Professional Documents

Culture Documents

Professional SH New Const Structural Test

Uploaded by

api-2576774290 ratings0% found this document useful (0 votes)

84 views12 pagesOriginal Title

professional sh new const structural test

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

84 views12 pagesProfessional SH New Const Structural Test

Uploaded by

api-257677429Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Archi tectural Testi ng

1140 Lincoln Avenue

Springdale, PA 15144

phone: 724-275-7100

fax: 724-275-7102

www.archtest.com

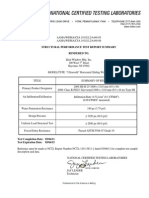

AAMA/WDMA/CSA 101/I.S.2/A440-05

TEST REPORT

Rendered to:

IDEAL WINDOW MANUFACTURING

SERIES/MODEL: NC Professional Single Hung

PRODUCT TYPE: PVC New Construction Single Hung Window

Report No.: 88928.02-501-44

Test Dates: 01/16/09

Through: 01/26/09

Report Date: 07/27/10

Expiration Date: 01/26/13

Archi tectural Testi ng

1140 Lincoln Avenue

Springdale, PA 15144

phone: 724-275-7100

fax: 724-275-7102

www.archtest.com

AAMA/WDMA/CSA 101/I.S.2/A440-05

TEST REPORT

SUMMARY OF RESULTS

Summary of Results

Title Test Specimen #1 Test Specimen #2

Primary Product Designator H-LC35 1118 x 1905 (44 x 75) H-LC35 1016 x 1600* (40 x 63*)

Design Pressure 1680 Pa (35.11 psf) 1680 Pa (35.11 psf)

Operating Force (in motion) 133 N (30 lbf) N/A

Air Infiltration

0.36 L/s/m

2

(0.07 cfm/ft

2

)

N/A

Water Penetration Resistance

Test Pressure

260 Pa (5.43 psf) N/A

Uniform Load Structural Test

Pressure

2520 Pa (52.66 psf) 2520 Pa (52.66 psf)

Forced Entry Resistance Grade 10 N/A

Test Completion Date: 01/26/09

Reference must be made to Report No. 88928.02-501-44, dated 07/27/10 for complete test

specimen description and data.

Archi tectural Testi ng

AAMA/WDMA/CSA 101/I.S.2/A440-05 TEST REPORT

Rendered to:

IDEAL WINDOW MANUFACTURING

100 West 7th Street, P.O. Box 48

Bayonne, New J ersey 07002-0048

Report No.: 88928.02-501-44

Test Dates: 01/16/09

Through: 01/26/09

Report Date: 07/27/10

Expiration Date: 01/26/13

Project Summary: Architectural Testing, Inc. was contracted by Chelsea Building Products to

perform testing on two Series/Model 730/930, PVC single hung windows. The samples tested

successfully met the performance requirements for the following ratings: Test Specimen #1: H-

LC35 1118 x 1905 (44 x 75); Test Specimen #2: H-LC35 1016 x 1600* (40 x 63*). This

report is a reissue of the original Report No. 88928.01-501-44. This report is reissued in the

name of Ideal Window Manufacturing through written authorization of Chelsea Building

Products. Test specimen description and results are reported herein. The samples were provided

by the client.

General Note: An asterisk (*) next to the size designation indicates that the size tested for

optional performance was smaller than the Gateway test size for the product type and class.

Test Specification: The test specimens were evaluated in accordance with

AAMA/WDMA/CSA 101/I.S.2/A440-05, Standard/Specification for Windows, Doors, and Unit

Skylights.

Test Specimen Description:

Series/Model: NC Professional Single Hung

Product Type: Poly Vinyl Chloride (PVC) New Construction Single Hung Window

Test Specimen #1: H-LC35 1118 x 1905 (44 x 75)

Overall Size: 1118 mm (44") wide by 1905 mm (75") high

Operable Sash Size: 1038 mm (40-7/8") wide by 933 mm (36-3/4") high

Fixed Daylight Opening Size: 984 mm (38-3/4") wide by 857 mm (33-3/4") high

Archi tectural Testi ng

88928.02-501-44

Page 2 of 8

Test Specimen Description: (Continued)

Test Specimen #1: H-LC35 1118 x 1905 (44 x 75) (Continued)

Screen Size: 1013 mm (39-7/8") wide by 911 mm (35-7/8") high

Overall Area: 2.1 m

2

(22.9 ft

2

)

Glazing Type: The unit was glazed with nominal 7/8" thick sealed insulating glass

fabricated from two sheets of 1/8" clear annealed glass and a "U" shaped steel spacer

system embedded in sealant, single sealed.

