Professional Documents

Culture Documents

7.powder Metallurgy 14

Uploaded by

caveshgmailcomOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.powder Metallurgy 14

Uploaded by

caveshgmailcomCopyright:

Available Formats

1

7. POWDER METALLURGY

Powder metaurgy s the art and scence of producng ne meta powders and then makng

ob|ects from ndvdua, mxed or aoyed meta powders wth or wthout the ncuson of non-

metac consttuent.

ADVANTAGES OF POWDER METALLURGY PROCESS:

LIMITATIONS of POWDER METALLURGY PROCESS:

APPLICATIONS OF POWDER METALLURGY:

1

1. Automotve: (ANSWER FOR SELF LUBRICATED BEARINGS)

Sef-ubrcated bearngs are made by mxng copper (90%), tn (10%) powder

and a sma amount of graphte n correct proportons, cod pressed to the

desred shape and then sntered at about 800 C.

Szng operaton s done n order to get correct dmensona accuracy.

In Impregnaton process the bearngs soak up consderabe quantty of o.

Hence durng servce, these bearngs produce a constant suppy of ubrcant

to the surface due to capary acton and as soon as the shaft stops rotatng,

the o comes back agan and settes down n the pores.

2. Refractory Materas:

Metas wth hgh metng ponts are termed as refractory metas.

These bascay ncude four metas tungsten, moybdenum, tantaum and

nobum. Refractory metas as we as ther aoys are manufactured by powder

metaurgy.

The appcatons are not mted to amp aments and heatng eements, they

aso ncude space technoogy and the heavy meta used n radoactve

shedng.

3. Cemented Carbdes:

These are very mportant products of powder metaurgy and nd wde

appcatons as cuttng toos, wre drawng des and deep drawng des.

These consst of carbdes of tungsten, tantaum, ttanum and moybdenum. The

actua proportons of varous carbdes depend upon ts appcatons; ether

cobat or ncke s used as the bondng agent whe snterng.

4. Aerospace appcaton:

Powder metaurgy pars are used n rockets, msses, satete etc.

Sntered bronze bearng and other bushng are used n exporer satete,

magnetc materas such as Anco.

5. Defense Appcatons:

Powder metaurgy parts and powders are used n rockets, msses, cartrdge

cases, gun powder, frage buets etc.

6. Other Appcatons: (WRITE THIS IF ASKED ONLY FOR 2 MARKS)

Typewrters, cacuators, permanent magnets etc.

Porous ncke eectrodes are used n N-Cd batteres.

POWDER METALLURGY PROCESSES

1

A. Producng of meta powders

B. Mxng / Bendng

C. Compactng

D. Snterng

E. Secondary Operatons.

F. Inspecton/Testng.

A. PRODUCTION OF METAL POWDERS:

Varous methods for manufacturng powders are

1. Mechanca Processes

2. Physca Processes

3. Chemca Processes

MECHANICAL PROCESSES: (ANSWER FOR POWDER MAKING PROCESSES)

1. Machnng.

In ths method rst chps are produced by ng, turnng etc. and subsequenty

puverzed by crushng and mng.

The powders produced by ths method are coarse n sze and rreguar n shape.

Hence, ths method s used for speca cases such as producton of magnesum

powder.

2. Crushng.

1

Process of passng the meta

powders aganst two roers so

that the meta powders are

crushed to requred sze.

Crushng requres equpment

such as stamp, hammers, |aw

crushers.

3. Mng.

Mng s carred out by usng

equpment such as ba m, rod

m, mpact m, dsk m etc.

In ba mng, matera to be

powdered s coected n a

contaner wth a arge number of

hard stee bas. These bas ht

the matera and break t n

powder form

4. Shottng

The process of pourng moten meta through a seve or orce and coong by

droppng nto water s known as shottng.

Ths process gves spherca or pear shaped powder partces.

5. Atomzaton.

The process of meta sprayng

aganst a stream of compressed

ar or nert gas s Atomzaton.

It s an exceent means of

producng meta powders from

many of the ow temperature

metas such as ead, aumnum,

znc and tn.

PHYSICAL PROCESSES:

1. Condensaton:

1

In ths method, metas are boed to produce meta vapours and then

condensed to obtan meta powders.

Ths process s apped to voate metas such as znc, magnesum and

cadmum.

2. Therma Decomposton:

Fne meta powders of N, Mo, Mg, Co etc are manufactured by ths method.

Ths method s hghy sutabe for manufacturng of Fe and N powders.

CHEMICAL PROCESSES:

1. Reducton

Pure meta s obtaned by reducng ts oxde wth a sutabe reducng gas at

an eevated temperature (beow the metng pont) n a controed furnace.

The reduced product s then crushed and med to a powder.

Sponge ron powder s produced ths way

Fe3O4 + 4C = 3Fe + 4CO

Fe3O4 + 4CO = 3Fe + 4CO2

Copper powder by

Cu2O + H2 = 2Cu + H2O

Tungsten, Moybdenum, N and Cobat are made by ths method.

2. Eectroyss.

Ths method s commony used for producng ron and copper powders. Ths process

s smar to eectropatng.

For makng copper powder, copper pates are paced as anodes n the tank of

eectroyte, whereas the aumnum pates are paced nto eectroyte to act as

anode.

