Professional Documents

Culture Documents

Technical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: Danger

Uploaded by

vickers0 ratings0% found this document useful (0 votes)

240 views9 pages3RW33 soft starter for Carrier NGC IV DANGER Hazardous voltage. Will cause death, serious personal injury, or property damage. Only qualified personnel should perform maintenance. Use of unauthorized parts in the repair of the equipment or tampering by unqualified personnel may result in dangerous conditions.

Original Description:

Original Title

3RW3346-2D0EC34

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document3RW33 soft starter for Carrier NGC IV DANGER Hazardous voltage. Will cause death, serious personal injury, or property damage. Only qualified personnel should perform maintenance. Use of unauthorized parts in the repair of the equipment or tampering by unqualified personnel may result in dangerous conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

240 views9 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: Danger

Uploaded by

vickers3RW33 soft starter for Carrier NGC IV DANGER Hazardous voltage. Will cause death, serious personal injury, or property damage. Only qualified personnel should perform maintenance. Use of unauthorized parts in the repair of the equipment or tampering by unqualified personnel may result in dangerous conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 1

Technical data sheet 3RW33 soft starter for Carrier

NGC IV

DANGER

Hazardous voltage.

Will cause death, serious personal injury,

or property damage.

Always de-energize and ground the equipment before maintenance. Read and under-

stand this technical data sheet before installing, operating, or maintaining the equip-

ment. Only qualified personnel should perform maintenance. The use of unauthorized

parts in the repair of the equipment or tampering by unqualified personnel may result in

dangerous conditions, which may cause death or serious personal injury, or equipment

or property damage. Follow all safety instructions contained herein.

Qualified Person

For the purposes of this manual and product labels a qualified person is one who is famil-

iar with the installation, construction, operation, or maintenance of the equipment and the

hazards involved. In addition this person has the following qualifications:

a is trained and authorized to energize, de-energize, clear, ground, and tag cir-

cuits and equipment in accordance with established safety practices.

b is trained in the proper care and use of protective equipment such as rubber

gloves, hard hat, safety glasses or face shields, flash clothing, etc., in accordance

with established safety practices.

c is trained in rendering first aid.

Table of Contents

Brief Description...................................................................................................................................................................2

Areas of Application.............................................................................................................................................................2

Product data for 3RW3346-0EC34.....................................................................................................................................2

Liquid Crystal Display and Keypad.........................................................................................................................3

LCD Menu ...............................................................................................................................................................4

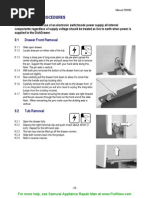

Picture 1: Mechanical layout..............................................................................................................................................5

Picture 2: Typical schematic...............................................................................................................................................6

Picture 3: Control Terminal Connections ..........................................................................................................................7

Picture 4: Nameplate 3RW3346-0EC34.............................................................................................................................7

Picture 5: Parameter Adjustment Values............................................................................................................................7

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 2

Brief Description

Soft starters protect electric motors by reducing the starting torque. The power supply is protected against dan-

gerous current peaks by reducing the current input during the start.

Areas of Application

Smooth starting of three-phase AC induction motors.

For all applications where up to now star-delta starters have been used.

For example: Fans, pumps, compressors, conveyor belts, grinding machines, saws, textile machines, mixers,

presses, etc.

Product data for 3RW3346-0EC34

Standards: IEC 947-4-2 (EN60947-4-2); UL/CSA; CE

Rated voltage: Ue 400 VAC, 50 or 60 Hz, range 200 to 460 V 10%

Ambient temperature -18C to 55C inside enclosure (acc. EE038 Carrier spec)

Control voltage (Terminals A1 + A2): Uc 115 VAC +/10 %, 50 or 60 Hz; 5 VA @ 115 VAC.

Lifetime 15 years with 4800 h / year

Humidity 95 %

Environmental conditions / requirements acc. CEI 364 3.2 class 4Z1, 4Z4, 4Z7.

Degree of protection IP 00.

Overload protection supplied by Carrier.

Current limit starting. (Setting Range is 223 811 In Line Amps/129 468 Inside the Delta Amps).

No fans, vertical mounting for correct cooling necessary.

Dimensions refer also to the drawing 1: 197 x 230 x 137mm (W x L X D).

