Professional Documents

Culture Documents

ASPE PSD - Standpipe System Design

Uploaded by

miniongsky0 ratings0% found this document useful (0 votes)

315 views4 pagesFIRE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFIRE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

315 views4 pagesASPE PSD - Standpipe System Design

Uploaded by

miniongskyFIRE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

28 Plumbing Systems & Design May/June 2004

FOCUS ON FIRE PROTECTION

Standpipe System Design

Part 1

David R. Hague, PE

Id like to clarify a few things about

standpipe system layout and design.

Although these systems have been

around for some time, there are still

some questions about how they

should be designed and installed and

just what is the intent of the design

standard (NFPA 14-2003 Standard for

the Installation of Standpipe and Hose

Systems).

Types and Limitations

Lets start with the basics and dis-

cuss the types of standpipe systems

and their limitations. First of all, it is

important to note that NFPA 14 does

not require the installation of stand-

pipe systems. The need to install a

standpipe, or sprinkler system for that

matter, resides in either a building

code, state or local ordinance, Life

Safety Code NFPA 101, or a similar

document. Once the need for a stand-

pipe system is established, NFPA 14

can then be used as a guide on how to

design and install a standpipe system.

One of the more common types of

standpipe systems is the Manual-Wet

System, which is connected to a water

supply that keeps the system lled with

water at all times. This type of system

does not provide the ow and pres-

sure needed for reghting without

re-department

intervention.

The re depart-

ment must

supplement

the pressure

through the

re department

connection in

order to achieve

the design pres-

sure of 100 psi. The manual-wet system

is limited in Section 5.4.1 of NFPA 14 to

buildings that are not dened as high-

rise and to areas that are not subject to

freezing.

An Automatic-Wet System is con-

nected to a water supply that is capa-

ble of providing the needed ow and

pressure for reghting automatically,

without re-department intervention.

Ordinarily an automatic-wet system

needs a re pump to achieve the pres-

sures needed. This type of system is

limited to areas

that are not subject

to freezing.

A Manual-Dry

System has no per-

manently attached

water supply and

must rely on a re-

department pumper (through the re-

department connection) for the needed

ow and pressure. A manual-dry

system is restricted in use to buildings

that are not high-rise and to areas that

are subject to freezing.

An Automatic-Dry System operates

much the same as a dry-pipe sprinkler

system, in that it is pressurized with

air and admits water to the system

only when the air pressure has been

relieved. An automatic-dry system is

attached to a water supply that auto-

matically provides the needed ow

and pressure without re-department

intervention.

A Semi-

Automatic Dry

System oper-

ates similar to a

deluge system

by employing

a deluge valve

that admits

water into the

system after

being activated

by a remote control, such as a manual

release located near a hose valve. A

semi-automatic dry system is attached

to a water supply that automatically

provides the needed ow and pressure.

All dry-type standpipe systems are

limited to use in areas that are subject

to freezing and further, cannot be used

in high-rise buildings.

Each system type has limitations.

These limitations also hold true for the

system classications. Standpipe sys-

tems are classied as Class I, II, or III.

A Class I system

supplies 2-inch

(65 mm) hose

valves for re-

department use.

A Class II system

provides 1-inch

(40 mm) hose sta-

tions (complete with hose and nozzle)

for use by either re-department or

re-brigade personnel. This is a change

in the 2003 edition of the standard

where previously Class II systems were

to be used by building occupants. It

is important to note that it is now the

intent to have building occupants exit

the building in the event of a re rather

than attempt to ght the re.

Class III systems are simply a combi-

nation of Class I and Class II standpipe

systems. In a Class III system, you may

nd a 2-inch (65 mm) hose valve and

a 1-inch (40 mm) hose rack on the

same system. In buildings protected

by an approved automatic sprinkler

system, a Class III system can be pro-

vided with a 2-x1-inch (65 mm x

40mm) reducer, cap, and chain in lieu

of a 1-inch (40 mm) hose rack. This

is important because some building

codes require a Class III system for

high-rise buildings. Remember, if a

standpipe system has hose in a hose

rack that hose must be pressure tested

every three years. Such an installation,

if not required, can be an unnecessary

expense to the building owner.

System Layout

System layout is the next area for

examination with the focus on Class I

NFPA 14 does not require the installation

of standpipe systems. The need to install

a standpipe, or sprinkler system for that

matter, resides in either a building code,

state or local ordinance, Life Safety Code

NFPA 101, or a similar document.