When D. C. current s passed

through the eectroyte, the copper

gets deposted on cathode. The

cathode pates are taken out from

eectroyte tank and the deposted

powder s scrapped oh. The powder

s washed, dred and puverzed to

produce powder of the desred

gran sze. The powder s further

sub|ected to heat treatment to

remove work hardness ehect.

The cost of manufacturng s hgh.

B. MIXING / BLENDING of meta powders

1

Bendng: mxng powder of the same chemca

composton but dherent szes

Mxng: combnng powders of dherent chemstres.

The above gure shows the contaner n whch the

powder to be mxed s added

The bade contnuousy rotates and mxes the powder.

Fgure (b) shows a rotatng drum n whch powder s ed

and the drum keeps on rotatng and smutaneousy

mxng the powders.

Wet or dry mxng s generay empoyed.

For wet mxng water or dry sovent s used to obtan

better mxng.

Bendng and mxng s necessary for

Addton of ubrcants coats the powders and reduces de

wear and owers pressure requred for pressng of powders.

Mxng powders of dherent materas

Obtanng unform dstrbuton of partce szes.

C. COMPACTING / PRESSING of meta powders.

Compactng: Pressng the powders nto desred part shape as cosey as possbe

to na dmensons.

Powders are compacted usng hgh pressure.

The na product s known as "Green Compact"

Degree of pressure requred depends upon:

Requred densty of na product

Ease wth whch powder partces w wed together.

Compactng processes are:

1. De pressng

2. Ro pressng

3. Extruson.

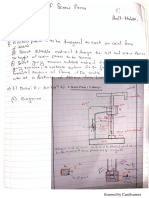

1. De pressng.

1

It conssts of upper punch and ower punch as shown n gure.

Powder s ed on the space above ower punch.

Upper punch appes hgh pressure to the powder.

Fnay the green compact powder s receved as shown n gure.

2. Ro pressng.

Two ros of approprate szes are

used.

Stream of powder s guded, so that

the ros are abe to appy the

necessary compactng pressure n

a contnuous sequence.

3. Extruson method.

Ram s used for appyng

force.

Two des are used for

achevng proper

thckness.

As seen n the gure the

green compact s

extracted whch s

further sent for snterng

process.

1

D. SINTERING

Snterng s the Heat treatment process, to bond the metac partces, thereby

ncreasng strength and hardness.

Snterng conssts of heatng pressed meta compacts n batch or contnuous

furnaces to a temperature beow the metng pont of matera.

It conssts of three steps: Surface Dhuson, Denscaton, Gran Growth

Most metas are sntered at 70% to 80% of metng temperature.

Ehect of snterng on the propertes of matera:

1. Densty - Increases

2. Strength & Hardness - Increases

3. Porosty - Decreases

Types:

A) Sod Phase Snterng: Here, the compact s heated above the

recrystazaton temp of ow metng meta powder.

B) Lqud Phase Snterng: Here, the green compact s heated above the metng

pont of one of the aoyng eement

C/D. HOT COMPACTING:

Hot pressng nvoves appyng pressure and temperature smutaneousy, so

that the compactng and snterng of the powder takes pace at the same tme

n a de.

Its appcaton s mted and can be used for compactng.

Fe and Brass powders at much ower pressure than conventona pressng and

snterng operatons.

E. SECONDARY /FINISHING operatons:

These are secondary operatons ntended to provde dmensona toerances,

physca and better

surface nsh. A number of secondary and nshng operatons can be apped after

snterng, some of them are:

1. Szng 5. Intraton

1

2. Conng 6. Heat treatment

3. Machnng 7. Patng

4. Impregnaton

1. Szng: It s repressng the sntered component n the de to acheve the requred

accuracy.

2. Conng: It s repressng the sntered components n the de to ncrease densty,

acheve the requred accuracy and to gve addtona strength.

3. Machnng: Machnng operaton s carred out on sntered part to provde under

cuts, hoes, threads etc. whch cannot be removed on the part n the powder

metaurgy process.

4. Impregnaton:

It s ng of o, grease or other ubrcants n a sntered component such as

bearng.

Sntered parts may be mpregnated wth o,

grease, wax or other ubrcatng materas s

sef-ubrcatng propertes are requred.

Parts are mmersed n ubrcants and are

heated upto approx. 93 C. The porous structure

gets competey mpregnated n 10-20 mns.

The ubrcant s retaned n the part by capary

acton.

It s done n order to:

a. Improve corroson resstance

b. Sea pror to patng

c. Improve machnabty

d. Introduce pressure tghtness

e. Reduce the frcton between parts.

5. Intraton:

It s ng of pores of sntered product wth moten meta to mprove physca

propertes.

Once the part s sntered, t has about 77% theoretca densty.

Then an ntraton pank of Copper or Brass s paced over the part whch s

sent through the furnace. The ntraton mets and soaks through the porous

part, producng hgh densty product.

It provdes hgh strength, hardness and densty whch straght snterng

cannot.