Test Specimen #2: H-LC35 1016 x 1600* (40 x 63*)

Overall Size: 1016 mm (40") wide by 1600 mm (63") high

Sash Size: 937 mm (36-7/8") wide by 778 mm (30-5/8") high

Daylight Opening Size: 878 mm (34-9/16") wide by 703 mm (27-11/16") high

Screen Size: 910 mm (35-13/16") wide by 759 mm (29-7/8") high

Overall Area: 1.6 m

2

(17.5 ft

2

)

Glazing Type: The unit was glazed with nominal 7/8" thick sealed insulating glass

fabricated from two sheets of 3/32" clear annealed glass and a "U" shaped steel spacer

system embedded in sealant, single sealed.

The following descriptions apply to all specimen.

Finish: All PVC was white.

Frame Construction: The extruded PVC frame was of mitered and welded corner

construction. The fixed meeting rail was secured to the jambs with using two drywall

blocks, one at each end. Each drywall block was fastened to the mating jamb with one #6 x

1-1/2" long screw, and to the fixed meeting rail with one #6 x 1/2" long screw.

Sash Construction: The extruded PVC sashes were of mitered and welded corner

construction.

Archi tectural Testi ng

88928.02-501-44

Page 3 of 8

Test Specimen Description: (Continued)

Weatherstripping:

Description Quantity Location

0.187" backed by 0.350" 1 Row Lock rail, and fixed meeting rail

high center fin pile

0.187" backed by 0.270" 1 Row Sill

high center fin pile

0.187" backed by 0.250 2 Rows Sash stiles

high center fin pile

0.187" backed by 9/16" 1 Row Bottom rail

high offset foam-filled bulb

Glazing Details: The sash was exterior glazed and the fixed lite was interior glazed. The

glass was set against a double-sided adhesive tape and secured with rigid vinyl glazing

beads.

Drainage:

Description Quantity Location

3-7/8" wide by 3/16" high 2 Sill screen leg, one at each end

weep notch

3/8" wide by 3/16" deep 2 Fixed meeting rail glazing pocket,

weepslot one at each end

1/4" wide by 1/8" deep 10 Fixed meeting rail bottom surface,

weepslot one at each end; bottom rail

glazing pocket, one at each

each end; bottom rail bottom

surface, three at each end

Archi tectural Testi ng

88928.02-501-44

Page 4 of 8

Test Specimen Description: (Continued)

Hardware:

Description Quantity Location

Metal cam lock 2 Lock rail, one 7" in from each end

and keeper with mating keeper on fixed meeting

rail

Plastic tilt latch 2 Lock rail, one at each end

Metal pivot bar 2 Bottom rail, one at each end

Block and tackle balance 2 One per jamb

system with tilt shoes

Reinforcement: The lock rail contained a "U" shaped steel reinforcement, reference

Drawing No. 742. The fixed meeting rail contained a "U" shaped steel reinforcement,

reference Drawing No. 740.

Screen Construction: The screen frame was constructed from formed aluminum. The

corners were square-cut and secured using plastic corner keys. The mesh fabric was held-

in-place with a flexible vinyl spline.

Installation: The unit was installed in a wood buck constructed of Spruce-Pine-Fir

construction lumber and secured through the nailing fin with #6 x 1-1/4" long screws spaced

approximately 11" on center, and beginning 2" in from each corner. A nominal 3/16" gap

was maintained at the perimeter between the test unit and wood buck. The nail fin perimeter

was sealed with a silicone sealant.