Note: Any opinion expressed in this article is the personal opinion of the author, and does not necessarily represent the

ofcial position of the NFPA or its Technical Committees. In addition, this correspondence is neither intended, nor should

be relied upon, to provide professional consultation or services.

It is important to note that it is now

the intent to have building occupants

exit the building in the event of a re

rather than attempt to ght the re.

May/June 2004 Plumbing Systems & Design 29

and III standpipes since Class II stand-

pipes are not very common. First, every

required exit stairway must have a

standpipe hose connection. The stand-

pipe should always be located in the

stairway whenever possible. Doing so

provides protection for the reghter

and the equipment since the stairway

provides a level of re resistance and

in some cases positive air pressure to

prevent lling the stairway with smoke.

If the standpipe cannot be located in

the stairway, it must be protected by a

level of re resistance (or enclosed in

a re-rated pipe chase) equal to that

of the stairway, an added expense that

can be avoided, as described above.

The maximum distance between

standpipes differs based on whether

the building is protected by an auto-

matic sprinkler system. NFPA 14

refers to this as travel distance. For

buildings with no sprinkler or partial

sprinkler protection, standpipes should

be located so that a reghter does

not have to travel more than 150 feet

(45.7m) from any point on any oor to

reach a standpipe hose connection. For

a building protected throughout by an

automatic sprinkler system, a reghter

should not have to travel more than

200 feet (61m). If exit stairs happen to

be located further than these restric-

tions, an additional riser must be pro-

vided. This is a case where a riser may

have to be installed in a corridor or in

the corner of a room and boxed-in to

protect the piping.

There is also some confusion sur-

rounding the interconnection of

standpipes. First, standpipes must be

interconnected by a common feed

main from one or more water supplies.

Each standpipe must have a riser isola-

tion valve so that a single riser can be

shut down while keeping other risers

in the system operational. Sprinkler

systems that are supplied by standpipe

systems (i.e., combined systems) can

be connected to multiple standpipes.

However, the sprinkler system cannot

serve as the interconnection required

by NFPA 14.

In the next article Ill discuss location

of standpipe system hose connections,

hydraulic calculation of standpipes, and

the requirements for pressure-regulat-

ing devices.

FOCUS ON FIRE PROTECTION

David Hague,

PE, is Senior Fire

Protection Specialist

for the National Fire

Protection Association,

located in Quincy,

Mass. He is NICET-

certied in Sprinkler

and Special Hazards

Systems Layout. Prior to joining NFPA,

he worked as an engineering technician

designing re-protection systems for the

sprinkler industry.

C

H

A

RT

E

R

A

D

V

E

R T

I

S

E

R

Circle 13 on your reader response card for product information.

32 Plumbing Systems & Design July/August 2004

FOCUS ON FIRE PROTECTION

Standpipe System Design

Part 2

David R. Hague, PE

Part one of this article (May/June

2004 Plumbing Systems & Design, pp.

28-9) focused on the types and limita-

tions of standpipe systems and system

layout. It concluded with a brief discus-

sion of sprinkler systems supplied by

standpipe systems, noting that these

sprinkler systems can be connected to

multiple standpipes.

Hose-Connection Locations

The next consideration in standpipe

system design should be hose-con-

nection locations. An important aspect

of hose connection location is acces-

sibility. Hose connections should be

located 3 to 5 feet (0.9 to 1.5m) above

the floor for ease of use, and must be

located at each intermediate landing

between floors (or on the main land-

ings when approved by the authority

having jurisdiction) in stairways. Hose

connections must also be available at

the highest landing where stairways

access the roof or on the roof where

stairways do not access the roof. The

roof outlet is needed to assist the fire

department in fighting a roof fire.

While there is no exception to

this requirement in NFPA 14, some

codessuch as NFPA 5000 Building

Construction and Safety Codewill

allow the roof outlet to be omitted

when the roof pitch exceeds 3 inches

in 12 inches for specific occupancies.

In my personal opinion, a roof outlet is

only required above a single stairway.

In other words, you are not required

to provide a roof outlet for each stand-

pipe even if the system consists of two

or more risers.

Pipe Sizing

Once the system type and layout

have been determined, it is then time

to consider pipe sizing. Every stand-

pipe system, whether manual or auto-

matic, must be calculated to verify that

the design requirements are met.