Power and Control Terminals:

Control- (2) 12 - 22 AWG / 2.5 - 0.5 mm (flexible) Control Terminal block is removable

Line In- Prewired with # 2 AWG wire

Load Out- Prewired with # 2 AWG wire

Earth connection- max. cross section 16 mm; two terminals each on top and bottom connection via screw

M4

Torque for control terminal screws and power connection lugs:

Control terminal: 0.8 1.1Nm

Power terminals: Supplied with #2 wire

Only designed for inside delta operation with external bypass,

IEC 947-4-2 80A: AC53b: 6-2: 240 at 55C

80A: Ie rated current

AC53-b: utilization category = induction motor / external bypassed

6-2: maximum starting current 6 * Ie for 2 s (480 A for 2 s) (required by Carrier 469 A for 2 s)

240: minimum off time = 240 s

Duty cycle based on (6) starts/hour at 480 A for 2.0 s

Input data (Terminals 4 (Run)):

10 mA typical @ 115 VAC

1500 VAC optical isolation;

on-state Voltage: 85 VAC (minimum)

on-state Current 6 mA (minimum)

off-state Voltage: 40 VAC (maximum)

off-state Current: 3 mA (maximum)

Input impedance: 13 kOhm typical

Bypass contactor is controlled by "Motor Up To Speed" output (Terminals 5 + 6):

Output data:

10 A make, 1 A break @ 120 V (solid state),

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 3

1500 VAC optical isolation;

on-state Voltage drop: 1,2 VAC (typical)

off-state Leakage current: 2 mA (typical), 9 mA (maximum)

The thyristors are gated on during bypass. A 0.5 second turn off delay of thyristors is added at stopping.This allows the

bypass contactor to open without arcing!

Liquid Crystal Display and Keypad

Upon power up the LCD display will display the status of the starter. If a fault is present, it will be displayed.

Top Line of LCD

Bottom Line of LCD

Up Button

Exit Menu Button

Enter menu Button

Down Button

Up Button This key is used to move up in all of the menu struc-

tures. It also is used to increase or select different

parameters in the parameter adjust mode.

Exit Button This key is used to exit menus and to exit the para-

meter adjustment menus after selections have been

made.

Enter Button This key is used to enter menus and to enter the

parameter adjustment menus.

Down Button This key is used to move down in all of the menu

structures. It also is used to decrease or select

different parameters in the parameter adjust mode.

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 4

LCD Menu

Main Menu Sub Menus

Status Menu The submenus for the Status menu show line voltages, actual and peak motor and

line currents, control power status, motor configuration, operating frequency, line

rotation, and fault or warning messages.

Configuration Me-

nu

The sub-menus for the Configuration menu display the units catalog number, rated

volts, software revision, serial number, and final test date.

Parameter Menu The submenus for the Parameter menu control the following adjustments of the

elevator starter:

Starting Current

Overload Current

Line Rotation

Off Delay in milliseconds

On Delay in milliseconds

To edit any of the above parameters, select the parameter and press the right arrow

key. If the parameter is a numerical field, the flashing digit is the only digit currently

being changed. Use either the Up or Down keys to adjust each digit to the desired

setting. Using the right key will move you to the next digit. If you are at the last digit,

the right key will move you to the first. Once the adjustment is finished, the left

arrow key will take you back and display an Accept or Reject request. The up key

will accept the setting and the down key will reject the setting. If a value outside the

range of a particular units is entered then either the lowest or highest setting will be

displayed.

Diagnostics Menu The submenus for the Diagnostic menu display the following:

Power on time

Running time

Starting time

Number of Starts

Power Ups

Total Faults

This information cannot be changed.

Faults Menu The submenus for the Faults Menu show the following information for the last four

faults:

Type of fault

Run Status when the fault occurred

Time that the fault occurred

Amount of time in the run that the fault occurred

The motor currents when the fault occurred

This information cannot be changed.

Measured in Hours:

Minutes: Seconds

See Picture 5 for ad-

justment ranges and

default settings

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 5

System Menu This menu allows users to reset the starter, reset the settings to the default values. A

password is required for further setup adjustment.