Test Results: The temperature during testing was 21C (70 F). The results are tabulated as

follows:

Paragraph Title of Test - Test Method Results Allowed

Test Specimen #1: H-LC35 1118 x 1905 (44 x 75)

5.3.1 Operating Force per ASTM E 2068

Initiate motion 120 N (27 lbf) Report Only

Maintain motion 135 N (30 lbf) 155 N (35 lbf)

Latches 9 N (2 lbf) 100 N (22.5 lbf)

Locks 22 N (5 lbf) 100 N (22.5 lbf)

Archi tectural Testi ng

88928.02-501-44

Page 5 of 8

Test Results: (Continued)

Paragraph Title of Test - Test Method Results Allowed

5.3.2.1 Air Leakage Resistance per ASTM E 283

75 Pa (1.6 psf) 0.36 L/s/m

2

1.5 L/s/m

2

(0.07 cfm/ft

2

) (0.3 cfm/ft

2

) max.

Note #1: The tested specimen meets (or exceeds) the performance levels specified in

AAMA/WDMA/CSA 101/I.S.2/A440-05 for air leakage resistance.

5.3.3.2 Water Penetration Resistance per ASTM E 547 See Note #2

5.3.4.2 Uniform Load Deflection per ASTM E 330 See Note #2

5.3.4.3 Uniform Load Structural per ASTM E 330 See Note #2

Note #2: The client opted to start at a pressure higher than the minimum required. Those

results are listed under "Optional Performance".

5.3.5 Forced Entry Resistance per ASTM F 588

Type: A Grade: 10

Disassembly Test No entry No entry

Tests A1 through A6 No entry No entry

Test A7 No entry No entry

Sash Manipulation Test No entry No entry

Lock Hardware Manipulation Test No entry No entry

5.3.6.2 Thermoplastic Corner Weld Test Meets as stated Meets as stated

5.3.6.3 Deglazing Test

In operating direction - 320 N (72 lbf)

Lock rail 3.0 mm (0.12") 11.4 mm (0.45")

Bottom rail 3.3 mm (0.13") 11.4 mm (0.45")

In remaining direction - 230 N (52 lbf)

Right stile 2.8 mm (0.11") 11.4 mm (0.45")

Left stile 3.0 mm (0.12") 11.4 mm (0.45")

Archi tectural Testi ng

88928.02-501-44

Page 6 of 8

Test Results: (Continued)

Paragraph Title of Test - Test Method Results Allowed

Test Specimen #1: H-LC35 1118 x 1905 (44 x 75) (Continued)

Optional Performance

4.4.2.6 Water Penetration Resistance per ASTM E 547

(with and without insect screen)

260 Pa (5.43 psf) No leakage No leakage

4.4.2.6 Uniform Load Deflection per ASTM E 330

(Deflections were taken on the fixed meeting rail)

(Loads were held for 10 seconds)

1680 Pa (35.11 psf) (positive) 6.4 mm (0.25") See Note #3

1680 Pa (35.11 psf) (negative) 5.8 mm (0.23") See Note #3

Note #3: The deflections reported are not limited by AAMA/WDMA/CSA 101/I.S.2/A440-05

for this product designation. The deflection data is recorded in this report for special code

compliance and information only.

4.4.2.6 Uniform Load Structural per ASTM E 330

(Permanent sets were taken on the fixed meeting rail)

(Loads were held for 10 seconds)

2520 Pa (52.66 psf) (positive) 0.5 mm (0.02") 4.1 mm (0.16") max.

2520 Pa (52.66 psf) (negative) 0.5 mm (0.02") 4.1 mm (0.16") max.

Test Specimen #2: H-LC35 1016 x 1600* (40 x 63*)

Optional Performance

4.4.2.6 Uniform Load Deflection per ASTM E 330

(Deflections were taken on the fixed meeting rail)

(Loads were held for 10 seconds)

1680 Pa (35.11 psf) (positive) 3.3 mm (0.13") See Note #3

1680 Pa (35.11 psf) (negative) 3.6 mm (0.14") See Note #3

4.4.2.6 Uniform Load Structural per ASTM E 330

(Permanent sets were taken on the fixed meeting rail)

(Loads were held for 10 seconds)

2520 Pa (52.66 psf) (positive) 0.3 mm (0.01") 3.6 mm (0.14") max.

2520 Pa (52.66 psf) (negative) 0.5 mm (0.02") 3.6 mm (0.14") max.

Archi tectural Testi ng

88928.02-501-44

Page 7 of 8

Tape and film were used to seal against air leakage during structural testing. In our opinion, the

tape and film did not influence the results of the test.

Drawing Reference: The test specimen drawings have been reviewed by Architectural Testing

and are representative of the test specimen reported herein.