6. Heat Treatment: The processes of heatng and coong sntered parts are to

mprove

1

Wear Resstance

Gran Structure

Strength

7. Patng: Patng s carred out n order to:

Import a peasng appearance (Cr patng)

Protect from corroson (N patng)

Improve eectrca conductvty (Cu and Ag patng)

F. INSPECTION / TESTING:

Before the component s put to the servce, t shoud be tested for any

naccuracy or defect.

The varous tests to be conducted are comp. & tense strength, porosty,

densty, hardness.

Non-Destructve Testng methods can aso be used to nd defects.

Once the component satses the propertes, t s ready for use.

CHARACTERISTICS OF METAL POWDERS / POWDER TESTING:

Powders can be dened as a ney dvded partcuate sod.

Engneerng powders ncude metas and ceramcs.

The man purpose of powder testng s to ensure whether or not the powder s

sutabe for further processng.

Prncpe characterstcs of meta powders are:

1. Chemca composton. (Purty)

It s the term to understand the type and percentage of mpurtes that the powder

contans.

2. Partce sze and ts dstrbuton.

The partce sze s dened by the mesh count

Mesh count refers to the number of openngs per near nch of mesh.

3. Partce shape.

Varous shapes of meta powders observed accordng to the method of producton.

4. Partce porosty :-

Rato of the voume of the pores (empty spaces) n the powder to the buk voume

(ed space).

Porosty ncreases stress n the part so t s not desrabe.

Dherence between destructve and non destructve testng

1

1

1

6. NON METALLIC MATERIALS

1

1. Polymer:

The word poymer s derved from two Greek words Poy and

Meros. Poy means mutpe and meros means parts. Poymers are organc

materas havng carbon as common eement nked wth other eements.

The process of nkng the monomers together to form a poymer s caed as

poymersaton.

2. Plastics:

Characterstcs/Propertes Uses/Appcatons

1. These are havng ow

densty.

1. Water pot, mugs,

Buckets.

2. Corroson resstance s hgh.

2. Drums, Contaner for

storage.

3. These are havng good

moud abty.

3. Bottes, contaners for

storng food stuhs or

ktchen tems.

4. They can be used as

transparent or wth coours.

4. Decoratve artces ke

show pece, artca

owers.

5. They have exceent surface

nsh.

5. Ar-tght boxes.

6. They are economca.

6. Insuators, eectrc shock

proof grps and heat proof

grps.

7. They are havng poor

strength.

7. Tabes, chars, cupboards.

8. They are havng poor temp.

resstance.

9. They are bad conductors of

heat and eectrcty.

1

3. Types of Plastics:

Thermopastcs:

Thermopastcs are those whch soften on heatng, can be heated any

number of tme and then subsequenty cooed for obtanng desred shape.

3 a. Types of Thermoplastics:

Names

Characterstcs/Properte

s

Uses/Appcatons

1. Acryontr

e

butaden

e styrene

1. Hgh tense strength.

2. Hgh wear and tear, abrason

resstance.

3. Hgh mpact oad resstance.

1. Resstance to acds and

akaes.

1. Used n automobe

ndustry for pane

work.

2. Used for teevson

and camera back

bodes.

3. ABS wth Chromum

patng can be used

n

Radator grs.

2. Acrycs-

Poymeth

y Metha

cryate

(PMMA)

1. Hgh nsuaton propertes.

2. Hgh ndex of refracton.

3. Lght n weght, tough but

not scratch-proof.

1. Santary ware.

2. Contact enses.

3. Snks, Wash Basns,

other bathroom

ttngs.

4. Hospta Equpment

for patents hygene

and heath care.

1

3. Nyons

(Poyamd

es)

1. Aong wth beng tough and

strong, these are exbe too.

2. Hgh mpact resstance.

3. Poor resstance to hot water,

acoho and utra voet rays.

1. Nyon ropes have

wde domestc and

commerca uses.

2. Tooth-brush and

other washng brush

brstes.

4. Poy Vny

chorde

(PVC)

1. Good dmensona stabty.

2. Water resstant.

3. It s sef-extngushng when

gnted.

Becomes soft above 80

o

C.

1. Water ppes,

chemca tubng.

2. Cabe |ackets.

3. Lead wre nsuaton.

Thermosettng Pastcs:

1

Thermosettng pastcs are those whch become soft durng ther rst

heatng and become permanenty hard when cooed thus cannot be

recyced.

3 b. Types of Thermosetting Plastics:

Names

Characterstcs/Propert

es

Uses/Appcatons

1. Epoxd

es

1. These are ght and

transparent n coour.

2. Exceent chemca

resstant.

3. Good eectrca

nsuatng propertes.

4. Extremey hgh bondng

strength.

1. In automobe panes and

ght covers.

2. Insuatng materas n

cabes, transformers.

3. Used as adhesve for

|onng and repar work.

2. Meam

ne

Formad

eh-yde

(M.F.)

1. They have hgh resstance

to chemcas, heat and

mosture.

2. Better eectrca resstance

3. Lghty ahected by sunght.

1. Used n pants, surface

coatng.

2. Used as gues, adhesve

for |onng.

3. Pugs, swtches, buttons

are made from M.F.

3. Baket

e

1. It s Back and Brown n

coour.

2. Strong, rgd and

dmensonay stabe.

3. It gets dscooured on

ageng by sunght.