Lets consider flow first. Again, our

discussion will only involve Class

I and III standpipes, since Class II

standpipes are not very common. The

most hydraulically demanding stand-

pipe must be designed to handle a

flow of at least 500 gpm (1893 lpm).

This flow is based on calculating 250

gpm (946 lpm) at each of the two

topmost outlets. Notice I said the most

hydraulically demanding, not the

most remote standpipe. By saying,

most demanding, I am referring to

the standpipe that creates the highest

demand of flow and pressure. The

most demanding standpipe may not

always be the one furthest from the

point of supply.

For systems with more than one

standpipe, an additional flow of 250

gpm (946 lpm) must be added for each

standpipe. For buildings that are not

sprinklered or are only partially sprin-

klered, the total flow for the standpipe

system is not required to exceed 1250

gpm (4731 lpm). For a building that is

completely sprinklered, the standpipe

system flow is not required to exceed

1000 gpm (3785 lpm).

We have defined the flow require-

ments for standpipe systems. Now, lets

take a look at pressure. Once again,

our calculations will begin at the top-

most outlet of the most hydraulically

demanding standpipe. Our starting

pressure must be not less than 100 psi

(6.9 bar) for all systems, whether auto-

matic or manual. The only difference

is for an automatic system, the perma-

nently attached water supply (usually a

fire pump) must be capable of meeting

or exceeding the system demand. For

manual systems, the calculations must

provide flow and pressure demand

information at the fire department con-

nection (FDC). Remember, in part 1 of

this column I said that a manual system

relies on the pressure provided by the

fire department as supplied through

the fire department connection. This

is why we calculate manual standpipe

systems to the FDC; the FDC is our

point of supply.

Frequently, standpipe and sprin-

kler systems are combined or use

common feedmain piping. This is a

common practice and is intended to

keep the costs associated with the

installation of these systems as low as

possible. When calculating a combined

system, the sprinkler system demand

must be added to the standpipe system

demand only when the building is pro-

vided with partial sprinkler protection.

In such cases, the calculated demand

must be added by 150 gpm (568 lpm)

for light hazard occupancies or by

500gpm (1893 lpm) for an ordinary

hazard occupancy. For buildings pro-

tected in every area by an approved

automatic sprinkler system, no sprin-

kler demand is required to be added

to the standpipe system calculations.

This illustrates the ability of a sprinkler

system to contain and control a fire.

In some high-rise building applica-

tions, exceptionally high pressures

may be needed to achieve the above

referenced design requirements. First,

it is important to note that system

pressures are not permitted to exceed

300 psi (24.1 bar) since most listed

system components are not rated for

pressures higher than that. Second,

pressures exceeding 175 psi (12.1 bar)

can be hazardous to the firefighter. In

cases such as this, pressure-regulating

devicessuch as a pressure-control,

pressure-reducing, or pressure-regulat-

ing valvesmust be used. Depending

on the exact type and manufacture,

these valves will either be factory or

field adjusted. It is critical that the cor-

rect valve be installed in its proper

place due to pressure adjustment. In

the case of a field-adjusted valve, it

is also critical that the adjustment be

made during system commissioning.

Note: Any opinion expressed in this article is the personal opinion of the author, and does not necessarily represent the

official position of the NFPA or its Technical Committees. In addition, this correspondence is neither intended, nor should

be relied upon, to provide professional consultation or services.

July/August 2004 Plumbing Systems & Design 33

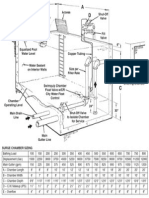

When pressure-regulating devices are

used in a standpipe system, a drain and

test riser must be installed to facilitate

testing of these devices. Figure 1 illus-

trates a combined sprinkler/standpipe

system with an accompanying drain

riser. The drain riser, in addition to

serving the sprinkler system as illus-

trated, must be equipped with a 2-

inch (65mm) fitting for

connecting hose to the

riser for testing.

Like sprinklers, stand-

pipe systems must be

tested prior to being

placed in service. As with

all water-based fire-protec-

tion systems, standpipes

must be hydrostatically

pressure-tested to 200 psi

(13.8 bar) for two hours or

50 psi (3.5 bar) in excess

of the minimal static pres-

sure when that static pres-

sure is in excess of 150 psi

(10.3 bar). In addition to

this test, a flow test at the design flow

and pressure must be conducted and

documented. A contractors material

and test certificate for standpipe systems

must be completed and submitted with

the as-built drawings as part of the proj-

ect closeout.