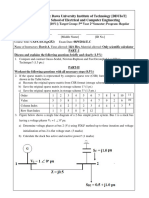

Picture 1: Mechanical layout

3RW3346-0EC34

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 6

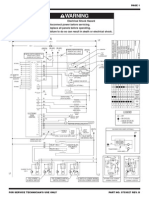

T1 L1

Reverse operation and conti-

nuous current above 80A not

Motor

Win-

Note: I

start

(In Delta) is

equal to I

start

(In Line)/1.732

3TF

IAC1=149A

3RW3

In Line:

I

motor

= 258A

I

start

=812A

In Delta:

Ie soft starter= 80A

I

start

= 469A

Picture 2: Typical schematic

s

Automation & Drives Group

Low-Voltage Control Systems

P.O. Box 32 40, D-91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

05/03

Version 2.0 page 7

Picture 3: Control Terminal Connections

Picture 4: Nameplate 3RW3346-0EC34

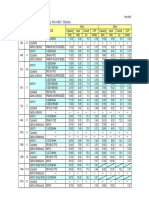

Parameter Setting Adjustment Range Factory Default

Starting Current 223A to 811A in 1 amp increments 811A

Overload Current 63A to 238A in 1 amp increments 238A

Line Rotation ABC or CBA rotation ABC

Off Delay 0 to 2500 milliseconds .500 milliseconds

On Delay 0 to 2500 milliseconds 0 milliseconds

Picture 5: Parameter Adjustment Values

Status

Menu

Status

Line-Line Volts

Min Line Volts

Motor Amps

Line Amps

View Peak Motor Amps

Peak Line Amps

Power Status

Line Freq

Starter Config

Line Rotation

Configuration

Menu

Fault

Menu

Diagnostics

Menu

Parameter

Menu

Catalog Number

Rated Volts

Software Revision

Serial Number

View

Calibration Date

System

Menu

Reset Fault

Password

Use this menu to Reset the starter

and access further information

through the Password.

Starting Amps

Overload Amps

Line Rotation

Off Delay mS.

Set

On Delay mS

Power On Time

Running Time

Starting Time

Number of Starts

Power Ups

View

Total Faults

Last Fault

Last Fault 1

Last Fault 2

Select

Last Fault 3

Fault Type

Fault Run Status

Fault Time

Running Time

Fault Amps

View

Fault Type

This is the default screen for the

starter. After 2 minutes of inactivity

on the keypad, the menu will default

to the first line of the Status Menu.

System

Menu

Perform Reset Fault

Enter Password

OEM

Menu

Perform Reset Defaults

Starting Mode

Overload Mode

Amp Imbalance

Imbalance Enable

Low Amp UTS

Cycle Fault Contactor

Stall Detect

Set

Stall Time

Correct Password must

be given to proceed in

menu structure

All Faults may also be

reset by pressing the Up

and Down Keys at the

same time.

You might also like

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangerDocument6 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC IV: DangervickersNo ratings yet

- Washing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CDocument44 pagesWashing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CMelissa MorganNo ratings yet

- Tech Sheet - W10591246 - Rev ADocument2 pagesTech Sheet - W10591246 - Rev AKarl Turner100% (1)

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- FRS-25NC Manual ServicioDocument57 pagesFRS-25NC Manual ServicioCiclismo Sexta Región100% (2)

- 31-9153 ManualDocument66 pages31-9153 ManualTrish Pierce WhiteNo ratings yet

- Samsung Refrigerator RF4287HA ManualDocument56 pagesSamsung Refrigerator RF4287HA Manualujjval10No ratings yet

- Frid Ffhs26 Tech SheetDocument2 pagesFrid Ffhs26 Tech Sheetdan themanNo ratings yet

- Service Data Sheet 240389646Document2 pagesService Data Sheet 240389646Arianna IsabelleNo ratings yet

- Dryer Service Guide for Model DWR-WE32/DWR-WG32Document82 pagesDryer Service Guide for Model DWR-WE32/DWR-WG32AlioverBetancourtNo ratings yet

- Technical Training Pointer: For Immediate Attention of Your Service DepartmentDocument21 pagesTechnical Training Pointer: For Immediate Attention of Your Service DepartmentmoiNo ratings yet

- Electrical Sequence of Operation For A BoilerDocument2 pagesElectrical Sequence of Operation For A BoilerPrecisionetica100% (2)

- Daikin Indoor Unit Manual FTKS50 60 71 FTXSDocument34 pagesDaikin Indoor Unit Manual FTKS50 60 71 FTXSThais G QuinonesNo ratings yet

- Fast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAADocument9 pagesFast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAAMaugrys CastilloNo ratings yet

- GTF916PZPM ApzqeurDocument87 pagesGTF916PZPM ApzqeurMonete FlorinNo ratings yet

- LGE WM3632HW Service ManualDocument43 pagesLGE WM3632HW Service ManualJeffrey JimenezNo ratings yet

- 3G3EV Installation ManualDocument55 pages3G3EV Installation ManualHajrudin SinanovićNo ratings yet