List of Official Observers:

Name Company

J oe Allison Architectural Testing, Inc.

Mike Clay Architectural Testing, Inc.

J im Grippo Architectural Testing, Inc.

This report is reissued in the name of Ideal Window Manufacturing through written

authorization of Chelsea Building Products to whom the original report was rendered. The

original Chelsea Building Products Report No. is 88928.01-501-44.

Detailed drawings, data sheets, representative samples of test specimens, a copy of this report, or

other pertinent project documentation will be retained by Architectural Testing, Inc. for a period

of four years from the original test date. At the end of this retention period, such materials shall

be discarded without notice and the service life of this report will expire.

Results obtained are tested values and were secured by using the designated test methods. No

conclusions of any kind regarding the adequacy or inadequacy of the glass in the test specimen

can be made. This report does not constitute certification of this product nor an opinion or

endorsement by this laboratory. It is the exclusive property of the client so named herein and

relates only to the specimen(s) tested. This report may not be reproduced, except in full, without

the written approval of Architectural Testing, Inc.

For ARCHITECTURAL TESTING, INC.

_________________________________________________ ____________________________________________________

J ames P. Grippo Lynn George

Technician Director Regional Operations

J PG:sld

Attachments (pages): This report is complete only when all attachments listed are included.

Appendix-A: Alteration Addendum (1)

Appendix-B: Drawings: Complete drawings packet on file with Architectural Testing, Inc.

Archi tectural Testi ng

88928.02-501-44

Page 8 of 8

Revision Log

Rev. # Date Page(s) Revision(s)

0 07/27/10 N/A Original report issue

This report produced from controlled document template ATI 00156, revised 12/01/07.

Archi tectural Testi ng

88928.02-501-44

Appendix A

Alteration Addendum

Note: No alterations were required.

Archi tectural Testi ng

88928.02-501-44

Appendix B

Drawings

Note: Complete drawings packet on file with Architectural Testing, Inc.

You might also like

- Garden Window FactsDocument3 pagesGarden Window Factsapi-257677429No ratings yet

- Coil Caulk Worksheet 2013Document1 pageCoil Caulk Worksheet 2013api-257677429No ratings yet

- Garden WindowDocument2 pagesGarden Windowapi-257677429No ratings yet

- Garden Window InstallationDocument6 pagesGarden Window Installationapi-257677429No ratings yet

- Air Infiltration Full PageDocument2 pagesAir Infiltration Full Pageapi-257677429No ratings yet

- Buckingham Eco 2pgDocument2 pagesBuckingham Eco 2pgapi-257677429No ratings yet

- Commercial WarrantyDocument1 pageCommercial Warrantyapi-257677429No ratings yet

- Duraweld SLDDocument2 pagesDuraweld SLDapi-257677429No ratings yet

- Double Hung Install InstructionsDocument4 pagesDouble Hung Install Instructionsapi-257677429No ratings yet

- Blinds Tech SheetDocument1 pageBlinds Tech Sheetapi-257677429No ratings yet

- Buckingham Stock ListDocument1 pageBuckingham Stock Listapi-257677429No ratings yet

- Adjusting Balance FrictionDocument2 pagesAdjusting Balance Frictionapi-257677429No ratings yet

- Casement Install InstructionsDocument17 pagesCasement Install Instructionsapi-257677429No ratings yet

- Buckingham Eco 6pgDocument2 pagesBuckingham Eco 6pgapi-257677429No ratings yet

- New Construction Bronze Linen PF ProfessionalDocument1 pageNew Construction Bronze Linen PF Professionalapi-257677429No ratings yet

- Eco Friendly Buckingham RollersDocument1 pageEco Friendly Buckingham Rollersapi-257677429No ratings yet

- Ultratite Slider Structural TestDocument28 pagesUltratite Slider Structural Testapi-257677429No ratings yet

- 2011 Tax Cert ProfessionalDocument1 page2011 Tax Cert Professionalapi-257677429No ratings yet

- Ideal PresDocument40 pagesIdeal Presapi-257677429No ratings yet

- Professional SH Replacement Structural TestDocument12 pagesProfessional SH Replacement Structural Testapi-257677429No ratings yet

- Buckingham Stock ListDocument1 pageBuckingham Stock Listapi-257677429No ratings yet