1. Used n non-conductng

parts of rados and bases

& sockets for ght bubs

& vacuum tubes.

2. Automobe dstrbutor

caps and other nsuators,

brake pads and reated

automotve components.

3. Ktchenware such as

cansters and tabeware.

Rubbers:

1

Rubbers are hghy eastc and resent poymerc materas,

they are organc poymers those are capabe of beng sub|ected to

arge eastc strans wthout pastc yedng natura and synthetc

rubbers are caed as eastomers.

4. Types of Rubbers:

Names Characterstcs/Propertes Uses/Appcatons

1. Neopren

e

1. It s resstant to os,

chemcas, sunght, ozone,

etc.

2. It retans propertes up to

120

o

C.

3. Exceent resstance to

permeabty by gases.

4. It s havng mechanca

propertes smar to those of

natura rubber.

1. Heavy duty conveys

or bets.

2. V-bets, horse covers.

3. Foot wears, shoe

soes.

4. Brake daphragms,

gaskets.

2. Styrene

Butade

ne

Rubber

(Buna S)

1. Low o and chemca

resstance.

2. Hgh mpact and abrason

resstance.

3. Low tense strength and

resence than natura

rubber.

1. Vehce tyres are

made of Buna S.

1

3. Ntre

Butade

ne

Rubber

(Buna

N)

1. Good resstance to o, fue,

other chemcas.

2. Low n mechanca

propertes.

3. Low n tense strength.

4. Good resstance to

weatherng.

1. Used n exbe

coupngs, prntng

bankets, rubber

roers.

2. Washng machne

parts.

5. SILICO!S:

There are unque poymers whch are Scon based nstead of carbon

based. They have -SI-O-SI- bondng, are wdey used s n organc poymer.

Propertes:

1. Exceent resstance to hgh & ow temperature.

2. Exceent resstance to os & chemcas.

3. Poor tense strength.

4. Exceent eectrca propertes.

5. Poor physca propertes.

". OT#!R !$I!!RI$ %&T!RI&LS:

Names Characterstcs/Propertes Uses/Appcatons

1. CERAMIC

S

1. They are very hard, strong and

dense.

2. They have a very hgh

resstance to the acton of

chemcas & weatherng.

3. They have a very hgh

resstance to hgh

temperature creep.

4. They have a very hgh

strength, both n tenson as

we as compresson.

1. Glassware, Windows, Pottery,

Dinner ware.

2. Catalytic converters, Ceramic

filters, Air bag sensors, Spark

plug.

3. rt!opaedic "oint replacement,

Dental restoration, #one

implants.

4. $efractory bricks, %ab

e&uipment's, cutting tools.

2. GLASSES

1. No dente crystane

structure.

2. It absorbs, refracts or

1. In eectrc amps &

eectrons tubes.

2. In wndows gass,

1

transmts ght.

3. It can be made avaabe n

beautfu coours.

4. It s capabe of beng worked

n severa ways.

doors and other

decoratve artces.

3. Laboratory

equpments and

apparatus resstant

to acds and other

chemcas.

3. GLASS -

WOOL

1. It usuay conssts of soda me

gass bres.

2. It provdes exceent nsuator

aganst heat and cod.

3. It has a very hgh tense as

we as we as compressve

strength.

4. It s havng a unform as we

as dente formuaton not

there n mnera woo.

1. It s wdey used n

exteror was and n

cengs of houses.

2. Extremey ow

densty woo s used

as therma as we as

sound nsuator n

aeropanes.

3. Used as nsuators n

refrgerators and

freezng.

4. LAMINAT

ED

COMPOSI

TE

1. They are havng two or more

ayers of dherent materas

bonded physcay to each

other.

2. Hgh corroson resstance,

eectrca and magnetc

propertes can be obtaned.

3. Hgh sthness and hgh

strength.

1. Cadded aumnum

aoy s used for

varous automotve

appcatons.

2. Cadded staness

stee wth md stee

wth md stee s

used for heat

exchangers.

1

5.REINFORC

ED

COMPOSITE

S

1. Fber renforced pastc have

exceent strength toughness

and corroson resstance.

2. Meta matrx ber compostes

(MMFC) have exceent

resstance to hgh

temperature creep and mpact

strength.

3. Renforced cement concrete

(RCC) have hgh tense

strength of stee as we as

hgh compressve strength of

concrete.

1. Water as we as

chemca storage

tanks, uggage bags,

hemets, fans bades

of wnd turbnes.

2. Marne and wnd

aerospace

components.

3. Used n coumns and

beams of varous

structures, such as

brdges and

budngs.

6. NANO

MATERIALS

1. Partce sze ranges from

0.1mm to 100mm whch are

extremey sma.

2. At ow temperatures hardness

and strength of Nano matera

ncreases wth reducton n

partce sze.

3. Wth decrease n partce sze

even non-magnetc propertes.

4. The use of Nano-materas

reduces the sze of a

component by more than

50%.

1. Cuttng toos ke

tungsten carbde are

Nano-technoogy

made; mcro drs of

har sze can aso be

made.

2. Zrcona s a ceramc

based matera Nano

made used for

sprngs, ba bearngs

and other automotve

appcatons.