- Refrigerator: Service ManualDocument36 pagesRefrigerator: Service Manualjose_suko49No ratings yet

- Washing Machine Service ManualDocument44 pagesWashing Machine Service ManualLuisAlhodaSilvaNo ratings yet

- Panasonic Split AC CS-S18JKQ PDFDocument81 pagesPanasonic Split AC CS-S18JKQ PDFMelfin MatalangNo ratings yet

- Tech Sheet - W10607408 - Rev F PDFDocument48 pagesTech Sheet - W10607408 - Rev F PDFNolan HicksNo ratings yet

- Cooling Brochure - September 2008Document16 pagesCooling Brochure - September 2008monique5617No ratings yet

- Manual Electrolux Ewp10742 PDFDocument100 pagesManual Electrolux Ewp10742 PDFfiraNo ratings yet

- Tech Sheet - W10280489Document48 pagesTech Sheet - W10280489Rafael Abel GonzalezNo ratings yet

- Service manual for Sharp refrigerator models SJ-44L and SJ-48LDocument28 pagesService manual for Sharp refrigerator models SJ-44L and SJ-48LJoseph AlbertNo ratings yet

- Fisher-Paykel DD603 Drawer RemovalDocument1 pageFisher-Paykel DD603 Drawer RemovalSamurai Appliance Repair Man100% (3)

- Samsung Frontier WasherDocument88 pagesSamsung Frontier Washerpetre333No ratings yet

- MFL30574776 F1403RD EukDocument51 pagesMFL30574776 F1403RD EukApril Scott100% (1)

- 2000A Auto Ranging True RMS Clamp + DMM MODEL 380926: User's ManualDocument10 pages2000A Auto Ranging True RMS Clamp + DMM MODEL 380926: User's ManualEmerson GarciaNo ratings yet

- GE Built in Dishwashers Generation II Technicians Service ManualDocument14 pagesGE Built in Dishwashers Generation II Technicians Service ManualsublimemasterjwNo ratings yet

- Wiring Diagrams For Maytag Heritage Gas & Electric Ranges Failure Codes andDocument124 pagesWiring Diagrams For Maytag Heritage Gas & Electric Ranges Failure Codes andAndre VPNo ratings yet

- 2009-11 Service Hsv-Series Stdinverter Wall-Mount System Mfl41161605 20120105132900Document64 pages2009-11 Service Hsv-Series Stdinverter Wall-Mount System Mfl41161605 20120105132900Ioannis OrfanoudakisNo ratings yet

- Control board troubleshooting and diagnostics guideDocument2 pagesControl board troubleshooting and diagnostics guideEdison EspinalNo ratings yet

- DWB056C001 Room Air Conditioner ManualDocument16 pagesDWB056C001 Room Air Conditioner ManualWalter Ivan Peña FloresNo ratings yet

- Electronic Expansion Valves Type TQPHTQDocument2 pagesElectronic Expansion Valves Type TQPHTQvickersNo ratings yet

- Repair Manual Neptune Maytag Mah7500awwDocument26 pagesRepair Manual Neptune Maytag Mah7500awwgruvinonu33% (3)

- Operation Manual for RAS Inverter Dyna Doctor ToolDocument9 pagesOperation Manual for RAS Inverter Dyna Doctor ToollunghiatrungNo ratings yet

- Samsung RA20VHSW Service ManualDocument32 pagesSamsung RA20VHSW Service Manualnuk1doe50% (2)

- Whirlpool Fault CodesDocument43 pagesWhirlpool Fault Codesdineshlathia0% (2)

- Ge Wall Oven Touchpad Ohm TestDocument1 pageGe Wall Oven Touchpad Ohm TestSamurai Appliance Repair ManNo ratings yet

- ARISTON Freeze Mba 4033 CviDocument20 pagesARISTON Freeze Mba 4033 CviLjupco MihajlovskiNo ratings yet

- Upgrade your 2020 Samsung TV firmware in under 40 stepsDocument6 pagesUpgrade your 2020 Samsung TV firmware in under 40 stepsKarmen ONo ratings yet

- KitchenAid Range KESC3008WH11 - Service ManualDocument6 pagesKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNo ratings yet

- Service Manual Guide for Daewoo RefrigeratorsDocument45 pagesService Manual Guide for Daewoo RefrigeratorsAndreea Delia100% (1)

- 1.4 File - 20210328 - 180749 - 002 Cncq Series Tc Set-free σ (Vrf), CoDocument335 pages1.4 File - 20210328 - 180749 - 002 Cncq Series Tc Set-free σ (Vrf), Cokhanh phanNo ratings yet

