- Elecments of Mechanical Engineering June 2012 PDFDocument4 pagesElecments of Mechanical Engineering June 2012 PDFManjunatha EikilaNo ratings yet

- Questions and AnawersDocument5 pagesQuestions and AnawersManjunatha EikilaNo ratings yet

- Flame 2010 BrochureDocument13 pagesFlame 2010 BrochureManjunatha EikilaNo ratings yet

- 07 PotholeInducedContactForceSimpleVehicleModel JSV JournalArtiDocument8 pages07 PotholeInducedContactForceSimpleVehicleModel JSV JournalArtiManjunatha EikilaNo ratings yet

- Title: Structural and Vibration Analysis of Bellow System For Gravitational LoadsDocument2 pagesTitle: Structural and Vibration Analysis of Bellow System For Gravitational LoadsManjunatha EikilaNo ratings yet

- Main Reason of Bellow FailureDocument10 pagesMain Reason of Bellow FailureManjunatha EikilaNo ratings yet

- Development of Validated Finite Element Model of Rigid TruckDocument10 pagesDevelopment of Validated Finite Element Model of Rigid Trucksalscal100% (1)

- A Novel Approach To The Calculation of Pothole-Induced Contact Forces in MDOF Vehicle ModelsDocument36 pagesA Novel Approach To The Calculation of Pothole-Induced Contact Forces in MDOF Vehicle ModelsManjunatha EikilaNo ratings yet

- Literature Survery On BellowsDocument5 pagesLiterature Survery On BellowsManjunatha EikilaNo ratings yet

- GKDocument16 pagesGKManjunatha EikilaNo ratings yet

- Literature Survery On Bellows22Document7 pagesLiterature Survery On Bellows22Manjunatha EikilaNo ratings yet

- PMMA Strengths and Limitations in 38 CharactersDocument1 pagePMMA Strengths and Limitations in 38 CharactersManjunatha EikilaNo ratings yet

- Literature Survery On Bellows22Document7 pagesLiterature Survery On Bellows22Manjunatha EikilaNo ratings yet

- Strengths and Limitations of High-Performance PEEK PolymerDocument1 pageStrengths and Limitations of High-Performance PEEK PolymerManjunatha EikilaNo ratings yet

- Objectives: To Study TheDocument1 pageObjectives: To Study TheManjunatha EikilaNo ratings yet

- Insulating MaterialsDocument8 pagesInsulating MaterialsManjunatha EikilaNo ratings yet

- Annex F2.8 - Manufacturing FacilitiesDocument2 pagesAnnex F2.8 - Manufacturing FacilitiesPrakasa Spectro CastNo ratings yet

- Experiment NoDocument8 pagesExperiment NoNavin YadavNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument38 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingCh TalhaNo ratings yet

- LH-630 服務手冊Document378 pagesLH-630 服務手冊LndIngenieria50% (2)

- @seminar USDDocument76 pages@seminar USDlawi100% (4)

- Micro MachiningDocument302 pagesMicro Machiningapulavarty100% (2)

- Drilling MachineDocument79 pagesDrilling MachineMunem ShahriarNo ratings yet

- Presentation of Drilling Machine by Anil Dahiya SirDocument72 pagesPresentation of Drilling Machine by Anil Dahiya SirRAMAKANT RANA100% (1)

- Boring Head ManualDocument2 pagesBoring Head ManualnevadablueNo ratings yet

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- TrainingManual VisualMILLDocument250 pagesTrainingManual VisualMILLmegclay100% (1)

- DownloadDocument28 pagesDownloadmoonstarNo ratings yet

- Aditya Lakshmana Reddy Tetala Industrial Training Report 24-08-2021Document44 pagesAditya Lakshmana Reddy Tetala Industrial Training Report 24-08-2021Aditya Laxmana ReddyNo ratings yet

- My Internship Report Y2Document24 pagesMy Internship Report Y2Nji Munang OfMbamluNo ratings yet

- Syllabus 5th Sem?Document42 pagesSyllabus 5th Sem?Dhruv DubeyNo ratings yet

- Turning and Drilling PPT MFG Chapter23 FinalDocument78 pagesTurning and Drilling PPT MFG Chapter23 FinalRavichandran GNo ratings yet

- Specially Tailored DrillsDocument70 pagesSpecially Tailored DrillszaqNo ratings yet

- Komet TurningDocument102 pagesKomet TurningIrwandi TrinovNo ratings yet

- CNC G-Code and M-Code ReferenceDocument2 pagesCNC G-Code and M-Code ReferenceJobanjit SinghNo ratings yet

- Millat TractorDocument34 pagesMillat TractorAbdul Rauf75% (4)

- ISO 14001 ISO 9001 Safety GuideDocument20 pagesISO 14001 ISO 9001 Safety Guidenoragarcia76No ratings yet

- Boring OperationDocument7 pagesBoring OperationBeth WalkerNo ratings yet

- Machine ShopDocument5 pagesMachine Shopkainat latifNo ratings yet

- QIS College Engineering & Tech Session Plan Metal CuttingDocument13 pagesQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNo ratings yet

- Barrel Making TutorialDocument101 pagesBarrel Making TutorialDiegoMartinezCastrillon100% (8)

- Machine Tools for Machining Processes and OperationsDocument56 pagesMachine Tools for Machining Processes and OperationsUmberto PriscoNo ratings yet

- Siddhesh Raul Internship ReportDocument51 pagesSiddhesh Raul Internship ReportSiddhesh RaulNo ratings yet

- Ready To Export MachineDocument5 pagesReady To Export Machinesanthosh.smtsNo ratings yet

- AlliedMachine Media AlliedMasterPageImages Support Literature Pdffiles A30-TAS - PDF ExtDocument160 pagesAlliedMachine Media AlliedMasterPageImages Support Literature Pdffiles A30-TAS - PDF ExtDante AristaNo ratings yet

- Bhel UtDocument14 pagesBhel UtAnonymous 6k4VeeRNo ratings yet