3. Nano crystas ke

znc suphde are

used for at pane

eectronc dspay n

T.V and computer

screens.

4. Nano materas are

aso used for hgh

power magnets used

n MRI and other

1

dagnostc purpose.

Applications of Polyester: (2 MARKS)

Pants, Bnders for gass bers, Safety hemets, Fber gass boats, |onng and repar

works, Caddng panes, Automobe body components, Fans, Chars.

Applications of Asbestos: (2 MARKS)

Fre proof textes, Fre proof theatre curtan, Boer nsuaton, Brake shoes, Ppe

nsuaton, gaskets, Protectve pads.

Classifcation of polymer materials: (2 MARKS)

1. ACCORDING TO ORIGIN

a. Natura Poymer b. Synthetc or artca Poymer

2. ACCORDING THERMAL BEHAVIOUR

a. Thermopastc poymer b. Thermosettng pastc poymer

3. ACCORDING TO STRUCTURE

a. Lnk poymer. b. Branched poymer c. Crossed nk poymer

4. ACCORDING TO FORM

a. Pastc b. Eastomers c. Fber and resns

Properties of composite materials: (EACH POINT MARK)

1

NON FERROUS METALS

COPPER

PROPERTES APPLCATON

Reatvey soft gears

Maeabty Automobes,

utenss

Ducte Wres

Hgh toughness Gears

Eectrc conductvty Wres

Therma conductvty Utenss

Corroson resstance Ppng

Machnbty Bots and nuts

COPPER!"NC!TN ALLO#S

NAME COMPOSON PROPERTES APPLCATON

1

BRASS Znc-50%

Copper-50%

1. Ducte

2. Hgh tense

strength

3. Non

corrosve

4. Power

eectrcty

conductor

1 Ppes

2 Bearngs

3 Bushes

NAVEL METAL COPPER-60%

ZINC-39%

TIN- 1%

1 Corroson

resstance

2 Hgh tense

strength

3 Good

hardness

1 Nave

constructo

n

2 Pston rods

3 Bushes

4 Ornament

MUNTZ

METAL

COPPER-60%

ZINC-40%

1 REDDISH IN

COLOUR

2 HIGH

TENSILE

STRENGTH

3 HOT

WORKBALIT

Y

4 CORROSION

RESISTANCE

1 Utenss

2 Bushes

,bots

3 Marne

BRONZE 1 ZINC

2 COPPER

3 TIN

1 Corroson

resstance

2 Ant frcton

3 Hgh

hardness

4 maeabe

5 ducte

1 cons

2 shp

budng

3 bushes

4 cutch dsk

1

PHOSPHORUS

BRONZE

COPPER-97.7%

PHOSPHOURUS

-0.3%

TIN-0.6%

1 hgh tense

strength

2 corroson

resstance

3 hgh

hardness

4 can be

forged,

ducte&

meeabe

1 dsk of

cutch

2 marne,

worm&

worm

whee

3 ppes

4 foundry

SILICON

BRONZE

COPPER-97%

SILICON-3%

MAGNESIUM-

1%

1 hgh tense

strength

2 corroson

resstance

3 hgh

hardness

4 can be

forged,

ducte&

maeabe

5 good castng

6 conductvty

1 marne

ppes

2 bots, nuts

3 foundry

4 tanks

ALUMINIUM

BRONZE

COPPER-88%

A-8%

Fe-3%

Tn-0.5%

1 hgh tense

strength

2 hgh

hardness

3 corroson

resstance

4 dmcut to

cast

5 magnetc

1 marne

2 bots

3 wndng

GUN METAL COPPER-88%

TIN-10%

ZINC-2%

1 hgh tense

strength

2 very strong

3 resstance to

corroson

4 castabe

5 machnabe

6 can be

forged

1 bushes

2 nuts

3 marne

4 ppng

5 gears

1

ALLUMNUM

PROPERTES APPLCATON

HIGH HEAT CONDUCTIVITY CABLES

GOOD CONDUCTOR OF ELECTRICITY AIRCRAFTS

RESISTANCE TO CORROSION UTENSILS

DUCTILE AND HIGH TENSILE STRENGTH CONTAINERS

LIGHT WEIGHT Arcraft

EASILY MACHINED

NON TOXIC Vesse

ALLO# COMPOSTON PROPERTES APPLCATON

DURALUMIN A- 94%

Cu-4%

Mg-0.5%

Mn-0.6%

Scon-0.4%

1. Lght wegh

2. Hgh tense

strength

3. Hgh eectrc

conductor

4. Good

machnng

5. Shock

resstance

1 cabe

2 automobe

3 rvets

4 arcraft

Y-ALLOY Cu-4%

Mg-1.5%

N-2%

A-92.5%

1. hgh tense

strength

2. shock

resstance

3. hgh heat

conductor

4. easy

machned

1 engne parts

2 Pston and

cynder

heads.

HINDALIUM Aumnum

Magnesum

Manganese

Chromum

Scon

1 easy

machned

2 non toxc

3 hgh tense

strength

4 corroson

resstance

1 contaner

2 automobe

1

$EARN% MATERALS

Materas used to manufacture bearngs are caed as bearng materas.

