Professional Documents

Culture Documents

Pipe Designing Basic Material1

Uploaded by

Jessica HerringOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Designing Basic Material1

Uploaded by

Jessica HerringCopyright:

Available Formats

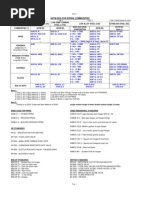

Basic Material

A) Carbon Steel

General

Using within min. -29 C to max. 425C

The Carbon Equipvalent (CE) for carbon steel intended for welding

shall not exceed 0.43% base on the long formula: CE=C + Mn / 6 +

( Cr + Mo + V ) / 5 + ( Cu + Ni ) / 15

Applications

Service Non-corrosive piping system ( fresh water, plant air, nitrogen, fuel gas, etc.)

Pipes ASTMA106 Gr.B, API 5L Gr.B

Fittings ASTMA234 Gr.WPB

Forgings ASTMA105

B) LowTemp Carbon Steel

General Using if the minimum service temperature is below -29 C

Applications

Service Low temperature non-corrosive piping system ( flare system )

Pipes ASTMA333 Gr.6

Fittings ASTMA420 Gr.WPL6

Forgings ASTMA350 Gr.LF2

C) Austenitic Stainless Steel

General

The use of austenitic stainless steel in offshore is

limited to a maximum service temperature of 60 C

Using when the corrosion rate is too high to use carbon steel ( typical

more than 3mm or 6mm max. corrosion allowance for the design life )

Any hydrostatic testing of austenitic stainless steel shall be conducted with water

containing less than 2 mg/kg chlorides, and any open ends sealed after drying to

ensure no moisture ingress.

Application

Service

Fuel gas, chemical injection, instrument air, wet

hydrocarbon ( corrosive ).

Pipes ASTMA312 Gr.TP304/304L, ASTMA312 Gr.TP316/316L

Fittings

ASTM403 Gr.WP304/304L, ASTM403

Gr.WP316/316L

Forgings ASTMA182 Gr.F304/304L, ASTMA 182 Gr.F316/316L

D) Duplex Stainless Steel

General

Using when the the design condition is exceed the limit do SS316

Any hydrostatic testing of austenitic stainless steel shall be conducted with water

containing less than 2 mg/kg chlorides, and any open ends sealed after drying to

ensure no moisture ingress.

Application

Service

Pipes ASTMA790 UNS S31803

Fittings ASTMA815 UNS S31803

Forgings ASTMA182 Gr.F51

E) Alloy Steel

Elevated Temperature Services

General

Cr-Mo heat resistant steel contain 0.5~9% Cr and

0.5~1.0% Mo. Carbon content max 0.20%

Supplied in normalized and tempered, quenched and

tempered or annealed condition

These Alloy Steels are used up to max temperature about 650 C

Appication

Pipes ASTMA 335 Gr.P11, A335 Gr.P22

Fittings ASTMA234 Gr.WP11, A234 Gr.WP22

Forgings ASTMA182 Gr.F11, A182 Gr.F22

Low Temperature Services

General

Application with temperature form 0 C to

195C, Nickel steels is typically used

Application

Pipes ASTMA 333 Gr.3

Fittings ASTMA420 Gr.WPL3

Forgings ASTMA350 Gr.LF3

F) Non-Ferrous Alloy

Nickel Alloys

Including Inconel and incoloy

Commonly used because of the high ppm

Monel

Monel is a nickel-copper alloy, 10%~90% commonly used

Service: sea water

Copper-Nickel

Cu-Ni 90/10, Cu-Ni 70/30

Services: sea water piping system

Titanium

Non-Alloyed grade

Good corrosion resistance, especially chlorite

induced pitting and stress-corrosion cracking

Good resistance to oxidizing media, e.g. nitric acid

Alloyed grade Resistance to reducing media superior to non-alloyed titanium

G) Thermoplastic

Plasticised Polyvinyl chloride->PVC

Unplasticised PVC->UPVC

Polyethylene->PE

Polyamide->PA

Polypropylene->PP

Fluoropolymers

PolyTetraFluoroEthyleme->PTFE

Polychlorotrifluoroethylen->PCTFE

Perfluoralkoxy->PFE

Fluorinated ethylene propylene->FEP

Polyvinylidenefluoride->PVDF

Polyphenylenesulpone->PPS

Cross-linked Polyethylene->PEX

Polyketone->PK

Polyetheretherketone->PEEK

H) Non-Metallic

Glassfibre Rainforced Plastic->GRP

Glassfibre Rainforced Epoxy->GRE

Glassfibre Rainforced Vinylester->GRV

Using

No use in hydrocarbon and methanol system

Maxinternal design temperature 20 bargs

Design temperature range for -40 C up to

95C for epoxy and up to 80 C for

vinylester

Commonlly used for the sea water system in offshore

I) Elastomeric

Natural Rubber->NR

Styrene Butadiene Rubber->SBR

Neoprene Rubber->CR

Butyl Rubber->IIR

Chlorosulphonated polyethylene->CSM

Nitrile Butadiene Rubber->NBR, HNBR

Ethylene Propylene Rubber->EPDM

Fluoroelastomers->FKM

Perfluoro Polymer->FFKM

Fluor-Silicone Rubbers->VMQ, PMQ, FMQ

Polyurethane Rubbers->AU,EU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pipe Design Basic MaterialDocument1 pagePipe Design Basic MaterialpandiangvNo ratings yet