This two-part column is not intended

to be a comprehensive design pro-

cedure for standpipe systems, but I

thought it would be helpful to address

some pertinent facts about the finer

points of standpipe system design.

At some point in the future, I will re-

visit the topic of pressure regulating

devices. I hope you find this informa-

tion useful.

References

1. NFPA 5000 Building Construction

and Safety Code, 2002 Edition,

Chapter 55 (Fire Protection Systems

and Equipment).

FOCUS ON FIRE PROTECTION

David Hague,

PE, is Senior Fire

Protection Specialist

for the National Fire

Protection Association,

located in Quincy,

Mass. He is NICET-

certified in Sprinkler

and Special Hazards

Systems Layout. Prior to joining NFPA,

he worked as an engineering technician

designing fire-protection systems for the

sprinkler industry.

Source: NFPA 14, Figure A.7.10.1.3.1(a)

Figure 1. Combined Standpipe/Sprinkler System

Advance Tabcos new A.D.A.

Compliant Tapered Bowl

Drop-In and Undermount Sinks

provide complete, unrestricted

wheelchair access.

Sink includes wrist handle faucet,

and flat strainer drain.

Phone: 800-645-3166 Fax: 631-242-6900

NATIONAL MANUFACTURING AND DISTRIBUTION

Georgia Tennessee Texas Mississippi

New York South Carolina Nevada

www.advancetabco.com

New!

Rear drain design allows for

standard P-trap installation

DI-1-146 Shown with

Optional Drinking Bubbler

& Soap Dispenser

ACCESS UN-DENIED!

TAPERED BOWL A.D.A. DROP-IN SINKS

Circle 16 on your reader response card for product information.

C

H

A

RT

E

R

A

D

V

E

R T

I

S

E

R

You might also like

- Standpipes PDFDocument2 pagesStandpipes PDFAhmed Omar100% (1)

- Pressure Regulation in Standpipe & Sprinkler SystemDocument2 pagesPressure Regulation in Standpipe & Sprinkler SystemHenry Suarez100% (1)

- Cha 4 Standpipe and Hose SystemsDocument48 pagesCha 4 Standpipe and Hose SystemsYoesof HilabyNo ratings yet

- Dampers: Air Chem Systems, IncDocument12 pagesDampers: Air Chem Systems, Inchector.pineda7111No ratings yet

- SLXBobinwoundfiltersDocument1 pageSLXBobinwoundfiltersKAMALNo ratings yet

- OSHA 1926.1053 Subpart X LaddersDocument2 pagesOSHA 1926.1053 Subpart X LaddersEmmanNo ratings yet

- MIFAB Control Flo Roof DrainsDocument5 pagesMIFAB Control Flo Roof DrainsjavedwestNo ratings yet

- Standpipe and Hose SystemsDocument58 pagesStandpipe and Hose SystemsRipper VasuNo ratings yet

- Information For Man LiftDocument2 pagesInformation For Man LiftYadi KusmayadiNo ratings yet

- SDS ConceptDocument4 pagesSDS ConceptssarangNo ratings yet

- Xerxes Above Ground Tanks BrochureDocument16 pagesXerxes Above Ground Tanks Brochurebruno383No ratings yet

- PLUMBIM GB-High Definition PDFDocument74 pagesPLUMBIM GB-High Definition PDFMARIA DEL VALLE rodriguez leonNo ratings yet

- Pavementdesign PDFDocument95 pagesPavementdesign PDFอัชวิน เจริญสินNo ratings yet

- 2009 Uniform Plumbing Code (UPC)Document15 pages2009 Uniform Plumbing Code (UPC)jologscresenciaNo ratings yet

- Flexible Sprinkler Hose Installation GuideDocument7 pagesFlexible Sprinkler Hose Installation GuideSopi LabuNo ratings yet

- Standpipe System Types and RequirementsDocument11 pagesStandpipe System Types and Requirementsequalizer12345No ratings yet

- Blasting Booth Design ReviewDocument3 pagesBlasting Booth Design Reviewnewnse2008No ratings yet

