Professional Documents

Culture Documents

Troubleshooting Fluid Coupling

Uploaded by

Bahtiar Yudhistira100%(3)100% found this document useful (3 votes)

3K views2 pageser

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenter

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

3K views2 pagesTroubleshooting Fluid Coupling

Uploaded by

Bahtiar Yudhistiraer

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

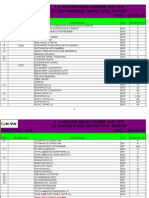

Troubleshooting Fluid Coupling

Problem Possible Cause Corrective Action

Abnormal

starting cycle

Oil level either to high

or low

Check Oil level and rectify as required with

correct grade oil as specified by the

manufacturer

Driven machine

does not reach

full speed

Incorrect Oil level

Check Oil level, and fill to specified level with

correct grade of oil as specified by the

manufacturer.

Resistance in the

Driven machine

Remove resistance form system

Motor Stalling or

not getting to

speed

Coupling overfilled

Check coupling oil level and rectify as

required.

tar to Delta Change

over to late

Changeover should be no more than !

seconds

"otor electrically or

mechanically damaged

Check condition of the motor. In stall condition

check the motor amps being drawn. Check

against fluid coupling rating.

Overheating #ow Oil #evel

Check Oil level, and fill to specified level with

correct grade of oil as specified by the

manufacturer.

Incorrect $rade of Oil

Remove oil, flush with suitable fluid, and

replace to specified level with correct grade of

oil as specified by the manufacturer.

%locked &entilation

holes in the coupling

guard.

Clean out ventilation holes

Resistance in Driven Remove resistance from the system

"achine

Fusible Plug

Failure

"achine stalled

Clear stall, refill the coupling to the specified

level with the correct grade of oil as specified

by the manufacturer. 'it new fusible plug

sourced from the original coupling

manufacturer.

#ow Oil level

Identify reason for low oil level. Refill the

coupling to specified level with the correct

grade of oil as specified by the manufacturer.

'it new fusible plug sourced from the original

coupling manufacturer

Incorrect $rade of Oil

Remove oil, flush with suitable fluid, and

replace to specified level with correct grade of

oil as specified by the manufacturer. 'it new

fusible plug sourced for the original coupling

manufacturer.

Vibration "isalignment Re(align coupling to manufacturers tolerances

Connecting Couplings

loose)worn)broken

Check the integrity of the connection coupling.

Rectify as required. Re(align coupling to

manufacturers tolerances.

%edplate loose

Check bedplate for security and)or suitability for

use. Rectify as required. Re(align coupling to

manufacturers tolerances.

%ent motor)driven

machine shafts

Check motor, driven machine shafts for

concentricity. Rectify as required. Re(align

coupling to manufacturers tolerances

%earing damage

Identify damage, and rectify as required. Re(

align coupling to manufacturers tolerances

You might also like

- Standard Operating Procedure - KilnDocument7 pagesStandard Operating Procedure - KilnJCS100% (2)

- Raw Mill Startup and Operation GuideDocument4 pagesRaw Mill Startup and Operation GuideJCS100% (1)

- Kiln Startup and Operation ProcedureDocument4 pagesKiln Startup and Operation ProcedureJCS100% (3)

- Chinese Standard GBDocument76 pagesChinese Standard GBmrjoshiroshanNo ratings yet

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Cement Mill DrivesDocument29 pagesCement Mill Drivessumit jain100% (1)

- Pre Commissioning Checks For ID FanDocument2 pagesPre Commissioning Checks For ID Fanchcrr100% (1)

- SKF Spherical Roller Bearing ClearanceDocument2 pagesSKF Spherical Roller Bearing ClearanceKumaran GopalNo ratings yet

- Export Product Hand BookDocument94 pagesExport Product Hand Bookamit singhNo ratings yet

- Centrifugally Cast Inserted Grinding Rollers SpecificationDocument6 pagesCentrifugally Cast Inserted Grinding Rollers Specificationsiva100% (1)

- 1568 GB 02Document7 pages1568 GB 02Andra EneNo ratings yet

- 1-SOP For Raw Mill StartDocument2 pages1-SOP For Raw Mill Startvinodsn100% (2)

- Inspection Check List (Raw Mill-II)Document1 pageInspection Check List (Raw Mill-II)Irfan Ahmed100% (1)

- Boiler Ash Handling Operation & Maintenance PDFDocument64 pagesBoiler Ash Handling Operation & Maintenance PDFdreamboy87No ratings yet

- Commissioning Guide LinesDocument53 pagesCommissioning Guide LinesthurawinNo ratings yet