- ArcGIS9.3 Installation1Document2 pagesArcGIS9.3 Installation1Jessica HerringNo ratings yet

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- Piping Task1Document1 pagePiping Task1Jessica HerringNo ratings yet

- AutoCAD Keyboard Shortcuts GuideDocument6 pagesAutoCAD Keyboard Shortcuts GuideJessica HerringNo ratings yet

- Story Behind Your Date of BirthDocument6 pagesStory Behind Your Date of BirthJessica HerringNo ratings yet

- Piping Feature1Document1 pagePiping Feature1Jessica HerringNo ratings yet

- AutoCAD Keyboard Shortcuts GuideDocument6 pagesAutoCAD Keyboard Shortcuts GuideJessica HerringNo ratings yet

- Energy Meter Classification1Document2 pagesEnergy Meter Classification1Jessica HerringNo ratings yet

- Reporting Reference ManualDocument34 pagesReporting Reference ManualMohamad FaifNo ratings yet

- CAPILLA - Welding Consumables For Welding of Creep and Heat ResistantDocument40 pagesCAPILLA - Welding Consumables For Welding of Creep and Heat ResistantdantegimenezNo ratings yet

- Welding Guides Lincoln ElectricDocument49 pagesWelding Guides Lincoln Electricpkn_pnt9950No ratings yet

- VẬT LIỆU THEO TIÊU CHUẨN - JIS - ASTMDocument3 pagesVẬT LIỆU THEO TIÊU CHUẨN - JIS - ASTMThanh BuiNo ratings yet

- Garnet - Rock-Forming MineralsDocument16 pagesGarnet - Rock-Forming MineralsMelroy DsouzaNo ratings yet

- CV Ir. Muhammad Fahrullah, ST., IPM - Update Oktober 2019Document1 pageCV Ir. Muhammad Fahrullah, ST., IPM - Update Oktober 2019Yusri RahmanNo ratings yet

- Appendix: Galling Threshold StressDocument8 pagesAppendix: Galling Threshold StressGarcia RafaelNo ratings yet

- Alloy Steel For StructuDocument8 pagesAlloy Steel For Structurooter2000bkaNo ratings yet

- Catalogue of Plates NewDocument36 pagesCatalogue of Plates NewCarlo Ulises Conteras Siuentes0% (1)

- Miller Periodic TableDocument2 pagesMiller Periodic TableMehmet SoysalNo ratings yet

- Trademarks On Base-Metal Tableware PDFDocument347 pagesTrademarks On Base-Metal Tableware PDFobericaaa100% (1)

- Clad-Plates EN 140520 Einzel PDFDocument40 pagesClad-Plates EN 140520 Einzel PDFDHAVAL PANCHALNo ratings yet

- Cupola Furnace Project ReportDocument32 pagesCupola Furnace Project Reportadelina ednandaNo ratings yet

- Comparison Between Imf EafDocument14 pagesComparison Between Imf EafmetudgnNo ratings yet

- Crystallography Revision GuideDocument8 pagesCrystallography Revision GuideNgala FabriceNo ratings yet

- Periodic Table Color 2017Document1 pagePeriodic Table Color 2017yahooincNo ratings yet

- Unicast Datasheet Jaw Crusher Wear Parts PDFDocument2 pagesUnicast Datasheet Jaw Crusher Wear Parts PDFramonguitNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument30 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNo ratings yet

- Materials Quiz and Properties WorksheetDocument4 pagesMaterials Quiz and Properties WorksheetSamantha AshmanNo ratings yet

- Nature of MaterialsDocument20 pagesNature of MaterialsBALBIDO John LesterNo ratings yet

- Valve and Pipe ListDocument22 pagesValve and Pipe ListZakky Rohman0% (1)

- Metallurgy: List of Ores and Their Na MesDocument14 pagesMetallurgy: List of Ores and Their Na MeszohaibsalamNo ratings yet

- Abrasive Catalogue 19 PagesDocument19 pagesAbrasive Catalogue 19 PagesWade CockfieldNo ratings yet

- European Steel and Alloy Grades: G-Nicr50Nb (2.4680)Document2 pagesEuropean Steel and Alloy Grades: G-Nicr50Nb (2.4680)farshid KarpasandNo ratings yet

- AWS Vs CSADocument29 pagesAWS Vs CSAEl Shin100% (2)

- Assignment 02 - IPE2230 3Document4 pagesAssignment 02 - IPE2230 3MD Al-AminNo ratings yet

- Ferro Silicon Magnesium Manufacturers in IndiaDocument10 pagesFerro Silicon Magnesium Manufacturers in IndiasumayamguptaNo ratings yet

- Article CSIRO TRC-MG Magnesium Technology 2001Document5 pagesArticle CSIRO TRC-MG Magnesium Technology 2001Frederic BassonNo ratings yet

- PFI ES 29 - 2006 EditionDocument5 pagesPFI ES 29 - 2006 EditionArcadio DuranNo ratings yet

- Trim Chart API 600Document2 pagesTrim Chart API 600Ercan YilmazNo ratings yet

- Fontargen Product+catalog EN 2017 PDFDocument89 pagesFontargen Product+catalog EN 2017 PDFJose Luis Meseguer ValdenebroNo ratings yet