- SmallGhsePresentation PDFDocument36 pagesSmallGhsePresentation PDFArvind PalNo ratings yet

- Comparison GuideDocument20 pagesComparison GuideMartin SabahNo ratings yet

- Weigh Module System Handbook Def enDocument136 pagesWeigh Module System Handbook Def enSamith BuddikaNo ratings yet

- Wavin QuickStream Specification Oct 14Document6 pagesWavin QuickStream Specification Oct 14Syahrisal SaputraNo ratings yet

- Sump Pump Manual (6!15!2016)Document14 pagesSump Pump Manual (6!15!2016)mfhaleem@pgesco.comNo ratings yet

- Inspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 MonthsDocument8 pagesInspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 Monthsm.sofiqur rahmanNo ratings yet

- Geberit Gulf Siphonic Rainwater Systems Techtalk February 2021Document41 pagesGeberit Gulf Siphonic Rainwater Systems Techtalk February 2021Kim Duy DoanNo ratings yet

- Bale Clamp - CascadeDocument11 pagesBale Clamp - CascadearyangeraNo ratings yet

- Torque Requirement For High Solid Centrifugal Sludge DewateringDocument5 pagesTorque Requirement For High Solid Centrifugal Sludge DewateringArdyanto WijayaNo ratings yet

- Kaiflex MasterSpecificationDocument8 pagesKaiflex MasterSpecificationnaseema1No ratings yet

- ACIDENTE IOSH HS Forum 17-10 Safety Alert Sling FailureDocument2 pagesACIDENTE IOSH HS Forum 17-10 Safety Alert Sling FailureGustavo CassiolatoNo ratings yet

- CPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookDocument106 pagesCPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookMark FessendenNo ratings yet

- Manhole and Sewage Disposal PDFDocument3 pagesManhole and Sewage Disposal PDFprincesaleemNo ratings yet

- Plastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011Document2 pagesPlastic Pipe Pressures in Siphonic Roof Drainage Systems: Building Research and Information February 2011imam muhsinNo ratings yet

- HT Tank Insulation SystemsDocument2 pagesHT Tank Insulation SystemssabinNo ratings yet

- Pipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechamDocument7 pagesPipe Wall Buckling in Siphonic Systems - IAHR Conference 2011 by Terry Lucke and Simon BeechampradiptyaNo ratings yet

- Non-Uniform Hydraulic Calculation Areas - Part 2Document2 pagesNon-Uniform Hydraulic Calculation Areas - Part 2wastedsunsetsNo ratings yet

- Saint Gobain PAM Cast Iron Drainage SystemsDocument120 pagesSaint Gobain PAM Cast Iron Drainage SystemsParveez HusnooNo ratings yet

- Trambeam CatalogDocument252 pagesTrambeam CatalogMuthu Barathi ParamasivamNo ratings yet

- Chemguard Bladder Tank Maintenance and Inspection ManualDocument8 pagesChemguard Bladder Tank Maintenance and Inspection Manualkkchung123No ratings yet

- SPEC For Chilled Water Pipework and FittingsDocument4 pagesSPEC For Chilled Water Pipework and FittingsonspsnonsNo ratings yet

- Chemguard Aircraft HangarsDocument7 pagesChemguard Aircraft HangarsRaymond ZuYang HngNo ratings yet

- ANSI Requirements For Overhead and Gantry CranesDocument7 pagesANSI Requirements For Overhead and Gantry CranesRizki SadikinNo ratings yet

- Bladder Tank PresentationDocument5 pagesBladder Tank PresentationNikhil RajanNo ratings yet

- Plumb Ling VentingDocument30 pagesPlumb Ling VentingNatthasart MuangsuankwanNo ratings yet

- Taco Expansion TankDocument20 pagesTaco Expansion TankDhirendra Singh RathoreNo ratings yet

- Getting The Most Out of Your Rupture Disc: March 2009Document4 pagesGetting The Most Out of Your Rupture Disc: March 2009madbakingNo ratings yet

- Fitting in Process PipingDocument18 pagesFitting in Process Pipingadel zahedNo ratings yet

- Thermoplastic Pipe & FittingsDocument100 pagesThermoplastic Pipe & FittingsAhrian BenaNo ratings yet

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11No ratings yet

- DuraSystems - Grease Duct Access Doors BrochureDocument2 pagesDuraSystems - Grease Duct Access Doors BrochureDuraSystemsNo ratings yet