- Dip Tube Inspection - SMPDocument7 pagesDip Tube Inspection - SMPPravesh Modi100% (2)

- Coarse Feed ValveDocument34 pagesCoarse Feed ValveRahmat Yusuf0% (1)

- Kerosene Test ProcedureDocument1 pageKerosene Test ProcedureAshwani Dogra100% (1)

- FL SmidthDocument4 pagesFL SmidthTanmay MajhiNo ratings yet

- Phillips Kiln Kiln Alignment Gebhart 2006Document36 pagesPhillips Kiln Kiln Alignment Gebhart 2006mustaf100% (2)

- Green Co Best Practice Award 2016 PresentationDocument22 pagesGreen Co Best Practice Award 2016 PresentationSivakumaran RajuNo ratings yet

- Alignment Cooling Water Pump 4A: Halaman: 1 Dari 1 HalamanDocument3 pagesAlignment Cooling Water Pump 4A: Halaman: 1 Dari 1 Halamanpemeliharaan.turbin03No ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- Boiler Tube Leakage ArrestingDocument2 pagesBoiler Tube Leakage ArrestingKarthi Keyan100% (2)

- Heat-Resistant Cast Steel Data SheetDocument3 pagesHeat-Resistant Cast Steel Data Sheetgraduate100% (1)

- 1.inter Lock List For Rotary KilnDocument3 pages1.inter Lock List For Rotary KilnRaji SuriNo ratings yet

- Radial Clearance of BearingDocument1 pageRadial Clearance of Bearingstenly massieNo ratings yet

- Motor PDFDocument1 pageMotor PDFSwapnil JoshiNo ratings yet

- Iom DSM100-36Document27 pagesIom DSM100-36rogueatdoorNo ratings yet

- Airslide Calculation Form Project: Department: Equipment NoDocument3 pagesAirslide Calculation Form Project: Department: Equipment NoManoj Thakur0% (1)

- Flender Manual GeneralDocument42 pagesFlender Manual GeneralYenny LaraNo ratings yet

- Katalog Produk General ARITADocument72 pagesKatalog Produk General ARITAanon_969520527No ratings yet

- Kiln Thruster LogicDocument3 pagesKiln Thruster LogicSameer kumar GOGOI0% (1)

- Inspection Check List Rotary KilnDocument4 pagesInspection Check List Rotary KilnTeuku Alkhaitami100% (1)

- Parts list with prices under 40 charactersDocument4 pagesParts list with prices under 40 characterslibin francisNo ratings yet

- Mpam-Kiln 2Document7 pagesMpam-Kiln 2sreeganeshrNo ratings yet

- VRM - PaperDocument9 pagesVRM - PaperJoko DewotoNo ratings yet

- FK Pump Operation and ComponentsDocument9 pagesFK Pump Operation and ComponentsAli Hüthüt100% (1)

- Maintenance Checklist Screw ConveyorDocument1 pageMaintenance Checklist Screw Conveyorshamsheer ikram100% (1)

- Instruction Manual Multisilo Peters PDFDocument266 pagesInstruction Manual Multisilo Peters PDFRoger FarjeNo ratings yet

- HTDDocument18 pagesHTDSami YouseefNo ratings yet

- Standardize Operating Procedure for Grinding Media ChargingDocument1 pageStandardize Operating Procedure for Grinding Media ChargingJCS100% (1)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedgraduateNo ratings yet

- Grate Cooler CFGDocument3 pagesGrate Cooler CFGfetniNo ratings yet

- Raw Mill Vertical Roller Mill PDFDocument58 pagesRaw Mill Vertical Roller Mill PDFganong itbNo ratings yet

- Check List Rotary Packer: Packing Plant General StatusDocument3 pagesCheck List Rotary Packer: Packing Plant General StatusTITUS YUSUF100% (1)

- Cement Details PDFDocument292 pagesCement Details PDFcristyjayNo ratings yet

- Is 2708 - Manganize Steel CastingDocument6 pagesIs 2708 - Manganize Steel CastingJanak MistryNo ratings yet

- Kiln MigrationDocument3 pagesKiln MigrationfaheemqcNo ratings yet

- Hammer Crusher User ManualDocument10 pagesHammer Crusher User ManualJuan MoralesNo ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- Motors CatalogueDocument32 pagesMotors CatalogueosbianiNo ratings yet

- Ppi CL PDFDocument3 pagesPpi CL PDFMaxflowNo ratings yet

- 1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerDocument2 pages1.SOP-Castable Refractory Work at Pre-Heater. Kiln Inlet, TAD & CoolerJCSNo ratings yet