- Ka MW SM - Khms1850sDocument68 pagesKa MW SM - Khms1850sdan themanNo ratings yet

- Service Washing Manual 3Document35 pagesService Washing Manual 3Nelson Araujo100% (1)

- Washing Machine: Service ManualDocument37 pagesWashing Machine: Service ManualHenry RosaNo ratings yet

- یخچال Service ManualDocument19 pagesیخچال Service ManualMadjid RahmaniNo ratings yet

- Energy Efficient Samsung Refrigerator ManualDocument59 pagesEnergy Efficient Samsung Refrigerator ManualjicoelhoNo ratings yet

- MXG 30 50 Manual Usa Etl 09-07Document77 pagesMXG 30 50 Manual Usa Etl 09-07Sanu PhilipNo ratings yet

- Toshiba Estia Tcb-Pcmo3eDocument1 pageToshiba Estia Tcb-Pcmo3esimamNo ratings yet

- Basic Service Training: Cooling Circuit R600a and R134aDocument64 pagesBasic Service Training: Cooling Circuit R600a and R134aKyaw San OoNo ratings yet

- Automatic Transfer Switch Panel Operation GuideDocument23 pagesAutomatic Transfer Switch Panel Operation Guideyorgo7002100% (2)

- 3 Phase Auto Change Over SwitchDocument23 pages3 Phase Auto Change Over Switchajaykeshav100% (3)

- EPM-3790 en MDocument36 pagesEPM-3790 en MCarmen SerbanoiuNo ratings yet

- Smartgen Mgc100 v1.0 en User ManualDocument15 pagesSmartgen Mgc100 v1.0 en User ManualMd Shariful Islam ShohelNo ratings yet

- Instructions Alptec 3.2 5.2Document16 pagesInstructions Alptec 3.2 5.2Cris_eu09No ratings yet

- 1/16 Din Microbased Controller: Operators ManualDocument69 pages1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- EL Meaure MeterDocument40 pagesEL Meaure MeterRangasamyNo ratings yet

- Danfoss Facts Worth Knowing About ACDrivesDocument208 pagesDanfoss Facts Worth Knowing About ACDrivesvickersNo ratings yet

- Danfoss Banana Ripening Application BrochureDocument6 pagesDanfoss Banana Ripening Application BrochurevickersNo ratings yet

- Chillers and Heat Pumps Control-EngDocument4 pagesChillers and Heat Pumps Control-EngvickersNo ratings yet

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersNo ratings yet

- Chilled Beam Design GuideDocument46 pagesChilled Beam Design GuiderjchpNo ratings yet

- Thermal Applications CategoryDocument19 pagesThermal Applications CategoryvickersNo ratings yet

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 pagesASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Sanyo ScrollDocument24 pagesSanyo Scrollworker359567No ratings yet

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootNo ratings yet

- Frequency of Maintenance TestingDocument5 pagesFrequency of Maintenance TestingIsmael AhmedNo ratings yet

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 pagesDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersNo ratings yet

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 pagesReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersNo ratings yet

- CC - Quick Load CalculationsDocument2 pagesCC - Quick Load CalculationsvickersNo ratings yet

- NTC Thermistor Temperature to Resistance ChartDocument1 pageNTC Thermistor Temperature to Resistance ChartvickersNo ratings yet

- Copeland Scroll Designation 2005Document1 pageCopeland Scroll Designation 2005vickersNo ratings yet

- Basics of HVACDocument119 pagesBasics of HVACUmar FarooqNo ratings yet

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersNo ratings yet

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 pagesChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersNo ratings yet

- CC - Rapid Load Calculator PDFDocument1 pageCC - Rapid Load Calculator PDFvickersNo ratings yet

- Comparative Table of ScrollsDocument11 pagesComparative Table of ScrollsvickersNo ratings yet

- Cypetherm SuiteDocument72 pagesCypetherm SuitevickersNo ratings yet

- Refrigerant Charge CalculatorDocument1 pageRefrigerant Charge CalculatorBala Krishna GallaNo ratings yet

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- ThermostatCatalog 570-280Document12 pagesThermostatCatalog 570-280vickersNo ratings yet

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 pagesMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionNo ratings yet

- ZB Scroll Compressors ManualDocument70 pagesZB Scroll Compressors ManualJavier AffifNo ratings yet

- Supco TimersDocument7 pagesSupco Timersvickers100% (1)