BEARING MATERIALS:

1 COPPER RED ALLOY

2 SILVER BEARING

3 ALLUMINIUM ALLOY.

PROPERTES OF $EARN% MATERALS:

1 Hgh tense strength

2 Good corroson resstance

3 Good compresson resstance

4 Hard and wear resstance

5 Low cost and easy avaabe

6 Hgh hardness

7 Low coemcent of frcton

8 Shock resstance and ducte

POROUS SELF LU$RCATN% $EARN%:

& PRODUCED BY POWEDER METULLERGY

' IT CONSIST 40-50% POROSITY

( PORES ARE SATURATED WITH OIL AN ON APPLYING PRESSURE OIL COMES OUT OF

PORES .THUS NO EXTERNAL LUBRICATION IS NOT REOUIRED.

1

You might also like

- Max Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Document132 pagesMax Born, Albert Einstein-The Born-Einstein Letters-Macmillan (1971)Brian O'SullivanNo ratings yet

- Powder MetallurgyDocument79 pagesPowder MetallurgyTrevor Menezes100% (1)

- Powder Metallurgy PDFDocument85 pagesPowder Metallurgy PDFharsurajNo ratings yet

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Pneumatic Tyres: CMR Engineering CollegeDocument17 pagesPneumatic Tyres: CMR Engineering CollegeHemanth Rama Krishna YernagulaNo ratings yet

- Chapter 7Document85 pagesChapter 7tilki2007No ratings yet

- Powder Metallurgy: Ms C MawareDocument41 pagesPowder Metallurgy: Ms C Mawarechris mushunjeNo ratings yet

- Introduction to Powder Metallurgy ProcessDocument43 pagesIntroduction to Powder Metallurgy ProcessthirumalaikumaranNo ratings yet

- Powder Metallurgy PDFDocument9 pagesPowder Metallurgy PDFetamil87No ratings yet

- Powder MetallurgyDocument83 pagesPowder Metallurgyrahul72No ratings yet

- Powder MetallurgyDocument7 pagesPowder Metallurgykawsar_002100% (2)

- Powder MetallurgyDocument79 pagesPowder MetallurgyhavalNo ratings yet

- Powder MetallurgyDocument33 pagesPowder MetallurgyMohanakumara K CNo ratings yet

- Manufacturing Process: Powder MetallurgyDocument35 pagesManufacturing Process: Powder MetallurgyPANKAJ KUMARNo ratings yet

- 8 Metal Powder ProcessingDocument25 pages8 Metal Powder ProcessingLahiru JananjayaNo ratings yet

- Powder Metallurgy: Production and Characterization of Metal PowdersDocument84 pagesPowder Metallurgy: Production and Characterization of Metal PowdersNyanda MadiliNo ratings yet

- Unit Iv Powder MetallurgyDocument39 pagesUnit Iv Powder MetallurgyNyanda MadiliNo ratings yet

- Particulate Processing of Metals and CeramicsDocument98 pagesParticulate Processing of Metals and CeramicsDamy Manesi0% (2)

- Lost Wax Casting Lab ReportDocument8 pagesLost Wax Casting Lab ReportAsad ZahidNo ratings yet

- Powder MetallurgyDocument11 pagesPowder MetallurgyChandan PathakNo ratings yet

- Audio CH 552 Lesson 3 Powder Prep 2021Document69 pagesAudio CH 552 Lesson 3 Powder Prep 2021Vihanga SenanayakeNo ratings yet

- Engineering Metallurgy: Mohammed Idreesh Mohamed Naduthodi Mohamed Suhail Mohamed Yaser Arafat NaushadDocument15 pagesEngineering Metallurgy: Mohammed Idreesh Mohamed Naduthodi Mohamed Suhail Mohamed Yaser Arafat NaushadYaser MohamedNo ratings yet

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument40 pagesDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc LeNo ratings yet

- Module 5 Powder Metallurgy & Injection MouldingDocument72 pagesModule 5 Powder Metallurgy & Injection MouldingMaheshNo ratings yet

- Unit V Powder Metallurgy and Plastic MoldingDocument48 pagesUnit V Powder Metallurgy and Plastic MoldingGayatri KanwadeNo ratings yet

- Powder manufacturing and conditioning processes for metal powder productionDocument14 pagesPowder manufacturing and conditioning processes for metal powder productionAditya BishtNo ratings yet

- Basic Engineering MaterialDocument14 pagesBasic Engineering MaterialNur Husnina NinaRamanNo ratings yet

- Powder MetallurgyDocument24 pagesPowder MetallurgyAyan BhardwajNo ratings yet

- Casting Proceses and Defects_UADDocument23 pagesCasting Proceses and Defects_UADrushabhkhotNo ratings yet

- Hot Press MouldingDocument10 pagesHot Press Mouldingmuhd daneNo ratings yet

- Crown & Bridge: Lec. (13, 14) يدسلاا يكز ةسمه .د Laboratory work (Investing, burnout, casting and finishing procedures)Document7 pagesCrown & Bridge: Lec. (13, 14) يدسلاا يكز ةسمه .د Laboratory work (Investing, burnout, casting and finishing procedures)Wasan AhmNo ratings yet

- Casting ProceduresDocument69 pagesCasting ProceduresAatish Dilip ShahNo ratings yet