- Patriot 2008 2.4LDocument260 pagesPatriot 2008 2.4LCynthia MartinezNo ratings yet

- Commissioning Procedure For Diesel GeneratorDocument3 pagesCommissioning Procedure For Diesel Generatorthilanka0650% (4)

- Engine Trouble ShootingDocument6 pagesEngine Trouble Shootingcedro08No ratings yet

- Geareducer Model 32.2: UsermanualDocument8 pagesGeareducer Model 32.2: UsermanualR BhattacharyaNo ratings yet

- 2.4l EngineDocument237 pages2.4l EngineRene SanchezNo ratings yet

- 4 - HPN Sugar Monthly Review AprilDocument2 pages4 - HPN Sugar Monthly Review AprilBahtiar YudhistiraNo ratings yet

- 15 Chapter 5Document44 pages15 Chapter 5Taufik Binasr100% (1)

- Desuperheater Drawing PDFDocument3 pagesDesuperheater Drawing PDFBahtiar YudhistiraNo ratings yet

- Struktur Organisasi Rev 1rDocument4 pagesStruktur Organisasi Rev 1rBahtiar YudhistiraNo ratings yet

- Spot Check Your Car's Oil with a Blotter TestDocument2 pagesSpot Check Your Car's Oil with a Blotter TestBahtiar YudhistiraNo ratings yet

- Vibrotip Web PAM1Document8 pagesVibrotip Web PAM1Bahtiar YudhistiraNo ratings yet

- TN 7 VibxpertDocument1 pageTN 7 VibxpertBahtiar YudhistiraNo ratings yet

- Heat Loss Chart SnaiderDocument1 pageHeat Loss Chart SnaiderBahtiar YudhistiraNo ratings yet

- Desuperheater DrawingDocument3 pagesDesuperheater DrawingBahtiar YudhistiraNo ratings yet

- CalculationsDocument2 pagesCalculationsAliAliNo ratings yet

- Flow in Pipe - Manning FormulaDocument1 pageFlow in Pipe - Manning FormulaBahtiar YudhistiraNo ratings yet

- Thickness Measurement of Pipe Panel Roof A July 2011Document9 pagesThickness Measurement of Pipe Panel Roof A July 2011Bahtiar YudhistiraNo ratings yet

- Steam Systems III Distribution, Control & Regulation of Steam TRANSCRIPTDocument15 pagesSteam Systems III Distribution, Control & Regulation of Steam TRANSCRIPTBahtiar YudhistiraNo ratings yet

- Table of ContentDocument3 pagesTable of ContentBahtiar YudhistiraNo ratings yet

- Book 1Document4 pagesBook 1Bahtiar YudhistiraNo ratings yet

- Asset Management: Maintenance Management Implementation GuideDocument11 pagesAsset Management: Maintenance Management Implementation GuideBahtiar YudhistiraNo ratings yet

- Pt. Corelab Indonesia: Oil Analysis ResultDocument1 pagePt. Corelab Indonesia: Oil Analysis ResultBahtiar Yudhistira100% (1)

- Analysis of Bolt Torquing CalculationsDocument6 pagesAnalysis of Bolt Torquing CalculationsBahtiar YudhistiraNo ratings yet

- 11249-Ispat Indo-500 Mill Rolling Mill BDocument1 page11249-Ispat Indo-500 Mill Rolling Mill BBahtiar YudhistiraNo ratings yet

- Inspeksi Pipa BajaDocument5 pagesInspeksi Pipa BajaBahtiar YudhistiraNo ratings yet

- Poas (Predictive Oil Analysis Service) ReportDocument1 pagePoas (Predictive Oil Analysis Service) ReportBahtiar YudhistiraNo ratings yet

- 07468-Ispatindo-Cellar 1 Rolling MillDocument1 page07468-Ispatindo-Cellar 1 Rolling MillBahtiar YudhistiraNo ratings yet

- BPVC-IV Interp Stnd-56 2005Document3 pagesBPVC-IV Interp Stnd-56 2005Bahtiar YudhistiraNo ratings yet

- ASME InterpretationDocument4 pagesASME Interpretationhrh_pogcNo ratings yet

- Soal Psikotest - Antonim (Lawan Kata)Document3 pagesSoal Psikotest - Antonim (Lawan Kata)SigmaAdi PengenNgertiNo ratings yet

- BPVC-I Interp Stnd-56 2005Document2 pagesBPVC-I Interp Stnd-56 2005Bahtiar YudhistiraNo ratings yet

- BPVC-IV Interp Stnd-56 2005Document3 pagesBPVC-IV Interp Stnd-56 2005Bahtiar YudhistiraNo ratings yet