- 201 Tax Cert UltraweldDocument1 page201 Tax Cert Ultraweldapi-257677429No ratings yet

- Professional SH Replacement Structural TestDocument12 pagesProfessional SH Replacement Structural Testapi-257677429No ratings yet

- Professional Ro ChartsDocument22 pagesProfessional Ro Chartsapi-257677429No ratings yet

- Perfectfit Gen Glass Performance PageDocument1 pagePerfectfit Gen Glass Performance Pageapi-257677429No ratings yet

- Hampton Patio Door Structural TestDocument30 pagesHampton Patio Door Structural Testapi-257677429No ratings yet

- Hampton Patio Door Structural TestDocument30 pagesHampton Patio Door Structural Testapi-257677429No ratings yet

- Duratrust PW Replacement Structural TestDocument11 pagesDuratrust PW Replacement Structural Testapi-257677429No ratings yet

- Duratrust PW Replacement Structural TestDocument11 pagesDuratrust PW Replacement Structural Testapi-257677429No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Write UpDocument5 pagesWrite Upmourad baNo ratings yet

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Document19 pagesMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldNo ratings yet

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CNo ratings yet

- Book Networks An Introduction by Mark NewmanDocument394 pagesBook Networks An Introduction by Mark NewmanKhondokar Al MominNo ratings yet

- DC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlDocument5 pagesDC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlAlisson Magalhães Silva MagalhãesNo ratings yet

- Disaster Management Plan 2018Document255 pagesDisaster Management Plan 2018sifoisbspNo ratings yet

- Survey Course OverviewDocument3 pagesSurvey Course OverviewAnil MarsaniNo ratings yet

- Phys101 CS Mid Sem 16 - 17Document1 pagePhys101 CS Mid Sem 16 - 17Nicole EchezonaNo ratings yet

- Pub - Essentials of Nuclear Medicine Imaging 5th Edition PDFDocument584 pagesPub - Essentials of Nuclear Medicine Imaging 5th Edition PDFNick Lariccia100% (1)

- GlastonburyDocument4 pagesGlastonburyfatimazahrarahmani02No ratings yet

- Hindustan Motors Case StudyDocument50 pagesHindustan Motors Case Studyashitshekhar100% (4)

- Ujian Madrasah Kelas VIDocument6 pagesUjian Madrasah Kelas VIrahniez faurizkaNo ratings yet

- Assignment 2 - Weather DerivativeDocument8 pagesAssignment 2 - Weather DerivativeBrow SimonNo ratings yet

- Music 7: Music of Lowlands of LuzonDocument14 pagesMusic 7: Music of Lowlands of LuzonGhia Cressida HernandezNo ratings yet

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47No ratings yet

- Pre Job Hazard Analysis (PJHADocument2 pagesPre Job Hazard Analysis (PJHAjumaliNo ratings yet

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocument12 pagesMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNo ratings yet

- Movement and Position: Question Paper 4Document14 pagesMovement and Position: Question Paper 4SlaheddineNo ratings yet

- Moor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsDocument4 pagesMoor, The - Nature - Importance - and - Difficulty - of - Machine - EthicsIrene IturraldeNo ratings yet

- PRODUCTDocument82 pagesPRODUCTSrishti AggarwalNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- Innovation Through Passion: Waterjet Cutting SystemsDocument7 pagesInnovation Through Passion: Waterjet Cutting SystemsRomly MechNo ratings yet

- Briana SmithDocument3 pagesBriana SmithAbdul Rafay Ali KhanNo ratings yet

- Modified Syllabus of Control SystemDocument2 pagesModified Syllabus of Control SystemDigambar PatilNo ratings yet

- Free Radical TheoryDocument2 pagesFree Radical TheoryMIA ALVAREZNo ratings yet

- John Titor TIME MACHINEDocument21 pagesJohn Titor TIME MACHINEKevin Carey100% (1)

- Nursing Care Management of a Client with Multiple Medical ConditionsDocument25 pagesNursing Care Management of a Client with Multiple Medical ConditionsDeannNo ratings yet

- Tension field beams: Aircraft wing spar analysisDocument19 pagesTension field beams: Aircraft wing spar analysisPrajeesh RajNo ratings yet

- QueriesDocument50 pagesQueriesBajji RajinishNo ratings yet

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)