- MECH202 - 2022-23 FALL - L04 - Powder MetallurgyDocument46 pagesMECH202 - 2022-23 FALL - L04 - Powder MetallurgyMeriç DinçbilekNo ratings yet

- FOUNDRY WORKSHOP ASSESSMENT PROJECTDocument27 pagesFOUNDRY WORKSHOP ASSESSMENT PROJECTSahil YadavNo ratings yet

- Week 07 (Powder Metallurgy)Document59 pagesWeek 07 (Powder Metallurgy)Umair MalikNo ratings yet

- Processing of Powder Metals, Ceramics, Glass & SuperconductorsDocument27 pagesProcessing of Powder Metals, Ceramics, Glass & SuperconductorsMahesh CnNo ratings yet

- Class5 - Types of CastingDocument94 pagesClass5 - Types of CastingSriharsha SarmaNo ratings yet

- BMP Report G6Document3 pagesBMP Report G6Damage SinghNo ratings yet

- M3-Casting TechnologyDocument103 pagesM3-Casting Technologynr satiraNo ratings yet

- محاضرات بودر دزعراقيDocument5 pagesمحاضرات بودر دزعراقيMohammed GhisheerNo ratings yet

- Lec 5Document39 pagesLec 5Omar AssalNo ratings yet

- Mechanical Engineering Manufacturing-Process Powder-Metallurgy NotesDocument14 pagesMechanical Engineering Manufacturing-Process Powder-Metallurgy NotesSiddheswar BiswalNo ratings yet

- Casting and Powder Metallurgy Processes ExplainedDocument11 pagesCasting and Powder Metallurgy Processes ExplainedVisan NaiduNo ratings yet

- Powder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument46 pagesPowder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeShivam DixitNo ratings yet

- Material HandlingDocument8 pagesMaterial HandlingSuman MukherjeeNo ratings yet

- Casting Process Guide: Steps, Terminology and Design ConsiderationsDocument289 pagesCasting Process Guide: Steps, Terminology and Design ConsiderationsVikrant SinghNo ratings yet

- Unit 8 (Class15) Powder Metallurgy: Part BDocument8 pagesUnit 8 (Class15) Powder Metallurgy: Part BrajarajanNo ratings yet

- Foundry processes for tractor partsDocument10 pagesFoundry processes for tractor partsSri Ram VikasNo ratings yet

- Powder MetallurgyDocument5 pagesPowder Metallurgyমুকসেতিন আল রাজী রিফাতNo ratings yet

- Steps Involved in Powder Metallurgy ProcessDocument6 pagesSteps Involved in Powder Metallurgy ProcessAtul ParabNo ratings yet

- Lecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal AhmadDocument99 pagesLecture 2 - Manufacturing Processes - Fundamentals of Metal Casting and Casting Design - DR Bilal Ahmadjawad khalidNo ratings yet

- Powder Metallurgy ProcessDocument8 pagesPowder Metallurgy ProcessRabi Narayana SahuNo ratings yet

- Production and Manufacturing of Automotive Engine ComponentsDocument24 pagesProduction and Manufacturing of Automotive Engine ComponentsMr. Jerome Nithin Gladson100% (1)

- Casting Procedures and Casting DefectsDocument70 pagesCasting Procedures and Casting DefectsRohan Grover100% (1)

- HMT Pinjore Industrial Training ReportDocument12 pagesHMT Pinjore Industrial Training ReportAnurag KumarNo ratings yet

- Concrete Technology: Sem (Iii) Scheme - I Cha - 1. CementDocument30 pagesConcrete Technology: Sem (Iii) Scheme - I Cha - 1. CementKanishka roll28No ratings yet

- Part - CDocument27 pagesPart - CAnonymous 9HNJxBNo ratings yet

- DENTAL INVESTMENT MATERIALSDocument30 pagesDENTAL INVESTMENT MATERIALSAnnaAffandie100% (1)

- Foundry TechnologyDocument16 pagesFoundry Technologynikhil110705No ratings yet

- Metal Powders: A Global Survey of Production, Applications and MarketsFrom EverandMetal Powders: A Global Survey of Production, Applications and MarketsNo ratings yet

- CamScanner Scans PDFs from PhotosDocument5 pagesCamScanner Scans PDFs from PhotoscaveshgmailcomNo ratings yet

- 3 Night 4 Day Goa Enquirry No 1177Document2 pages3 Night 4 Day Goa Enquirry No 1177caveshgmailcomNo ratings yet

- Design Data BookDocument639 pagesDesign Data BookVasanth Chakravarthy100% (2)

- Knuckle Joint: Design Procedure, Problems and QuestionsDocument11 pagesKnuckle Joint: Design Procedure, Problems and QuestionscaveshgmailcomNo ratings yet

- Formation of Boundary LayerDocument11 pagesFormation of Boundary LayercaveshgmailcomNo ratings yet

- FM IMP Chapter 2 TO 6Document1 pageFM IMP Chapter 2 TO 6caveshgmailcomNo ratings yet

- Design of Press ScrewDocument10 pagesDesign of Press ScrewcaveshgmailcomNo ratings yet