- BPVC-IIA Interp Stnd-56 2005Document2 pagesBPVC-IIA Interp Stnd-56 2005Bahtiar YudhistiraNo ratings yet

- Steam Systems I OutlineDocument1 pageSteam Systems I OutlineBahtiar YudhistiraNo ratings yet

- WEG Installation, Operation and Maintenance ManualDocument55 pagesWEG Installation, Operation and Maintenance ManualMichael HailuNo ratings yet

- TE Syllabus Mech PDFDocument40 pagesTE Syllabus Mech PDFSanket JadhavNo ratings yet

- Maintain Machinery EffectivelyDocument55 pagesMaintain Machinery EffectivelyvaisakhNo ratings yet

- PVR6 Service Manual 265664 REV 04 19Document8 pagesPVR6 Service Manual 265664 REV 04 19Partagon PowNo ratings yet

- Yb08 5Document6 pagesYb08 5장영훈No ratings yet

- 14 Shaft Alignment 이해와 절차Document25 pages14 Shaft Alignment 이해와 절차Rini Dwi AstutiNo ratings yet

- Your Propulsion Experts - SCHOTTEL STT 1 FP User ManualDocument290 pagesYour Propulsion Experts - SCHOTTEL STT 1 FP User ManualJosé Verdejo QuirozNo ratings yet

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsDocument11 pagesPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarNo ratings yet

- 9900-4009 0211 PTcat PDFDocument120 pages9900-4009 0211 PTcat PDFFelipe CiolNo ratings yet

- Axially Split Pump Series Wilo-SCPDocument52 pagesAxially Split Pump Series Wilo-SCPnitinctaeNo ratings yet

- Fenner Engineering Products Price ListDocument24 pagesFenner Engineering Products Price Listmanoj_doshi_1No ratings yet

- FIRE PUMPS Download PermissionDocument45 pagesFIRE PUMPS Download PermissionKrishna JashaNo ratings yet

- Towcon Manual PDFDocument124 pagesTowcon Manual PDFThiago LimaNo ratings yet

- TASKalfa181-221 Parts ListDocument64 pagesTASKalfa181-221 Parts ListRoberto Pinheiro Moura SantosNo ratings yet

- Rotex: Torsionally Flexible Coupling With T-PURDocument34 pagesRotex: Torsionally Flexible Coupling With T-PURbd54No ratings yet

- World Encoders CatalogDocument78 pagesWorld Encoders CatalogQuantumAutomation100% (1)

- Combo PDFDocument209 pagesCombo PDFBasem Al-HajNo ratings yet

- 1861 SDV Series Manual Rev C 041921Document58 pages1861 SDV Series Manual Rev C 041921lichNo ratings yet

- Cat Code Item Description Electrical Items & Spares: Oscom Chavara Manavalakuruchi REDDocument18 pagesCat Code Item Description Electrical Items & Spares: Oscom Chavara Manavalakuruchi REDManishDwivediNo ratings yet

- ACG-UCG (K7-N7) Low Pressure PumpDocument4 pagesACG-UCG (K7-N7) Low Pressure PumpChhoan NhunNo ratings yet

- Grundfosliterature 1073112Document120 pagesGrundfosliterature 1073112Suhas JadhavNo ratings yet

- Oil Country WF Model 57802-100TK Hydraulic Tubing TongDocument83 pagesOil Country WF Model 57802-100TK Hydraulic Tubing Tongwuillian barretoNo ratings yet

- Betriebsanleitung - Instruction Manual: Motor - MotorDocument133 pagesBetriebsanleitung - Instruction Manual: Motor - MotordeskonhecydoNo ratings yet

- Hydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect CorrectDocument88 pagesHydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect Correctcristian100% (2)

- GRID COUPLING TYPESDocument83 pagesGRID COUPLING TYPESWaqas WakeelNo ratings yet

- Shaking Moment Cancellation of Self Balanced Slider Crank Mechanical Systems by Means of Optimum Mass RedistributionDocument5 pagesShaking Moment Cancellation of Self Balanced Slider Crank Mechanical Systems by Means of Optimum Mass RedistributionFlamez_02No ratings yet

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNo ratings yet

- 9 - Flanged Bolt CouplingDocument15 pages9 - Flanged Bolt CouplingPatrick Antonio Orge ChingNo ratings yet

- Handbook of Loss PreventionDocument433 pagesHandbook of Loss Preventionsujan723100% (4)

- Fan Inspection ReportDocument24 pagesFan Inspection Reportsaisssms9116No ratings yet