- EMF NotesDocument87 pagesEMF NotesLex FrancisNo ratings yet

- xRayTube PDFDocument19 pagesxRayTube PDFAkhil ABNo ratings yet

- BX SOL DS T800999 enDocument2 pagesBX SOL DS T800999 enGrace ZuluetaNo ratings yet

- Power Transformers: Principles and ApplicationsDocument14 pagesPower Transformers: Principles and Applicationsvikalp321No ratings yet

- Installation InstructionsDocument2 pagesInstallation InstructionsFreddy MartinezNo ratings yet

- Case Expansion Measurements: Configuration and Verification ManualDocument44 pagesCase Expansion Measurements: Configuration and Verification ManualRabah AmidiNo ratings yet

- Servo Weld Guns - VX TYPE: 2M MTBF 100% BodyshopDocument2 pagesServo Weld Guns - VX TYPE: 2M MTBF 100% BodyshopLuciana LuNo ratings yet

- Ferrite Core For Internal Dpi Cables On Powerflex® 700S Frame 3 and 4 DrivesDocument6 pagesFerrite Core For Internal Dpi Cables On Powerflex® 700S Frame 3 and 4 Driveshuangxj722No ratings yet

- Philips Lighting 1987 Lamp Specification GuideDocument102 pagesPhilips Lighting 1987 Lamp Specification GuideAlan Masters100% (1)

- Half & Full Wave Rectifier Circuits, Zener Diode Voltage Regulator ExperimentDocument22 pagesHalf & Full Wave Rectifier Circuits, Zener Diode Voltage Regulator ExperimentHardik RangwaniNo ratings yet

- CAPA Test 1 2014 RegularDocument3 pagesCAPA Test 1 2014 RegulardaveadeNo ratings yet

- JHCP BRUTE Literature PDFDocument2 pagesJHCP BRUTE Literature PDFandreodeoNo ratings yet

- XcelEnergy Standard For Electric Installation and Use2014Document180 pagesXcelEnergy Standard For Electric Installation and Use2014CorbyFrielNo ratings yet

- Electronics For Technician EngineersDocument618 pagesElectronics For Technician EngineersIan Moree100% (12)

- 800w Rms Mosfet AmplifierDocument12 pages800w Rms Mosfet AmplifierpraveenNo ratings yet

- Definite Purpose Control Class 16 product nomenclatureDocument1 pageDefinite Purpose Control Class 16 product nomenclatureBostan EverNo ratings yet

- 773 G Plano ElectricoDocument26 pages773 G Plano Electricoandres gomezNo ratings yet

- Water Level Indicator KitDocument4 pagesWater Level Indicator KitVijay KrishnaNo ratings yet

- Chapter 4Document35 pagesChapter 4Nithindev GuttikondaNo ratings yet

- 16BT70408 - Low Power Cmos Vlsi DesignDocument1 page16BT70408 - Low Power Cmos Vlsi DesignS KkNo ratings yet

- Lesson 3 Electric FieldsDocument7 pagesLesson 3 Electric FieldsRachel LaserNo ratings yet

- RPH ElectricityDocument7 pagesRPH ElectricityNajiha AlHabsyiNo ratings yet

- A Medium Frequency Transformer-Based Wind Energy Conversion System Used For Current Source Converter Based Offshore Wind Farm PDFDocument4 pagesA Medium Frequency Transformer-Based Wind Energy Conversion System Used For Current Source Converter Based Offshore Wind Farm PDFLeMeniz InfotechNo ratings yet

- ORBIKDocument96 pagesORBIKNizarNo ratings yet

- W211 Rear SAM LightsDocument1 pageW211 Rear SAM LightsbinhpaNo ratings yet

- Under Voltage Over Voltage & ND RelayDocument2 pagesUnder Voltage Over Voltage & ND RelayDave Chaudhury100% (1)

- Interface Power Relay RT: General Purpose RelaysDocument3 pagesInterface Power Relay RT: General Purpose Relaysfrancisco fernandezNo ratings yet

- Configure sensor formats using remote inputsDocument2 pagesConfigure sensor formats using remote inputsLuis Arturo RicoNo ratings yet

- Little Fuse Powersafe Littelfuse Fuse Holder LPSM LPSCDocument1 pageLittle Fuse Powersafe Littelfuse Fuse Holder LPSM LPSCnickelchowNo ratings yet

- Quick Reference Install Guide: Installation PointsDocument2 pagesQuick Reference Install Guide: Installation PointsJonNo ratings yet