- Design of Unprotected Flange CouplingDocument7 pagesDesign of Unprotected Flange CouplingcaveshgmailcomNo ratings yet

- Design of Screw JackDocument3 pagesDesign of Screw JackcaveshgmailcomNo ratings yet

- FM IMP Chapter 2 TO 6Document1 pageFM IMP Chapter 2 TO 6caveshgmailcomNo ratings yet

- Design of C - ClampDocument4 pagesDesign of C - ClampcaveshgmailcomNo ratings yet

- Sem 3 Time TableDocument2 pagesSem 3 Time TablecaveshgmailcomNo ratings yet

- Crash 2019 Time TableDocument2 pagesCrash 2019 Time TablecaveshgmailcomNo ratings yet

- ME Product Design and Development CHBCGS 2016Document76 pagesME Product Design and Development CHBCGS 2016caveshgmailcomNo ratings yet

- Cad Cam Notes FinalDocument21 pagesCad Cam Notes FinalcaveshgmailcomNo ratings yet

- Withdrawal Benefit Form for EPS PensionDocument4 pagesWithdrawal Benefit Form for EPS Pensionsandee1983No ratings yet

- Environmental Science MCQ QuizDocument29 pagesEnvironmental Science MCQ QuizcaveshgmailcomNo ratings yet

- Excellent Pamphlet CC 2Document2 pagesExcellent Pamphlet CC 2caveshgmailcomNo ratings yet

- EVS MCQDocument39 pagesEVS MCQcaveshgmailcomNo ratings yet

- PED and PipingDocument8 pagesPED and PipingcaveshgmailcomNo ratings yet

- HI-8592, HI-8593, HI-8594: Single-Rail ARINC 429 Differential Line DriverDocument14 pagesHI-8592, HI-8593, HI-8594: Single-Rail ARINC 429 Differential Line DriversameeppaiNo ratings yet

- MongoDB Replication Guide PDFDocument106 pagesMongoDB Replication Guide PDFDante LlimpeNo ratings yet

- Data AnalysisDocument7 pagesData AnalysisAndrea MejiaNo ratings yet

- 08 Candelaria Punta Del Cobre IOCG Deposits PDFDocument27 pages08 Candelaria Punta Del Cobre IOCG Deposits PDFDiego Morales DíazNo ratings yet

- SBM Level of Practice Validation FormDocument43 pagesSBM Level of Practice Validation Formelvira pilloNo ratings yet

- CD IK Tools v1.5 Plugin for C4D 9.6Document20 pagesCD IK Tools v1.5 Plugin for C4D 9.6Syed Aal-HussainNo ratings yet

- Spesifikasi Produk SL-500Document2 pagesSpesifikasi Produk SL-500tekmed koesnadiNo ratings yet

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioNo ratings yet

- Defense Cheat SheetDocument4 pagesDefense Cheat SheetCarl Dhaniel Garcia SalenNo ratings yet

- Ikan Di Kepualauan Indo-AustraliaDocument480 pagesIkan Di Kepualauan Indo-AustraliaDediNo ratings yet

- Transportation Planning ProcessDocument43 pagesTransportation Planning ProcessAncheta Suzanne ClarisseNo ratings yet

- Die Science - Developing Forming Dies - Part I - The FabricatorDocument6 pagesDie Science - Developing Forming Dies - Part I - The FabricatorSIMONENo ratings yet

- 2N3866 Datasheet Rev BDocument5 pages2N3866 Datasheet Rev Bardier34No ratings yet

- THKDocument1,901 pagesTHKapi-26356646No ratings yet

- Pipeline Corrosion Assessment MethodsDocument21 pagesPipeline Corrosion Assessment MethodsGilletNo ratings yet

- UG WeibullDocument776 pagesUG WeibullCharles GuzmanNo ratings yet

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocument1 pageSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)

- San Unit-Wise QuestionsDocument6 pagesSan Unit-Wise QuestionsSushmitha KodupakaNo ratings yet

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDocument16 pagesGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNo ratings yet

- 2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMDocument3 pages2 To 12F SM UT Armoured OFC-2Steel Wire Design Sheet-7.5 MMTropic BazarNo ratings yet

- Wartsila CPP PaperDocument4 pagesWartsila CPP Papergatheringforgardner9550No ratings yet

- Valve Actuator Data SheetDocument1 pageValve Actuator Data SheetRob StorrowNo ratings yet

- MITRES 6 002S08 Chapter2Document87 pagesMITRES 6 002S08 Chapter2shalvinNo ratings yet

- 3RP15 05-1aDocument3 pages3RP15 05-1atycristinaNo ratings yet

- Recommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Document38 pagesRecommended Procedures For Internet-Based Connections Between Rths and Nmcs (VPN, Ipsec)Crismaruc Maria-madalinaNo ratings yet

- Excel Gantt Chart Template: Enter Your Project Details HereDocument14 pagesExcel Gantt Chart Template: Enter Your Project Details HereBarselaNo ratings yet

- © Ncert Not To Be Republished: AlgebraDocument12 pages© Ncert Not To Be Republished: Algebrakritagyasharma29No ratings yet

- Control Lights with SOU-1 Twilight SwitchDocument1 pageControl Lights with SOU-1 Twilight SwitchjsblNo ratings yet