- Icc Model Codes IbcDocument40 pagesIcc Model Codes IbcDavid Ezequiel BethancourtNo ratings yet

- Rectify issues from site visitDocument1 pageRectify issues from site visitSaqib_Manzoor__9876No ratings yet

- Filter media and filtration typesDocument9 pagesFilter media and filtration typesAli AimranNo ratings yet

- Frequently Asked Questions: Geberit SupertubeDocument9 pagesFrequently Asked Questions: Geberit Supertubemohaideen kasimNo ratings yet

- Et 321 06-23-15Document2 pagesEt 321 06-23-15Shishan AhmadNo ratings yet

- NFPA 20 Fire Pump Requirements for High-Rise BuildingsDocument8 pagesNFPA 20 Fire Pump Requirements for High-Rise BuildingsRaj KamalNo ratings yet

- High-Rise Fire Protection System Design - Zoning & Series PumpingDocument4 pagesHigh-Rise Fire Protection System Design - Zoning & Series PumpingminiongskyNo ratings yet

- Standpipe System Installation Standard PDFDocument5 pagesStandpipe System Installation Standard PDFAdrian bambaNo ratings yet

- Combination Standpipe Sprinkler Systems GuideDocument10 pagesCombination Standpipe Sprinkler Systems Guideodemircioglu2No ratings yet

- Fire Fighting ResearchDocument6 pagesFire Fighting ResearchRaymond ZuYang Hng100% (1)

- Sprinklers in Elevator ShaftDocument3 pagesSprinklers in Elevator ShaftradusettNo ratings yet

- Terrain Drainage Design Dubai MunicipalityDocument16 pagesTerrain Drainage Design Dubai MunicipalityChamara Chinthaka Ranasinghe100% (2)

- Combining DOAS and VRF, Part 2 of 2Document9 pagesCombining DOAS and VRF, Part 2 of 2miniongskyNo ratings yet

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDocument6 pagesBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyNo ratings yet

- Types and efficiencies of fuel-fired boilersDocument4 pagesTypes and efficiencies of fuel-fired boilersminiongskyNo ratings yet

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocument6 pagesGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyNo ratings yet

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyNo ratings yet

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDocument4 pages16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyNo ratings yet

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyNo ratings yet

- CIH Taco7aExpansionTankAirSepDocument16 pagesCIH Taco7aExpansionTankAirSepminiongskyNo ratings yet

- Sugar - Fluid Flow VelocitiesDocument4 pagesSugar - Fluid Flow VelocitiesminiongskyNo ratings yet

- Combining DOAS and VRF, Part 1 of 2Document8 pagesCombining DOAS and VRF, Part 1 of 2miniongskyNo ratings yet

- Expert Cooling Tower Repair, LLC - 303.790Document4 pagesExpert Cooling Tower Repair, LLC - 303.790eimrehNo ratings yet

- FMDS 1-35 Green Roof SystemsDocument27 pagesFMDS 1-35 Green Roof SystemsminiongskyNo ratings yet

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocument8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyNo ratings yet

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDocument3 pagesCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- ACH Recommended air changes per hourDocument2 pagesACH Recommended air changes per hourminiongskyNo ratings yet

- Air King Ventilation Ashrae 62Document5 pagesAir King Ventilation Ashrae 62miniongskyNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument13 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyNo ratings yet

- APEC Building Codes, Regulations and StandardsDocument227 pagesAPEC Building Codes, Regulations and StandardsminiongskyNo ratings yet

- Table - Hot Water Temperatures22Document2 pagesTable - Hot Water Temperatures22miniongskyNo ratings yet

- Table - Hot Water Temperatures NHSDocument1 pageTable - Hot Water Temperatures NHSminiongskyNo ratings yet

- Table 6 - Demographic2Document1 pageTable 6 - Demographic2miniongskyNo ratings yet

- Surge ChamberDocument1 pageSurge ChamberminiongskyNo ratings yet

- Table - First Hour RatingDocument1 pageTable - First Hour RatingminiongskyNo ratings yet

- Back To Basics - Water HeatersDocument5 pagesBack To Basics - Water HeatersminiongskyNo ratings yet

- Back To Basics - Water Pipe SizingDocument5 pagesBack To Basics - Water Pipe Sizingminiongsky100% (1)

- Table 1MDocument2 pagesTable 1MminiongskyNo ratings yet

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDocument2 pagesCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyNo ratings yet

- Design Considerations of Water FeaturesDocument102 pagesDesign Considerations of Water Featuresminiongsky100% (1)

- Evaporative Pool DehumidificationDocument9 pagesEvaporative Pool DehumidificationminiongskyNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual FLDocument10 pages2003 Nissan Altima 2.5 Serivce Manual FLAndy DellingerNo ratings yet

- MSD 338 (Operation Safety Checklist)Document4 pagesMSD 338 (Operation Safety Checklist)catalin100% (1)

- Catalogue SD3 2010Document44 pagesCatalogue SD3 2010Adrian OprisanNo ratings yet

- Practical English Grammar 1.1Document4 pagesPractical English Grammar 1.1Anemaria ManeaNo ratings yet

- Annexure1 PSSR CheklistDocument12 pagesAnnexure1 PSSR Cheklistanjna100% (1)

- 2 HLL PpaDocument18 pages2 HLL Ppaomar benounaNo ratings yet

- Borderland ProvincesDocument244 pagesBorderland ProvincesCraig Mawson92% (12)

- Airport Fuel Installation FireDocument10 pagesAirport Fuel Installation Firermaffireschool100% (1)

- 66898-SAMPLE Fire AlarmDocument1 page66898-SAMPLE Fire AlarmSooraj VsNo ratings yet

- 1 OCT 2015 Type EA-1 Protectospray-MjrDocument6 pages1 OCT 2015 Type EA-1 Protectospray-MjrBdSulianoNo ratings yet

- Dust Collector Fire ProtectionDocument6 pagesDust Collector Fire ProtectionJose Alfredo Rodriguez ColladoNo ratings yet

- SE 07 (EN) EvacuationDocument3 pagesSE 07 (EN) EvacuationAnh Thư NguyễnNo ratings yet

- TCVN 5760-1993 Fire Extingishing SystemDocument6 pagesTCVN 5760-1993 Fire Extingishing Systemochocomike100% (1)

- HSE Plan TemplateDocument8 pagesHSE Plan Templatederson50% (2)

- WTC7 LiesDocument109 pagesWTC7 LiesLazarus1956No ratings yet

- 12 JSanMiguel EFFIS EuropeFireDocument29 pages12 JSanMiguel EFFIS EuropeFireValPal2013No ratings yet

- Fire Safety TrainingDocument215 pagesFire Safety Trainingmercy83% (6)

- MSDS - 4 I 220Document3 pagesMSDS - 4 I 220Sj Comp UtaNo ratings yet

- The Great Fire of London Differentiated Reading ComprehensionDocument15 pagesThe Great Fire of London Differentiated Reading ComprehensionmahaNo ratings yet

- Safety Considerations When Blasting Off The Solid in Underground Fiery Coal MinesDocument10 pagesSafety Considerations When Blasting Off The Solid in Underground Fiery Coal MinesSuresh SharmaNo ratings yet

- Part 3-Chap 1 - General Building RequirementsDocument30 pagesPart 3-Chap 1 - General Building Requirementsfaruque65No ratings yet

- RMCI Tool Box Meeting FormDocument3 pagesRMCI Tool Box Meeting FormhampshireiiiNo ratings yet

- Blake London and The Tyger Passage AnalysisDocument2 pagesBlake London and The Tyger Passage AnalysislauradewNo ratings yet

- Kido List BleachDocument5 pagesKido List BleachJosé Bernardo Tenan VieiraNo ratings yet

- Fire & Explosion EngineeringDocument123 pagesFire & Explosion EngineeringSepty Dewi KurniawatiNo ratings yet

- Fire Incident 10th Mar 2014Document4 pagesFire Incident 10th Mar 2014Tran ThanhNo ratings yet

- DRRDocument4 pagesDRRRenzy Myer D. BulahanNo ratings yet

- DRRR - Q4 - Week5 - FIRE EMERGENCY AND EVACUATION PLAN PROCEDURE DURING A FIRE INCIDENTDocument21 pagesDRRR - Q4 - Week5 - FIRE EMERGENCY AND EVACUATION PLAN PROCEDURE DURING A FIRE INCIDENTHeader QuiliopeNo ratings yet

- Security Program ManualDocument39 pagesSecurity Program ManualBert CruzNo ratings yet